As well as providing metal fabricated equipment, including filters and extraction systems we are able to provide a similar range of equipment manufactured in various plastic corrosion resistant materials.

These can all be made suitable for applications in chemicals, pharmaceuticals and waste treatment industries in various materials to suit the requirements.

This includes manufacture in PVC, polypropylene and glass reinforced materials, together with a combination of surface treatments of metal fabricated components to suit corrosive environments. The full range of equipment including fans, ductwork, scrubber units, exhaust hoods and tanks can be provided for various process systems ranging from basic fume control in corrosive environments up to exhaust from complete process lines involving acid, alkaline and rinsing systems.

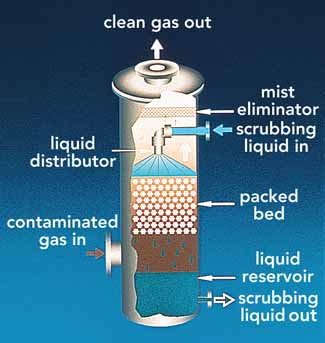

Dependent upon the requirements of the system we can provide various scrubbing units in order to clean the pollutant from the air stream before discharging to atmosphere. These can be provided in either horizontal or vertical packed systems, or alternatively, utilising multi-vane elimination systems with or without spray washers. All of these items can be provided either from our standard range or as a ‘custom built’ to suit a particular application.

Case Studies

Case Study 1

The larger blue scrubber (below) was supplied to a customer in Finland to be installed on a strip treatment line to remove caustic fumes. The horizontal packed scrubber continuously recirculates…

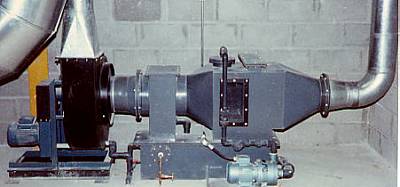

The larger blue scrubber was supplied to a customer in Finland to be installed on a strip treatment line to remove caustic fumes. The horizontal packed scrubber continuously recirculates the scrubbing liquor as the air passes horizontally through the packed section. The increased surface area developed by the packing increases the absorption of the contaminant and the dosing system maintains the correct pH balance within the scrubber. Run and standby pumps also ensure continuous operation. The smaller horizontal scrubber (above) has no packing but utilises a high intensity spray zone to wet the incoming dusts and remove these from the air stream. Droplet eliminators on the outgoing side then remove any residue mists before discharging to atmosphere.

Case Study 2

Vertical packed tower scrubbers or counter current scrubbers are utilised to absorb fumes and chemical vapours from the air stream. The central packed section contains a large…

Vertical packed tower scrubbers or counter current scrubbers are utilised to absorb fumes and chemical vapours from the air stream. The central packed section contains a large volume of rashings that increase the surface area over which the liquor will flow. This increases the absorption rate of the chemicals into the solution. The counter current system ensures that the liquor enters the top of the column at its lowest concentration where the contaminated air is also at its lowest concentration. As the liquor flows down the back it gradually absorbs the substance being removed from the air stream increasing in concentration. However, the concentration of the contaminant increases as you descend maintaining the concentration gradient such that the pollutant will always move into the liquor. Chemical additives or dousing also assist in the removal of any chemicals absorbed into the liquor.