ABOUT THE PROCESS

About the Process

A HOLLOW MOULD IS FILLED WITH A POWDER RESIN AND THEN ROTATED BI-AXIALLY IN AN OVEN UNTIL THE RESIN COATS THE INSIDE OF THE MOULD AND CURES.

The mould is then cooled and the part removed. There are many advantages to this process. A primary advantage over other processes is size; some of the largest ovens now incorporate a 5.5m swing. Entire boat hulls and automobile bodies are being roto-moulded in one piece. On the small part end, many small PVC parts such as ear syringes and face masks are rotationally moulded.

Another advantage is unrestricted design. Complex geometry is easy to incorporate into a one-piece product design. The application of solid modelling and low cost tools enables the moulder to produce virtually any design. Rotational moulding is a very cost effective method of redesigning four or five thermoformed or sheet metal pieces into one hollow plastic product.

Rotationally moulded products are recognized for their strength and durability. In this no-stress process, material tends to collect in corners and ribs making these areas thicker and thus stronger. The material does not thin out in corners as with other processes.

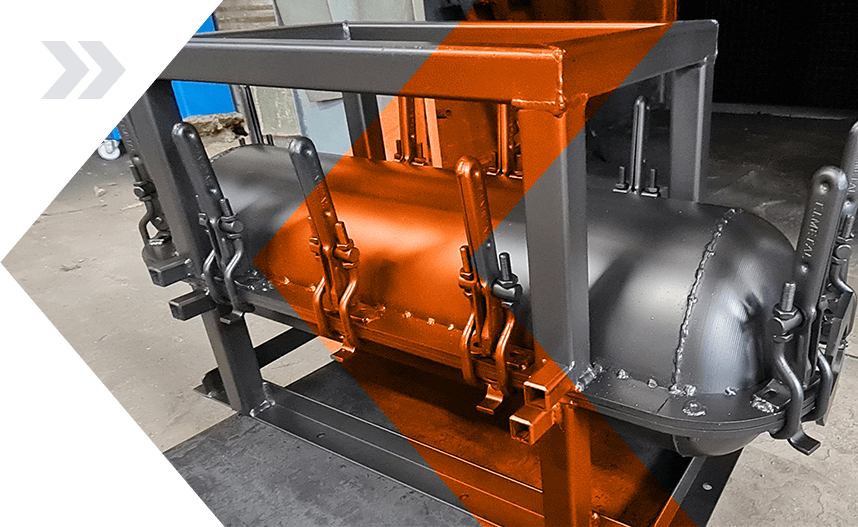

Finally, ease in prototyping. One of the reasons that Rotational moulding is a cost effective alternative to other processes is the low cost of the tooling used in this process. Since Rotational moulding is a stress free process, tools are primarily a thin hollow shell and can be produced from aluminium, stainless steel, mild steel and nickel. The product forms on the inside of the mould therefore tools do not require internal cores. Tooling can be produced quickly and relatively inexpensively to other processes.

THE PROCESS

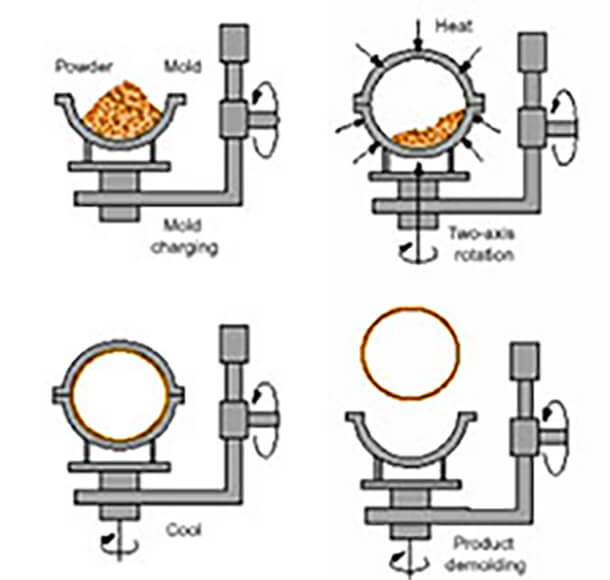

Step 01

Plastic is introduced to a mould in powder form up to the mass required for the required product.

Step 02

The mould is then closed and passed into an oven chamber. The mould is then heated externally to a temperature typically between 220°C and 400°C and is rotated around both vertical and horizontal axes.

As the mould rotates, the inner surface passes through the mass of powder at the bottom of the mould. As the mould heats up, the powder begins to melt and adhere to the inner surface of the mould.

The mould continues to rotate in the presence of heat and more plastic melts and builds up to produce an even layer over the surface of the mould.

Step 03

The mould is then withdrawn from the oven whilst still rotating and moved into a cooling chamber. Cool air is directed at the mould and in some cases a water mist is used to cool the mould. When the plastic inside the mould has solidified, the mould can be removed from the cooling chamber.

Step 04

The plastic component is then removed from the mould and allowed to finish the cooling process unrestricted by the mould.

The plastic is formed without pressure or centrifugal force and as such has no moulded in stresses. The cycle length can vary from five minutes to one hour depending on the material used, the wall thickness and the machinery involved.