Croft Filters Ltd, based in Warrington England, have been supplying custom filtration and separation solutions for over 33 years. Throughout this time Croft has developed a reputation for their quality, bespoke service through manufacturing a variety of products for a range of different industries including: Chemical, Oil, Gas, Energy, Pharmaceutical, Food and Beverage amongst many others worldwide.

Bespoke Filtration Solutions

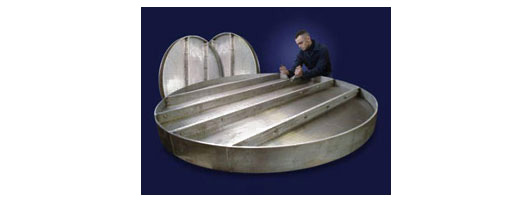

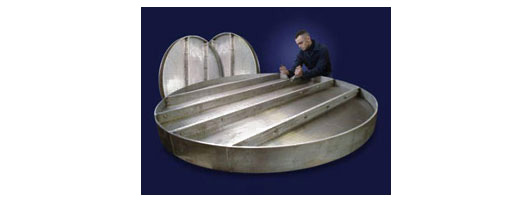

Croft specialise in custom filtration solutions, these are manufactured specifically to the Customer’s unique requirements and can be ordered as ‘one-off’s’ to large batches. Typical filter designs include: basket strainers, duplex filters, cone filters, cylinder filters and screen filters in perforated plate, wedge wire and woven wire mesh.

Croft’s experience within the market alongside their drive for innovation allows the company to solve unique filtration problems that Customers are faced with. Croft can design and manufacture specific filtration solutions for Customers in order to maximise the potential of Customer’s filtration processes.

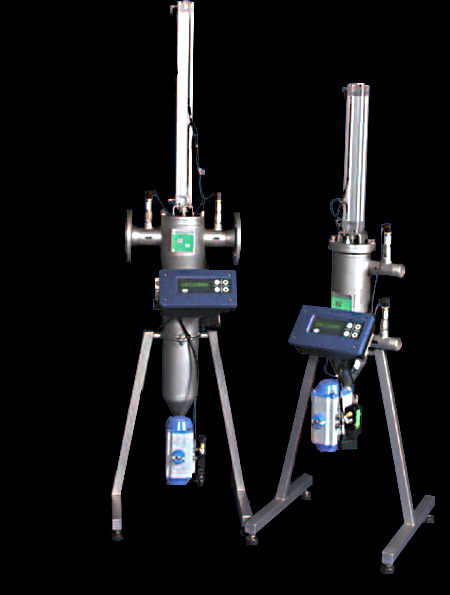

Self Cleaning Filters

In 2013 Croft became distributers for HiFlux Filtration A/S, a Danish manufacturer backed with 50 years experience within the filtration industry. As a result of this Croft have been supplying many industries with quality Self-Cleaning filters designed to reduce downtime and operating costs for the user.

With different models available for a wide range of applications such as: Cooling, Refining and Filtering, the Self-Cleaners use a plunger or a series of scrapers to remove waste caught on the filter element inside the process. This improves the flow through the filter and the lifetime of the element. The captured particles are then be ejected from the system without the need to stop the process or change the element, saving on downtime within the system.

Additive Manufacturing – Metal 3D Printing

In 2013 Croft invested into Additive Manufacturing, specifically Selective Laser Melting (SLM) in order to develop new innovative filtration solutions. Additive Manufacturing (AM), also known as metal 3D printing, is the process of creating a 3 dimensional component through a series of layers.

Benefits of the Additive Manufacturing process, such as: part weight reduction, multi-part to single component and expanded design capabilities, allow Croft’s customers to re-think their approach to their designs in order to improve the efficiency and utility of their parts or to deliver other supply chain advantages. Croft can advise on how to get the most out of the AM technology in order for Customers to achieve their desired advantages.

Whether that means to improve the function of a filtration solution or to develop a new solution all together.

Quality of both product and service has been the key to Croft’s success; the Company takes great pride in understanding their customer’s needs, quickly supplying them with a high quality product that exceeds Customer’s expectations.

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

Basket Filters

Basket Strainers

Bespoke Filters

Bespoke Filters

Bespoke Filters

Bespoke Filters

Bespoke Filters

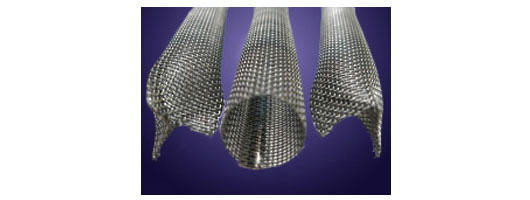

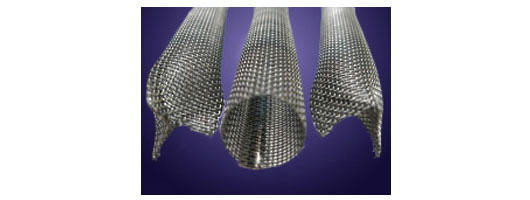

Cone Filters

Cone Filters

Cone Filters

Cone Filters

Cone Filters

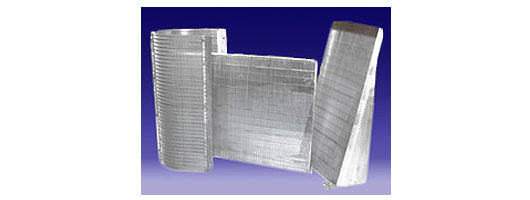

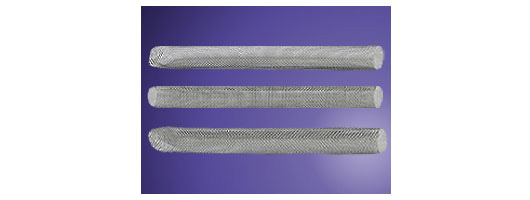

Cylinders

Cylinders

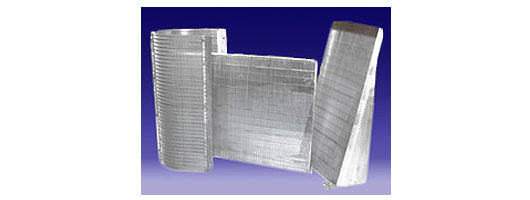

Screens

Screens

Wire Mesh

Wire Mesh

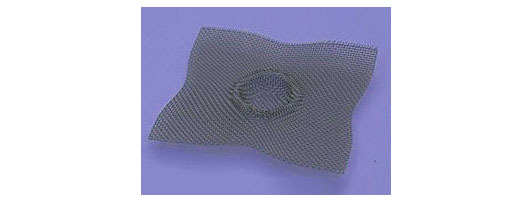

Witches Hat Filters

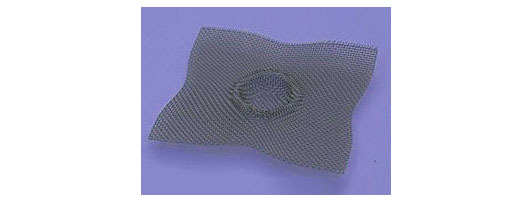

Woven Wire Mesh

Y-strainer

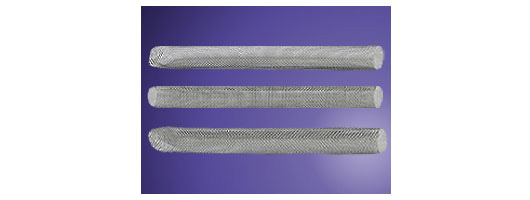

Anchor Mesh Sleeves

Anchor Mesh Sleeves

Wedge Wire

Previous

Next

approvedbusiness.co.ukCroft Filters Ltd Tel: 01925 766265

approvedbusiness.co.ukCroft Filters Ltd Tel: 01925 766265