VEGA non-contact radar level measurement

02 April 2009

Any chemical dosing system can be hazardous, but in a food manufacturing facility safety implications for handling and storage, can be exceptionally important.

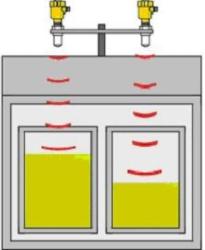

In a dosing system, there are often two containers kept in a protective outer enclosure. One container is used as ‘supply’ and the other is ‘standby’, which are switched over and replaced as they go empty. Monitoring the level inside the containers is paramount, so that a change over can be anticipated, to avoid running out of product.

The difficulty lies in that some chemicals are hazardous, corrosive or toxic and so opening the containers and checking the level manually is far from ideal. Any level probes requiring insertion into the vessels would have to be handled during change over, which is also hazardous, due to potential accidental contact.

Using non-contact radars with microwave technology enables the devices to be mounted well above the enclosure, yet still measure the level of the containers inside. That is because the microwave signals will pass through the plastic outer containers, yet reflect off the more conductive chemical liquids inside. This keeps the chemicals well out of contact with operators, as well as providing advance warning for replenishing.

The radar antenna generates millions of very short 1 nano second microwave pulses every second. Each pulse is transmitted to and reflected from a product surface. The elapsed time period between transmission and reception of the signal at the speed of light is measured and calculated as a distance.

This continuous stream of pulses gives real time level information which is updated and evaluated many times a second. Microwaves are unaffected by temperature, pressure, air movement and virtually all vapours or gases and they can pass through non-conductive materials.

Other Press Releases By This Company

- 18/01/2021 - Level and Pressure specialist VEGA invests in training centre and UK HQ

- 09/02/2018 - On the level, every mm counts

- 09/02/2017 - Not just 'Walking the Walk...'

- 18/10/2016 - It’s all in the price!

- 27/09/2016 - VEGA team steps up to the Plod Challenge!

- 13/04/2016 - Vegatruck has successful UK tour

- 21/03/2016 - Worlds first 80 GHz radar level sensor for liquids

- 15/01/2016 - Visit the VEGATRUCK on its tour of the UK

- 11/06/2015 - Narrow success for solids radar level sensor

- 07/05/2015 - Realising the flexibility of electronic differential pressure

- 07/05/2015 - Vegaflex: the standard for interface and level control

- 07/05/2015 - VEGAPULS 69 – The new radar sensor for bulk solids

- 08/05/2014 - Level Radar at Aston Martin works.

- 21/11/2013 - VEGA get interactive on water

- 20/08/2013 - Innovation Award for VEGAFLEX GWR Sensor

- 07/08/2013 - VEGA UK team feels the heat for charity!

- 19/04/2013 - 100,000 bulk solid radar sensors from VEGA installed worldwide

- 01/02/2013 - World first for tuning fork level switch

- 18/09/2012 - VEGA launch new Guided Wave Radar

- 05/09/2012 - Apps, Tools and more from Vega

- 19/04/2012 - VEGA PROTRAC nucleonic gauging systems

- 20/02/2012 - Let VEGA take the pressure

- 22/09/2011 - VEGAPASS and VEGAMAG

- 13/06/2011 - VEGA launch New remote monitoring solution for level and pressure

- 20/04/2011 - VEGA level radars help deliver £12M savings at TATA

- 25/05/2010 - VEGA DP transmitter features remote housing

- 19/01/2010 - Thames measured by VEGA Radar

- 16/06/2009 - New VEGA signal conditioner with host of solutions

- 20/05/2009 - BP use SIL 2 VEGA radars for floating roof high level

- 10/12/2008 - Renewing energy with every turn takes its toll

- 04/11/2008 - PACTware™ on the road again

- 23/09/2008 - Europe's Largest Newsprint Paper Machine Prints 400,000 tons Annually

- 12/09/2008 - VEGA TDR gets remote housing

- 12/09/2008 - New ATEX approved radiation survey meter from VEGA

- 12/06/2008 - Vibrating level switches for bulk solids up to 150 °C

- 07/04/2008 - Flush pressure transmitter, buy on-line, 2 day delivery

- 09/11/2007 - New VEGA level and pressure webshop extra 5% off offer!