Networked PACS chase metal cracks

07 March 2008

An unusual problem for Industrial Ethernet

An unusual problem for Industrial Ethernet: help find the cause of bearing damage in NASA’s giant Deep Space Network of ultra sensitive receiving systems and large parabolic dish antennas that enable and support interplanetary space missions and radio and radar astronomy observations of the solar system and universe.

NASA’s Deep Space Network (DSN) operates three deep space communications facilities located approximately 120 degrees apart around the world – in California’s Mojave Desert, near Madrid, Spain and near Canberra, Australia. These installations enable continuous monitoring of satellites, space probes, and spacecraft (even as the Earth rotates) and make the DSN scientific telecommunications system the largest in the world.

Among the many missions the DSN is currently tracking is the famed Voyager 1 and Voyager 2 space probes, launched in 1977 and currently more than 9 billion miles from earth headed for the outer reaches of our solar system. The Jet Propulsion Laboratory, founded in 1944 and managed by the California Institute of Technology, manages the DSN antennas for NASA, which uses these antennas to track Voyager and other probes and to receive scientific data about our planet and our universe. JPL has data coming in around the clock, some of it from probes that are traveling through space at a rate of more than 30,000 mph. As a result, all antennas have to be meticulously maintained or non recoverable data could be lost forever. Daisy-chained PACs connected by Ethernet will be used to measure loads as NASA’s 1800- tonne antenna changes its alignment

Last summer, at the DSN site in Madrid, during a time when a 70m antenna was already out of service for scheduled maintenance and upgrades, engineers detected cracks in the antenna’s large elevation bearing system. These bearings support the 1800 tonne weight as it rotates and tilts up and down. The cracks were detected in two pairs of elevation bearings in June 2006 and the antenna’s return to service was extended from four to seven months so repairs could be made.

Having one of the large antennas out of commission created a real but manageable problem. As a remedy, smaller antennas were arrayed together to support the higher data rate capabilities of a 70m antenna. Alternatively, spacecraft data rates were lowered so that these missions could be supported by a 34m antenna. Soon, however, JPL realised they were facing an even more serious problem. The cracking of the bearings in the Madrid installation marked the second time this has occurred in 16 years. Engineers determined there must be something unusual causing these premature failures.

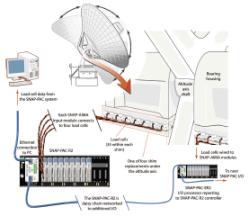

To determine the precise nature of the problem, the Madrid 70m antenna’s bearings will be lifted and the existing shim pack removed and replaced with load cell transducers – devices that convert and express light, sound, pressure and other non electrical forces as an electrical signal. The electrical signal output (normally in the order of a few millivolts) will then be plugged into an algorithm to calculate the force applied. Force will be measured to effectively weigh the antenna as it moves across the bearings. To accomplish this, JPL worked with an engineering company, Force Switch, to design and build custom 15mm thick plates (each with 35 load cells) that will fit perfectly underneath the antenna without disturbing the alignment or compromising its ability to move in any way.

Signal conditioning from the load cell plates will be handled by an Opto 22 SNAP PAC System.

Specifically analogue input modules will connect the four individual plates (one for each set of bearings) to SNAP PAC EB2 processors, which will receive accurate load cell readings—expressed as analogue current inputs in the 20 mA to +20 mA range once every second. The processors will use Ethernet in a multi drop architecture with 100m cable runs. Distributed I/O will be positioned at the four different load cell/bearing locations.

The PAC daisy chain will bring all the load cell readings aggregated by the EB2s back to a central controller for onwards analysis.

Once installed the system will read the 140 analogue signals once per second in a manner as close to synchronism as possible. Eventually, the sample frequency could be increased to 4Hz or possibly more. JPL will then begin studying the data, formulating theories, and determining why the bearings have been cracking

Other Press Releases By This Company

- 15/05/2014 - Introducing groov

- 05/12/2012 - Control without a Controller

- 15/08/2012 - See our refurbished EPSON Robots in action

- 10/05/2012 - Control systems Go Mobile

- 10/05/2012 - EPSON Robotic Arms