Established in 1991, Advanced Plastic Technology combines a vast amount of experience with outstanding plastic processing technologies to ensure high-quality, cost effective products and services to a diverse group of individual manufacturers.

Through developing new and innovative methods of designing plastic components, we at Advanced Plastic Technology are able to keep all operations and technologies flexible enough to ensure a wide variety of supplies and sub-assemblies.

Here at Advanced Plastic Technology, we believe that cost, quality and fast delivery are absolutely essential for excellent customer service, so we have a team of experienced specialists who are devoted to improving these factors and offering help and support wherever possible. We as a company ensure that all employees participate in ongoing improvement activities so that they can provide consistently reliable service.

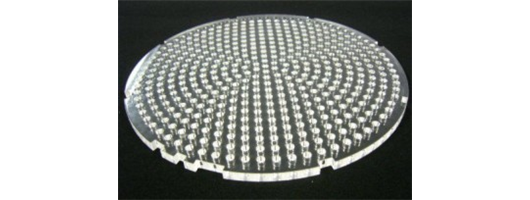

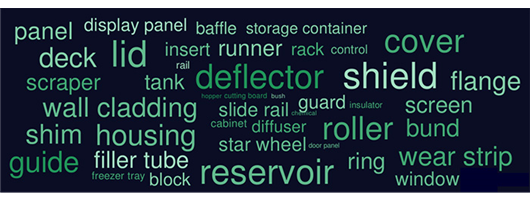

Here at Advanced Plastic Technology, we supply our wide range of products to a vast array of industries and sectors, which include Capital Equipment, Print, Construction, Shop Fitting, Aerospace, Industrial Equipment, Water, Electronics, Audio Equipment, Lighting, Nuclear, Specialist Automotive, Engineering, Lab Equipment, Chemical Plant, Food Processing Machinery, Oil and Gas, Rail, Building Materials, Kitchen Equipment and Medical Devices. Each of these industries have a need for plastic components and sub-assemblies, and rely on our extensive knowledge and experience as well as our excellent process capabilities.

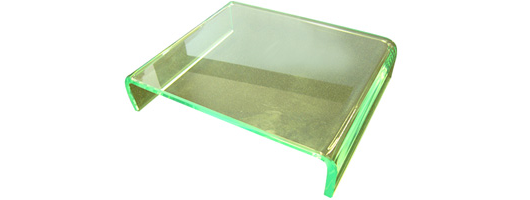

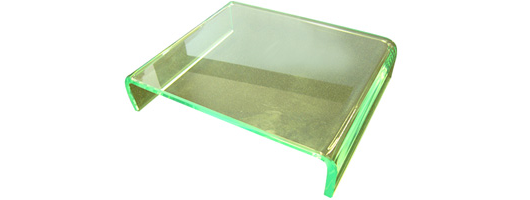

Through the use of plastic products and services, these industries and sectors will gain better quality, more reliable delivery and advanced materials expertise. For example, one advantage of choosing polycarbonate over glass is that it is a clear plastic material which is much stronger and more durable. Plastic panels are also less expensive to make and are more beneficial than using painted sheet metal.

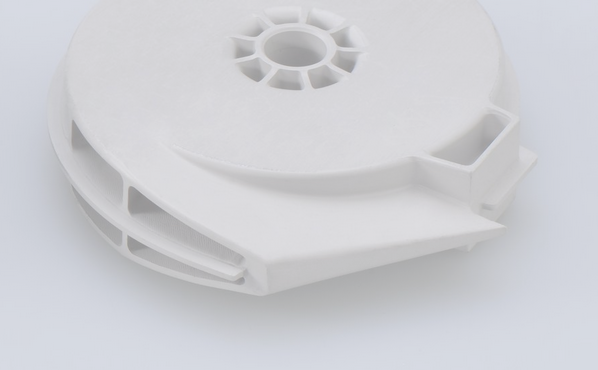

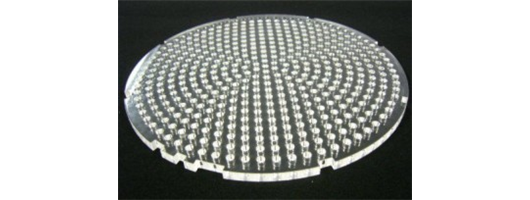

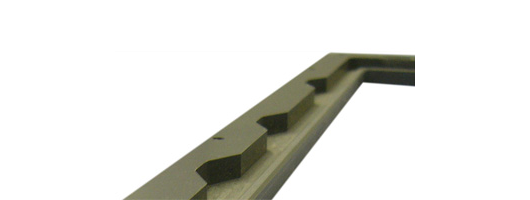

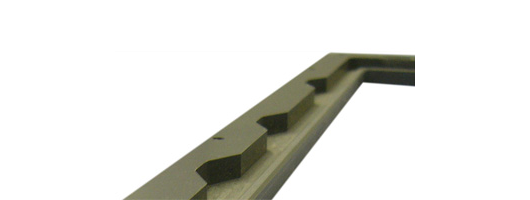

Advanced Plastic Technology has supplied a wide range of plastic-related services for over twenty years, including Plastic Laser Cutting, Laser Engraving, CNC Machining Plastic, CNC Routing Plastic, Line Bending, Drape Moulding, Fabrication, Welding and Assembly. We as a company work closely with clients and maintain positive working relationships to ensure that their needs are met quickly and efficiently. We are able to review designs and point customers in the right direction so that they can find the best fit for them.

We at Advanced Plastic Technology are always willing to offer and suggest a variety of options for clients to choose from and tweak designs to maintain high quality and low costs. Throughout the design process, our company offers product packaging, insert fitting, mechanical assembly, polishing, heat treatment and printing to all clients, which results in meeting their requirements and exceeding their expectations, therefore boosting our reputation and leaving customers satisfied every time.

-

-

-

-

-

-

-

-

-

-

-

-

Plastic Laser Cutting

Plastic Fabrication

Plastic Drape Moulding

CNC Routing Plastic

CNC Machining Plastic

Laser Engraving Plastic

Plastic Line Bending

Plastic Welding

Assembly

Industries

Materials

Components

Previous

Next

approvedbusiness.co.ukAdvanced Plastic Technology Tel: 01908 305710

approvedbusiness.co.ukAdvanced Plastic Technology Tel: 01908 305710