Established in 1940, Knight Strip Metal has gained an enviable reputation in premium quality precision strip metals and wire in a range of raw materials including stainless steel, high performance alloys, mild & carbon steels, copper & copper alloys, titanium & titanium alloys, aluminium and aluminium alloys.

Knight Strip Metal, also known as Knight Group are well established in the metal industry and as such are the supplier of choice for many global organisations throughout the world. Our success is built up by our core values ensuring that you get the very best from your metal and metal processing supplier. Our mission is to become not only a local manufacturer but also deliver results on a global scale providing you with the highest quality materials and processing services.

> Quality – Our commitment to all our customers it to provide them with the very best service and top quality products giving you the highest standards that you deserve.

> Efficiency – We work alongside our customers, offering the very best service and support, helping reduce production costs without compromising on quality as well as delivering on time.

> Innovation – We strive to provide the very best service to our customers, we embrace all new challenges, creating tailored solutions that exceed expectations.

> Trust – We want our customers to be completely satisfied with our work, we build long lasting relationships due to our focused approach on ethical, responsible and fair business practices.

> Partnership – We work alongside both customers, colleagues and suppliers and value their input on the best practices to achieve goals and maintain a sustainable business.

> Investment – We continue to invest time, effort and money to provide all business partnerships success not only for our customers but also on-going business growth.

In addition to the supply of the raw materials we are also recognised as industry leaders in the processing of strip, coil and wire. These services include;

> Recoiling – supplied in a range of coil sizes and weight options including pancake coils, traverse wound spools, open sided oscillate wound coils, up to 1000mm wide, low weight coils, coils on cardboard centres

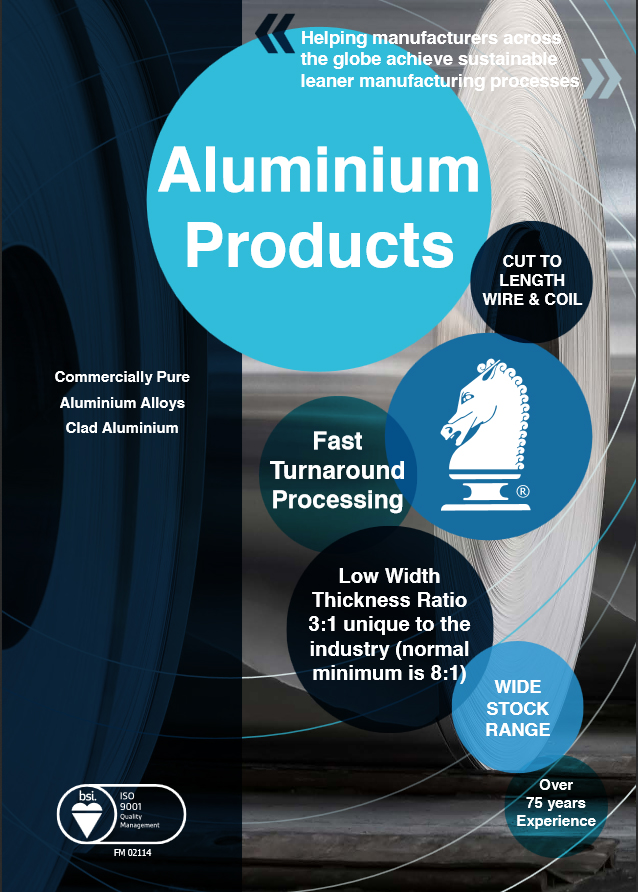

> Slitting & Shearing – for ultrafine tolerances and substantially superior width thickness ratios of 3:1

> Traverse Winding – an alternative to single coil pancake coils, increasing productivity and enables longer uninterrupted production runs

> Cut to Length – raw materials cut to exact customer specifications

> Edge Dressing – material edge dressing to your specifications reducing the risks of injury and manufacturing time.

Why choose us your metal and metal processing supplier?

With a dedicated and experienced production team with years of experience in the metal industry, the Knight Group are well equipped to offer a full range of high standard and efficient metal processing services. Whether you require slitting, shearing, traverse winding, material cut to length or edge dressing then we can help. All processing is based on a competitive price and all work carried out is flexible so that you only get the services you require.

We stock Europe's largest and most comprehensive range of precision metal strip and wire, in a variety of different grades including stainless steel, mild steel, nickel and nickel alloys, titanium and titanium alloys, aluminium and aluminium alloys, bronze and copper alloys.

We can work with all requests, whether its large volumes of metal or test materials for prototypes we can provide you with the materials you need for your project without comprising on quality or cost.

The Knight Group has worked with a number businesses including Rolls-Royce, BAE Systems, Airbus UK, Westland Helicopters and HS Marston Aerospace Ltd to name a few.

approvedbusiness.co.ukKnight Strip Metals Tel: 01707 650251

approvedbusiness.co.ukKnight Strip Metals Tel: 01707 650251