Etch Tech are a photo etching, chemical milling, photo fabrication and photochemical machining specialists offering our services to OEM customers and sole traders throughout the UK.

The chemical milling manufacturing process is known under different names due to the worldwide development and refinement process. Etch Tech commonly refer the process, Chemical milling, however it can also be named as Photo Etching, Photochemical Milling, Photochemical Machining, Photo Milling, Photo fabrication, PCM, Chemical Etching, Acid etching or Chemical Blanking.

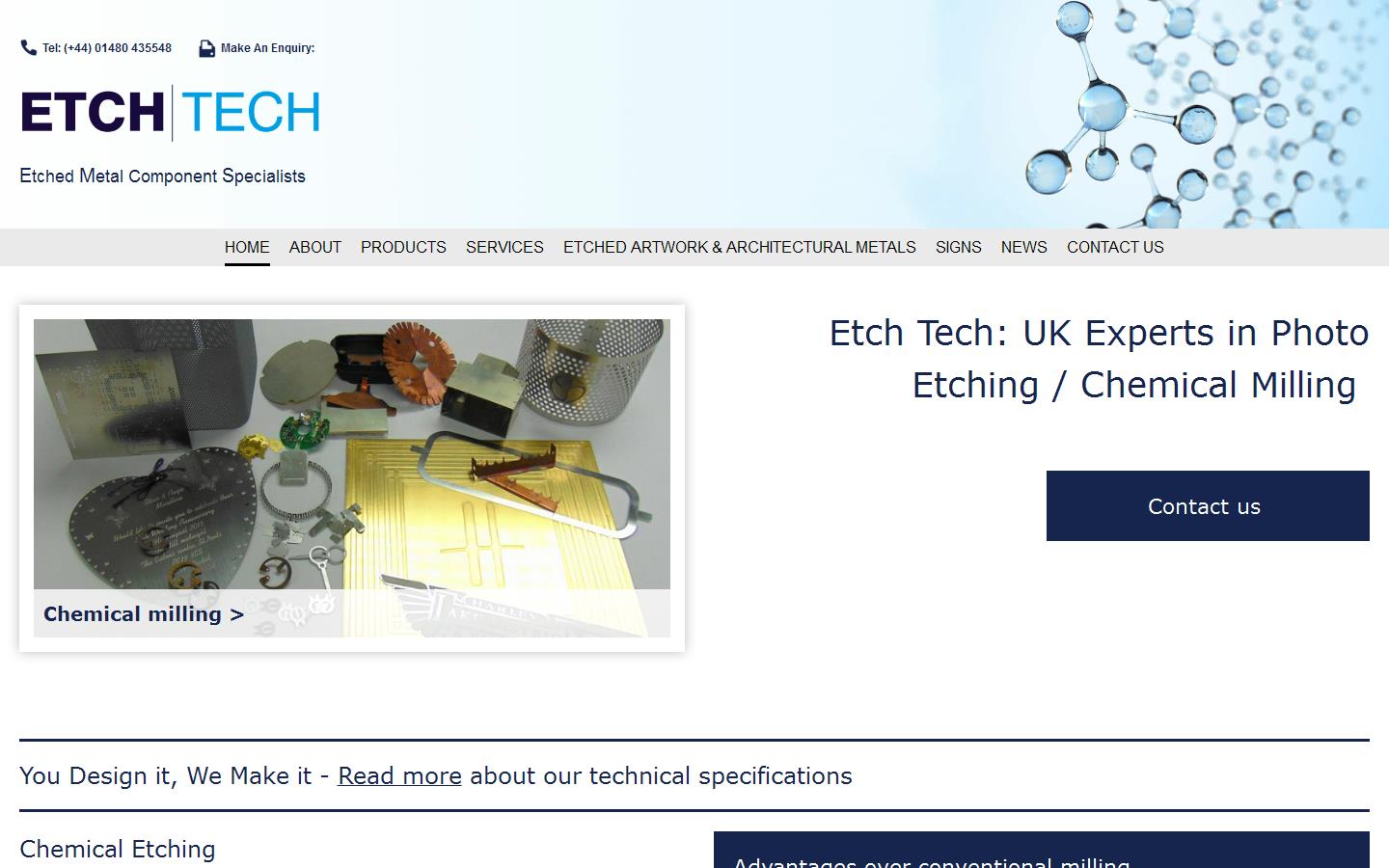

The long established chemical milling or photo etching process allows us to produce high precision fine gauge sheet metal components. We can produce thin (up to 3mm thick) metal components in both ferrous and non-ferrous metals. The process uses acids to dissolve away any unwanted material leaving you with the exact shape and size of your finished components.

Using the Chemical Milling process offers many advantages over traditional machining or stamping methods. The Main advantages include;

- Rapid manufacturing process

- Low cost

- Free from mechanical stresses and burrs

- Free from burnt edges or processing residue (dross)

- Ideal for prototype and production volumes

- Design changes and modifications rapidly and economically produced

- Half etched fold lines for part marking and cost effective forming

Due to the nature of its production Low Cost Tooling and Design Modifications are standard from Etch Tech. Tooling consists of a set of precision photographic negatives, produced on the industries best design and drafting programs. Once drawn and QA approved, they are stored on our dedicated server and available for printing at any time. As well as being very efficient, it gives you the added advantage of being able to modify your component at any time, without expensive tooling modification charges. Unlike hard tooling methods, the existing tooling does not have to be decommissioned in order to make modifications. Your production schedule is not at risk in any way whilst your modifications are implemented.

In addition there is also an option to have your component park marked which involves the chemical milling process to etch on one or both sides of the component at the time of manufacture. Your company logo, part numbers, address or even a picture can be permanently etched at your desired location.

approvedbusiness.co.ukEtch Tech Ltd Tel: 01480 435548

approvedbusiness.co.ukEtch Tech Ltd Tel: 01480 435548