11 April 2024 | Brady Corporation Ltd

Track printed circuit boards throughout production

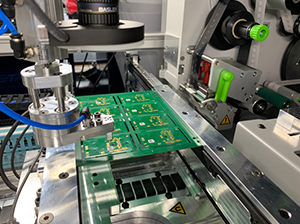

An electronics manufacturer fully automated printed circuit board identification at the start of production on all SMT-lines with A8500 FlexCell Printer Applicators from Brady.

Challenge: Track from the start of productionA large electronics manufacturer wanted to bring printed circuit board traceability labelling to the start of its SMT production lines. This would enable the company to track every PCB in production by scanning labels at any location along the line.

Because of label variety and the number of labels required on each PCB, labels could not be printed in advance. Any equipment used to enable the solution had to be fast, and able to place labels on both sides of a PCB with 0,1 mm maximum tolerance.

Solution: Dedicated labels, automatically printed and applied

Brady proposed its A8500 FlexCell Printer Applicator and extremely thin B-7727 polyimide labels for auto-apply. The system recognises PCB’s and automatically prints and applies every label required on both sides of a PCB, in 3 seconds per label.

A8500 FlexCell Printer Applicator

The A8500 FlexCell Printer Applicator can print and place a label anywhere on a PCB in 3 seconds. Designed as a production line module with SMEMA-compliance, it can be plugged in anywhere along an SMT production line.

To further support the electronics manufacturer, Brady equipped the system with a software package that automatically recognises barcodes on PCB base plates. When passing through, the system auto-recognises the project the PCB belongs to. The FlexCell then prints and places all required labels in the right locations. Each label is placed with pressurised air, at 0,1 mm maximum accuracy tolerance, both on the top and bottom of PCB’s. Label data are sourced from the customer’s central ICT systems.

FlexCell liners were adapted to also enable automatic label placement at the edge of PCB’s, making full use of the system’s high label placement accuracy and precision.

In addition, a pause option was added for quality checks at discretion. The FlexCell simply resumes serialisation where it left off, without any further manual intervention.

Dedicated PCB traceability labels

After label sample testing, the electronics manufacturer selected Brady’s B-7727 polyimide label. Designed to withstand multiple cycles of harsh condition washes for printed circuit boards, the label stays attached and remains legible throughout printed circuit board production. 0.1 mm thick, it is able to resist temperatures up to 300°C for 80 seconds without any visible effect. This allows tiny label QR-codes to be read by scanners throughout production.

Results: Traceability at 3 seconds per label

With multiple A8500 FlexCell Printer Applicators in place, the large electronics manufacturer can quickly label printed circuit boards at the start of production. This enables real-time tracking of PCB’s in production and generates data for efficiency analysis. All without delays or production bottlenecks, and in full compliance with printed circuit board traceability requirements from customers.

Print and apply at production pace

Brady offers a range of systems that can print and apply labels automatically to support compliance and traceability for manufacturers worldwide. Our labels are researched, tested and adapted for automatic application to enable compliance and traceability at production pace. Learn more about automated Print & Apply Systems on Brady’s websites.