10 July 2025 | Precision Waterjet Ltd

Waterjet Cutting Beyond Industrial Applications

At Precision Waterjet, we know that the potential of waterjet cutting extends far beyond the world of manufacturing and industry. Thanks to its unrivalled precision and versatility, waterjet technology is also an exceptional tool for creative, artistic, and architectural applications - helping bring even the most intricate designs to life.

The unique precision of waterjet technology

Waterjet technology offers heightened precision that is ideal for many creative projects. Using highly pressurised water mixed with abrasive particles, our advanced OMAX waterjet machines can cut through an impressive range of materials, all while maintaining extraordinary accuracy. This means that artists, architects, and designers are no longer limited by traditional cutting tools that struggle with fragile or intricate designs.

Unlike laser or plasma cutting, waterjet cutting uses no heat, which means there’s no risk of heat distortion. This cold-cutting process allows us to achieve perfectly smooth edges, making it ideal for materials that demand finesse as well as strength.

Unlocking artistic possibilities

At Precision Waterjet, we’ve worked with a wide range of creative professionals across the UK to help turn their visions into reality. Whether it’s producing bespoke glass panels for interior design, crafting custom marble inlays for luxury flooring, or creating intricate metal sculptures, our team thrives on projects that require both technical expertise and creative problem-solving.

More than just cutting — a full-service approach

At Precision Waterjet, our team brings years of experience and a genuine passion for problem- solving to every project. We work closely with each client, whether they’re artists, architects, or interior designers, to understand the unique demands of their vision. From initial concept discussions to choosing the right materials and fine-tuning every detail, we offer a bespoke service that many other providers simply can’t match.

Partner with Precision Waterjet for your creative projects

Whether you’re a designer dreaming up a one-of-a-kind centrepiece or an architect needing flawless precision for a complex installation, Precision Waterjet offers the expertise, technology, and dedication to bring your project to life.

If you’re exploring a unique project that requires absolute precision, contact us today to learn more about how our waterjet cutting services can support your vision.

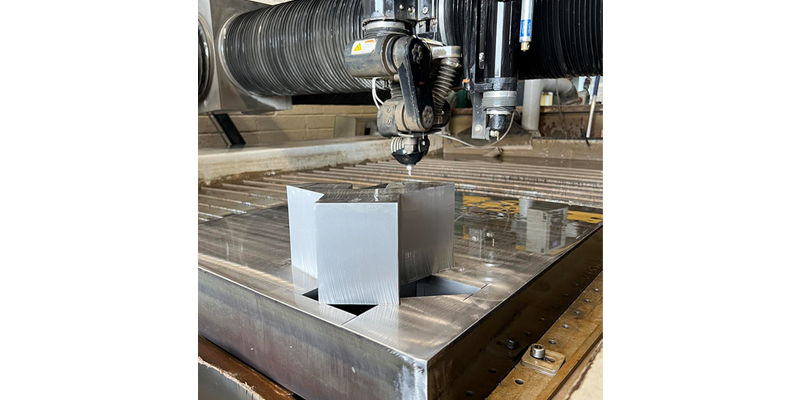

How we achieve square-edge accuracy with precise waterjet cutting

At Precision Waterjet, we understand the importance of delivering exceptional accuracy in every project we undertake. With our advanced technology and state-of-the-art OMAX waterjet cutting machines, our team produces components with precise square-edge accuracy. In this post, we’ll take a deeper dive into the technology behind our cutting-edge machinery and explain how we achieve such remarkable precision.

What is waterjet cutting?

Waterjet cutting is an advanced manufacturing process that uses a high-pressure stream of water, often mixed with abrasives, to cut through various materials. Unlike traditional cutting methods that rely on heat or mechanical tools, waterjet cutting remains cold throughout the process. This makes it ideal for materials that are sensitive to heat distortion.

At Precision Waterjet, we use OMAX waterjet machines, which are known for their superior precision, fast cutting speeds, and versatility. This technology ensures we achieve an exceptionally clean edge without compromising on detail.

Achieving square-edge accuracy

One of the defining features of our cutting process is our ability to achieve square-edge accuracy. Square-edge cutting refers to the ability to produce parts with edges that are perfectly perpendicular to the surface of the material. This allows you to achieve precise, uniform cuts without tapering or uneven edges.

This is particularly important for industries such as aerospace, automotive, and manufacturing, where precision is critical. In many cases, our square-edge cuts eliminate the need for secondary machining processes, which saves both time and money. The result is a higher- quality product with fewer steps in the production process.

Here’s how we ensure such high accuracy:

- Advanced OMAX Technology: Our OMAX machines are engineered with precision in mind. With advanced features like IntelliMAX® software, we can program intricate cutting paths that allow us to cut parts with unparalleled accuracy. The machines automatically adjust for variables such as material thickness, ensuring consistent, square edges on every piece.

- Dynamic waterjet stream control: OMAX waterjets are equipped with precise stream control mechanisms, which allow for the exact regulation of water pressure and speed. This ensures the cutting stream remains focused to prevent any tapering or distortion that can occur in traditional methods.

- Continuous monitoring and calibration: Our OMAX machines are equipped with sensors that continuously monitor and adjust the cutting process. This real-time feedback ensures that the waterjet is always operating at its optimal performance, allowing us to produce square-edge cuts with consistency and reliability.

- Fine abrasive cutting: For materials that require additional precision, we use a fine abrasive material. This further enhances the cutting power, creating smoother and sharper edges. The result is an incredibly clean and accurate cut that reduces the need for any further post-machining work.

Why choose Precision Waterjet?

With our focus on precision, quality, and efficiency, Precision Waterjet has earned a reputation for excellence in the cutting industry. Our square-edge cutting technology ensures that every project meets the high standards demanded by our customers in various sectors, including aerospace, automotive, and manufacturing.

If you’re interested in learning more about our OMAX waterjet cutting technology and how it can benefit your project, contact us today. Our expert team is ready to discuss your specific requirements and provide tailored solutions that will meet your exacting standards.

How waterjet cutting supports the aerospace industry

At Precision Waterjet, we understand the critical importance of precision when it comes to manufacturing components for the aerospace industry. The aerospace sector demands the highest standards in materials, design, and production processes. Waterjet cutting technology has proven to be an invaluable tool in meeting these rigorous requirements. By offering exceptional precision, waterjet cutting ensures that aerospace components are manufactured to exacting standards.

Precision Waterjet cutting for aerospace components

Waterjet cutting is a non-thermal process that uses high-pressure water to cut through various materials with high precision. This makes it an ideal solution for the aerospace industry, where the need for accuracy is paramount. Waterjet cutting provides a clean, smooth edge without the heat-affected zones (HAZ) commonly associated with other cutting methods such as laser or plasma cutting.

For example, in the aerospace industry, precision is needed for manufacturing parts like turbine blades, structural components, and cockpit panels. These parts are often subjected to extreme conditions. Waterjet cutting allows for intricate and complex cuts with extremely tight tolerances, which is essential for many components.

Case Study: Aerospace component manufacturing

To illustrate the benefits of waterjet cutting, consider the case of the carbon fibre composites we worked with. The company required a cutting solution that could maintain tight tolerances. By employing waterjet cutting, we were able to deliver the precision they needed without the risk of warping or thermal distortion that could compromise performance.

This is just one example of how Precision Waterjet's technology is utilised in the aerospace sector. Our waterjet cutting machines can handle a variety of materials that are commonly used in aerospace manufacturing, including aluminium, titanium, composites, and other high- performance materials.

Meeting the demands of highly specialised industries

Precision Waterjet has become a well-revered name in the aerospace industry, known for its ability to meet the specific needs of highly specialised sectors. We are proud to be a trusted partner to some of the UK’s most prestigious aerospace manufacturers. From prototyping and low-volume production to high-precision custom parts, our waterjet cutting services provide the ideal solution for creating components that perform under the most demanding conditions.

Why choose Precision Waterjet?

At Precision Waterjet, we pride ourselves on providing top-quality service and results for industries that demand nothing less than perfection. Our state-of-the-art technology, coupled with our experienced team, ensures that every project is executed with the highest level of precision and efficiency.

To learn more about our waterjet cutting services and how we support the aerospace industry, contact us today.

Precision Waterjet?