29 March 2012 | Fluid Conditioning Services Ltd

Maltby Colliery coalface equipment cooling

Maltby Colliery is a coal mine situated in the rural heart of the South Yorkshire countryside, twelve kilometres east of Rotherham. Its giant enclosed headgear dominates the nearby town of Maltby and the surrounding countryside in all directions.

The colliery has worked a number of seams and has been producing high quality coal for more than one hundred years and is now one of the few remaining deep mines in the UK. It is in fact the deepest mine in the UK and Maltby Colliery is also one of the most modern deep pits. It produces more than 1 million tonnes of coal per year, with around five hundred people employed there.About sixty percent of Maltby’s output is supplied to the Drax Power Station; Europe’s largest coal-fired power plant. Around thirty percent is supplied to its owner, Hargreaves Services plc, Monckton Coke Works near Barnsley.

With low phosphorous, low moisture and ash levels and a very high calorific value, Maltby coal is ideal for producing coke to a consistently high quality, making it ideal for use by a wide range of industrial customers, both in the UK and in Europe.

In October 2010 Maltby Colliery was awarded Carbon Trust Standard status in official recognition of its efforts to measure, manage and significantly reduce its carbon emissions. Maltby has reduced the amount of carbon dioxide released into the atmosphere by almost 76,000 tonnes.

Since meeting Graham Downes, Application Engineer from Environmental Treatment Concepts, (ETC) they are well down the road of making further significant efforts to improve their contribution to sustainability. This involves making their underground equipment work for longer at greater efficiency and reduced the need for replacements.

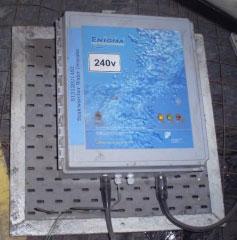

ETC introduced the Colliery to a method of dealing with hard water scaling problems using electronics rather than traditional chemical means, using their Scalewatcher Enigma. As they have a long history of equipment downtime and failure due to limescale, colliery staff were keen to try, what was for them, an untried method of dealing with the problem.

Water is used to cool many of the moving parts of mining machinery and as the quality of the mine water is low with high mineral content, heat causes precipitation of calcium etc, increasing friction and hence further heating resulting in further scale deposits and on it continues until something has to give.

Consequential failure often causes unplanned downtime resulting in massive costs, typically £20,000 per hour and downtime due to scaling can last days and even result in requirements for replacement plant and machinery. The equipment that actually cuts away the coal is called a shearer and the cost of a replacement is £1,000,000.

ETC’s twenty one year old technology has long proven to be effective at protecting even the largest hot water systems from energy sapping scale making a large impact on sustainability by reducing failure and subsequent need for replacement, now has added the mining industry to its long list of keen advocates.

Specific areas of excessive ochre / scale build up include the triple torque coupling which form part of the belt mechanism and the Shearer which requires a constant feed of cooling water. On the Shearer water creates a rotary air current which dilutes any flammable gasses to a safe level, making it essential that water supply lines are kept free of restrictions due to scale deposits.

Production Undermanager, Antony Camm, was well pleased with ETC’s response; a suitable unit arrived the day after the first formal meeting and Graham was one kilometre underground a few days later to assist with installation of their first unit Maltby are about to order their fourth system for fitting underground to protect machinery vital to the efficient operation of their mine. Coalface personnel also benefit from less disruption and risk from failing equipment. Face Worker, Nigel Freely stated “It is clear there have been far fewer delays due to scale formation since the Scalewatcher Enigma was installed”.

ETC’s MD, John Thompson, stated “We are extremely proud to be able to reduce costs and improve safety for a great and proud British industry”.