Company details for:

Alpha Converting Equipment Ltd

Unit 16,

Edison Road,

Elms Farm Industrial Estate,

Bedford,

MK41 0HU,

United Kingdom

Quick Links:

Products / Services

Slitter Rewinders

Duplex HR Slitter Rewinders

The web is arranged for overhead delivery to keep the clean web away from potentially dirty floors while allowing easy access for visual inspection.

Individual Arm Slitter Rewinders

The shaftless winding technology provides high speed unloading of the rolls either manually or, for larger rolls, directly onto roll carts. All models can be supplied with automatic knife positioning and powered or automatic arm positioning to improve productivity. The touch screen operator interface has simple recipe systems for multiple material types and slitting parameters.

Centre Surface Slitter Rewinders

Centre Slitter Rewinders

The ALPHALAB can be supplied with twin differential rewinding shafts for sensitive films and foams or with single winding shaft suited to labelstock, papers and rotary die cutting applications. The touch screen operator interface has simple recipe systems for multiple material types and slitting parameters.

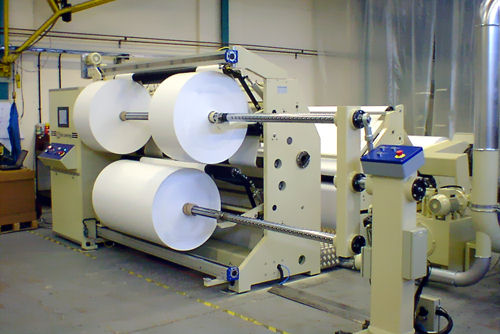

Shaftless Unwind Rewinders

The shaftless chucks are selected to suit the customer cores and may be air inflated, torque activated or mechanically expanding through end pressure. The shaftless winders are of heavy duty construction for long life.

Cantilevered Shafted Unwind Rewinders

Shafted Unwind Rewinders

The cantilevered air inflated shafts remain in the machine for easy loading and unloading of small rolls. ALPHAREEL winders are of heavy duty construction for long life.

Custom Built Unwind Rewinders

ALPHAREEL winders are of heavy duty construction for long life.

Salvage Rewinders and Inspection

Standard salvage (doctor) machines allow you to recover badly wound rolls or to remove faults identified in the roll. Inspection machines are supplied with bidirectional winding, whilst combining machines are optimised for loading of the small in-feed rolls for quick consolidation into one large roll.

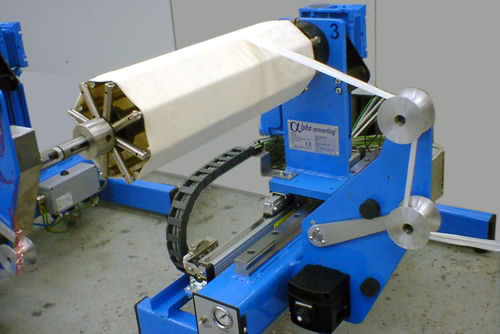

Stand Alone Pancake Spoolers

Non-Stop Spooling Machines

For high speed lines twin spoolers with automatic cut off can be supplied so that the tape only needs to be transferred from the finished spool to the new core before restarting.

Slit Spooling Machines

The cantilevered unwind and rewind shafts provide quick roll change whilst the servo control systems ensure precise spooling. All Alpha spooling machines are of heavy duty construction for long life.

Pancake rolls may be produced on a slitter rewinder such as an ALPHALAB TWIN slitter or on a single knife log slitter.

TWM Trim Winders

Pneumatic Trim Winders

Each trim winder is driven by its own variable speed motor running under closed loop tension control from a precision pneumatic dancer.

Automatic Slitter Rewinders

Automatic Turret Slitter Rewinders

Standard tapeless (cinching) start at the beginning of wind helps to prevent adhesive contamination in subsequent processes. Automated delivery out to a banding and printing head and automated unload of the finished roll is all achieved without any input from the operator.

Cut to Length Machines

The cutting method is selected to provide the optimum cut quality, reliability or product handling. Cut to length machines can sheet wide films with subsequent placing for laminating to the primary product or cut profiled product direct from an extruder with automatic batching into bags or boxes running on conveyorised system.

Web Handling Print Platforms

Alpha's expertise in web handling can be mixed with Alpha's expertise in sheet and product handling to print onto almost any product type. Together we are stronger.

About us

Alpha Converting are different from other companies within the converting industry in that we use the latest in innovative technology with exceptional high standards of technical engineering.

Alpha are continually developing all of our standard machine ranges as well as producing new custom made machines for a diverse range of industries. We also stock a range of materials which is regularly expanding to keep up with the rapid increase of products we have on offer.

Our equipment range processes materials such as;

Printed Film − Label stock, Nonwovens, waterproof membranes, food casings, brass strip, steel strip, scouring pads, magnetic strip, dry film photo resist, printing plates, polyester

Colour Filter − Foam adhesive, wound dressing, paper, newsprint, tissue, airbags, RFID, textiles, printing blankets, nickel foam, webbing

Cable Wrap − Metallised film, laminates, technical leather, polypropylene, polyester, polyethylene, polystyrene, polycarbonate, polyvinyl chloride