Company details for:

ASK Piearcey Ltd

7 Malvern Terrace,

Weymouth,

Dorset,

DT4 0NR,

United Kingdom

Quick Links:

Products / Services

Odour Control

VOC Abatement

Solvents and other organic, vapour releases, can be toxic to the environment (and humans), act as ozone depleting agents and cause nuisance effects such as odour , visible plumes or mild allergic reactions.

VOCs, depending on the process and whether it is an IPPC or LAPPC controlled installation, have set emission targets. The targets are generally given as carbon in mg/Nm3 (N denotes normalised -zero degrees centigrade flow.) Most VOCs fall between 20 -50 mg/Nm as carbon but dioxins and Isocyanates (amongst others) have more stringent limits.

VOCs are generally handled with activated carbon or oxidisers. Wet scrubbing is not usually applicable to this type of emission, however advanced bio-filtration techniques are now being successfully applied in some cases

Air Pollution & Energy Recovery Systems

The kind of work we undertake:

Scrubber, Adsorber, Bio-filter, Oxidiser, Solvent Recovery, Condap System Sizing, Specification and Selection, Design Vetting

PID, FDS, Control Philosophy, G/A, Commissioning Schedules, Technical Report Generation

Gastech Analysis, Arrangement for Olfactometry, Smoke Testing, Flow Measurement, Problem Definition and Reporting

Project Engineering, Site Supervision, Commissioning, Performance Testing and Trouble Shooting

Proposal Designs, Product Designs (e.g Standard Ranges), Document Reviews, Tender Management

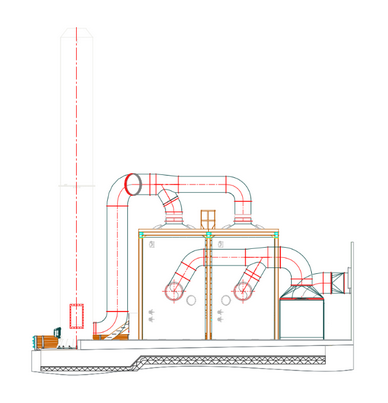

Full design briefs can start from site surveys to assess the processes causing emissions and then to characterise and quantify the emission. Suitable fume capture systems are then designed with a view to providing cost effective and reliable containment of emissions. Where appropriate the end-of-pipe technology required to abate the fume can be selected, sized and specified for tender.

ASK Piearcey can then manage the project to procure and install the various components (fans, ducting, electrics, controls, abatement units etc), we can even test and commission the system.

Wet Scrubbing

The most common types of scrubber that we design are the Counter Current Packed Tower (CCPT) and Venturi scrubbers.

Venturi Scrubbers

Energy Recovery

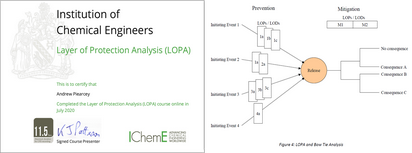

DSEAR Study Support

Quantification of possible scenarios

Characterisation of associated risk

Discussions on resulting proposed zoning/mitigation methods

General Process Engineering

P&ID generation

Equipment sizing

Pressure loss Calculations

Tender Specification & Evaluation

Control Philosophy generation

Operational Instructions Development

Safety reviews/analysis

LOPA Support

Selection of TMEL

Mitigation design

HAZOPS

Chair/Facilitator (in-house database driven system)

Reporting (Actions and HAZOP outcomes)

Node selection

About us

We also design chemical process systems, such as inorganic chemical production, torrefaction, and solvent clean-up systems, while exploring opportunities for energy recovery and optimisation where feasible. Additionally, we offer support for HAZOPs, LOPAs, and DSEAR studies.

Our Services Include:

Odour Control

Odour control is a specialised aspect of air pollution management that directly affects the public and involves complex performance measurement. ASK Piearcey Ltd employs a comprehensive approach to ensure effective solutions, which includes determining compliance and legislative requirements, investigating odour-generating processes, quantifying emissions, negotiating odour consent with authorities, and designing fume capture and abatement systems. They also develop an Odour Management Plan (OMP), oversee the tendering and procurement processes, supervise system installation, assist with commissioning and testing, and create monitoring protocols for ongoing compliance with the OMP.

VOC Abatement

Volatile Organic Compounds (VOCs) are carbon-based chemicals that exist in gaseous form under emission conditions. These compounds, including solvents and organic vapours, can be harmful to both the environment and human health, contributing to ozone depletion and causing issues such as odour and allergic reactions. Emission targets for VOCs vary depending on the process and whether the installation falls under IPPC or LAPPC regulations, typically measured as carbon in mg/Nm³. Most VOCs range from 20 to 50 mg/Nm³, while substances like dioxins and isocyanates have stricter limits. VOCs are typically managed using activated carbon or oxidisers, and advanced bio-filtration techniques are increasingly being utilised as well.

Air Pollution & Energy Recovery Systems

ASK Piearcey offers comprehensive Air Pollution Control solutions and carries Professional Indemnity insurance for design assurance. Our services include the sizing, specification, and design of scrubbers, adsorbers, bio-filters, oxidisers, and solvent recovery systems, along with PID, FDS, control philosophy, and technical report generation. We conduct gas analysis, olfactometry, smoke testing, and flow measurement, and provide project engineering, site supervision, and troubleshooting. Starting with site surveys to assess emission processes, we design effective fume capture systems and select appropriate end-of-pipe technologies for abatement. We also manage the procurement and installation of all necessary components and conduct testing and commissioning of the systems.

Our in-house engineering experience spans over 30 years and covers all key air pollution control technologies and their applications. We have worked across multiple industrial sectors, including nuclear, food, chemical, pharmaceutical, and waste management, acquiring significant expertise in tackling the various challenges of operating these processes under progressively stricter environmental regulations.

We offer unbiased advice, design, and evaluation for various schemes, including the option of zero abatement when in-process improvements are sufficient. With abatement systems ranging from £100k to £10M, we help you confidently choose the most effective route for compliance with current and future regulations.