Company details for:

CentraTEQ Ltd

Quick Links:

Products / Services

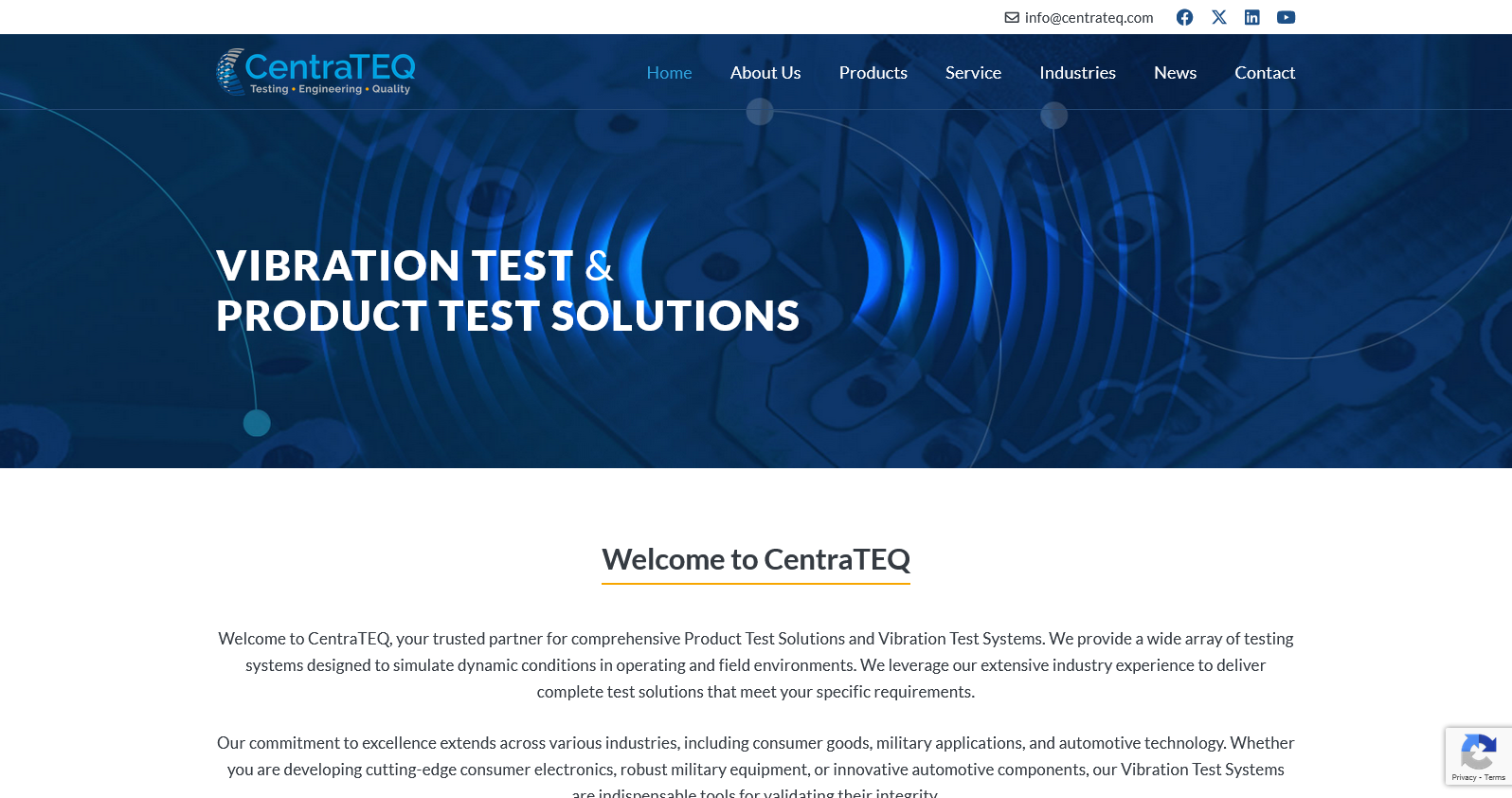

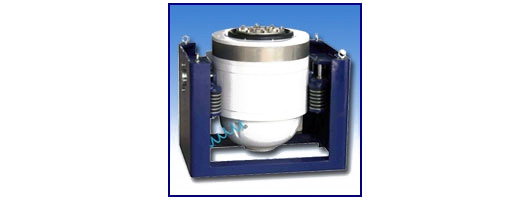

Electro Dynamic Vibration Test Shakers

CentraTEQ Ltd are the exclusive UK representative for ETS Solutions.

ETS Solutions shaker systems come in ranges from 20 Newton to 500 kN (440 lbf to 151,000 lbf), as well as custom engineered head expanders and fixtures.

The range of vibration test systems includes models suitable for simple tests on small electronics assemblies & storage devices through to large sized electronic assemblies and critical parts for automotive, aviation, aerospace and military systems.

All systems are designed to meet the requirements of endurance testing, a test environment typical in the automotive industry. All systems comply with international standards including MIL-STD, ASTM, IEC, ISO, BS, RTCA and European CE standards.

Low Force Vibration Shakers L SERIES

The L Series shakers are your ideal solution for a range of applications, including research & development, production, stress screening, and qualification testing of aviation instrumentation, satellite components, automotive parts, computer equipment, mechanical subassemblies, and small electronics assemblies.

Medium Force Vibration Shakers M SERIES

Vibration System Force Rating from 1,000 kgf to 7,000 kgf

The M Series electrodynamic shaker is designed for vibration and mechanical shock testing of medium to large sized articles including electronic assemblies, automotive parts, aviation and avionics parts.

High Force Vibration Shakers H SERIES

The H Series high force electrodynamic vibration shakers with high cooling efficiency are ideal for screening of large sized assemblies and specimens with high acceleration test requirements.

The “H” Series also meets typical vibration test requirements of other large sized electronic assemblies, automotive parts, aviation, avionics parts, satellites, aerospace and military systems.

Junction Boxes & Patch Panels Multi-Channel Junction Boxes

Multi-channel junction boxes, also known as patch panels are widely used in vibration shaker installations to provide a neat interface between shaker room and control room. This type of solution reduces the wear and tear on the cables which improves data quality and minimises intermittent faults. CentraTEQ’s range of junction boxes provides a multitude of solutions and finishes to suit your requirements.

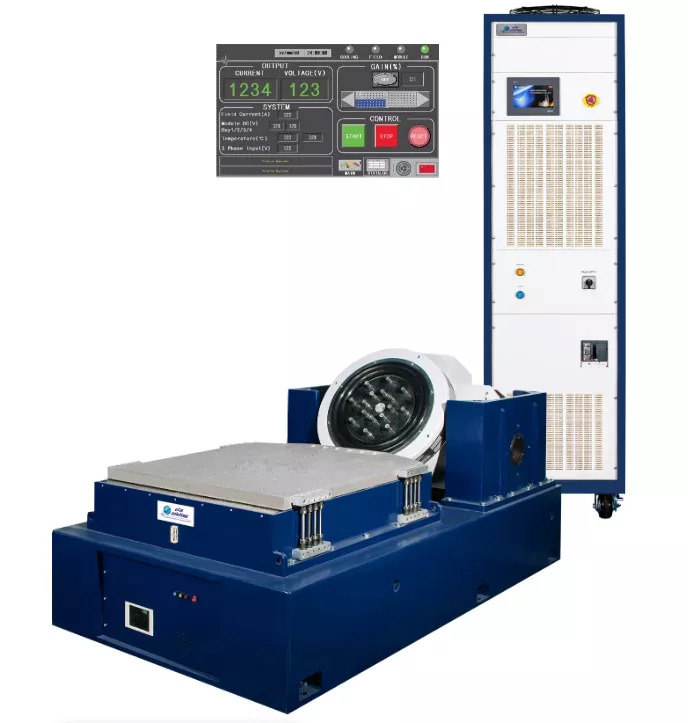

Vibration Test Fixtures & Head Expanders

Vibration testing and shock testing are part of many test programs, and there are a wide variety of vibration types, but the one thing every test has in common is that the equipment under test must be mounted with specialist vibration testing fixtures to interface between the vibration table and the product. These fixtures have to be custom designed to meet the holding points on the payload and the fixing points on the vibration system and must not compromise the results of the tests.

CentraTEQ offers design and manufacture of test fixtures for both new customers and users of vibration tables from any manufacturer.

HALT HASS Test Systems

Highly Accelerated Life Testing (HALT) and Highly Accelerated Stress Screening (HASS) are methods of testing product reliability aimed at finding stress-related defects in products. HALT/HASS Test Systems subject products to overstresses and accelerate fatigue to reveal weakness in design and composition by random six-degree-of-freedom vibration and rapid temperature change to test combined environmental factors.

At CentraTEQ, we offer Hanse Environmental’s extensive range of HALT/HASS Chambers. Hanse manufacture the largest standard line of HALT/HASS Chambers in the industry, and are committed to continually advancing the performance of their chambers. 8 standard models are available as well as customised configurations, providing temperature cycling and full 6-degrees-of-freedom.

In-Vehicle Noise Analysis Full Vehicle Shakers

Rattling, creaking, and squeaking noises can be effectively analysed and evaluated using the full vehicle shaker systems from MB Dynamics.

Conducting noise analysis in moving vehicles on various test tracks is often time-consuming and challenging. The vehicle shaker systems bring a wide array of global test tracks into your testing, quality management, and production areas.

Contact Measurement Systems Gnostic64

The Gnostic64 Ultra High Speed Contact Measurement Systems, available through CentraTEQ, offer a unique solution to monitoring electronic contacts during vibration or other environmental testing regimes.

The Gnostic 64 was developed by QED in response to a need within the Test and Development community to measure high speed electronic contact response to vibration and environmental testing in the laboratory. This need was originally driven by specifications within the Automotive industry but has now become a more widely specified requirement within all types of electronic equipment use.

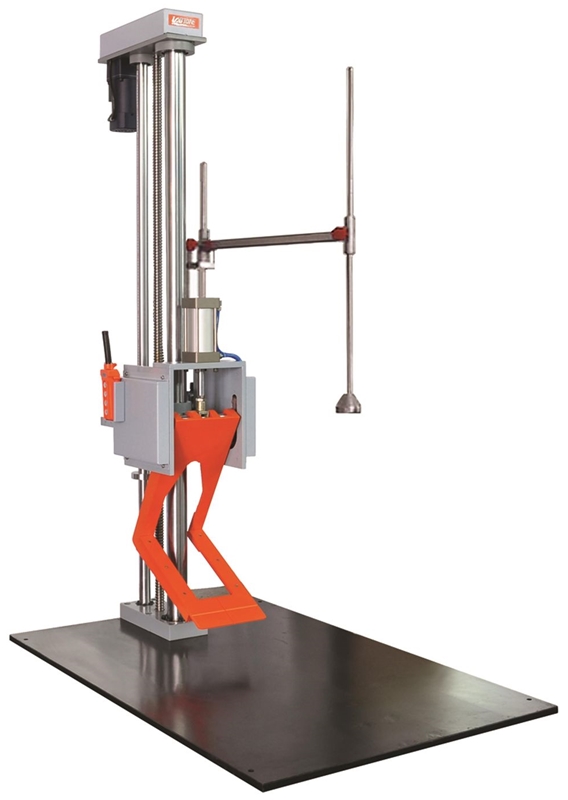

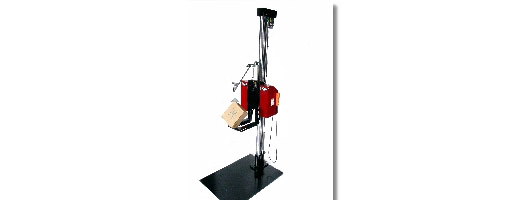

Drop Tester for Heavy Packages

For large, heavy packaging, the vertical drop height during transportation will be low necessitating drop tests with relatively low drop heights. The Zero Height Drop Tester is primarily employed for testing large packages. It utilises an E-shaped fork that swiftly moves downward as a bracket, with the specimen balanced according to test requirements (surface, edge, or corner drop tests). During testing, the bracket accelerates downwards at over 3G before the specimen separates away and achieves free fall. The standard drop distance ranges from 2.54cm to 120cm.

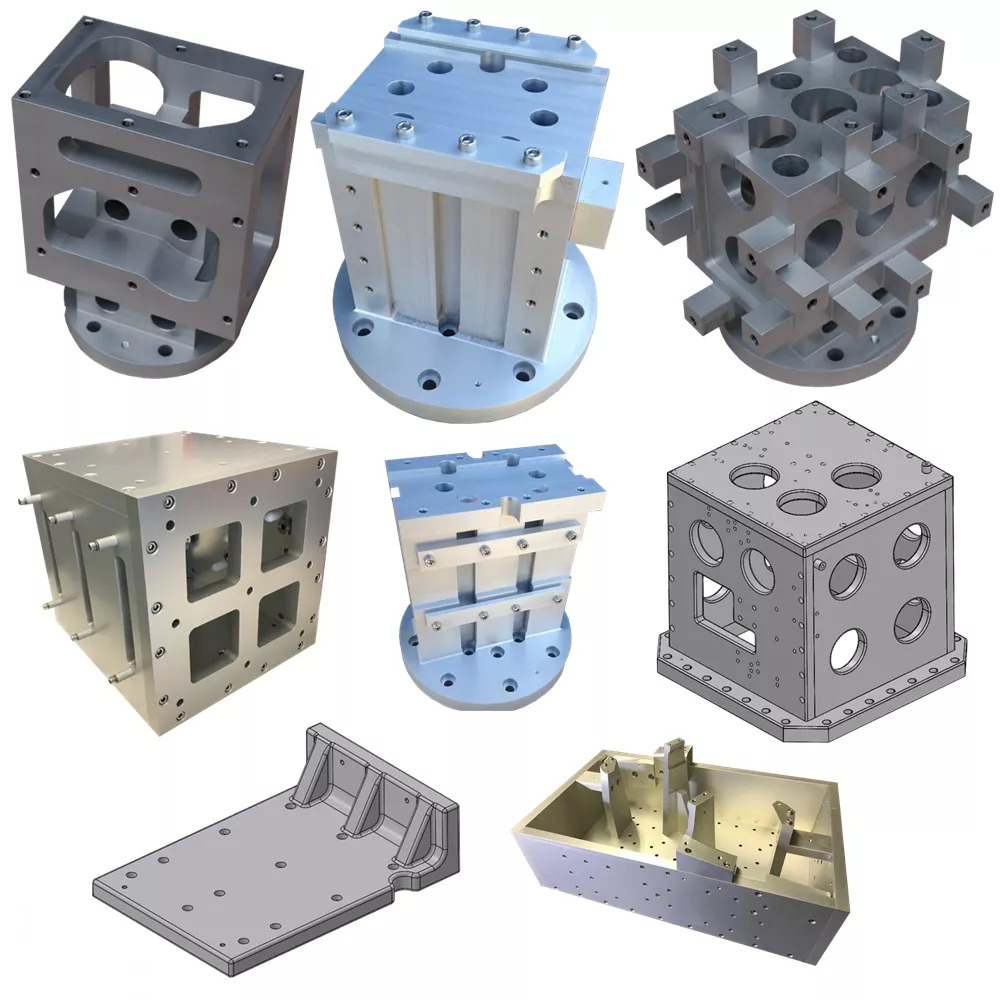

Accelerometers Sensors & Cables

CentraTEQ offers a broad range of piezoelectric accelerometers, with traditional charge output types for high-temperature applications and Integrated Electronics Piezoelectric accelerometers (IEPE) for simplified installation. Our product line also features high-performance electronic filters and signal conditioning instruments, including low-pass, high-pass, band-pass, and notch filters.

In addition, we provide low-noise and instrumentation coaxial cables, connectors, joiners, and sensor mounting accessories, ensuring optimal performance and seamless integration across various applications.

These products are manufactured by Kemo Limited, a global leader in pioneering electronic filters and signal conditioning instruments since 1965. With a steadfast commitment to innovation and precision, Kemo has cultivated a renowned reputation for delivering unparalleled quality.

Transportation Simulators

Transportation Simulators perform repetitive shock, loose load, or bounce tests in accordance with ISTA, ASTM, TAPPI, ISO, MIL-STD, UN, DOT, and other industry, government and international standards.

Frequency range is 2-5Hz with fixed displacement of 1 inch (25.4mm) and max acceleration of 1.25G.

These platforms apply an eccentric cam principle to achieve rotation, vertical and non-synchronised vibration modes.

High Speed Shock Test Systems

This high-speed shock tester is ideal for testing mobile phones, computer components, optical components, and connectors. It offers precise high-acceleration testing capabilities, meeting the stringent requirements for half-sine short waves as specified in JESD22-B110. This waveform ensures high repeatability, allowing for accurate and consistent test results.

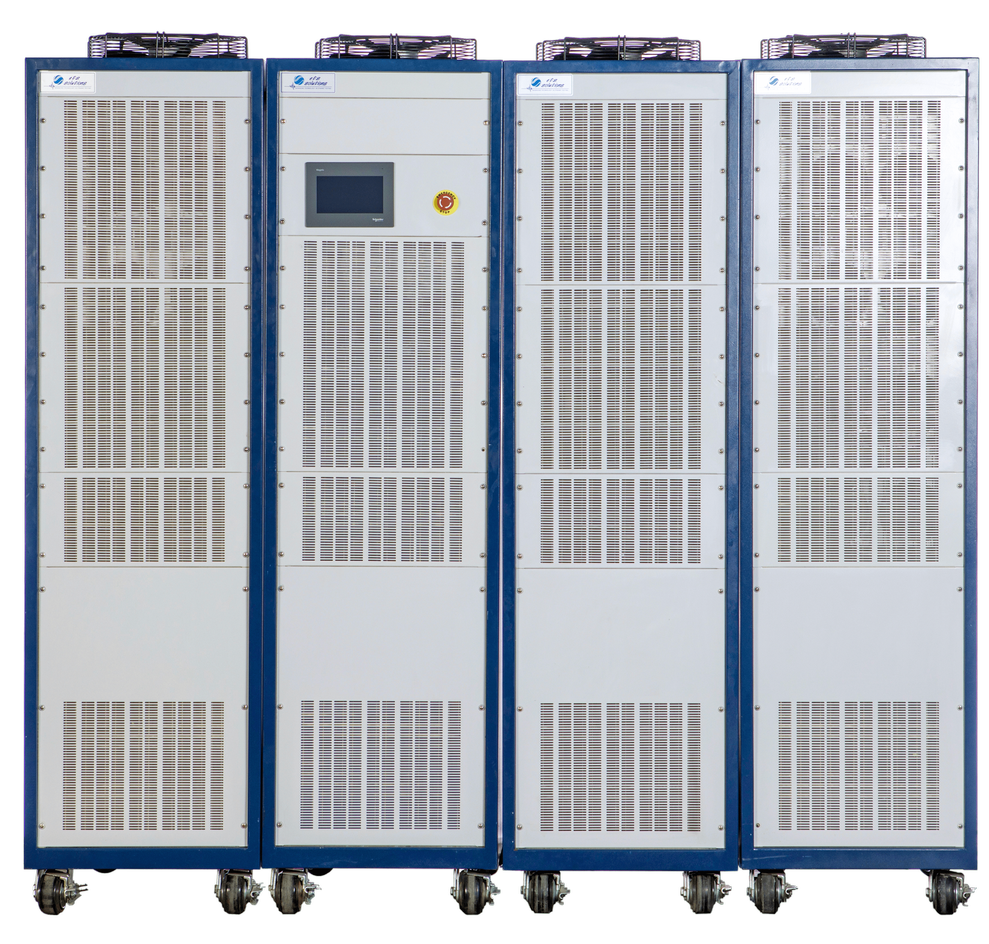

Vibration Test Power Amplifiers

CentraTEQ offers a range of ETS Power Amplifiers, designed for continuous operation with any electro-dynamic shaker.

Provide your shakers with the precise signals they need for peak performance. Our amplifiers combine strength, efficiency, and adaptability, offering a robust and reliable solution to power your vibration test systems to their limits.

When it comes to selecting the right power amplifier, there are critical factors at play. Considerations such as the mass of your shaker’s armature, head expander, device under test, and specific performance requirements all play a pivotal role in determining overall power needs. ETS Solutions offers a comprehensive range of amplifiers designed to meet diverse application requirements, ensuring that you find the match for your specific testing.

Our amplifiers, boasting a Class-D rating, deliver maximum power while minimising energy waste, resulting in lower running costs for your testing operations. Compatible with third-party vibration systems and ideal for multi-shaker applications, our amplifiers are both modular and scalable, allowing you to economically increase power capacity to meet evolving needs.

Vibration Controllers

Discover precision with the Dynatronic range of advanced vibration controllers from CentraTEQ Ltd. Engineered for use in vibration testing and control systems, these controllers ensure accurate management and regulation of vibration profiles applied to your test specimens or structures.

In close collaboration with DynaTronic Corporation, we provide closed-loop vibration control systems that cater to diverse applications and budgets. DynaTronic Corporation, established by an innovative and dedicated team, specialises in providing cutting-edge instrumentation for vibration testing and measurement. Our featured product, the VENZO 800 vibration controller, stands out with its comprehensive software modules, covering random, sine, classical shock, RSTD, SRS, SoR, SoS, RoR, SRoR, TTH, FDR, and other auxiliary applications.

The VENZO 800 series vibration controller is characterised by its user-friendly operation, robust control functions, enhanced analysis and reporting features, easy hardware and software upgrades, and high reliability and quality. These qualities contribute to the high cost-effectiveness of the VENZO 800 series, making it a valuable choice for vibration control in diverse testing scenarios.

Double Slip Table Unibase

The Unibase slip table design offers an optimal solution for horizontal vibration testing. Its common base reinforced assembly ensures easy and consistent alignment between the shaker and the slip table. The low-profile concept is ideal for environmental testing with a chamber.

The Double Slip Table Unibase offers users the flexibility of a dual slip table configuration to conduct various tests.

The shaker system can seamlessly rotate 180 degrees, allowing it to be paired with both tables. In the central position, the shaker can be combined with a Head Expander, facilitating vertical tests.

This versatile configuration is well-suited for both the GT Series and BT Series slip tables.

Drop Test Machines

Accurate Plane Fall Test, Edge Drop & Corner Drop Test

Packaging drop test is used to determine the effect of impact on the package during use, transportation, loading and unloading. Apart from accurate plane fall test, this Drop Test machine can also perform edge drop and corner drop test to make a complete evaluation on the performance of packaging and product.

Shock Test Systems

Enhance Product Durability with Advanced Shock Test Systems

Shock testing is essential for accurately measuring product fragility and evaluating the protective capabilities of product packaging. Whether you require boundary assessments for complete product breakage, adhere to industrial standard shock pulses, or meet internal company standards, we offer advanced shock test systems tailored to meet your specific needs. These shock test systems cater to a wide range of industries, including aviation, aerospace, marine, military, consumer electronics, automobiles, home appliances, and display devices. By selecting different waveform generators, you can conduct tests using half sinusoidal waves, sawtooth waves, and trapezoidal waves.

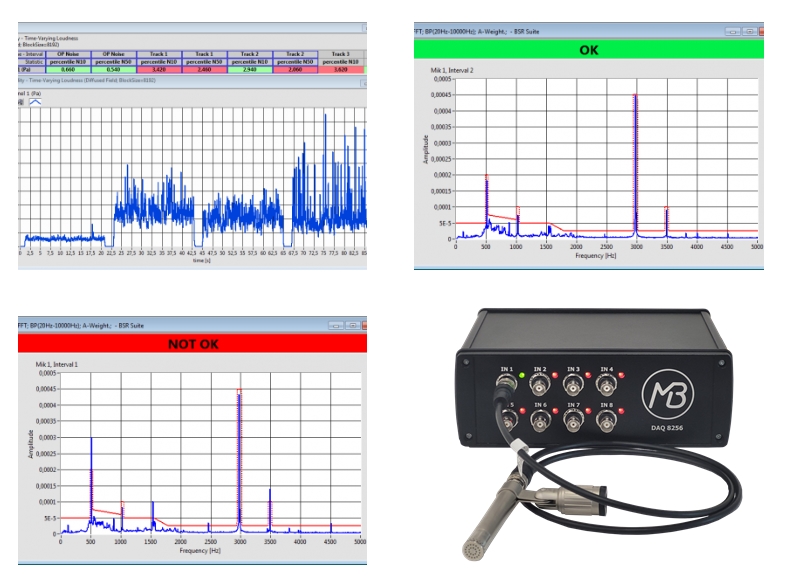

NVH Measuring System BSR Suite

For All Measurement Tasks In The Field Of NVH, Squeak & Rattle And Sound Quality Testing

The MB Dynamic BSR SUITE is a comprehensive solution for all measurement tasks related to NVH, Squeak & Rattle, and Sound Quality testing. Its extensive analysis and evaluation capabilities also make it suitable for assessing functional and operating noise, the effects of vibration on humans, as well as the acoustic and haptic feedback of controls and actuators.

With predefined test configurations for common tasks like multi-channel road load data acquisition, drive-file generation, and objective Squeak & Rattle and Sound Quality testing, the suite ensures quick and straightforward operation. Users can perform objective evaluations of various acoustic or haptic quality criteria using signal statistics and user-defined thresholds or reference curves.

Compact Shakers for Modal Analysis & Vibration Testing X-Act Exciters

The X-Act 325 is a versatile electromagnetic shaker offering a force of 300N sine pk and a maximum displacement of 25mm pk-pk. Unlike traditional shaker systems, the X-Act 325 features both air and water cooling. The highly efficient water cooling allows the X-Act 325 to operate continuously and quietly at high excitation forces, a scenario where typically only larger, more costly, and noisier air-cooled shakers would be suitable. The compact size and low weight of the X Act Exciter facilitates mobile use and simplifies the positioning and alignment of the system. For component testing, it uses an interchangeable vibration table with a 115mm diameter and integrated M6 threaded inserts. For modal analysis, the vibration table can be swapped out for a collet chuck. The lightweight moving element minimises interactions with the structure being tested while maximising peak accelerations. Additionally, a through-hole in the armature allows the use of pre-stressed wires to apply the generated forces to the structure under investigation. When using a stinger, its length can be adjusted by clamping it in a chuck.

Mechanical Vibration Test Systems

A Vibration System for Organisations with Budget Constraints.

The Mechanical Vibration Tester is ideal for electronic products, components, modules, mechanical and electrical products, instruments, meters, and other simulations of transportation vibration tests. It conforms to GB, UL, and IEC standards for vibration and reliability testing.

Mechanical vibration testers are generally more affordable compared to electro-dynamic vibration testers. This makes them a preferred choice for organisations with budget constraints.

Inclined Impact Test Machine

The Inclined Impact Test Machine, also known as an incline impact tester or incline shock tester simulates the impact strength of packaging under real transportation conditions, where packages may shift or experience sudden stops, akin to emergency braking situations. It serves as an invaluable tool for scientific research institutions, educational facilities, packaging technology test centers, manufacturers of packaging materials, and departments involved in international trade and transportation logistics.

The inclined shock tester complies with industrial standards for packaging, including ASTM, ISTA, ISO, and MIL-STD.

Permanent Magnet Vibration Shakers VT-MS SERIES

The small, benchtop VT & MS Series of electrodynamic, permanent magnet shakers offers versatile applications and is perfect for production testing of small components, electronic assemblies, sensor calibration, and laboratory research. This includes modal and structural analysis, measuring the vibration response of structures in both defense and civil engineering.

The permanent magnet shakers from the VT & MS Series are also invaluable for testing fatigue life and evaluating vibration effects on small electric and mechanical components or devices. Moreover, they find frequent use in the calibration of accelerometers and field vibration measurement systems.

High Acceleration Vibration Shakers I SERIES

The I Series high acceleration shakers are ideal for screening of medium sized assemblies with extreme high acceleration test levels over a long-duration and a high frequency range.

The “I” Series exceeds typical vibration test requirements of medium to large sized electronic assemblies, automotive parts, aviation and avionics parts.

Drop Test Quick Release Hooks

The KDT2000 Quick Release Drop Tester is designed to simulate the drops and mechanical hazards that occur in distribution. it is especially suited to very large, heavy payloads which cannot be tested on conventional drop test machines.

The system is capable of performing a variety of free fall drops ( flat, corner of edge). The KDT2000 comprises lifting ring, rapid release device, and release switch. The foot release switch activates the solenoid valve in the release mechanism which opens the jaws and allows the package to fall.

About us

CentraTEQ is the exclusive UK distributor for the ETS Solutions range of Electrodynamic Vibration Test Systems and shakers. We also provide a single source supply provision for the complete Environmental Testing Industry including vibration, climatic, accoustic and condition monitoring.

We have just joined forces with V-Mech Engineering to create a new company called V-TEQ Vibration Services. V-TEQ running alongside CentraTEQ providing service support and maintenance for all types of environmental test systems, specialising in vibration test systems of all makes.

- Amplifiers

- Condition monitoring

- Contact monitoring

- Head expanders

- Sensors − Accelerometers, displacement, force, pressure, torque, sound and velocity

- Slip tables

- Test facilities

- Vibration controllers

- Vibration shakers

Utilising our extensive background knowledge, CentraTeq are able to provide our clients a complete solution. Whatever your requirements, we can help with your vibration and test monitoring working with you to meet your application requirements as well as your budgets.

In addition we have the flexibility to put together solutions from multiple manufactures and suppliers to ensure you receive the most efficient and cost effective solution.

Images

Videos

Articles / Press Releases

Brochures

Trade Associations