Company details for:

CERTUSS UK Ltd

Quick Links:

Products / Services

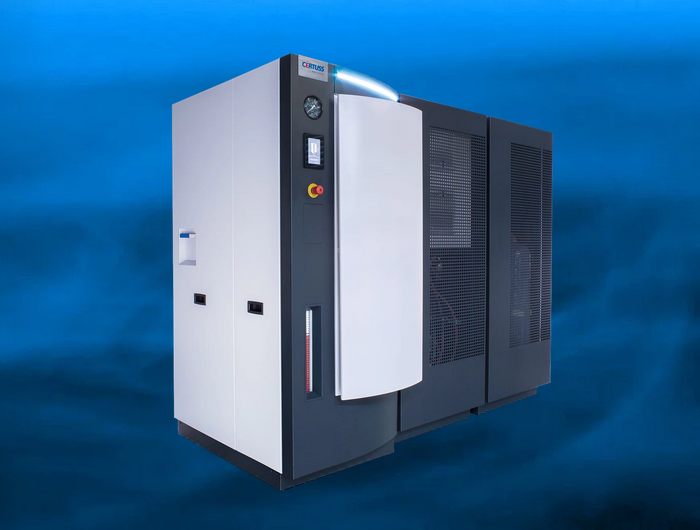

Universal TC Steam Generator

CERTUSS Universal TC Model Generator offers 5 fuel firing options of Natural Gas fired, Light Oil Fuel fired, LPG fired, Bio-Fuel fired and Dual fuel fired (combi fired).

Steam volumes ranging from 500 kg/h (328 kW) to 2,000 kg/h (1,320 kW) with a total of 10 output capacities are available within 4 construction groups, all offering pressure ranges from 5.5 bar G up to 29 bar G.

The CERTUSS Universal TC Model Generator offers a 2 stage burner operation, with full modulation feature (50 % to 100 %) in second stage burner position. With the CERTUSS Universal TC Model generator steam is produced in under 5 minutes and it can cope with both a constant or fluctuating steam demand. Lightweight in construction, compact in size and suitable for all steam industry sectors, the CERTUSS Universal TC Model generator is suitable for positioning on a mezzanine floor, therefore offering available free floor space below for other usages.

Junior TC – Small Steam Boiler

The CERTUSS Junior TC Model is a small steam generator version of the Universal TC Model, offering steam volumes ranging from 80 kg/h (53 kW) to 400 kg/h (262 kW) with a total of 8 output capacities over 3 construction groups.

Operating pressures available are between 5.5 bar G and 29 bar G. The CERTUSS Junior TC Model version offers a variation of gas fired burner options from Natural Gas fired to LPG fired and Light Oil Fired.

The burner facility is single stage. With a standard thermal efficiency of > 93 % the CERTUSS Junior TC Model steam generator offers a more efficient option than comparative small steam boilers available on the market. With no thermal insulation or fire brick used within the manufacturing construction of the CERTUSS Junior TC Model generator, customers are assured of the highest eco-friendly equipment available

Electric Steam Generator E10MX – E320MX

A new generation of electric steam boilers

- Steam output from 10 to 320 kg/h, continuously adjustable

- Full steam output is ready in 3-5 minutes after system start-up

- Long-life design with high durability

- Fully automatic 72-hour operation

- Remote maintenance, high process reliability

Electric Steam Generator E 6 M – E 72 M

This Electric steam boiler can be installed within production facilities and we can offer a full rear package assembly complete with water softener and blowdown vessel, which are pre- piped/ pre-wired and factory tested prior to dispatch to site. There is an output limitation feature available depending on the required volume capacity.

Access to all main function parts such as the stainless steel feed water tank, feed water pump, steam chamber and control panel is via the front enclosure doors, making maintenance of the unit simple to carry out.

Multiple Plant Steam Solution

If your steam capacity or load requirements exceed a single generator output, CERTUSS can cater for your requirements by offering a CERTUSS Multiple Plant Solution. CERTUSS can supply many options to serve your steam demand requirements.

Be it a simple Duty-stand by facility or a flexible cascade system for the more complexed varying load requirements. With connection of the Generators to the CERTUSS Skid Mounted Package Plant Module, steam capacities up to 16,000 kg/h are available.

Economiser

With a built-in Economiser the degree of efficiency of the CERTUSS steam boilers amounts to 98 %.

Feed Water Tank

CERTUSS offers feed water tanks in 5 sizes for unpressurized operation of the CERTUSS steam generators.

Heat Exchanger

The CERTUSS desalination heat exchangers with buffer storage are used solely in CERTUSS steam plants.

Water Softening

ERTUSS UK has appointed Catalyst Water as approved water treatment provider.

Economiser CERTECON 80 – 400

An innovative solution for saving energy during operation of the oil- or gas-heated CERTUSS Steam Generators of the Junior 80 – 400 series and the Universal 500 – 600 series.

Economiser CERTECON 850 – 1800

An innovative solution for saving energy during operation of the oil- or gas-heated CERTUSS Steam Generators of the Universal 700 – 1800 series.

Fully Pre-Installed Steam Boiler Plant

Manufactured with all the associated ancillary items required to complete a full steam boiler plant system. The CERTUSS Skid Mounted Package Plant Module (CVE) is compact, lightweight, and easy to manoeuvre into position. With all components pre-piped, pre-wired, interconnected to the Generators.

Finally a factory test is carried out prior to the equipment being dispatched to your site. With the equipment in position at your site, only site service connections are required before commissioning is carried out.

Container Plant – Steam Boiler House Solution

This special container has been designed and built for use in potentially explosive areas in a refinery. The ventilation system has also been specially developed and manufactured.

CERTUSS steam systems are inherently space saving. But container plants can give the customer even more flexibility in terms of location and installation.

These steam systems can be delivered to the customer completely piped, wired, insulated and ready to use. CERTUSS delivers individual container solutions all over the world.

Steam Generators for Hire

CERTUSS offer a range of Electric steam generators for hire, with capacities ranging from 8kg/h to up 160kg/h. All CERTUSS Electric Hire units, are delivered complete with blow down vessel and water softener, mounted to a rear skid for easy access and positioning on site, whilst leaving a simple plug & play facility for site services connection.

Our electric steam generators can be hired for a minimum of 4 weeks. Maybe you want to carry out some tests or research, prior to buying plant. Or you look for a temporary hire facility to bridge a gap in production. So if you have a requirement for hiring, please get in touch with us. Our Sales team will be able to offer you advice and options available.

Maximise Energy Efficiency

CERTUSS continually strive to achieve the highest standards of efficiency for our vertical Steam Generator. With the CERTUSS patented triple construction design, a forced air flow facility is introduced whilst the main burner is in operation.

The fan driven air is moved around the outer casing, creating a natural air insulation (keeping the heat around the coil chamber), it is then introduced into the inner casing and up to the burner mixer chamber in the form of pre-heated combustion air, before any waste gasses are finally exited through the chimney outlet to atmosphere.

It is this process that works towards achieving our high level of thermal efficiency of > 93 % as a standard.

Efficient & Safe Blow-Down Vessels

With all of CERTUSS Steam Boiler plant there is a requirement under regulatory standards such as PED or ASME, to ensure that there is a blow-down vessel installed. The requirement for a blow-down vessel, is to ensure that when a blow-down sequence (de-sludge of the steam chamber or coil) is carried out at the end of a working day. Usually a 12 hour maximum period of operation is recommended before a blow-down sequence is carried out. The water and sludge being displaced from the steam generator is safely collected in the blow-down vessel and displaced then to drain as a secondary motion de-pressurized and cooled.

However when a CERTUSS Generator blow-down sequence is carried out, the volume of water / sludge being displaced under pressure from the Steam Generator to the blow-down vessel, is relatively small in content when measured on a PED regulatory chart. Following the guideline for PED regulations the displacement volume from the CERTUSS Generator, does not warrant the requirement for a standard blow-down vessel, (EN2871 CAT 3 standard), as required for conventional steam boilers, which displace a large volume of water/sludge under pressure.

Therefore under PED regulations, the CERTUSS Generator only requires a suitable displacement vessel, which is CE Marked and supplied with an identification plate for Insurance purposes.

Hot Well Technology Boiler Systems

To accompany our CERTUSS Steam Generators, as part of the ancillary item supply, we offer our Stainless Steel feed water tank (hot-well).

The Stainless Steel feed water tank (hot-well) is the central point for collection of fresh make-up water, (softened / R.O. / De-mineralised / De-ionised etc.), and chemical dosage introduction prior to delivery of the boiler water into the Steam Generator. Any condensate return can also be introduced back into the feed water tank.

It is also at the feed water tank that any boiler water samples are taken and monitored. The water within the feed water tank is maintained at a temperature of circa 95°C with the use of a CERTUSS steam injection facility. The water levels on the feed water tank are controlled by a CERTUSS electronic level float gauge.

To assist with the containment of heat within the feed water tank and to minimise any heat loss, we fully insulate the tank.

Water Treatment - Feed Water Quality

CERTUSS can offer you a full range of water treatment equipment to ensure feed water quality is achieved. If you are looking to use either base exchange water softening plant, R.O. water facility, De-mineralised water supply or De-ionised water supply, then CERTUSS can accommodate your requirements.

Within our range of feed water treatment equipment, we also offer chemical dosing facilities (which can be either liquid or powder form), water monitoring facilities, water sample coolers and much more.

For details on the most suitable feed water facility available for you, please contact our Sales Team.

To accompany the supply of feed water equipment, CERTUSS UK Ltd, also offer the services of our recommended water treatment specialist – Catalyst Water. With many years of experience, high level skill and expertise in their field, Catalyst Water will work with you to ensure your water quality is maintained to an optimum level.

Catalyst Water offer you state of the art electronic monitoring equipment for your dosing systems, with an advanced internet based reporting facility. It offers an offsite monitoring of your water quality to give you a complete back-up to your own on site testing.

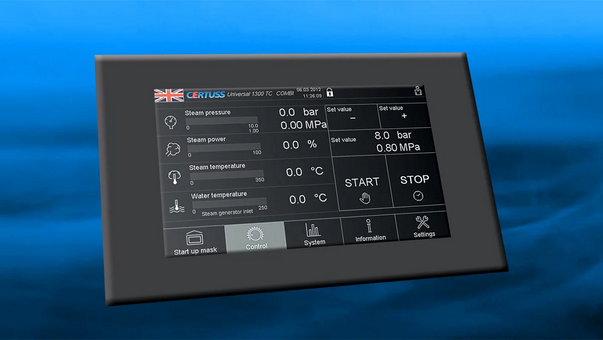

Touch Screen Interface & Remote Control

Offering the most up to date, innovative control system with remote control feature available for your CERTUSS Generator. The manual touch control facility offers a simple start, stop feature via the 175 mm graphic Touch Control screen on the front of the Generator. Operating, fault and service instruction messages are displayed on the Touch Control screen.

A selection of World languages are available for use on the screen to suit most needs.

With the selection of CERTUSS optional "Thermotimat" automatic control facility, the operation of the Generator start, stop, blow-down feature can be time selected to suit your production or operating requirements.

About us

CERTUSS UK Ltd offers highly efficient steam boilers that adapt flexibly to varying loads, ensuring safe operation.

When Hans Joachim Schroder established CERTUSS in Krefeld, Germany in 1957, he selected the company name thoughtfully. His vision was to innovate compact, quiet, and dependable steam generators unlike any others. This led him to choose the name CERTUSS, derived from Latin meaning safe and reliable, perfectly encapsulating the qualities he envisioned for the company's products. Today, CERTUSS not only represents our company name but also embodies the essence of our products.

CERTUSS Steam Generators can be installed directly in the working area without the need for a separate boiler housing. Even during full operation, the exterior of a CERTUSS Generator remains mildly warm, ensuring safety. Our commitment to reliability is evident in our practice of storing spare parts for over 20 years, reflecting the long lifespan of our generators. For any inquiries regarding your CERTUSS Generator, you can count on immediate assistance from our team.

Our Products Include:

Electric Steam Generators

The EMX model introduces a new era in electric steam boilers, offering a steam output range from 10 to 320 kg/h.

Oil, Gas, Multi-fuel Fired Steam Boilers

The steam generators range from 500 to 2,000 kg/h, with the option to connect up to 16,000 kg/h in series. They feature rapid steam generation, efficient energy transfer, and minimised radiation losses.

Complete Pre-Packed Plant

Complete turnkey steam boiler system, offering a compact alternative to traditional plant room installations.

Boiler Room (Container)

Versatile usage, such as replacing a boiler house, featuring a fully equipped steam system installed in a container for temporary or permanent use.

Built on these strong foundations, our company has become a global leader in the steam industry, expanding continuously worldwide.

Today, with our UK service center, main manufacturing base in Germany, and group members in the USA, alongside 34 other CERTUSS agencies globally, we provide cutting-edge steam technology and exceptional service.

Feel free to reach out to us for assistance. Please Contact Us.

...

Images