Company details for:

Contour Precision Ltd

Quick Links:

Products / Services

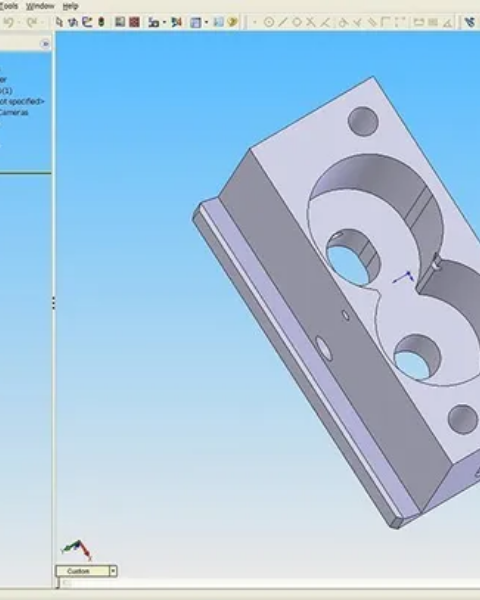

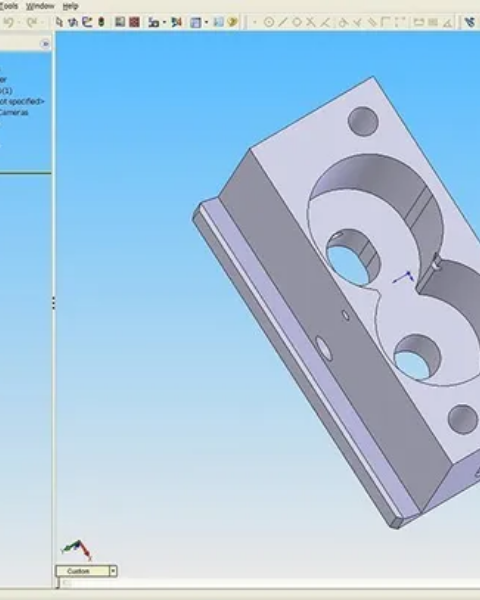

CAD/CAM - Concept to Production

At Contour Precision, we harness the transformative power of CAD/CAM (Computer-Aided Design and Computer-Aided Manufacturing) to bring precision and efficiency to the forefront of our engineering processes. CAD/CAM represents the synergy of design and production, enabling us to create intricate and accurate components essential in today’s advanced industries. This technology is a cornerstone in our commitment to delivering exceptional precision engineering solutions.

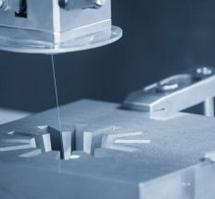

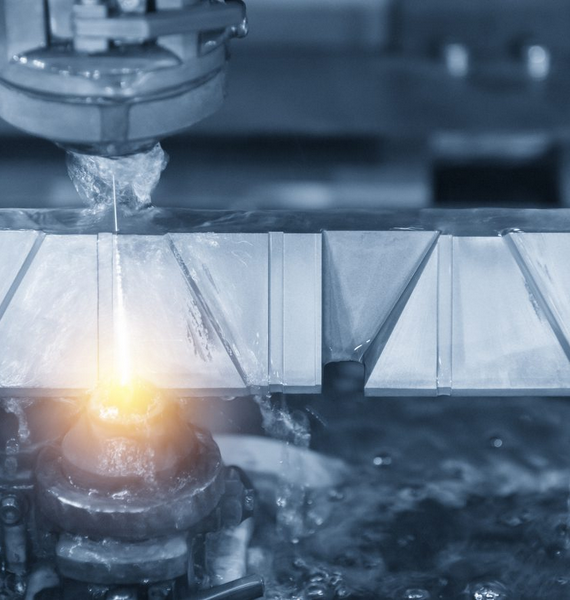

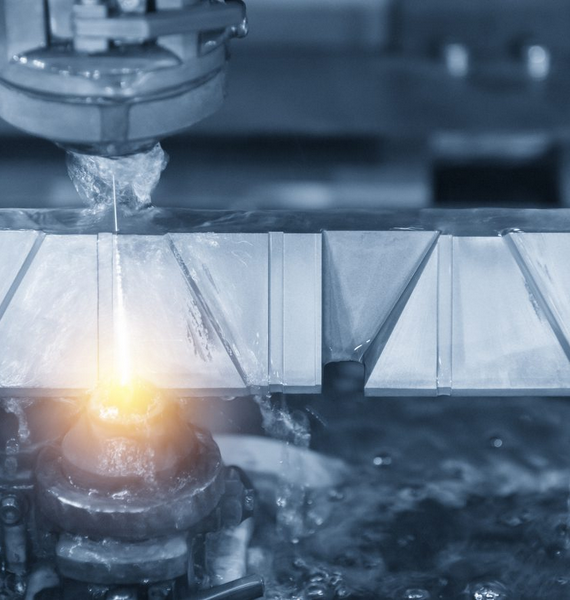

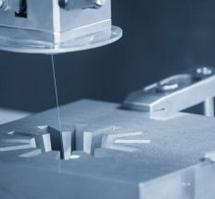

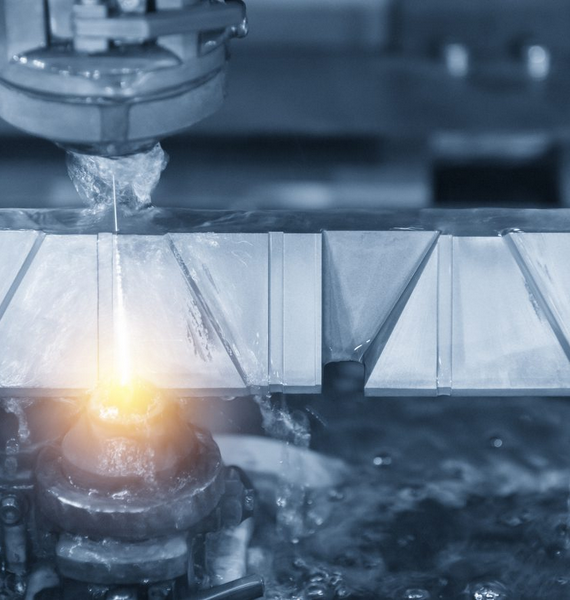

Wire Erosion - Wire Electrical Discharge Machining (EDM)

Wire Erosion, or Wire Electrical Discharge Machining (EDM), is a specialised technique we excel at Contour Precision. This advanced process allows us to shape materials with exceptional precision by using a thin, electrically charged Wire as a cutting tool. Wire Erosion is particularly effective for materials that are difficult to machine with traditional methods, making it an indispensable technique in precision engineering.

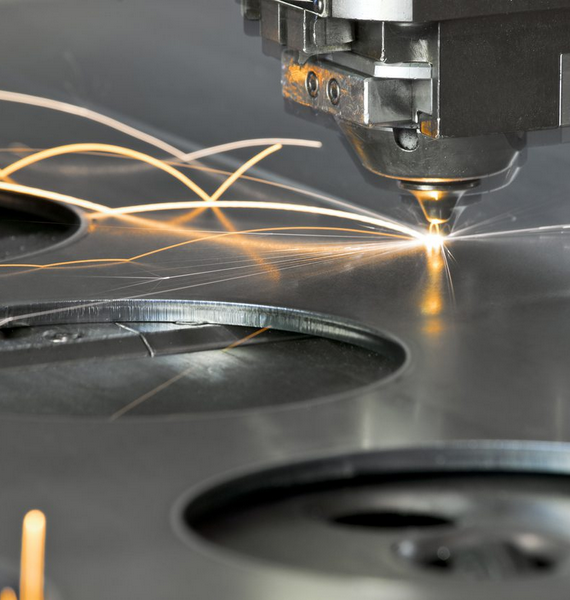

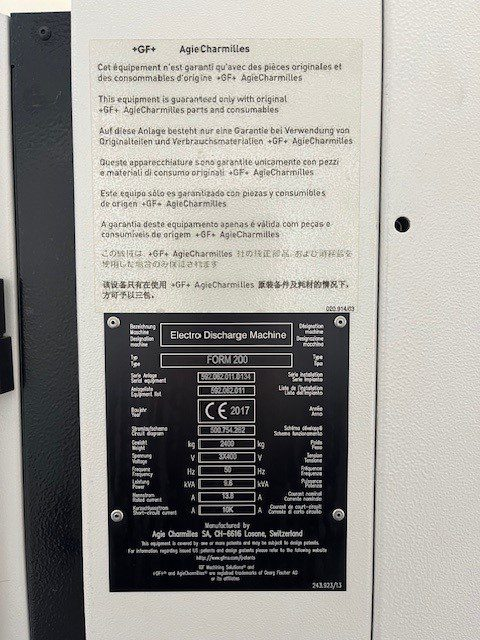

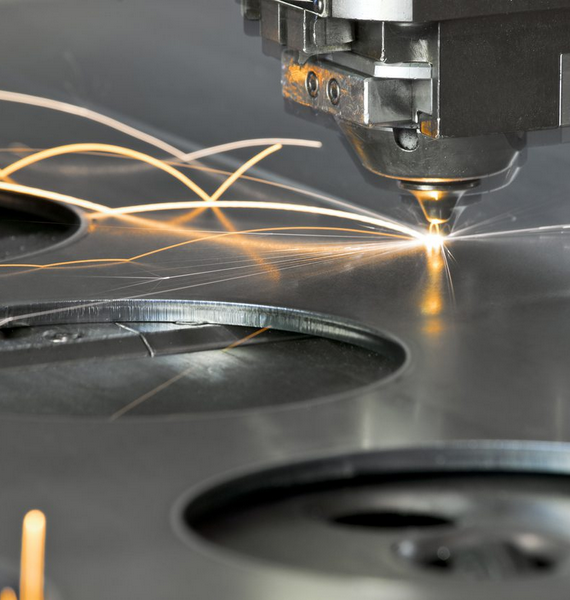

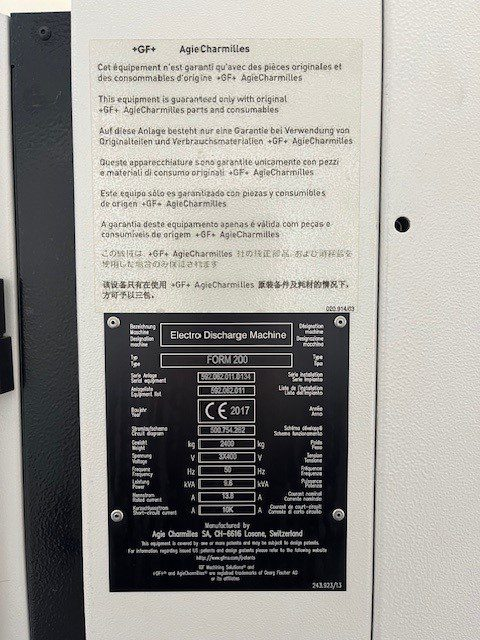

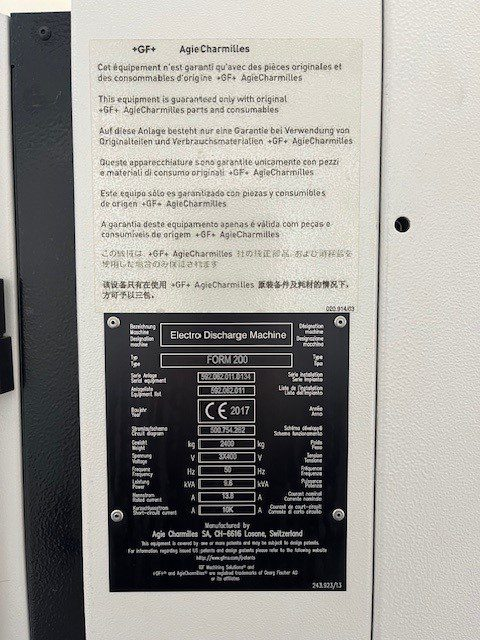

Spark Erosion - Spark Electrical Discharge Machining (EDM)

Spark Erosion, also known as Spark Electrical Discharge Machining (EDM), is a specialised manufacturing process employed by Contour Precision to achieve intricate details and supreme accuracy in machining hard materials. This advanced technique uses electrical discharges (sparks) to erode material from the workpiece, creating highly precise shapes and patterns. Spark Erosion is particularly effective for complex, hard-to-machine materials and is integral in industries requiring exceptional precision, such as aerospace, medical, and automotive.

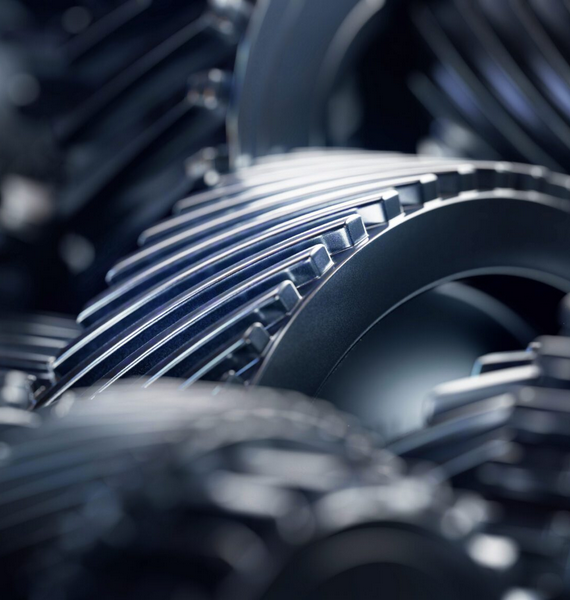

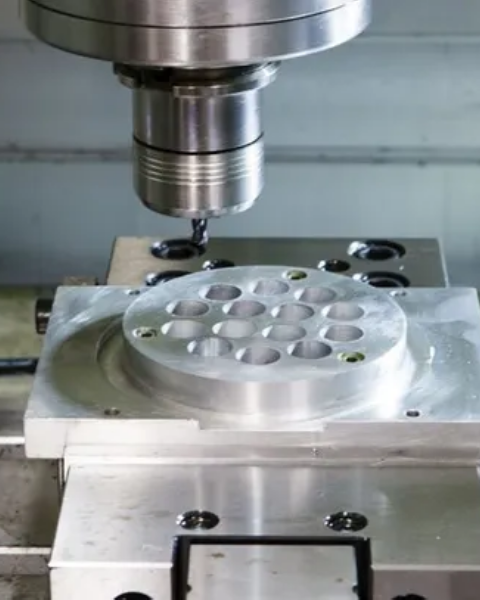

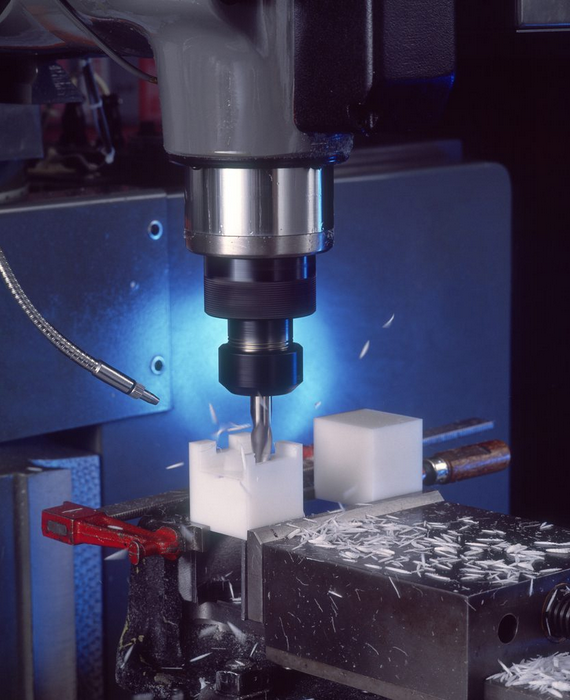

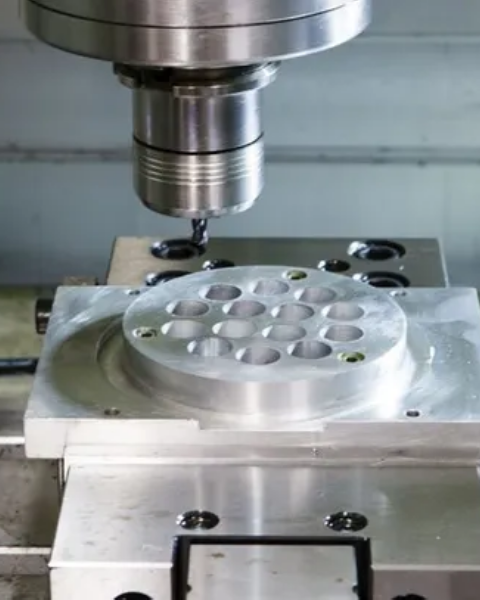

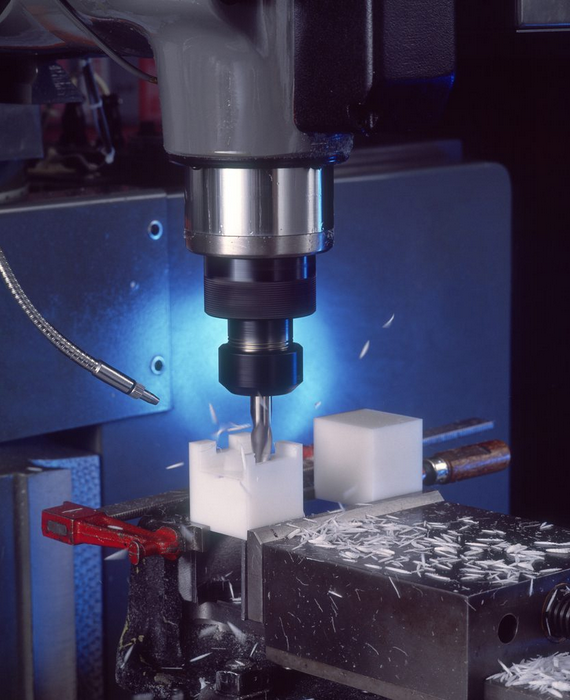

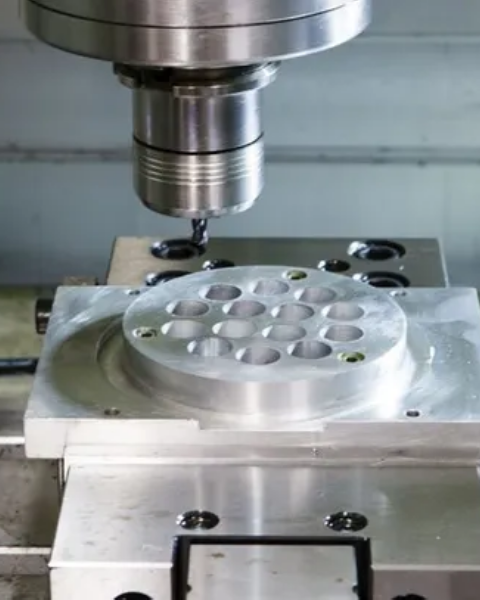

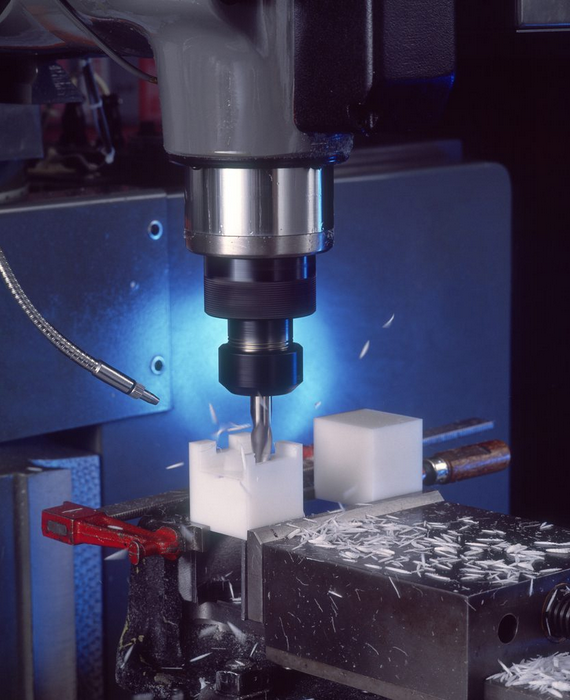

CNC Milling & Machining

Computer Numerical Control (CNC) Milling and Machining stands at the forefront of modern manufacturing. This process utilises computerised controls and machine tools to remove layers of material from a workpiece, achieving a custom-designed part or product. CNC milling and machining combine precision engineering with digital efficiency, catering to a wide range of materials, including metals, plastics, and composites. The adaptability and precision of CNC technology make it indispensable for industries requiring high levels of accuracy and consistency.

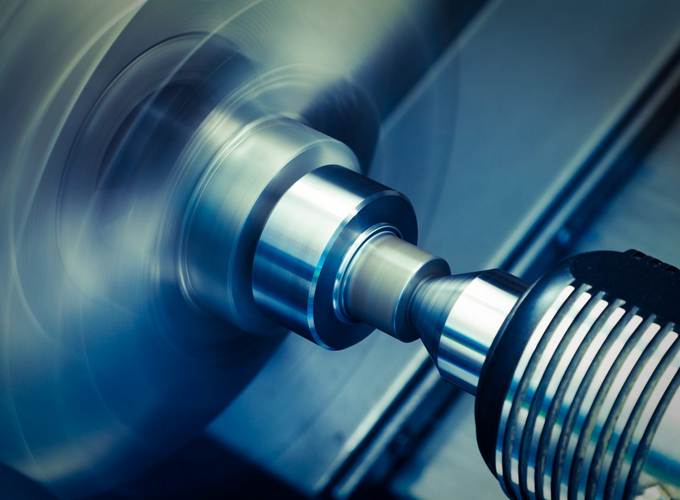

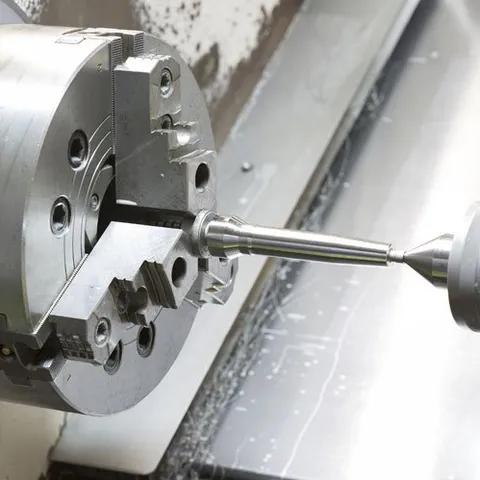

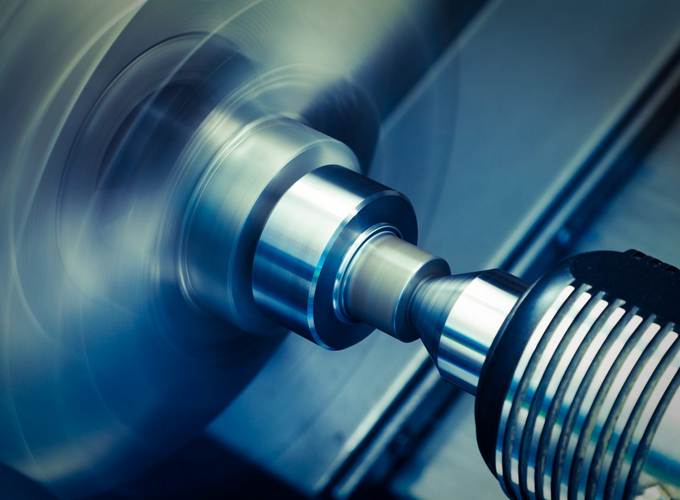

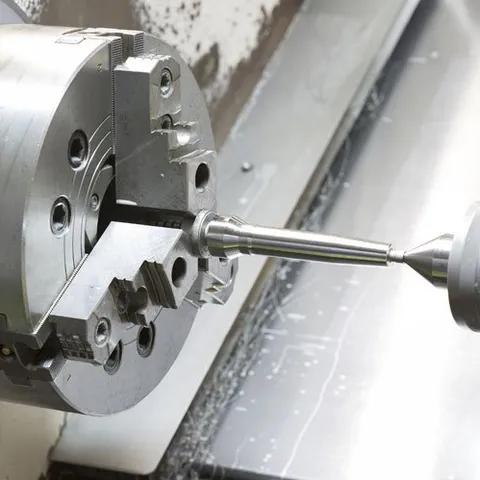

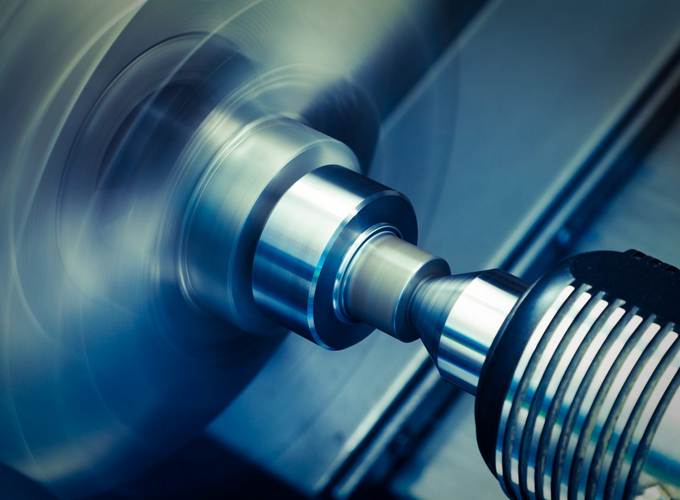

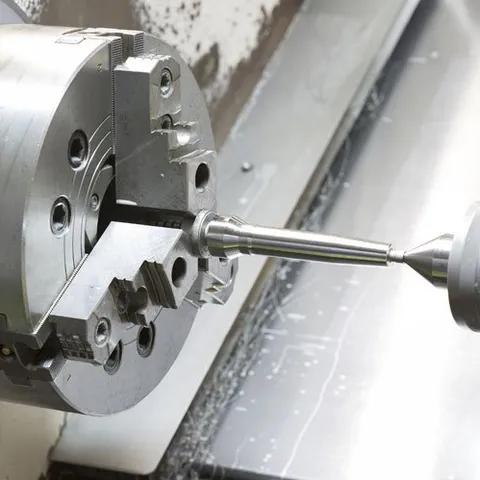

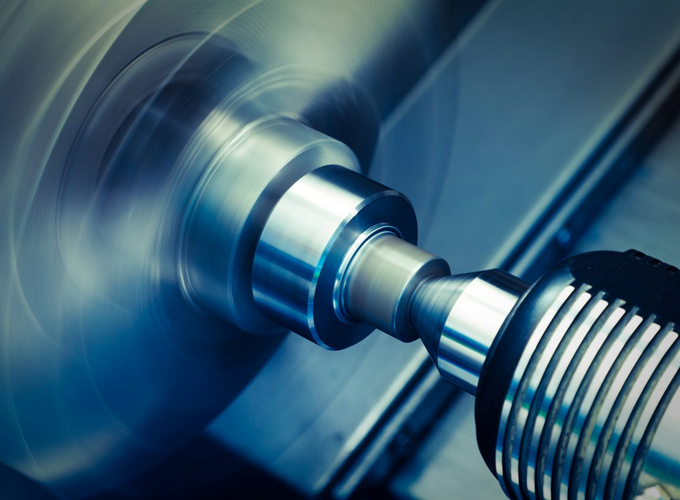

CNC Turning

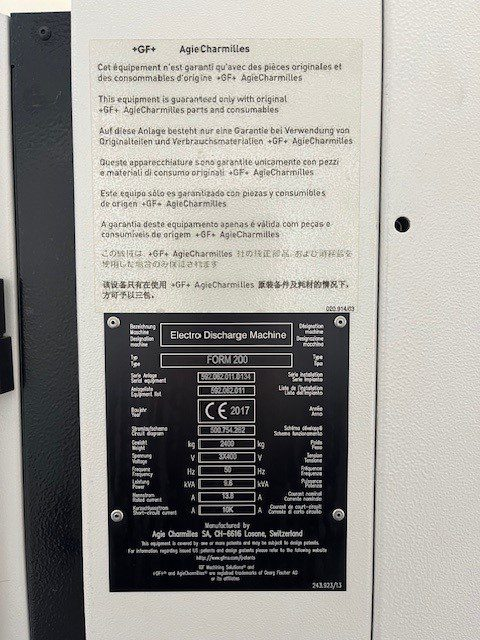

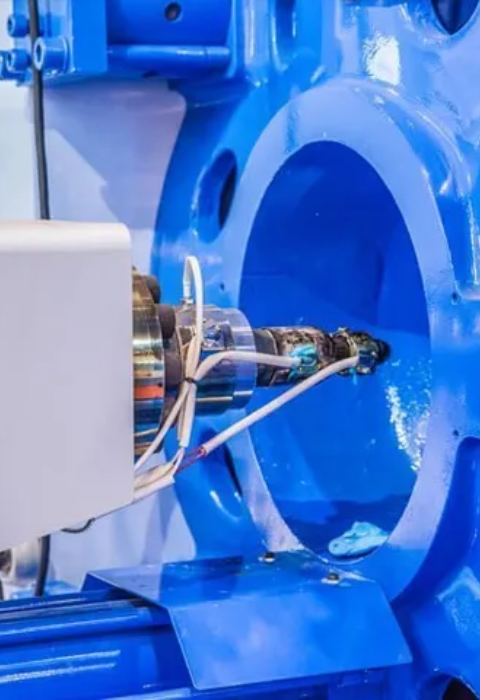

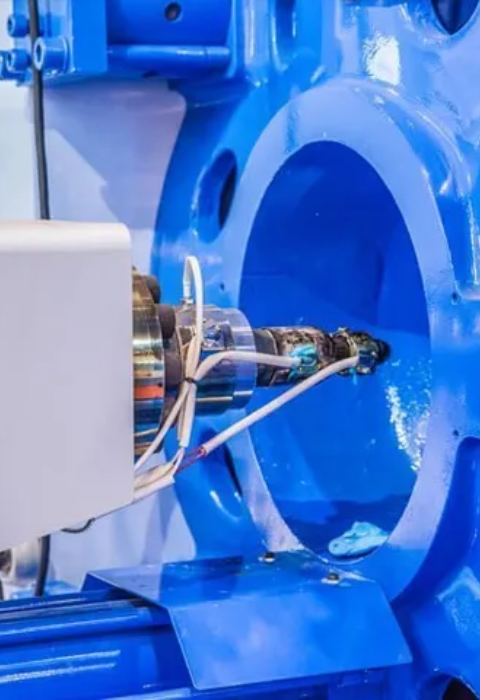

At Contour Precision Ltd, we pride ourselves on our extensive experience and expertise in CNC turning, a process that allows for the production of highly precise and accurately turned parts, components, and tools. Our state-of-the-art CNC turning centre, located in Aylesbury, is equipped with advanced machinery from Hurco and Charmilles, leaders in the field of engineering technology. This enables us to handle a wide array of projects, ensuring that the vast majority of jobs can be completed in-house with exceptional levels of precision and efficiency.

CNC turning is a subtractive manufacturing process where material is removed from a rotating workpiece using various cutting tools to shape it into a designed form. This method is particularly well-suited for creating round or cylindrical parts with intricate features and tight tolerances. Thanks to our sophisticated equipment and skilled technicians, Contour Precision Ltd can work with any material—be it metal, plastic, or composite—catering to any application across a multitude of industries, including automotive, pharmaceutical, medical, and more.

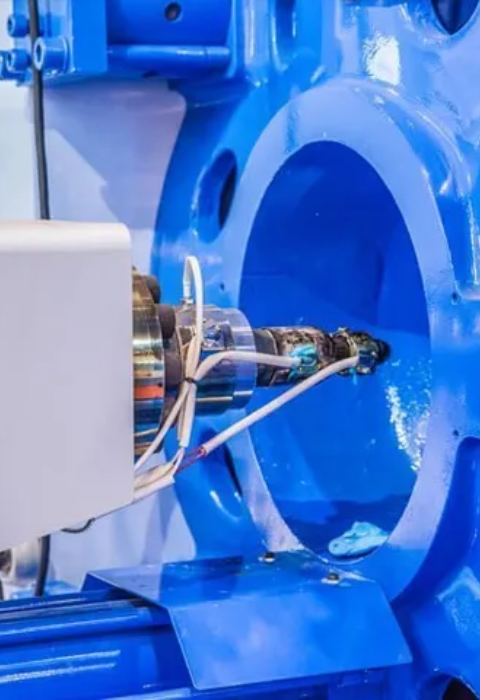

Precision Grinding

Precision Grinding is a critical process in the manufacturing sector, and at Contour Precision, it’s an area where we excel. This process involves removing material from a workpiece to achieve high dimensional accuracy and a fine surface finish. Precision grinding is essential for producing components that meet strict tolerances and surface specifications. It’s widely used in various industries, including aerospace, automotive, medical, and tool & die making.

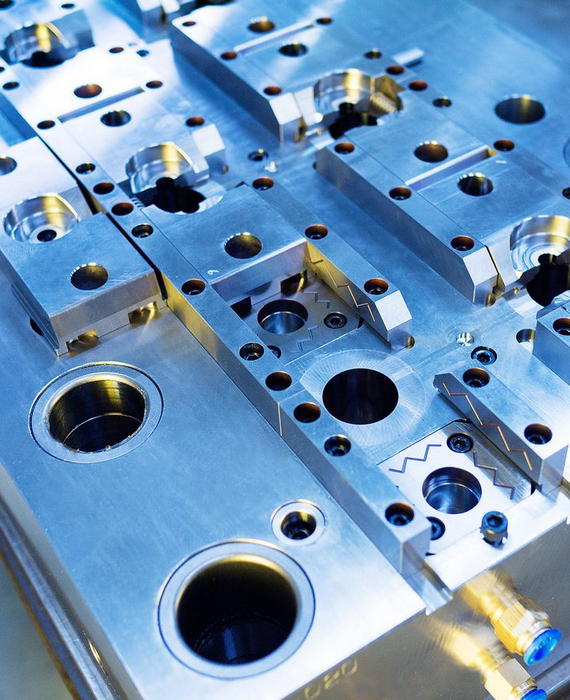

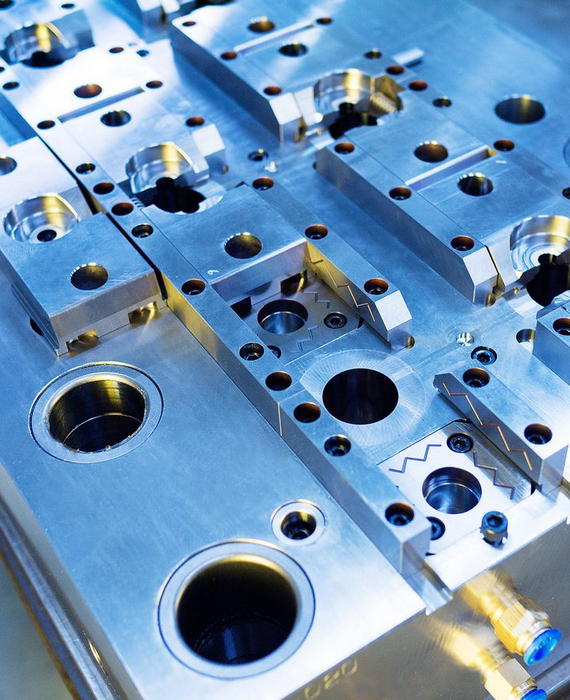

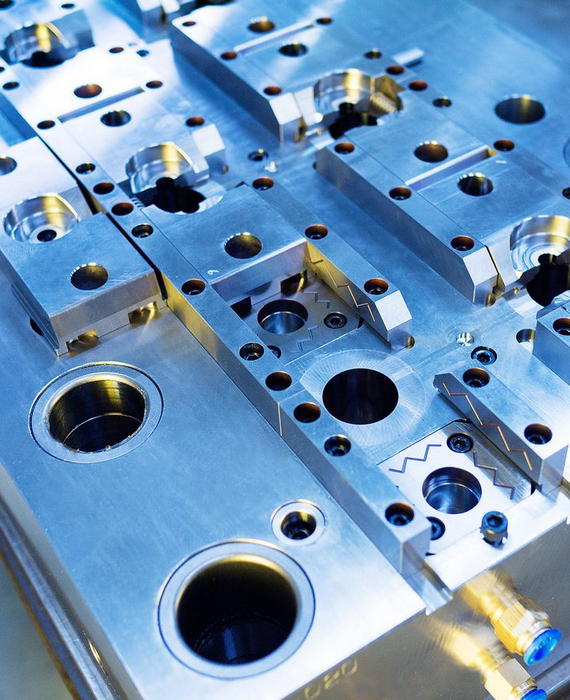

Plastic Injection Mould Tools

At Contour Precision, we understand that the foundation of successful plastic injection moulding lies in the precision and quality of the mould tools used. That’s why we specialise in designing and manufacturing high-precision, durable mould tools that cater to various industries. Our commitment is to deliver mould tools that meet and exceed the rigorous demands of modern production environments.

Comprehensive Tool Making from Design to Production

At Contour Precision Ltd, we pride ourselves on our extensive experience and expertise in the field of tool making. With decades of operation under our belt, we have become a trusted name in producing high-quality tools for some of the most demanding industries. Our clientele spans across the automotive, pharmaceutical, and medical sectors, industries known for their rigorous standards and precise requirements.

Our approach to tool making is comprehensive and client-focused, ensuring that from the initial consultation to the final production, every step is executed with precision and care. We understand the critical role tools play in manufacturing and the importance of reliability and accuracy in their design and function. That’s why we offer a full suite of services to meet the diverse needs of our clients, available throughout Aylesbury and the entire UK.

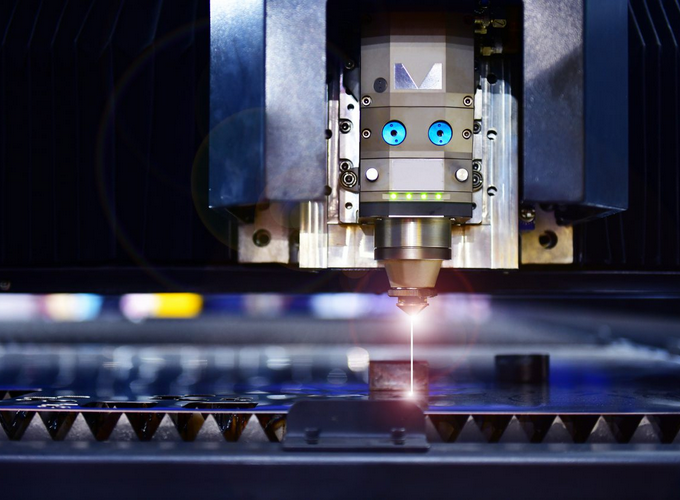

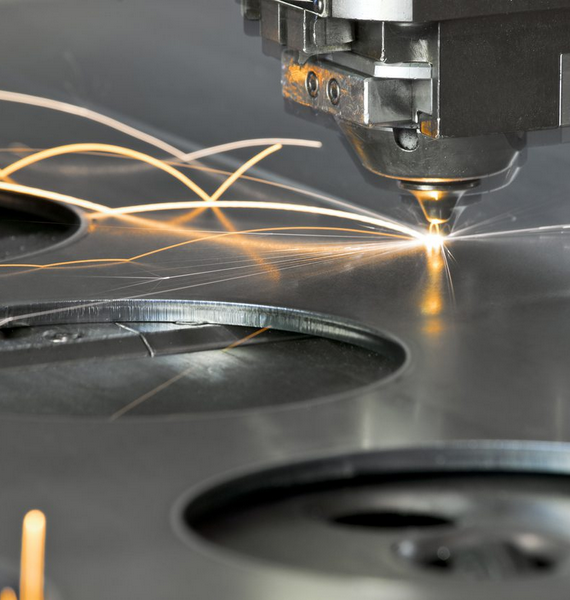

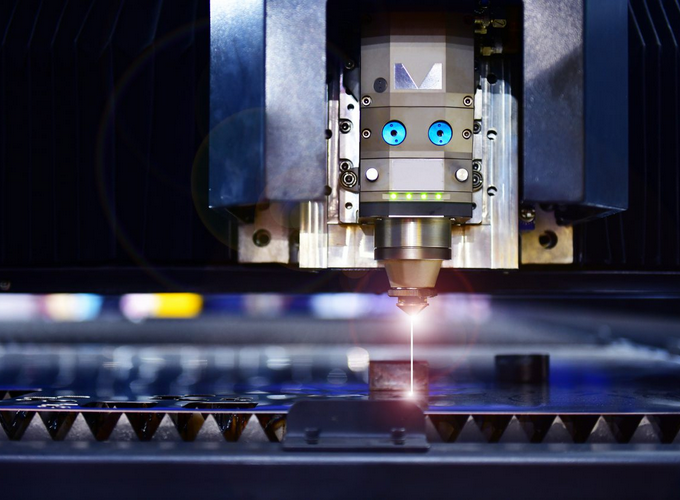

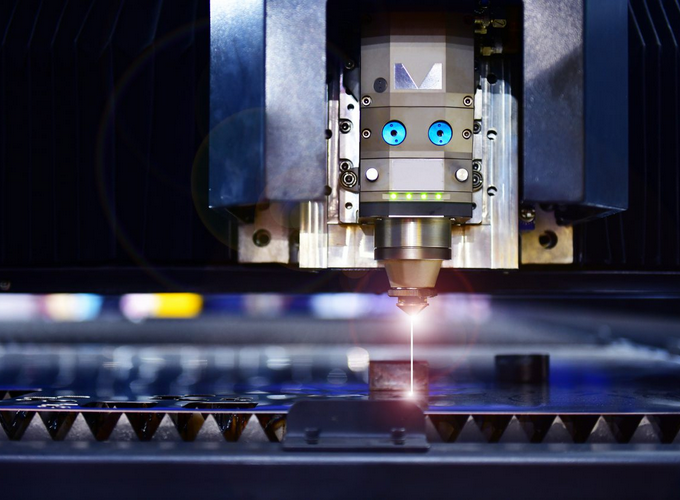

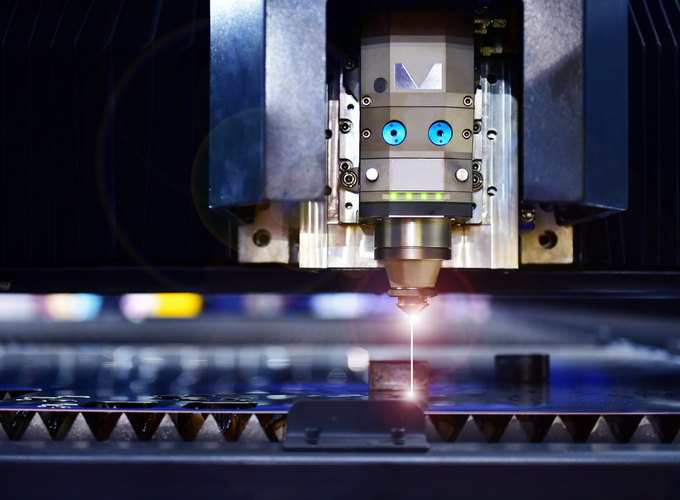

Precision Laser Welding Solutions

At Contour Precision Ltd, we specialise in providing state-of-the-art laser welding services that set the standard for precision, efficiency, and quality. Our advanced laser welding technology offers a superior alternative to traditional welding methods, making it the preferred choice for industries requiring the utmost accuracy and strength in their welds. Serving clients in Aylesbury and across the UK, we are committed to delivering bespoke welding solutions that meet the unique needs of each project.

Laser welding stands out for its ability to produce high-strength welds with exceptional precision. This innovative technique allows for the welding of dissimilar materials, offering unparalleled versatility in manufacturing and repair processes. The flexibility of beam manipulation further enhances the capability to achieve precise results in complex geometries, making laser welding ideal for mould and tool construction, repair, and precision engineering applications.

About us

Precision engineering drives innovation in modern manufacturing, and at Contour Precision Ltd, we’re dedicated to using this advanced discipline to deliver ultra-accurate components for today’s industries. It’s more than meeting specifications—it’s about redefining what’s achievable in engineering.

At Contour Precision, we combine technical skill and innovation to deliver tailored precision engineering solutions that surpass industry standards. Our strength lies in producing highly accurate components essential for demanding sectors such as aerospace, medical, and automotive, where precision is critical.

At Contour Precision, we’re dedicated to delivering exceptional accuracy in every project. By utilising advanced CAD/CAM systems, innovative materials, and strict quality controls, we consistently meet the highest performance standards. Our skilled team ensures precise results, even for the most complex tasks.

Our Services Include:

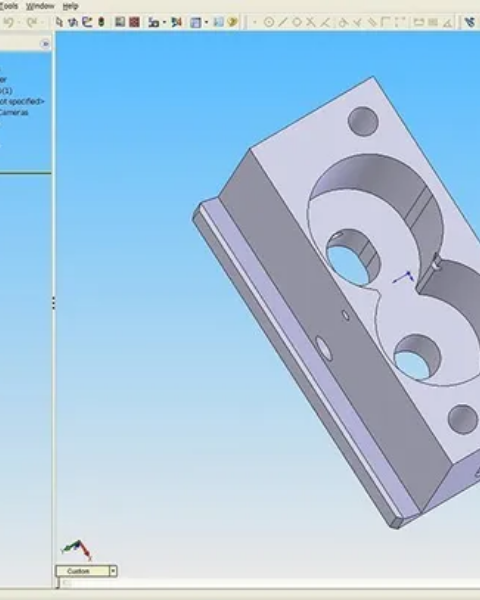

CAD/CAM

CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) form the foundation of modern precision engineering. At Contour Precision, we use these tools to bring intricate designs to life—CAD enables the creation of detailed 3D models, while CAM converts them into exact machine instructions.

Wire Erosion

Wire Erosion, also known as Wire EDM (Electrical Discharge Machining), is an advanced method Contour Precision employs to precisely cut hard materials. Using a fine wire as an electrode, it erodes material with controlled electrical discharges—perfect for producing detailed, complex shapes with high accuracy.

Spark Erosion

Spark Erosion, or Spark EDM, is another advanced electrical discharge machining technique expertly used by Contour Precision. Instead of a wire, it utilises an electrode to generate rapid, high-intensity electrical sparks that remove material. It’s especially effective for shaping complex designs in tough materials like steel and titanium.

Precision Grinding

Precision grinding is a key strength of Contour Precision’s manufacturing. This technique removes material through abrasion to achieve a superior finish with extremely tight tolerances. Our team is skilled in surface, cylindrical, and centreless grinding, meeting a wide range of client requirements throughout the UK.

Plastic Injection Mould Tools

Plastic injection moulding is fundamental to many manufacturing operations. At Contour Precision, we focus on producing top-quality mould tools essential for manufacturing large quantities of consistent, premium plastic components. Our precision engineering expertise is key to the design and production of these tools.

Select Contour Precision for expert precision engineering supported by a talented team, advanced CAD/CAM technology, and rigorous quality control. We provide customised solutions designed around your requirements, with a client-centred approach that guarantees every project achieves top-quality results.

Precision engineering delivers benefits beyond exact measurements, such as improved performance, increased reliability, and cost savings from lower maintenance. It drives innovation, enhances safety in vital industries like aerospace and healthcare, and fosters sustainability by reducing waste and resource consumption, making it valuable across diverse sectors.

We welcome your questions and feedback! Feel free to contact us via the form on our website, or get in touch by phone or email.

Images