Company details for:

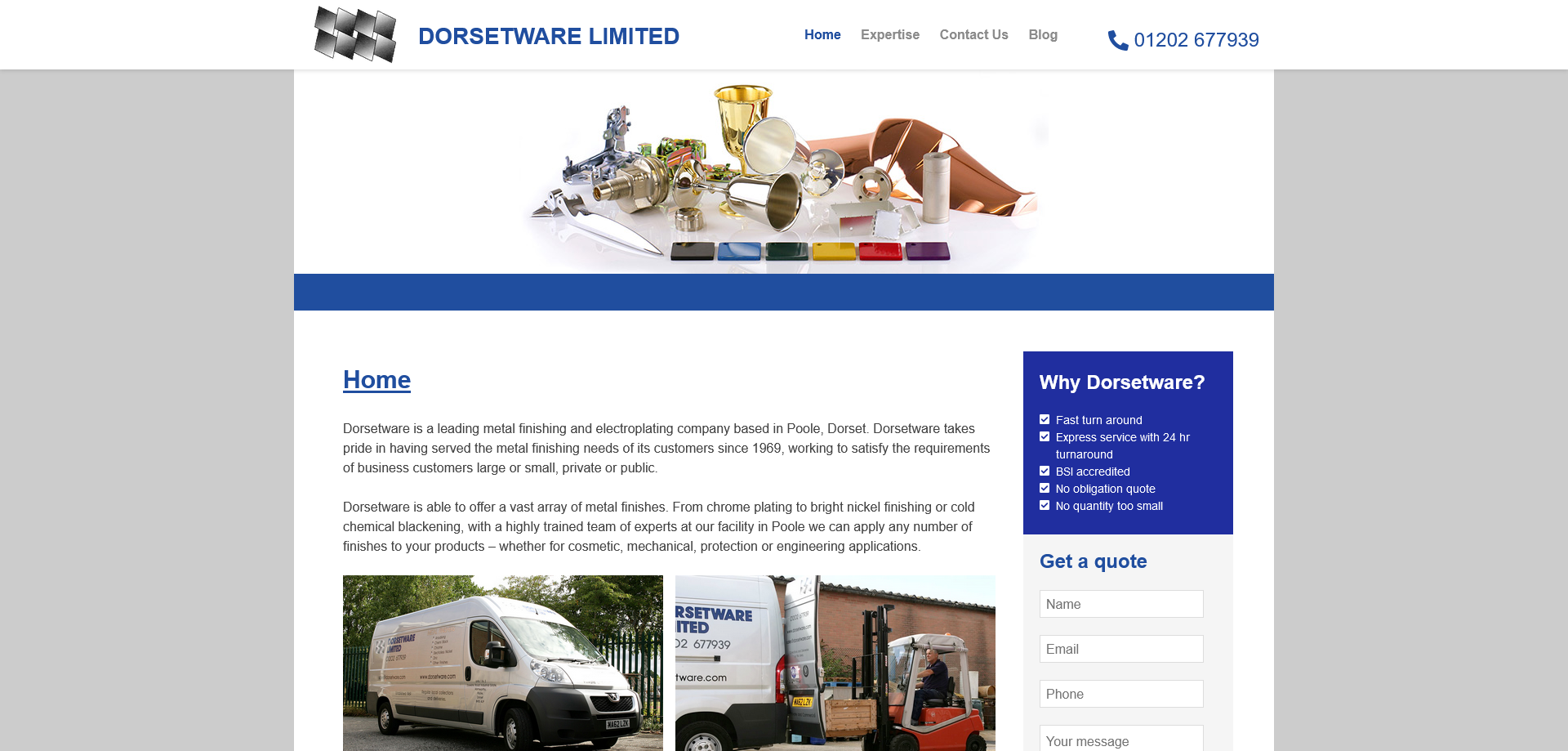

Dorsetware Ltd

Units 1-2,

Dawkins Road,

Poole,

Dorset,

BH15 4JP,

United Kingdom

Quick Links:

Products / Services

Anodising

During the anodic oxidation process the surface of the aluminium is converted to aluminium oxide. The thickness of the oxide layer is approximately twice that of the aluminium removed. For anodising your products, it is always useful to remember that if you require a material growth of 10um, then a 20um anodising thickness will be required.

Dorsetware also offers coloured anodising, available in a range of colours as well as natural anodising.

Bright Acid Tin

Bright acid tin also provides a bright clean and corrosion resistant finish that is popularly used in food processing, cookware or kitchenware for its ability to look clean, withstand heat, and non-toxic qualities. Discover more about it’s uses, the bright acid tin plating process and it’s chemical properties with our brief guide to bright acid tin plating.

If you would like further information and technical information about how our process of bright acid tin plating works then please don’t hesitate to get in touch with our technical department. You can contact us via telephone on 01202 677 939, via email on technical@dorsetware.com or via our online contact form.

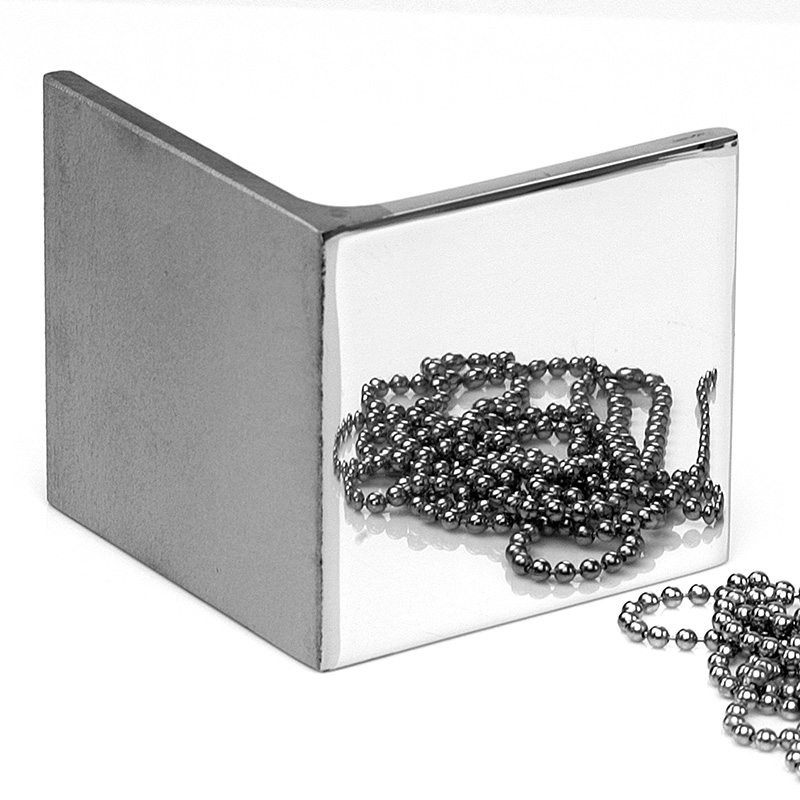

Bright Nickel

Bright nickel plating produces a fully bright, highly leveled, ductile nickel deposit that can be applied to ferrous and non-ferrous metals. It has an appearance similar to that of stainless steel. Bright nickel can be used on steel and aluminium for a bright, clean finish. Learn more about the anodising process, nickel finishes and common uses with our guide to bright nickel plating.

Chrome

We often apply a chrome finish onto everyday household items, classic car parts or bicycle parts having stripped away old chrome and replaced it with new, polished chrome.

Sometimes referred to as triple-chrome plating, chrome finishing involves electroplating copper as a precursor to the nickel and then the chrome onto the object. The copper and the nickel layer provide the smoothness, much of the corrosion resistance and the chrome provides reflectivity.

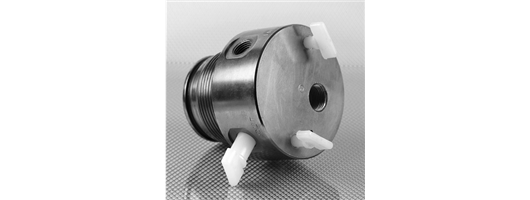

Cold Chemical Blackening

Cold chemical blackening provides a coating that is integral with the steel surface, providing virtually no dimensional change. Corrosion protection to this cold chemical black coating is obtained by applying oil.

From tool pieces to automotive parts, the finish will not chip, flake, rub or peel off and the effects of the blackening include reduced light glare or reflection and improved lubrication characteristics.

Copper

De-Embrittlement

Hydrogen embrittlement is the process by which various metals, most importantly high-strength steel, become brittle and fracture following exposure to hydrogen. Hydrogen embrittlement is often the result of unintentional introduction of hydrogen into susceptible metals during forming or finishing operations and it consequently increases cracking in the material.

De-embrittlement is essential for removing hydrogen. Dorsetware offers a range of temperatures and times suitable for your requirements and the scale of operation that you need.

Gold

Hard Anodising

Hard anodising is a branch of sulphuric anodising where the bath temperature is below freezing, the low temperature allows for a higher current density and voltage, which is necessary to form a thicker coat. In doing so, a hard anodised coating will give extreme hardness and resistance to abrasion and corrosion.

Iridite NCP

The iridite NCP, also known as non-Chrome Passivate, finishing process produces a protective conversion coating on aluminium and its alloys. Iridite NCP coating can be used as a final finish or can also serve as a base for paints, high performance topcoats, powdercoats, lacquers or rubber bonding.

Dorsetware’s iridite NCP service has been developed in response to the ELV, RoHS and WEEE directives. Iridite NCP does not contain lead, cadmium, chromium (hexavelant or trivalent), mercury or PBB/PBDE compounds.

Manganese Phosphate

The manganese phosphate coating will absorb oil and other lubricants that has its uses on moving and wearing steel surfaces. Its action is either as a solid lubricant until the two wearing surfaces can form matched mating surfaces, or as a porous base for liquid lubricants.

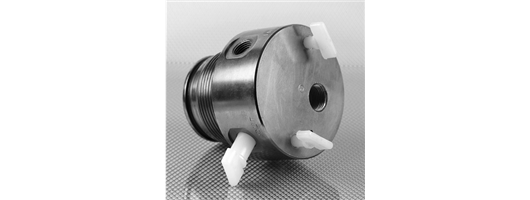

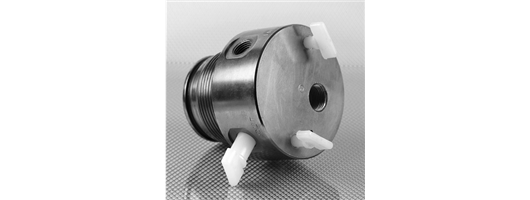

Masking

We understand that some of our customers will have perfected their own masking needs, but our sister company’s large supply of masking products on site mean we’re able to provide expert metal masking services in-situ.

Nickel Sulphamate (Dull Nickel)

Primarily used for engineering applications, nickel sulphamate has a dull appearance but its coating can be used for dimensional corrections, abrasion and wear as well as corrosion protection. Nickel sulphamate finishing can also be used as an undercoat for chromium. Discover what it can be applied to, what it is ideal for and it’s chemical properties with our guide to dull nickel plating.

Stainless Steel Passivation

These contaminations are potential corrosion sites that result in premature corrosion, ultimately causing deterioration of the component if it is not removed. The steel passivation process facilitates the formation of a thin, transparent oxide film that protects the stainless steel from corrosion.

Metal Polishing & Vacuum Blasting

Vacuum blasting and polishing results in a much smoother, much brighter finish before plating. Defects in the material will be visually enhanced after plating.

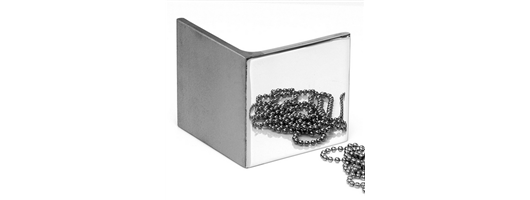

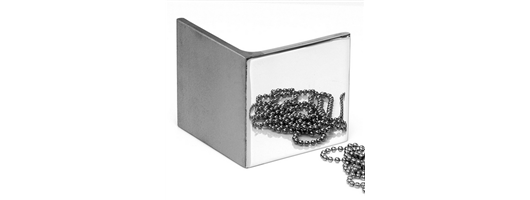

Silver

Silver contains no alloying brighteners, therefore deposit resistivity is equivalent to pure silver. Silver coating is suitable for electrical, electronic or microwave purposes. Furthermore, silver finishing is great for decorative and aesthetic applications.

Zinc

Passivation Range

Colour (Yellow Iridescent) Hexavalent

Colour (Yellow Iridescent) Trivalent − RoHS Compliant

Colour (Silver/Bluish Tinge) Trivalent − RoHS Compliant

BlackTrivalent − RoHS Compliant

About us

Dorsetware provide our customers with continuous top quality results using the finest state of the art technology. With the help of Fischer X-ray and dual-scope technology we can achieve coating thicknesses to meet customer specifications and Ministry, European and American standards. If required we can also provide a Certificate of Conformity.

We offer a wide range of metal finishes.

Aluminium Anodising & Colour Anodising - Aluminium anodising, also referred to as anodic oxidation, is widely utilised to create protective and decorative coatings on aluminium surfaces. We provide Anodising colours, Aluminium anodising, Black anodised aluminium, White anodised aluminium, Custom colour anodising, Sulphuric acid anodising.

Bright Acid Tin Electroplating - Dorsetware is a reputable electroplating and metal finishing company with full accreditation. They offer a bright acid tin electroplating service for various products. Bright acid tin is a top choice for electronics, wiring, and conduit due to its exceptional conductivity and soldering properties. This plating also delivers a shiny, clean, and corrosion-resistant finish.

Bright Nickel Plating - Bright nickel electroplating is a widely utilised form of nickel plating that is favoured for both decorative and engineering purposes. This type of plating, from bathroom fixtures to fasteners, offers excellent corrosion resistance and can be applied rapidly.

Chrome Electroplating - Chrome electroplating creates a desired chrome finish for decorative use, corrosion resistance, smooth surfaces, and durability. This technique is commonly used to coat everyday household items and to refurbish chrome on vintage cars or motorcycles by replacing old chrome with new, polished chrome.

Cold Chemical Blacking - Cold chemical blacking offers numerous advantages by creating a coating that seamlessly integrates with the steel or aluminum surface, resulting in minimal dimensional alterations. To enhance corrosion protection, oil is applied. From tool pieces to automotive parts, the finish is resistant to chipping, flaking, rubbing, or peeling off. Additionally, the metal blackening process results in reduced light glare or reflection and enhanced lubrication properties.

Copper Electroplating & Coating - Copper electroplating stands out as a top choice among our electroplating services for metal finishes. The copper coating provides numerous advantages, including enhanced conductivity, malleability, and antibacterial properties.

De-embrittlement - De-embrittlement is crucial for eliminating hydrogen. Dorsetware provides various temperature and time options tailored to your de-embrittlement needs and the scale of your operation.

Gold Plating - Gold electroplating is commonly used in jewellery and various decorative applications. The reason behind this is that gold plating closely resembles gold but is more cost-effective and functional.

Hard Anodising & Coating - The hard-anodising process is a type of sulfuric anodising that is conducted at temperatures below freezing. This lower temperature enables a higher current density and voltage, essential for creating a thicker coating. Consequently, a hard-anodised finish provides exceptional hardness and offers remarkable resistance to abrasion and corrosion.

Iridite NCP Plating & Coating - The iridite NCP process creates a protective conversion coating on aluminum and its alloys. This plating and coating can function as a final finish or as a foundation for paints, high-performance topcoats, powder coats, lacquers, or rubber bonding.

Manganese Phosphate Coating - Manganese phosphate coating produces a dense crystalline surface on steel, ideal for various engineering uses.

Electroplating & Anodizing Masking - Dorsetware, along with its sister company Hi-Tek Products Limited, provide electroplating masking products and anodising metal masking services in Dorset. They utilise plugs, dots, caps, and lacquers for these processes.

Dull Nickel Plating & Nickel Sulphamate - Dull nickel plating is perfect for addressing dimensional corrections, abrasion, wear, and providing corrosion protection. It is commonly utilised as a base layer for chromium applications.

Passivation of Stainless Steel - The process of stainless steel passivation eliminates any residual free iron contamination on the surface of the stainless steel. We conduct this procedure following machining and fabrication to ensure quality.

Metal Polishing & Vacuum Blasting - Polishing metals, such as brass and aluminum, will yield a smoother and shinier finish compared to the original plating. Vacuum blasting is an excellent choice for abrasive blasting as it efficiently smooths the product without generating dust.

Silver Electroplating & Coating - Silver electroplating and coating are commonly used for electrical, electronic, or microwave applications, selected for both their functional properties and attractive decorative appeal.

Zinc Plating, Coating & Passivation - Zinc plating offers enhanced corrosion protection for metals, which is why mild steel, zinc nickel plating, and tin zinc plating are widely used.

Please contact us if you require further information regarding Dorsetware, our processes or facilities.

Images

Articles / Press Releases

Brochures

Reviews

Trade Associations