Company details for:

Luhrfilter Ltd

Unit 1, Crompton Court,

Burntwood Business Park,

Attwood Road,

Burntwood,

Staffordshire,

WS7 3GG,

United Kingdom

Quick Links:

Products / Services

Range of Products & Services

As technology partner LÜHRFILTER offers all component parts necessary for the solution of applications from the gas and particle collection up to the stack. In combination with different, self-developed sorption procedures we find new and innovative solutions.

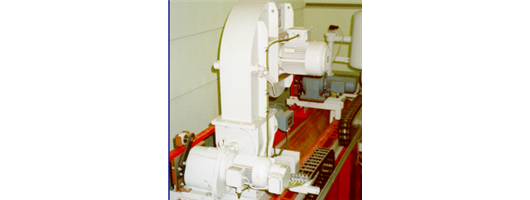

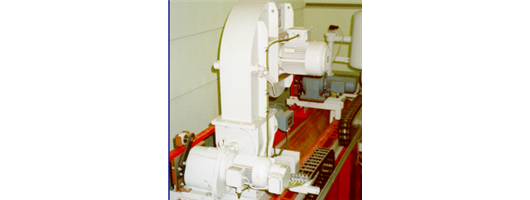

Bag Filter

The design features of the horizontally or vertically installed flat-bag filter elements especially in combination with the different -off line- cleaning systems included in the range of products allow

the reliable observance of requested residual particle contents in the clean gas

long filter fabric service lives

at low space requirement and low maintenance.

Flat Tube Heat Exchanger

Flat-tube heat exchangers are generally installed upstream of flat-bag filters in order to reduce the temperature of the gases to be cleaned to a temperature admissible for the filter fabric or to adjust the optimum process temperature.

During development of this heat exchanger special importance was attached to the objective to achieve a reliable continuous operation, combined with a constant cooling of gases, even in the case of high particle loads in the gas and a strongly adhesive character of these particles. Regular manual cleaning proved to be unnecessary for maintaining the heat transfer.

If necessary, we are taking additional measures to ensure a trouble-free continuous operation of the flat-tube heat exchanger and exceptionally long service lives of cooling tubes.

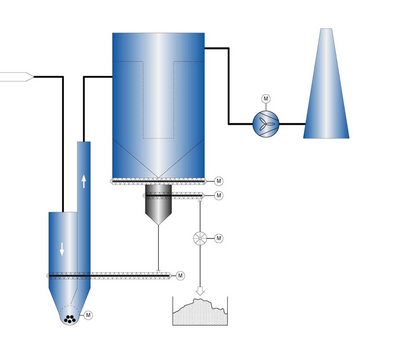

Evaporative Cooler

During the evaporative cooling liquid droplets are injected into the gas flow by means of spraying lances, serving for the heat reduction of gas during the evaporation process. A reliable operating mode of cooler requires the complete evaporation of droplets at low temperature fluctuations at the cooler outlet. The main features for a safe design of an evaporative cooler are:

Spraying technology

Homogeneous gas flow through the evaporation zone

Control technology

In most of the cases two-component nozzles (water and compressed air) are used for the spraying. As an alternative, one-component nozzles can be used. This, however, requires conveying pumps with a definitely higher pressure rise.

For corrosion protection and for the separation of acid crude gas components, a sorption agent such as lime slurry or sodium hydroxide solution can additionally be injected into the evaporative cooler together with water and compressed air, if necessary. In case of use of sorption agents and due to the longer evaporation times of injected liquids, the size of evaporative cooler/spray absorber has to be adapted accordingly.

Sorption Procedures

LÜHRFILTER has developed different procedures for the following applications:

Chemisorption of acidic pollutant gases such as HF, HCl and SO2, with Ca- or Na-based additives.

Adsorption of PCDD / PCDF as well as Hg and Hg compounds by means of activated carbon / activated coke or other additives with large internal surface.

It has been proven that the implementation of high additive particle re-circulation rates, especially when using Ca-based additives, leads to a significant improvement in the separation rate for acidic pollutant gas components such as HF, HCl and SO2 and/or to a reduction in the amount of additive added.

The LÜHRFILTER Conditioning Rotor – Recycle Process enables the operationally reliable re-circulation of large re-circulation quantities, even if problematic particles such as CaCl2 are present in larger quantities in the particle spectrum. A largely homogeneous mixing of the recycled particles with the flue gas flow is achieved. Pneumatic conveying systems, which are often susceptible to faults, are not required.

Services

LÜHRFILTER offers you a wide range of support services starting with project conception via assistance during project realisation through to provision of services on site. Our qualified, purpose-trained staff of the different technique and service departments will be pleased to assist you.

Engineering

LÜHRFILTER offers you all services required for a professional project realisation from the project study via the project handling and services on site through to support services after commissioning of plant.

More than 80 highly qualified members belong to our technical team in the departments process technology, project realisation, mechanical and electrical project handling, commissioning and service.

In our office we are using up-to-date software such as AUTOCAD, Inventor, ELCAD, EPLAN, MS-Project as well as different programming languages for the plant control. In addition, we are also realising flow simulations – CFD (computational fluid dynamics) – for the optimisation of flow procedures together with external institutions.

Assembly

LÜHRFILTER provides of a competent team for the implementation of mechanical and electrical installation works. We lay special emphasis on the fact that each construction site will be supervised by at least one member of our assembly staff. For many years we are working together with partners, who provide skilled assembly staff for our company.

Our professionally qualified assembly crews supervise and attend all projects from the first assembly works at the location of project until the final acceptance of plant.

Maintenance / Inspection

Nowadays all industrial production processes are subject to comprehensive requirements regarding environmental protection. A high availability of the air pollution control plants integrated in the process is compulsory necessary for this. Even after commissioning and take-over of gas cleaning plant, LÜHRFILTER offers you an extensive package of support and maintenance services.

A specially trained team is among other things available for the following services:

Inspection of plants, if necessary also in connection with contractually agreed several years’ maintenance contracts

Plant maintenance during scheduled downtimes

Troubleshooting

On-site measurements

Support service and training of operating staff

Electrical Engineering

LÜHRFILTER is a competent partner not only for the technical design and planning of a flue gas treatment plant but also for the realisation of all requirements of electrical engineering and/or automation technology. Whether new turn-key plant, integration into an existing process and control system or even conversion/upgrading of out-of-date automation technology, you will profit by LÜHRFILTER as system integrator.

After-Sales Service

Our spare and wear part management team will provide the assurance of your plant availability.

Based on our experiences we will prepare a recommendation for the storage of spare and wear parts, particularly provided for your plant.

Filter bags and other essential spare parts of filtration plants will be manufactured in our shops. In doing so we grant the provision of original spare parts, considering high quality demands.

As a result of our high vertical range of in-house production we can quickly and flexibly react on your requirements. By this we are manufacturing more than 30,000 filter bags per month, a large part of this being used for installation in plants in operation.

Spare parts and particularly also the flat-bags will be supplied with a new life time warranty.

Besides the delivery of spare and wear parts, our scope of services also comprises of course the optimisation of plant operation, based on your and our experiences

About us

Lührfilter Ltd, a wholly owned subsidiary of Lührfilter GmbH, specialise in gas cleaning systems and dust & fume extraction systems from supply only to turnkey systems with an option of five vertical or horizontal filter elements to choose from providing online or off-line cleaning for gas processing applications.

As a specialist in Sorption procedures, filtration, Lührfilter GmbH design, supply and install technically advanced filtration systems that allow users to collect particulate and dust, with the option for conditioning systems to remove acidic gases, heavy metals and dioxins by gas adsorption.

Lührfilter also manufacture forced convection heat exchangers for high temperature applications. In addition, our dry gas absorption systems enable the reduction of acidic elements, dioxins and heavy metals.

Our Product Range Includes:

- Flat Bag Filters & Cleaning Systems − a flat bag which can be mounted both horizontally and vertically to filter elements.

- Model MWF − Compressed Air ‘Semi-Offline’.

- Model DWF − Medium Pressure ‘Semi-Offline’.

- Model DF − Compressed Air ‘On-Line’.

- Model DFK− Compartmentilised ‘Off-Line’

- Flat Tube Heat Exchangers − an air to air heat exchanger operating through forced draught convection.

- Evaporative Coolers − an evaporative cooler unit with a vertical cylindrical vessel where spray nozzles are inserted to inject atomised water droplets in process gas.

- Conditioning Rotors & Additive Systems

- Mobile Bed Absorbers

- Ancillary Components − including Stand alone filters, Silos, Special design extract hoods, Control panels PLC & HMI, Fans, Dampers, Valves and Ducting.

We serve a wide range of industries including Waste to Energy, Biomass, Steel, Non Ferrous Metals, Glass, Lime, Aggregates, Chemicals, Incineration, Ceramics & Cremation.

Services Carried Out by Lührfilter Includes:

- System design and engineering

- Installation and commissioning

- Dust handling / transport systems

- LEV testing on site

- PLC and software design

- Site inspections / surveys

- Bag testing facilities

- Spare components

- After sales service

Images

Articles / Press Releases

Brochures

Trade Associations