Company details for:

Pillarhouse International

Quick Links:

Products / Services

Pilot

Entry-level, benchtop, single point selective soldering system

The all-new ultra-low-cost Pilot machine has been designed as an entry-level, handload, benchtop machine for small to medium batch manufacturers, combining high levels of production flexibility with economic running costs.

Offered with two universal, quick change tooling carriers, each one can be exchanged to optimise cycle time. Each carrier is capable of handling a board size up to 330mm x 250mm (13″ x 10″).

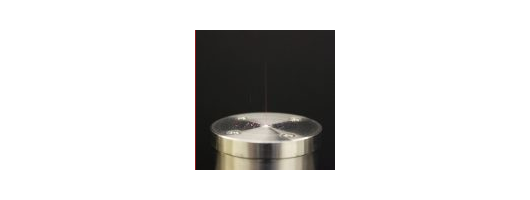

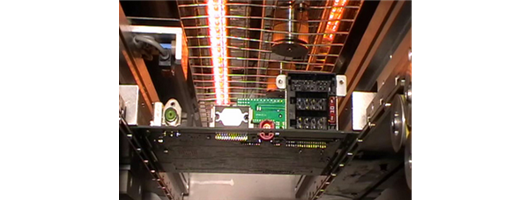

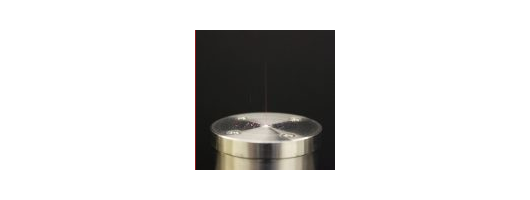

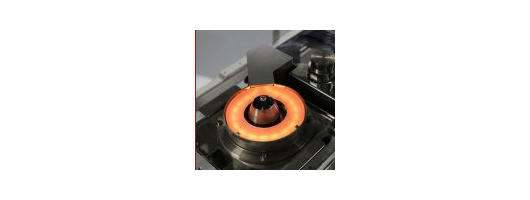

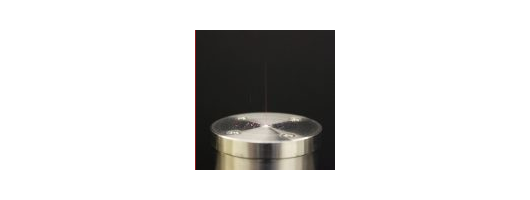

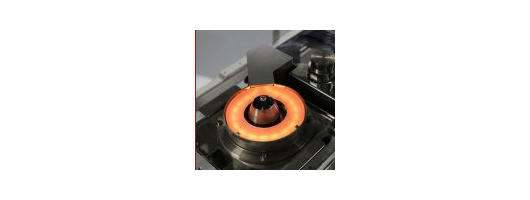

The Pilot incorporates, as standard, our patented Drop-Jet fluxer for quick, accurate flux deposition. An optional bottom side IR pre-heat is also available; this is particularly useful when processing multi-layer PCBs or using water-based flux types.

Jade MKII

Elementary, flexible, single point selective soldering system

Designed to meet the needs of the small/medium batch manufacturer who requires high levels of production flexibility, the Jade MKll entry-level system offers uncompromised selective soldering quality at a very low cost.

The Jade MKII is a handload system, incorporating a universally adjustable tooling carrier capable of accommodating PCBs or pallets up to 457 x 508mm (18″ x 20″).

Our patented Drop-Jet design fluxer offers quick and effective flushing of the pressurised flux chamber. This helps to keep maintenance levels to a minimum whilst enabling use of higher solid content fluxes as well as water-soluble fluxes.

Jade Pro

Ultra-flexible, offline, multi-platform selective soldering system

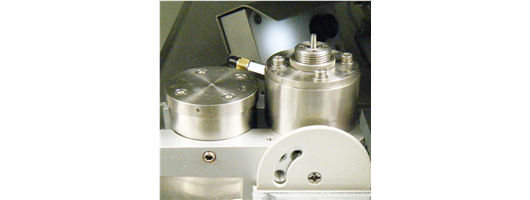

Designed to meet the needs of the small batch manufacturer who requires high levels of production flexibility. The Jade Pro offers the ability to regularly change solder alloys without incurring expensive down time, whilst the solder bath cools down and heats up during a regular manual changeover process.

Jade Prodex

Ultra-flexible, offline, multi-platform, quick load twin PCB rotary table selective soldering system

Designed to meet the needs of the small batch manufacturer who requires high levels of production flexibility. The Jade Prodex offers the ability to regularly change solder alloys without incurring expensive down time, whilst the solder bath cools down and heats up during a regular manual changeover process.

The Jade Prodex is an offline system, incorporating a quick load, twin PCB, universally adjustable, rotary table transport system to allow simultaneous load/unload during product processing.

Jade Handex

Designed to meet the needs of lean manufacturing, the Jade Handex offers high-speed flexible throughput at minimal cost.

The Jade Handex is equipped with a revolutionary twin PCB rotary table transport system to allow simultaneous load/unload during product processing.

Orissa Fusion

High speed, in-line, multi-platform selective soldering system

Incorporating high-speed PCB transfer, the Orissa Fusion platform offers the ultimate in flexibility, coupled with reduced line length at a lower cost compared to current market offerings.

Orissa Synchrodex

Flexible, in-line, modular selective soldering system

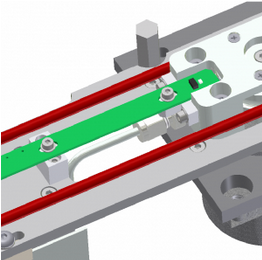

Designed as a modular system, the Synchrodex range of in-line equipment offers the ultimate in flexibility with the ability to upgrade to high-speed throughput when multiple modules are placed together.

Orissa Synchrodex Combo

In-line or stand-alone fluxer/pre-heater

This compact, modular, in-line system utilises the same design concept as the new generation Synchrodex soldering cell, and offers the user significantly reduced process time when compared to using a single soldering unit with on-board fluxing and pre-heat functions. It also provides a reduced footprint and cost savings over the conventional three module, fluxing, pre-heat and selective soldering work cell.

Orissa Synchrodex Pro

Enhanced, flexible, in-line, modular selective soldering system

Designed as a modular system, the Synchrodex Pro range of in-line equipment offers the ultimate in flexibility with the ability to upgrade to high-speed throughput when multiple modules are placed together.

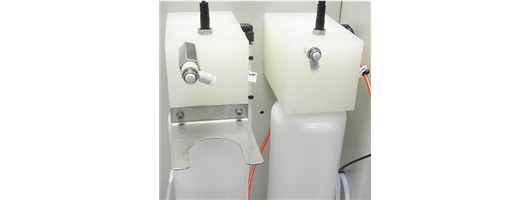

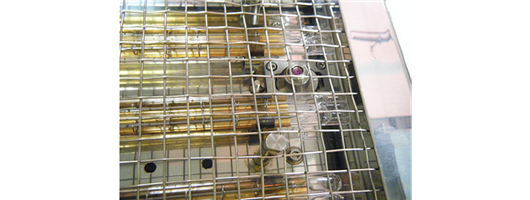

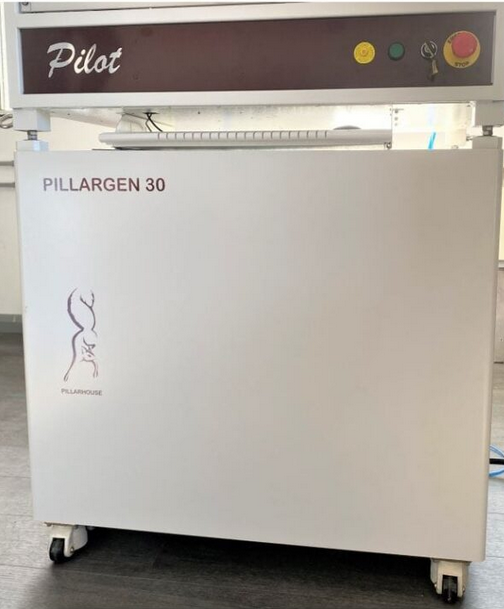

PillarGEN 30

The PillarGEN Nitrogen generation system has been specifically designed to meet the Nitrogen supply requirements of the current range of Pillarhouse selective soldering systems. The latest Nitrogen generation design technology combines compact size with ultra-quiet operation.

PillarGEN 40

The PillarGEN Nitrogen generation system has been specifically designed to meet the Nitrogen supply requirements of the current range of Pillarhouse selective soldering systems. The latest Nitrogen generation design technology combines compact size with ultra-quiet operation.

PillarGEN 80

The PillarGEN Nitrogen generation system has been specifically designed to meet the Nitrogen supply requirements of the current range of Pillarhouse selective soldering systems. The latest Nitrogen generation design technology combines compact size with ultra-quiet operation.

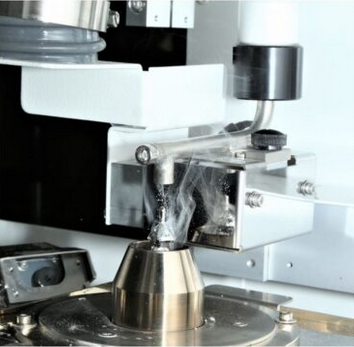

Optical Flux Plume System

Thermal Flux Sensing

Flux Flow Monitoring

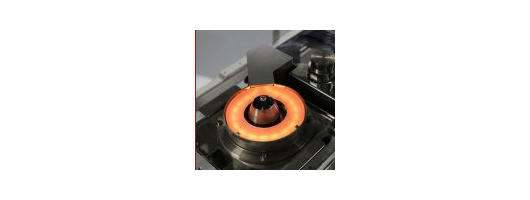

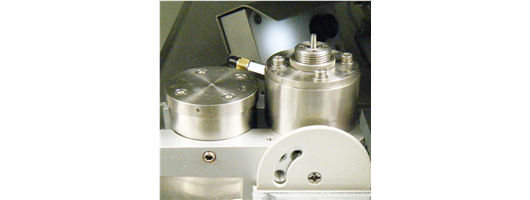

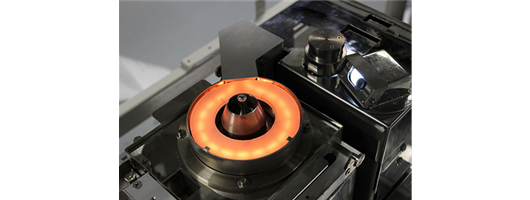

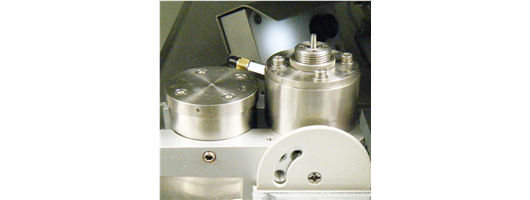

Dual Solder Pots

Heated Trollies

Nitrogen Purity Analyser

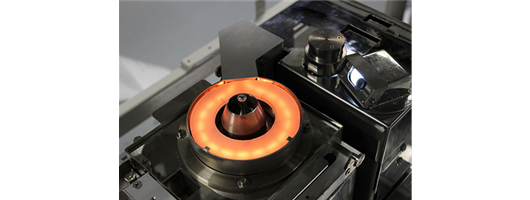

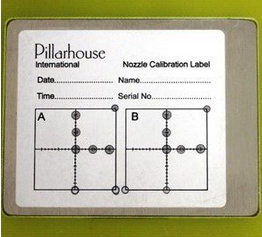

Thermal Nozzle Calibration

Wave Height Correction

Pump RPM Meter

Barcodes & Board Traceability

Fluxing Enhancements

Pillarhouse International is a leading name in selective soldering technology, and we take pride in delivering high-quality solutions to the electronics manufacturing industry. Our Fluxing Enhancements are designed to optimise the fluxing process, providing greater accuracy, efficiency, and reliability during soldering. These enhancements help improve wetting, minimise defects, and ensure consistent solder joint quality—even in complex or high-density PCB assemblies. With a strong focus on precision engineering and process control, we’re committed to meeting the evolving demands of modern electronics production through innovative and dependable fluxing solutions.

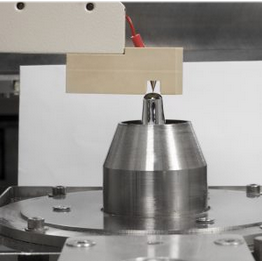

Soldering Enhancements

At Pillarhouse International, we specialise in advanced selective soldering technology and are proud to offer a range of Soldering Enhancements that improve precision, efficiency, and overall soldering quality. Our enhancements are engineered to support consistent, high-integrity solder joints, even on the most complex PCB assemblies. Whether it's improved thermal control, advanced nozzle designs, or process optimisation features, our solutions are designed to meet the evolving needs of modern electronics manufacturing. With decades of expertise and a commitment to innovation, we help our customers achieve reliable, repeatable results across a wide range of soldering applications.

Other Process Enhancements

At Pillarhouse International, we go beyond soldering by offering a range of Other Process Enhancements designed to elevate the entire selective soldering experience. These enhancements support key areas such as process monitoring, automation, data capture, and system integration—helping our customers improve efficiency, traceability, and overall production performance. From custom automation solutions to advanced software tools, we tailor our innovations to meet the unique challenges of modern electronics manufacturing. Backed by decades of experience and a commitment to continuous improvement, we provide the tools our customers need to stay competitive and future-ready.

About us

Founded in 1978 by current Chairman Alex Ciniglio, Pillarhouse International pioneered the design and manufacture of specialist equipment for the coil winding and associated industries.

Pillarhouse International produced its first production soldering system in 1984, and with continued growth throughout the 1980s, used this technology to develop the world’s first selective soldering machine in 1994.

Our mission statement is to produce high engineering standard products with a focus on innovation and cutting-edge development. This practice has led to Pillarhouse International holding several important patents that have been key to our continued success over many years and growing into a global company with sales and service facilities in over 50 countries.

We offer a wide range of selective soldering machines, covering the complexity of global demand for production across electronics, aerospace, and PCB contract manufacturing.

Pillarhouse International has its Design & Manufacturing headquarters in Chelmsford − UK; with Sales & Service Support facilities in Suzhou − China; Chicago − USA; and Guadalajara − Mexico.

Images