Company details for:

Sensor Technology Ltd

Apollo Park,

Ironstone Lane,

Wroxton,

Banbury,

Oxfordshire,

OX15 6AY,

United Kingdom

Quick Links:

Products / Services

Wireless Load Sensor

Wireless Load Sensor (LoadSense)

The Load Sensor is used with our HandHeld Receiver which can read several devices at the same time, (see data sheet WLS3626R for more details), and/or our stand alone Receiver Interface which is used to output the data via RS232/RS422, (see data sheet WLS3627R for more details)

Key Benefits:

- Wireless, so easy to install and remove between installations

- Transmits data up to a distance of 100m

- Transmits data at up to 10 times a second

- Internal Memory for up to 280 hours of data

- 11V to 28V external supply chargeable

- Connect to PC via USB

- PC software for customer settings

- Flexible automatic shutdown to conserve battery

- Dual ruggedised internal antennas

Handheld Receiver

The receiver is easy to install as it only requires DC power to be supplied to the unit. An SMA connector allows the use of an external antenna.

The wireless LoadSense HandHeld Receiver Display is used in conjunction with the wireless Load Sensor. It provides the user with an easy way to receive and view data from the Load Sensor.

Up to 9 Load Sensors can be selected from the HandHeld Receiver and individually displayed. These Load Sensors can be named by plugging the Load Sensor into a PC via USB and using the Load Sensor software.

They can then be easily distinguished on the display, which will show the current name of the Load Sensor being read.

The display shows the name of the current Load Sensor, the load, battery status of readout and Load Sensor and signal strength. By using the menu tree on the readout the user can select which Load Sensor to read, what units to be displayed, tare the data, display peak value and many more functions.

A 9 way D connector is provided to output data via RS232 / RS422 and a USB mini B to charge the battery and output data to a PC.

Key Benefits:

- Reads multiple Load Sensors

- Receives data up to a distance of 100m

- Receives data at 10 times a second

- Connect to PC via USB for user setup

- Output data via RS232 / RS422 / USB

- Ruggedized rubber case with back stand

- Long life rechargeable battery powered

Load Sensor Cabin Display

Using the 2.4GHz licence free band to receive the Load Sensor signal, it can display the load value in several views which are user selectable. It also allows the user to tare off any equipment weight to display just the load value of the cargo.

The system can operate from its rechargeable battery and does not need to be hard wired, enabling the equipment to be easily transferred between installations. The display can be operated and charged from a 28V supply

Load Sensor Handheld Receiver

Key Benefits:

- Reflective, sunlight readable LCD display

- Optional analog output for cirscale meters

- External antenna

- Units displayed: Tonne, Kg , lbs

- RAM® 1" ball mount. Base options on request

- Multiple display views. Digital, Analog Bar

- Tare function to zero out weight of equipment

Receiver Interface

The receiver is easy to install as it only requires DC power to be supplied to the unit. An SMA connector allows the use of an external antenna.

The receiver outputs a string of data from the Load Sensor which includes: Serial number, full scale, Load, Temperature, RSSI and battery voltage. The data is constantly outputted from the receiver straight from "power on" as long as the Load Sensor is in range. The output can be provided as either RS232, RS422, USB or Analog. This provides the functionality of being able to send the data over a longer distance if the receiver was to be in a remote location. The interface is suitable for applications where no user interaction is needed and data is fed into a data logger or remote display. An internal memory with real time clock is available for stand alone applications which may be interrogated from a PC.

Key Benefits:

- Small Footprint (133mm x 67mm x 43.5mm)

- Receives data up to a distance of 100M

- Receives data at 10 times a second

- Minimal startup time

- Very simple installation

- Operates on 2.4GHz licence free band

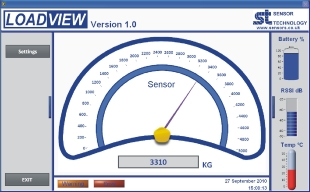

Advanced Load Monitoring Software

LoadView has been written using National Instruments LabVIEW, and as it is a self running executable file, LabVIEW is not required to run this software.

Key Benefits:

- Simple installation using serial port or USB

- Ease of operation (user friendly, a variety of user interface settings such as scales, units, etc.)

- Displays load, signal strength, battery and temperature.

- Output a text file compatible with Matlab, Excel

- LabVIEW VIs available for users to design their own Interfaces

- DLLs available for users to write their own custom software process control applications

- Data recording facility

- User configurable settings

- Multiple screen views

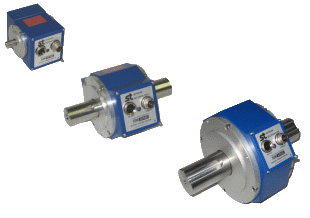

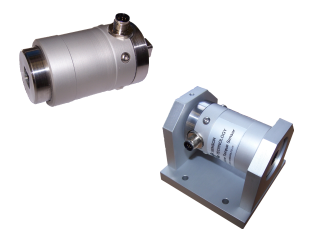

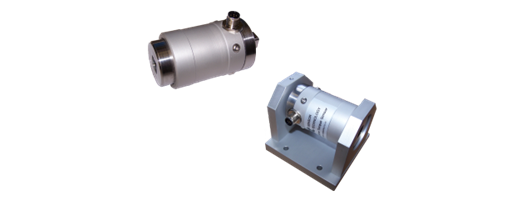

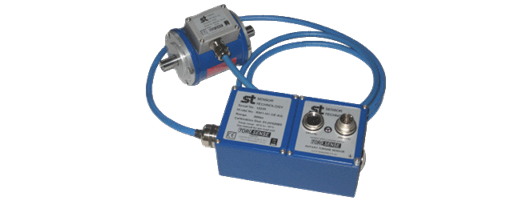

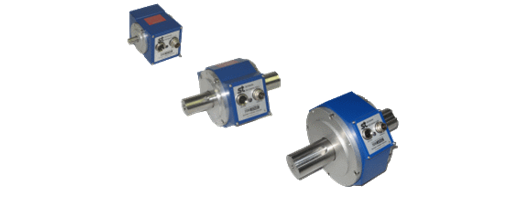

RWT410/420 Series Torque Sensors

TorqSense Digital RWT410/420 Series torque transducers with integral electronics are available in three different body sizes for torque ranges up to 13000Nm. The series offers a cost effective, non-contact digital rotary torque measurement solution, using TorqSense Surface Acoustic Wave technology, suitable for torque monitoring, testing or controlling drive mechanisms. TorqSense RWT410/420 series transducers and their technology are particularly appropriate for OEM applications.

If you require seperate electronics, please see our RWT430/440 Series transducers.

Rotary torque sensors manufactured by Sensor Technology Ltd

Key Benefits:

- Minimal shaft length - High shaft stiffness

- Low inertia - High Speed capability because electronics are not fixed on to shaft

- Non-contact/brushless measurement - simple RF couple for power/signal transmission

- High bandwidth 10kHz

- 300% mechanical safe overload

- High accuracy (0.25%) and resolution (0.02%)

- Excellent noise immunity

- Integral digital electronics

- Operates both statically and dynamically - Clockwise and anti-clockwise

- Any full scale torque can be specified within the standard range: 1Nm through to 13000Nm

- Sensors to monitor shaft temperature for better compensation and accuracy

- LED Status light

- Lifetime Warranty

TorqSense RWT410 Series transducers offer:

- Fixed voltage or current analog outputs (one for torque and the other for speed or power) for interfacing with analog instrumentation

- BIT Self-diagnostics for letting the manufacturer know that the transducers torque, speed ratings and calibration due date have not been exceeded

- Simple 'Sensor status' output pin

- Sensors to monitor shaft temperature for better compensation and accuracy

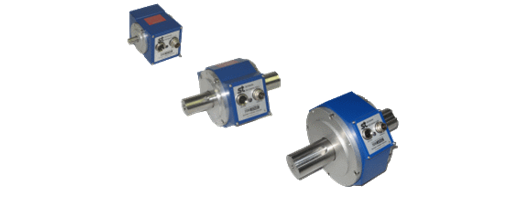

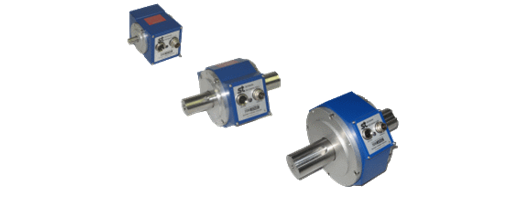

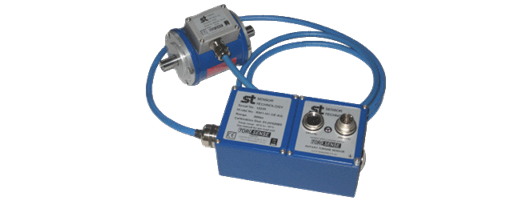

RWT430/440 Series Torque Transducers

Transducer overload has also been increased to 300%.

The digital TorqSense RWT430 and RWT440 Series use the latest and same non-contact TorqSense technology as used in the RWT410/420 Series in three different body sizes for torque ranges from 1Nm to 13000Nm, with above 13000Nm on request. The only difference for this Series is that it may be more appropriate for some applications to have the sensor unit separate from the electronics unit due to space and/or environmental limitations.

The series offers a cost effective, non-contact digital rotary torque measurement solution, using TorqSense Surface Acoustic Wave technology, suitable for torque monitoring, testing or controlling drive mechanisms and particularly appropriate for OEM applications.

If you require integrated electronics, please see our RWT410/420 Series transducers.

Torque sensors with separate electronics module by Sensor Technology

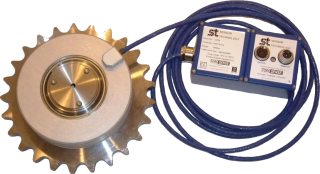

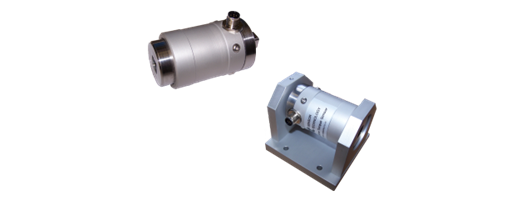

RWT450/460 Series Pulley/Sprocket Torque Sensor

TorqSense Digital RWT450 & 460 series pulley/sprocket transducers are suitable for torque monitoring and process control on any belt / chain driven machinery. They offer separate electronics and sensor either with fixed outputs (RWT450 Series) or user selectable outputs (RWT460 Series). USB and RS232 outputs are also available for direct PC interface.

RWT450/460 Pulley Sprocket torque measurement transducers

Key Benefits:

- Direct replacement for standard pulley / sprocket

- Low inertia - High Speed capability because electronics are not fixed on to shaft

- Non-contact/brushless measurement - simple RF couple for power/signal transmission

- High bandwidth 10kHz

- 300% mechanical safe overload

- High accuracy and resolution

- Excellent noise immunity

- Seperate digital electronics

- Operates both statically and dynamically - Clockwise and anti-clockwise

- Any full scale torque can be specified within the standard range:

- 100Nm through to 10000Nm

- Lifetime Warranty

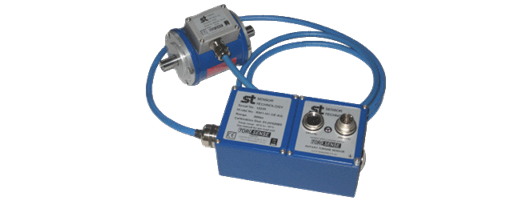

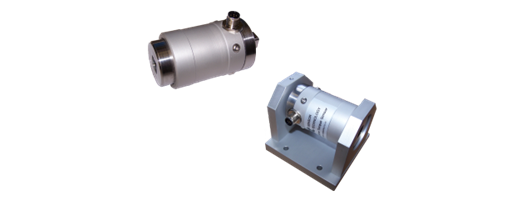

ORT230/240 Optical Torque Transducers

The new TorqSense ORT 230/240 torque sensors replace the E200 ORT series and feature all new electronics that have produced significant performance gains in resolution, frequency response, reduced sensor current consumption and faster digital data throughput.

Key Benefits:

- Low inertia − High Speed capability because electronics are not fixed onto shaft

- Non contact/brushless measurement

- High Bandwidth

- 200% safe mechanical overload

- Excellent noise immunity

- Separate digital electronics

- Operates both statically and dynamically

- clockwise/anti-clockwise

- Any full scale torque can be specified within standard range: 10mNm through to 100Nm

- Lifetime warranty

SIT 105/110/120 Series Strain Gauge Torque Sensors

Models are available in sizes ranging from 50Nm to 5000Nm, offering outputs from mV/V outputs, to ratiometric voltage outputs, to digital data connection via RS232 or USB.

An option of a bench mount housing is available for torque wrench test and calibration.

The SIT 105/110/120 torque transducers use modern wire foil strain gauge technology with the latest high performance stainless steel shafts

Transducer Display ETD

Key Benefits:

Displays torque, peak torque, speed* or power* in the units specified within the transducer

Automatically detects and displays the model, range, serial no. and calibration due date of the transducer

Provides auto reset of peak torque values

Provides power to the transducer in place of the standard power supply unit

Provides access to analog torque outputs and pulse speed* output

Provides USB output if used with RWT420/440 series with USB option fitted

Displays warnings and high temperature if appropriate

* Provided RWT transducer has speed option fitted and enabled

Bluetooth Interface Module

Our android app will enable you to view the current Torque, Speed, and temperature from the transducer, as well as peak values. It will also allow you to set filters and view the current configuration of the sensor. As the Interface also has a USB output it lets you connect to your PC at the same time, this allows you to run a full version of our TorqView software, for example to record at full speed while using your android device as a monitor.

Using a mobile device with Bluetooth and our software means you can quickly look at the transducer data without having to set up a computer and cables giving you fast access to the information when you need it.

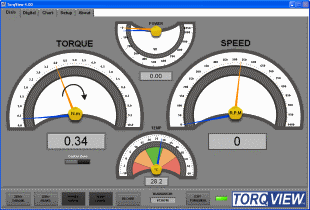

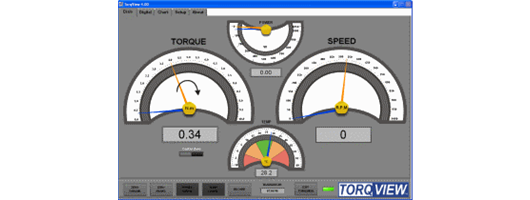

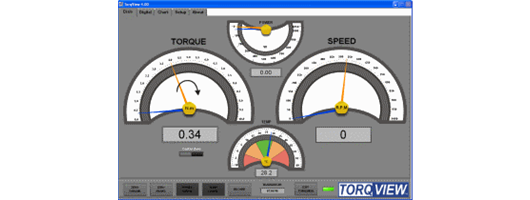

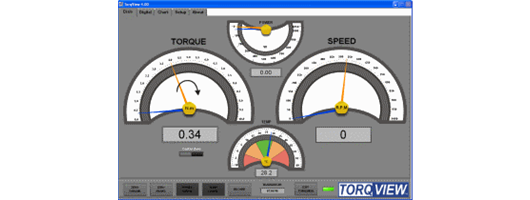

TorqView Advanced Torque Monitoring Software

TorqView 5 has been written using National Instruments LabVIEW, and is a self running executable file, so LabVIEW is not required to run this software.

Services

Calibration, Service & Repair of its own transducers and some other manufacturers transducers.

Rental Service whereby customers can rent a transducer for a minimum of one month.

Engineering Support for special demanding applications.

About us

For over 40 years Sensor Technology has researched and developed solutions for customers' measurement requirements, creating its own unique technologies for the instrumentation, test and OEM markets worldwide and supported by a global network of distributors.

The Industrial Division manufactures the TorqSense and LoadSense ranges of rotary torque and wireless load transducers, offering accurate, affordable, market leading products across the whole range of industrial applications.

TorqSense Rotary Torque Transducers

TorqSense Digital torque transducers offer cost effective, non-contact digital rotary torque measurement, suitable for torque monitoring, testing or controlling drive mechanisms. TorqSense transducers and their technology are particularly appropriate for OEM applications.

TorqSense SGR510/520 series features integral digital electronics with low power consumption of 3 watts, high accuracy of 0.1% with high frequency response, resolution of 0.02% of FSD and increased transducer overload to 400% and ranged available from 1Nm to 13000KNm.

Other ranges of TorqSense transducers available include the SGR530/540, with a smaller sensor head and separate electronics module. The newly redeveloped ORT230/240 series of Optical Rotary Torque Sensors range from 10mNm to 100Nm with speeds up to 30,000rpm. They feature low torque ranges, low inertia and high bandwidth.

The latest version of TorqView software has been written in NI LabVIEW, to provide a very simple yet user-friendly measurement analysis and data presentation interface. However, single VI's are available for users with LabVIEW.

LoadSense Wireless Load Sensors

The wireless LoadSense load sensor is a strain gauge based stainless steel tension type sensor with the capability of wirelessly transmitting its data to one of our compatible readouts and displays or recording its data locally. Its inbuilt 32MB memory can hold up to 149 hours of data, which can then be downloaded to a PC via its USB cable. The Load Sensor transmits using the worldwide licence free frequency of 2.4GHz on two built in antennas.

The new development allows weighing processes to be fully integrated with handling operations. All live data is captured in real time and can be transferred to a database, stored, totalised and analysed. The load sensor can be integrated with a crane hook, fork lift or other handling device.

The LoadSense load sensors − sizes from 1 Tonne to 50 Tonnes, can be used with our Handheld Receiver Display or Cabin Receiver Display which can read several devices at the same time, and/or our standalone Receiver Interface which is used to output the data via RS232/RS422 to a PC.

LoadView Virtual Instrumentation Display Software is available to provide the user with a very cost-effective solution to measuring, recording and displaying data from one or more load sensors.

Wireless Strain Gauge Transmitter

The WSG series of wireless strain gauge transmitters offers the ability to convert any strain gauge based sensor into a wireless one. Using the same 2.4GHz technology as the LoadSense series, data can be transmitted over 100m to one of our readouts/interfaces. Modules include DIN rail type and can also come with various battery options.

Images

Articles / Press Releases

Brochures

Reviews

Trade Associations