25 June 2025 | ENE Group

Why Choose Modular Belt Conveyors for Food and Pharma Lines

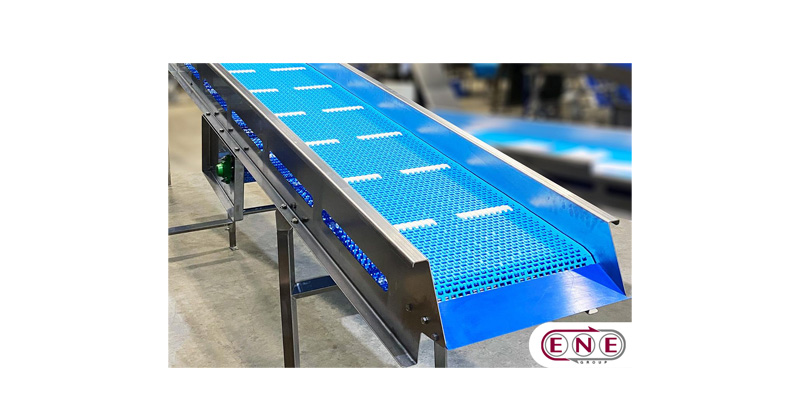

When hygiene, durability, and layout flexibility are key, modular belt conveyors offer a practical, proven solution. Built using interlocking plastic belts and stainless-steel frames, they withstand daily washdowns, temperature extremes, and continuous use in food and pharmaceutical environments.

Their open design improves airflow and cleaning access, making them a trusted choice for regulated production lines. Modular belt conveyors are especially valued in facilities where uptime and compliance are critical, helping maintain smooth production while meeting industry standards.

Versatile for Changing Layouts

Modular belt conveyors can be designed to fit even the most complex line configurations. They’re used for straight runs, curves, inclines, and spirals, allowing manufacturers to make the best use of floor space. Their ability to handle diagonal and lateral movement also helps streamline product transfers, reducing the need for additional equipment. This makes them particularly effective in facilities with limited space or evolving production demands. Whether integrating into new layouts or retrofitting older systems, the flexibility of modular belting supports a wide range of conveying paths without compromising on performance.

Durable and Easy to Maintain

The modular design means damaged sections can be replaced without removing the entire belt, reducing downtime and maintenance costs. Built from materials such as Polypropylene, Polyethylene, or Nylon, the belts are highly resistant to wear, chemicals, and impact. Whether you're conveying heavy packaged goods or abrasive items, these systems are designed to last. Their robust construction makes them suitable for 24/7 operation, with low wear rates even under high load or high-friction conditions. Maintenance teams benefit from the simple belt repair process, as components can be removed and replaced with minimal disruption to the line.

Designed for Hygiene Compliance

With smooth surfaces, wide openings, and easy-access components, modular belt conveyors are built to meet strict hygiene standards. The belt structure supports full washdown and quick visual inspection, helping reduce contamination risks in food and pharmaceutical environments. Their chemical resistance also supports the use of industrial sanitisers and cleaning agents. Open-hinge links and minimal dirt traps make it easier to maintain hygiene protocols between product runs or shift changes, especially where allergen separation or cross-contamination controls are required.

Suitable for High and Low Temperatures

Different modular belt materials are selected based on your process requirements. Polypropylene handles heat up to 100°C, making it ideal for cooking or sterilisation areas. Polyethylene is better suited for cold environments and can withstand temperatures as low as -75°C. Both materials are MHRA-approved for food contact, with Nylon providing added strength and resistance in aggressive conditions. This wide operating range allows modular belt conveyors to be used across chilled, ambient, and heated zones within the same facility, without compromising on performance or compliance.

A Scalable, Long-Term Solution

Whether you’re expanding production or upgrading part of a line, modular conveyors are easy to scale. Systems can be built to match existing equipment, modified to handle new products, or designed as complete new lines. At ENE, we work closely with you to manufacture each conveyor to suit your space, product, and hygiene requirements. With a wide range of belt styles, side guides, support frames, and drive units available, our modular systems are tailored for long-term performance. We also provide technical support post-installation to ensure seamless operation and integration across your line.