Company details for:

ENE Group

Quick Links:

Products / Services

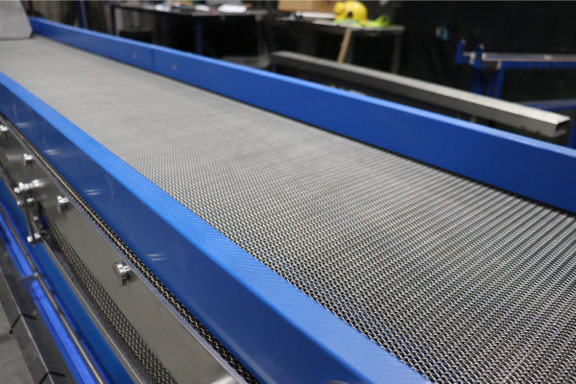

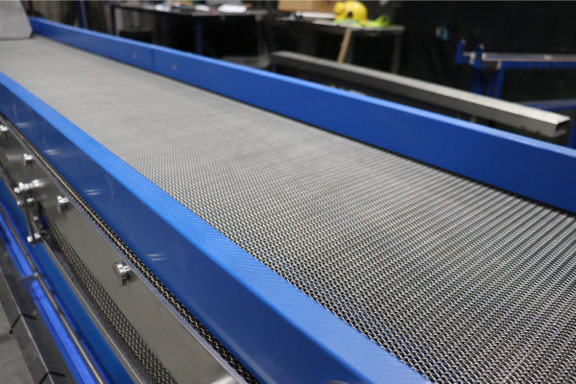

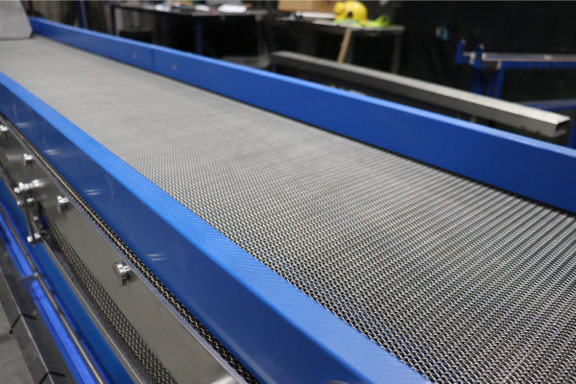

General Running Conveyors

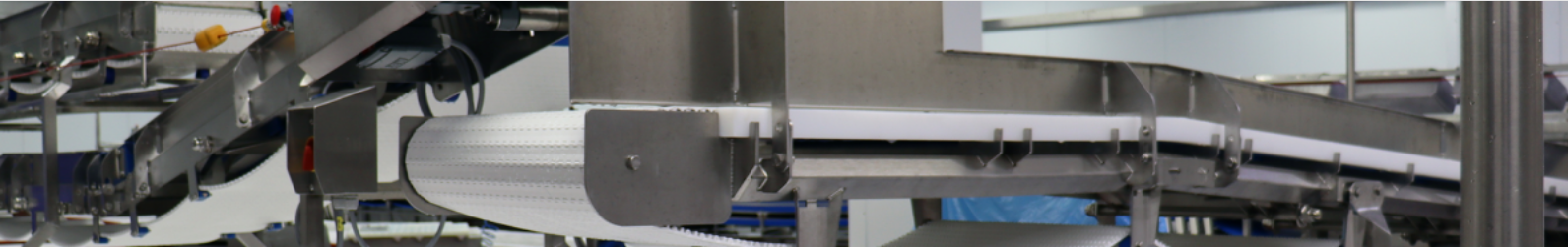

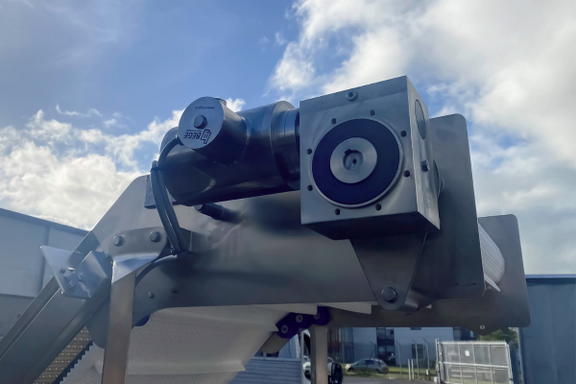

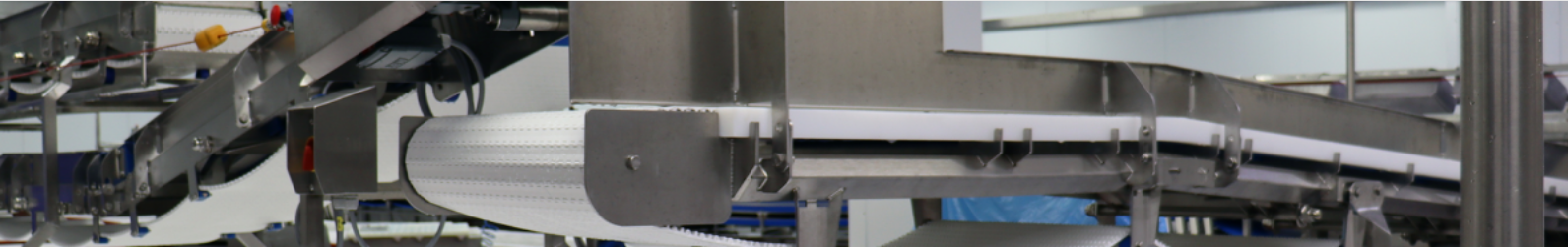

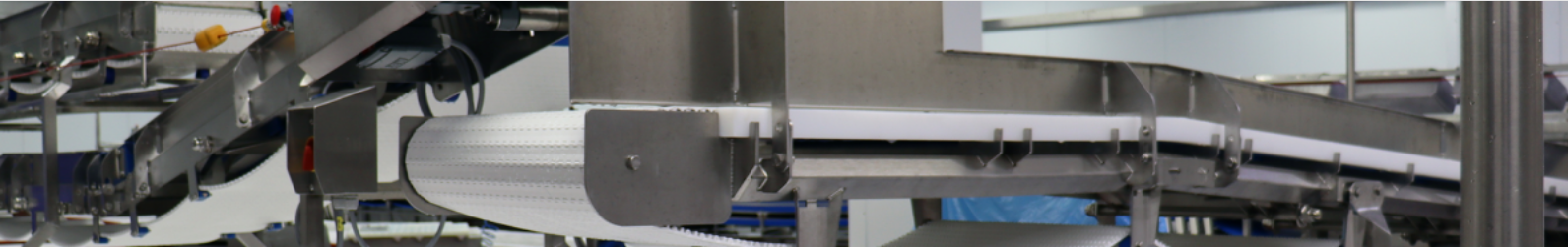

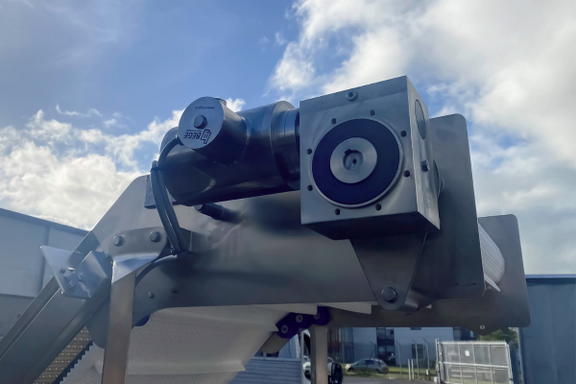

Our stainless-steel general running conveyors provide smooth and efficient product transfer between processing stages, ensuring reliability in food processing, pharmaceutical, and manufacturing environments. Manufactured from 304-grade stainless steel, they are designed for hygiene, durability, and long-term performance in demanding applications. Each conveyor is custom-built to specific lengths, widths, heights, and bend configurations, accommodating various belt types to suit different processing needs. Designed and manufactured at our UK and Ireland facilities, every system undergoes rigorous testing at our Kings Lynn, Norfolk or Banbridge sites to ensure efficiency, quality, and performance. Our conveyor systems integrate seamlessly into production lines, optimising workflow and minimising downtime. With a focus on hygiene and precision engineering, our general running conveyors provide dependable, high-quality solutions for industries requiring durable and efficient stainless-steel systems.

Processing Conveyors

Our stainless-steel processing conveyors integrate seamlessly into production lines, performing tasks such as slicing, detecting, and packing with precision and efficiency. Designed in-house by our experienced engineering team and programmed by skilled electricians and automation specialists, each conveyor is built to meet the demands of modern processing facilities. Manufactured from 304-grade stainless steel and rigorously tested at our Kings Lynn and Banbridge facilities, our conveyors ensure durability, hygiene, and reliable performance. They are engineered to handle the challenges of food processing, pharmaceutical, and manufacturing environments while maintaining compliance with industry standards. We understand that every processing line has unique requirements, which is why we provide fully customised conveyor solutions. Whether you need a system for a specialised process or a complex production setup, we manufacture conveyors tailored to your exact specifications, ensuring seamless integration and optimal efficiency.

Packaging/End Of Line Conveyor Systems

Our stainless-steel end-of-line conveyors handle final-stage processing, whether automating tasks or supporting manual operations. Designed for durability, they withstand the demands of packing, sorting, and palletising while ensuring efficiency. Each conveyor is developed in-house by our experienced engineering team and undergoes rigorous testing at our Kings Lynn and Banbridge facilities before dispatch. Manufactured from 304-grade stainless steel, they meet strict hygiene and performance standards, ensuring seamless integration into your production line. Every end-of-line process has unique requirements, so we provide fully customised conveyor solutions. Whether you need a conveyor for a specific task or a bespoke system to optimise workflow, we manufacture to your exact specifications. Our conveyors improve productivity, reduce downtime, and ensure smooth operation in demanding production environments, delivering reliability where it matters most.

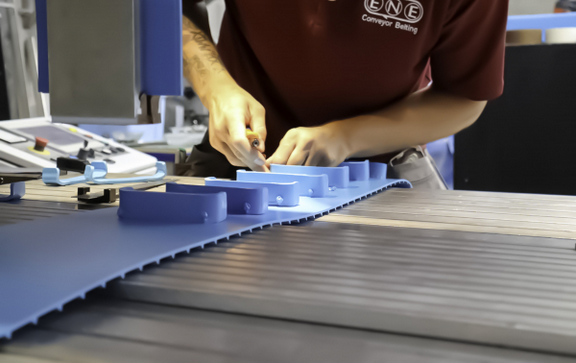

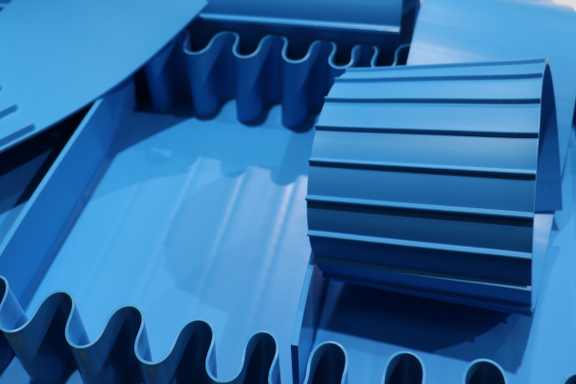

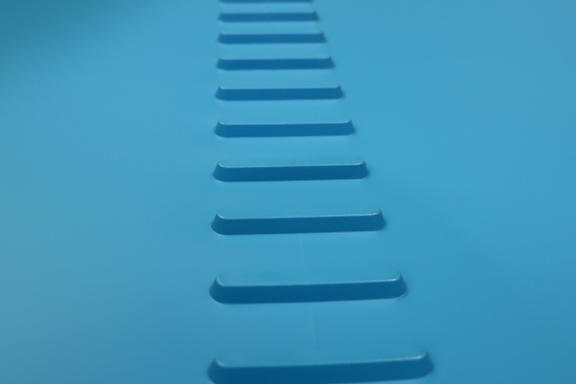

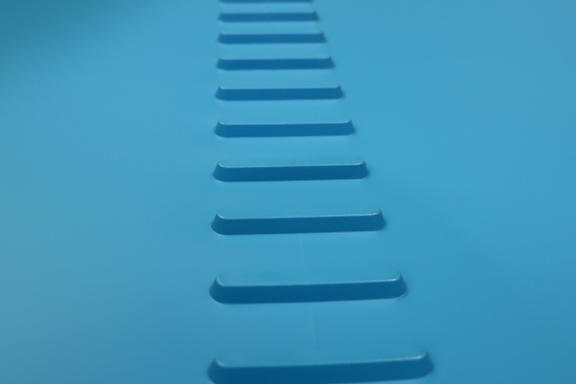

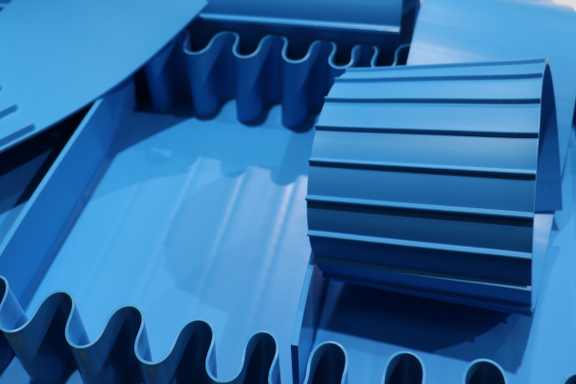

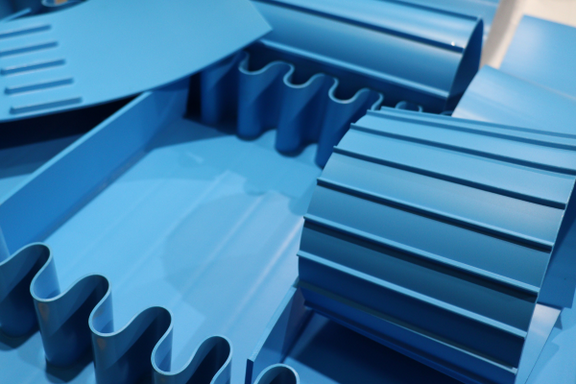

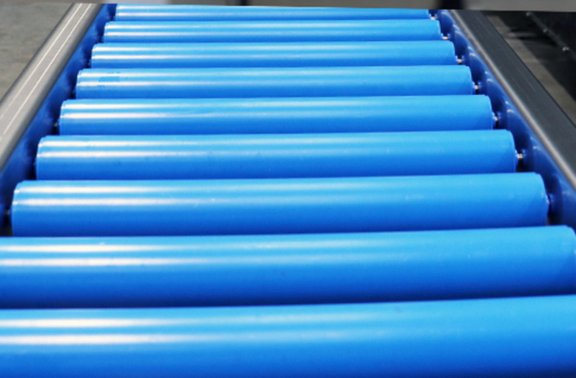

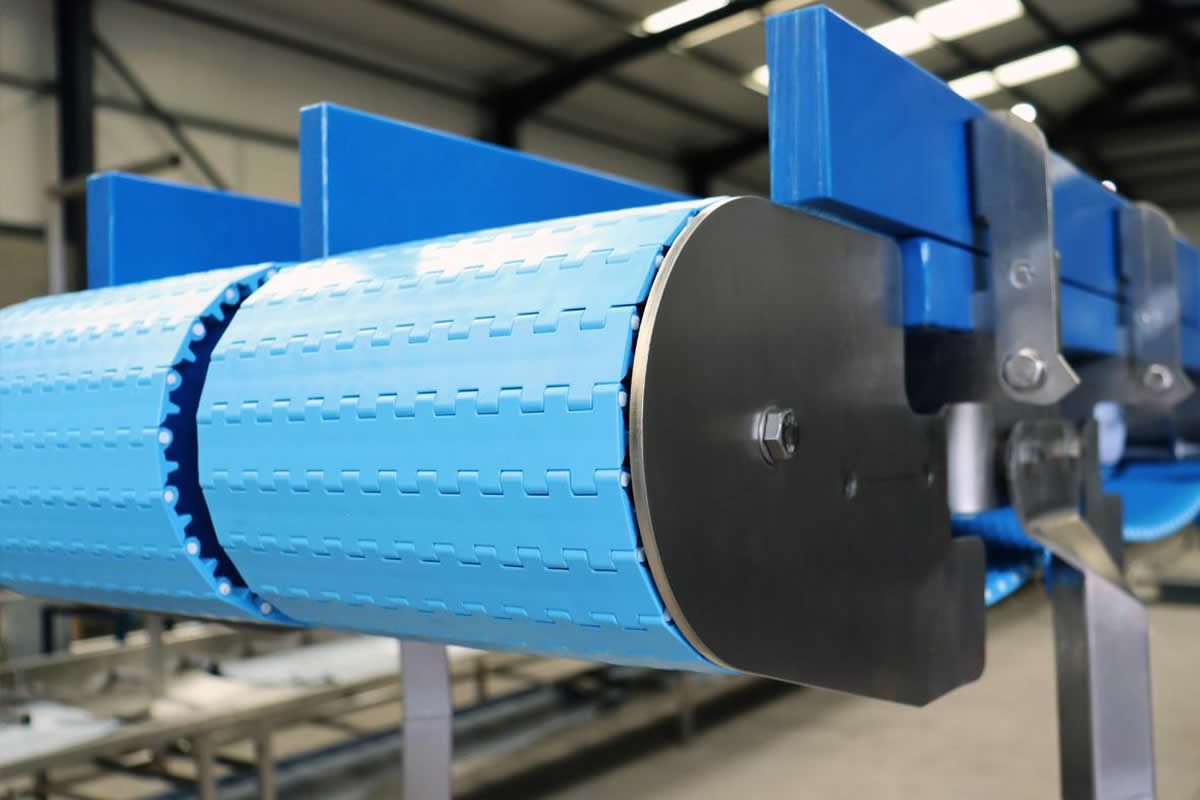

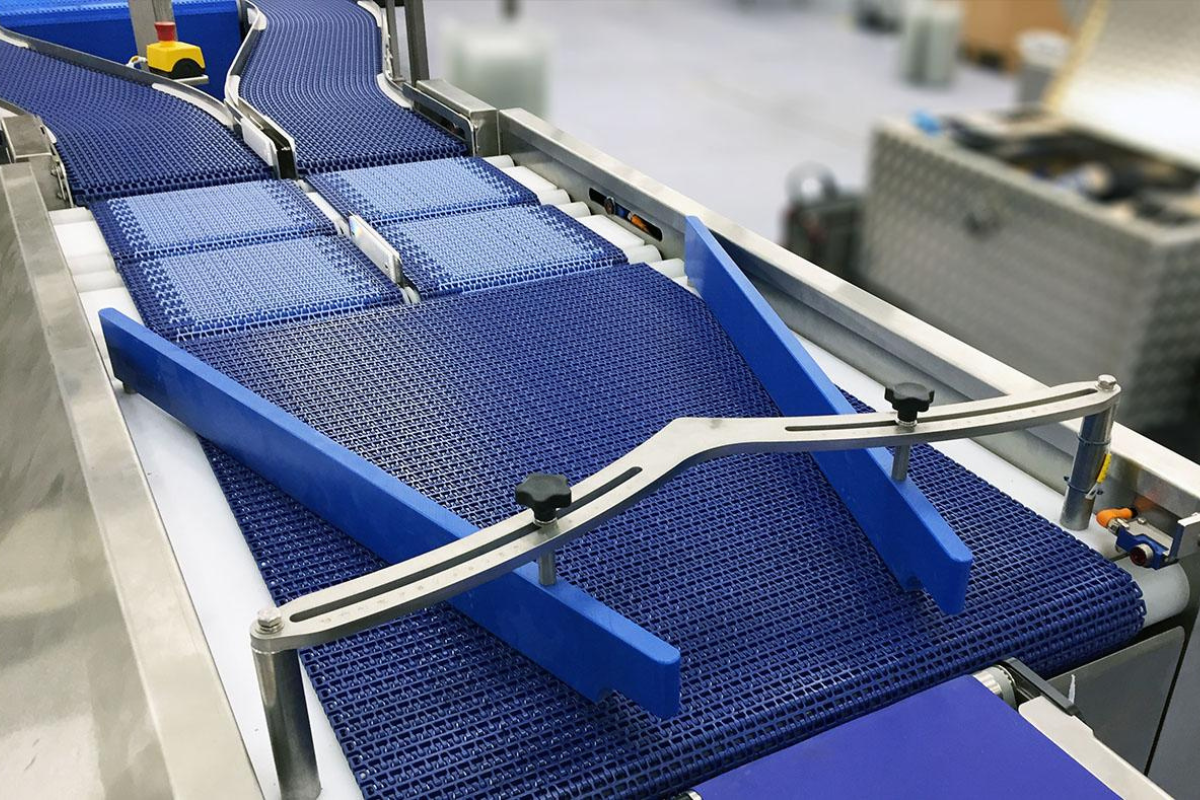

Modular Belt Conveyor

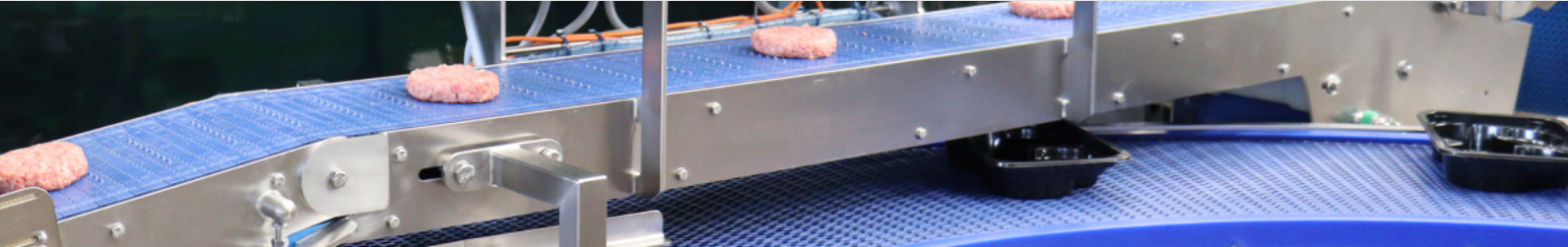

ENE Group’s modular belt conveyors are engineered to meet the exacting standards of the food, pharmaceutical, and packaging industries, including sectors such as meat, dairy, bakery, produce, and ready meals. Designed for hygienic and efficient material handling, each conveyor is manufactured in the UK and Ireland using FDA-approved, food-grade materials and 304-grade stainless steel. These systems are well-suited to high-demand production lines, offering incline, decline, and curved configurations to maintain consistent product flow across all stages of processing. Built with long-term reliability in mind, they integrate seamlessly into existing production environments while supporting quick belt replacement and minimal downtime. With customisable options, they can be tailored to fit specific workflow and layout requirements.

Our modular belt conveyors support a wide range of applications. In the food sector, they handle everything from raw poultry, meat, and dairy products to fresh produce and prepared meals, all while maintaining strict hygiene standards. For packaging lines, the conveyors ensure smooth transfer to filling or sealing stations. In pharmaceutical operations, they safely transport sensitive products such as blister packs and containers. The robust stainless steel frames, modular belt construction, and optional features such as side guards, automation integration, and tracking guides make these conveyors a reliable and versatile choice. We also offer a complete range of spare parts and ongoing support to keep your modular belt conveyor performing at its best. Contact us today to learn more about tailored solutions for your production line.

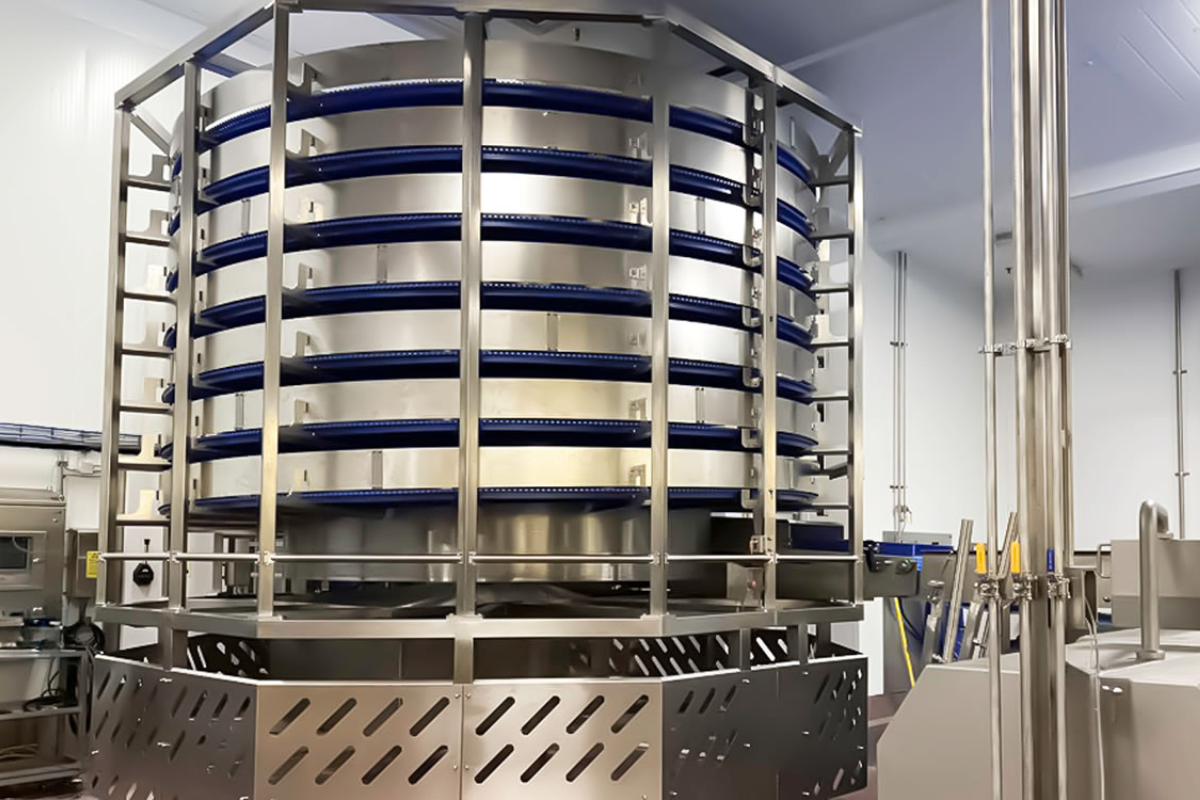

Spiral Conveyor

Manufactured and tested in the UK and Ireland, ENE Group’s Spiral Conveyors offer an efficient and hygienic solution for vertical product transport and natural cooling. Built from durable 304-grade stainless steel, each system is designed for long-lasting performance while meeting the hygiene requirements of the food, beverage, and pharmaceutical industries. The coiled spiral structure maximises air exposure to support gentle, energy-efficient cooling while minimising floor space usage. Whether for baked goods, frozen foods, or packaged items, our spiral conveyors maintain smooth product flow and can be tailored for incline, decline, double spiral, or bidirectional operation.

Designed for performance and flexibility, our Spiral Conveyors are suitable for a wide range of applications—from cooling bread and pastries to transporting sealed pharmaceuticals and frozen items in compact environments. With features like variable speed control, side guards, and automation compatibility, they can be configured to suit complex production layouts. The robust stainless steel construction ensures durability in demanding environments, while easy-clean components support hygiene compliance. For manufacturers looking to optimise vertical space and maintain efficient operations, our Spiral Conveyors provide a space-saving, reliable solution backed by full support and customisation options. Contact us today to discuss your specific production requirements.

Meat Processing Conveyor

Manufactured and tested in the UK and Ireland, ENE Group’s Primal and Flank Meat Processing Conveyors are designed to meet the specific demands of meat and poultry processing. Engineered for hygienic performance, durability, and efficiency, these conveyors ensure smooth handling of primal and flank cuts while complying with stringent sanitation standards. Built from stainless steel with reduced flat surfaces for easier cleaning, they integrate seamlessly into production lines. Whether you’re processing beef, pork, lamb, or poultry, these conveyors support continuous, low-maintenance operation to enhance productivity and maintain product quality.

Customisable with PU, wire, or modular belts, our Primal and Flank Meat Processing Conveyors can be tailored to suit a range of applications including deboning, trimming, and transporting raw meat cuts. Ideal for meat processing, poultry portioning, convenience foods, and pet food manufacturing, each system can be configured for incline, decline, or straight layouts with optional features like integrated cleaning systems and height-adjustable stands. With robust construction and versatile functionality, these conveyors help streamline your workflow, reduce manual handling, and support consistent output across demanding processing environments. Contact us today to discuss a tailored solution for your facility.

Bulk Hopper Conveyor

ENE Group’s Bulk Hopper Conveyors are designed for efficient and hygienic handling of bulk materials in food production environments. Manufactured from 304-grade stainless steel, these systems support the controlled transfer of ingredients such as grains, flour, dairy powders, chopped vegetables, and more. The integrated hopper stores and regulates the flow of materials, ensuring minimal spillage and consistent feed into downstream processes. Their hygienic, robust construction ensures compliance with food safety standards, making them suitable for bakery, dairy, convenience foods, and fruit and vegetable processing applications.

With a modular, customisable design, our Bulk Hopper Conveyors can be tailored to meet the demands of specific production lines. Options include adjustable hopper capacities, variable discharge rates, and a choice of belt types to suit different products. Systems can also be configured with fixed or mobile frames, flow control features, and tailored discharge outlets to optimise material handling. By reducing manual input and maintaining a steady, efficient flow, these conveyors support reliable operation and improved productivity. A full range of spare parts is available to ensure ongoing performance and easy maintenance. Contact us today to discuss your requirements.

Portion to Pack Conveyor

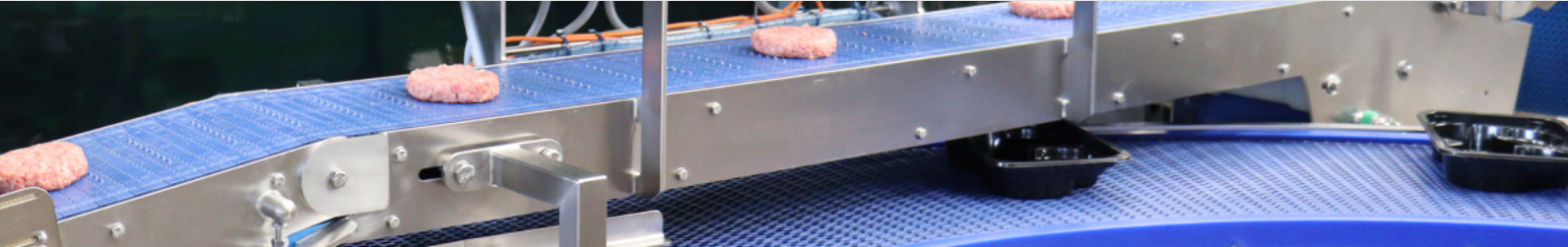

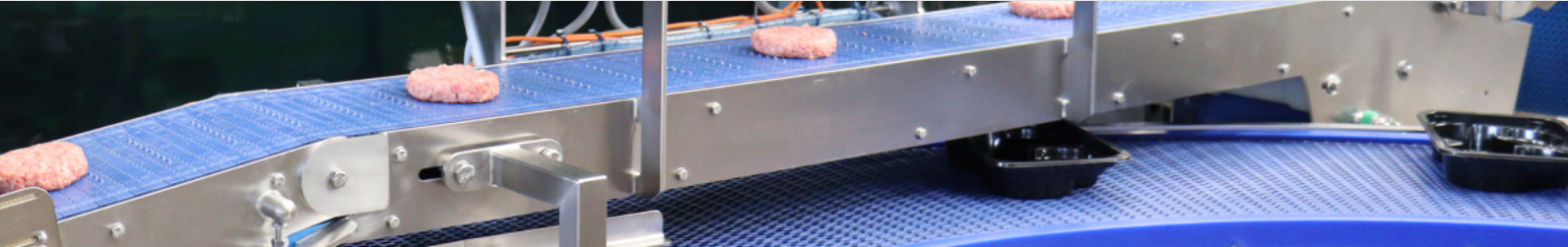

Manufactured for the UK food industry, ENE Group’s Portion to Pack Conveyors are purpose-built for hygienic, efficient tray packing of meat and convenience foods. Constructed from 304-grade stainless steel, these conveyors are designed to withstand the demands of raw and cooked meat handling while supporting consistent portioning and streamlined transfer into packaging trays. Ideal for integration into meat processing and packaging lines, each system is customisable in size, belt type, and tray guide configuration to meet specific production requirements. Whether handling chicken fillets, ready meals, or plant-based products, these conveyors ensure smooth, hygienic operation across every stage.

Engineered for flexibility and performance, our Portion to Pack Conveyors are suitable for a wide range of applications including seafood processing, convenience foods, and portioned bakery items. Their hygienic construction, combined with options for portion control systems and automation compatibility, supports efficient operation and consistent product presentation. Available with modular, PU, or wire belts, and tray alignment systems, they help reduce waste and improve output. With easy integration into upstream and downstream equipment, and full spare parts support, these conveyors are a practical choice for improving workflow and maintaining product quality in high-throughput food production environments.

Rotary Tables

Manufactured and rigorously tested in the UK, ENE Group’s Rotary Tables offer a dependable, hygienic solution for food packaging and product accumulation. Commonly known as Lazy Susans, these tables are built from stainless steel or hygienic plastic and are available in 1200mm or 1500mm sizes. Designed to support efficient end-of-line workflows, they help organise packaged goods, ready meals, and bakery items for sorting and further handling. With height-adjustable frames and optional guarding, they ensure ergonomic operation, safety, and productivity in demanding food processing and packaging environments.

Rotary Tables can be used as standalone units or integrated into larger production lines, making them suitable for food processing, bakery, dairy, beverage, and general manufacturing industries. From accumulating yogurt containers to organising trays of bread or beverage cartons, they offer flexible and efficient handling across a range of products. Their rotating tops simplify pick-and-place tasks, while variable speed controls and optional integration features allow for easy adaptation to production demands. Built for long-term use and available with a full range of spare parts, ENE’s Rotary Tables help optimise packaging operations and maintain consistent output across your line.

Crate Tumbler Conveyor

Manufactured in the UK and Ireland, ENE Group’s Crate Tumbler Conveyors offer a hygienic and efficient solution for debris removal in food, meat, and pharmaceutical processing environments. Designed to tip and clear crates before they enter production lines, these systems help maintain cleanliness and minimise contamination risks. Constructed from durable stainless steel, each unit can be customised for speed, height, and crate size compatibility, allowing seamless integration into existing workflows. Whether used as standalone systems or part of a larger setup, these conveyors support hygiene compliance and improved operational efficiency.

Our Crate Tumbler Conveyors are ideal for preparing crates in applications such as fresh produce, dairy, raw and processed meats, bakery goods, and pharmaceutical handling. Adjustable tipping angles and optional automated sensors ensure effective debris removal while minimising manual intervention. Designed for ease of maintenance and long-term durability, they contribute to a cleaner, more streamlined workflow. Custom options include noise reduction features for quieter environments and crate handling systems to support various sizes. Contact us today to discuss a tailored crate-cleaning solution for your facility.

PU Belt Conveyor

Manufactured in the UK and Ireland, ENE Group’s PU Belt Conveyors offer a dependable and hygienic solution for food processing environments, including fish, poultry, bakery, salad, and produce applications. Constructed from 304-grade stainless steel and fitted with food-safe PU belts, these conveyors are built to handle demanding conditions while remaining easy to clean and maintain. Available in a wide range of lengths and widths, each system is fully customisable with optional features such as tracking guides, side guards, and under trays to support safe and efficient product movement across your production line.

Designed for consistent, smooth transfer of raw and processed products, our PU Belt Conveyors integrate seamlessly into new or existing food production workflows. Their lightweight belt construction supports energy efficiency, while options such as integrated cleaning systems reduce manual labour and downtime. Whether transporting fish fillets, pastries, poultry portions, or fresh salads, these conveyors maintain hygiene and improve operational flow. Built and tested at our UK and Ireland facilities, they are supported by a full range of spare parts to ensure long-term performance. Contact us today to explore tailored options for your processing needs.

Decline Conveyor

Manufactured in the UK and Ireland, ENE Group’s Decline Conveyor Systems are engineered to provide smooth, controlled downhill transfer while maintaining strict hygiene standards. Built from 304-grade stainless steel, these conveyors are ideal for food processing, poultry, meat, beverage, and pharmaceutical industries. Their gravity-assisted design supports efficient movement of packaged foods, crates, bottles, and sensitive products between levels, reducing manual handling and operational costs. Customisable in length, width, and decline angle, they integrate easily into existing production lines for optimised flow and increased efficiency.

Our Decline Conveyor Systems are available with modular, PU, or wire belts to suit a wide range of product types and handling requirements. Easy-to-clean surfaces ensure hygiene compliance, while additional options like side guards and braking systems support safe and secure operation, especially for steeper declines. Whether you’re transferring meat trays, beverage cartons, or pharmaceutical packs, these conveyors provide a reliable solution that fits your specific needs. Full spare parts and support are available to maintain ongoing performance. Contact us today to discuss a tailored setup for your facility.

Potato Halver

ENE Group’s Potato Halver Machine provides an efficient and hygienic solution for potato processing across the UK and Ireland. Engineered for consistent, precise halving, it reduces waste and enhances productivity in food production lines. Constructed from durable, food-grade stainless steel, the system meets the hygiene and safety standards required by modern processing environments. With adjustable settings to accommodate various potato sizes, it integrates smoothly into existing workflows while delivering clean, uniform cuts that support high-quality output.

Ideal for food processing, frozen food production, ready meal preparation, and pet food manufacturing, the Potato Halver Machine is designed to handle a wide range of applications. Its automated operation minimises manual labour, while optional features such as variable speed control, specialised blades, and washdown-ready design allow full customisation. Whether halving raw potatoes for further processing or preparing uniform portions for packaging and distribution, this machine helps streamline operations and improve throughput. Contact us today to discuss how it can be tailored to meet your production needs.

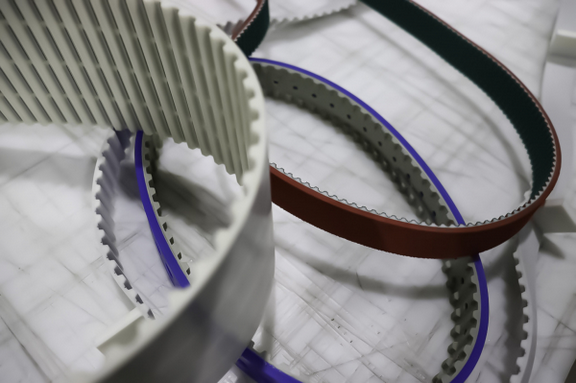

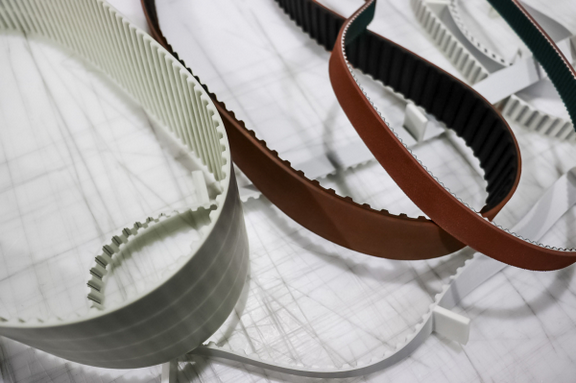

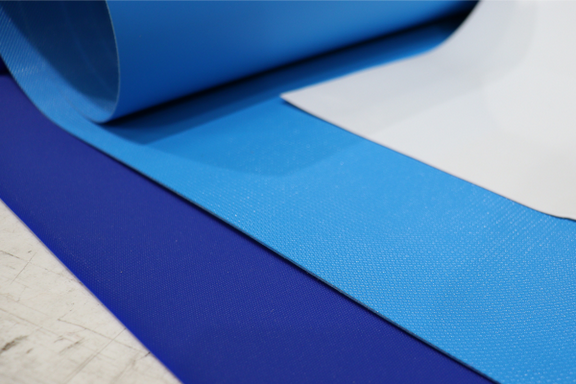

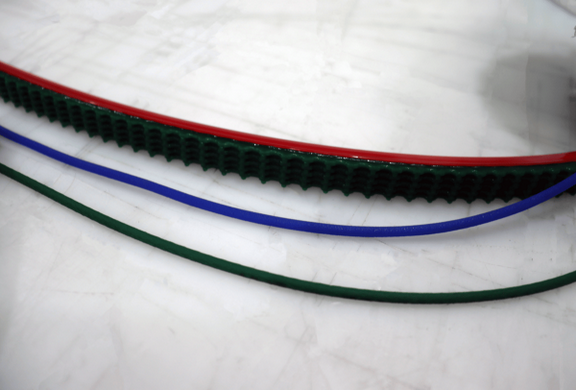

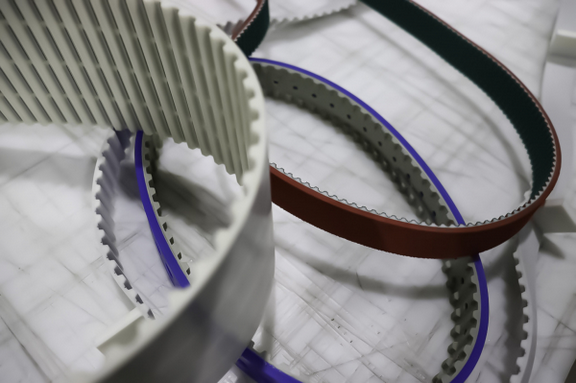

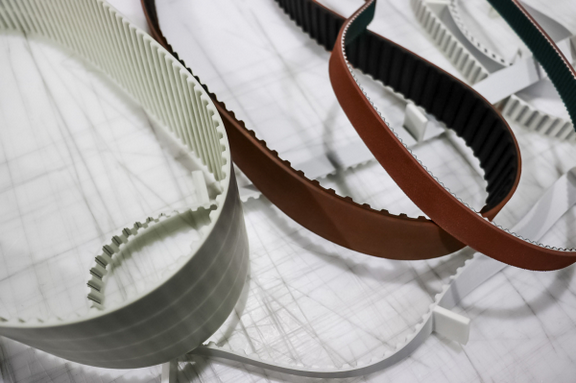

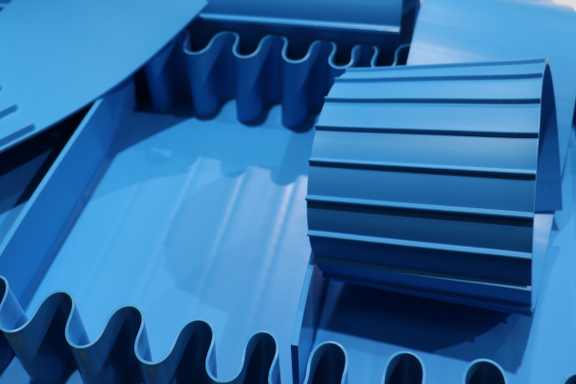

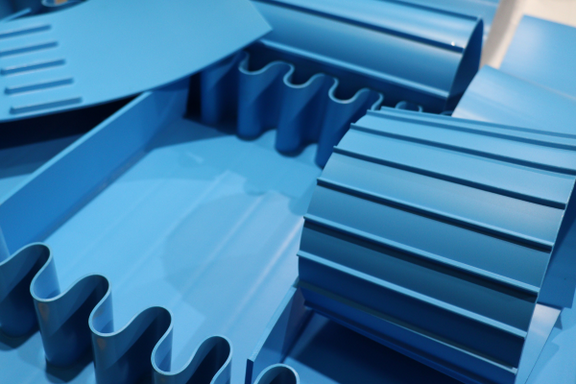

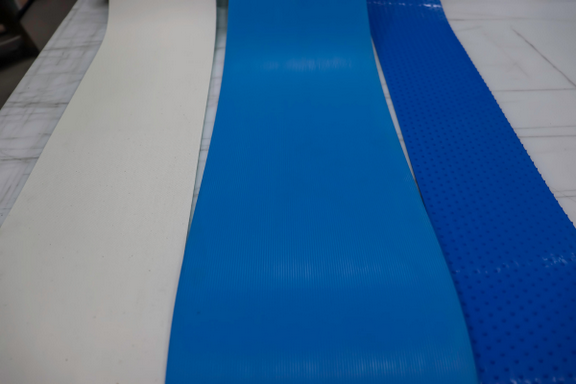

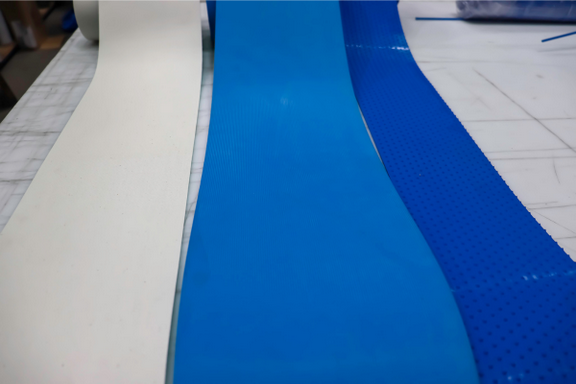

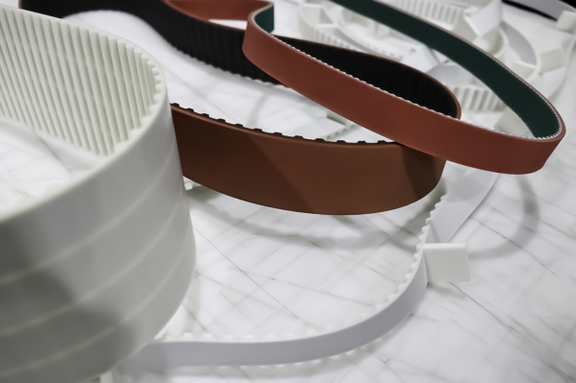

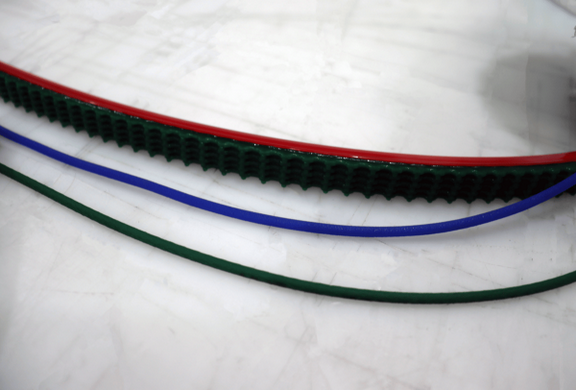

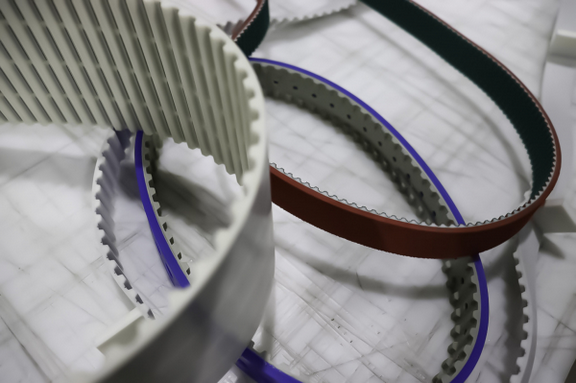

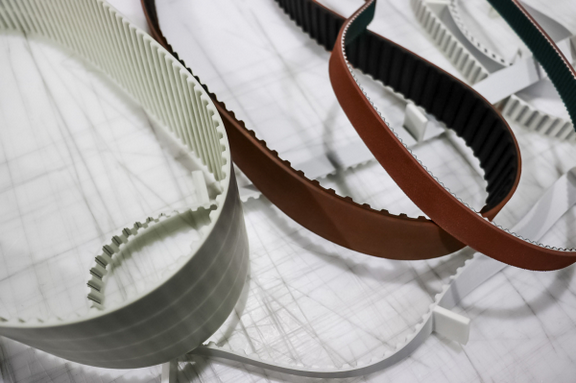

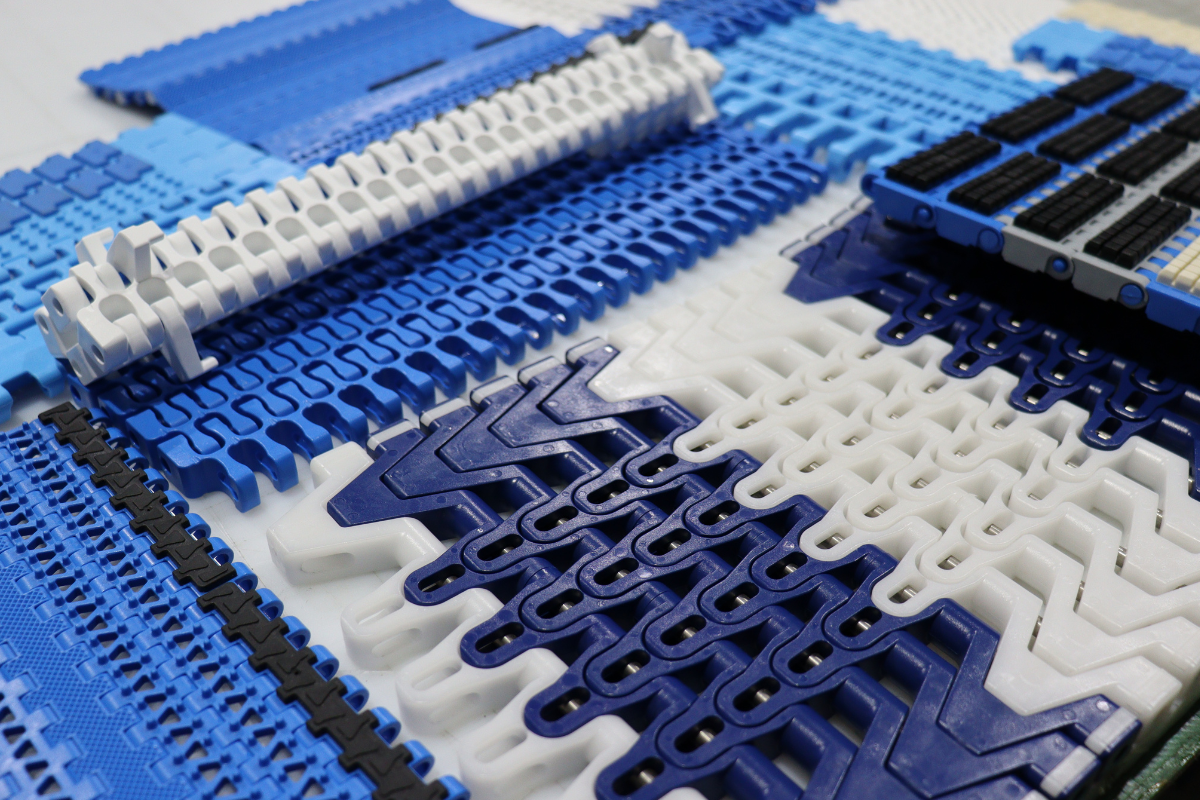

ENE Conveyor Belting

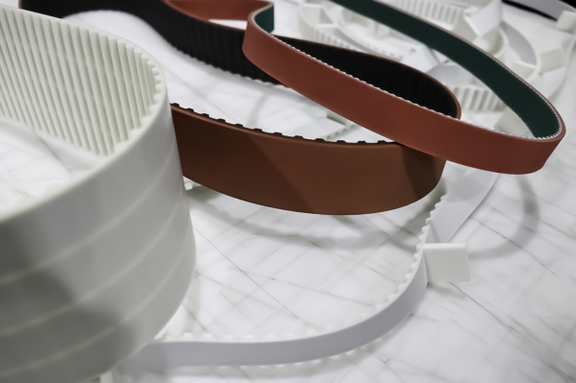

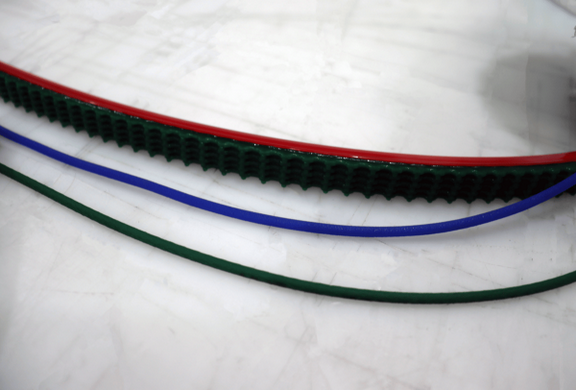

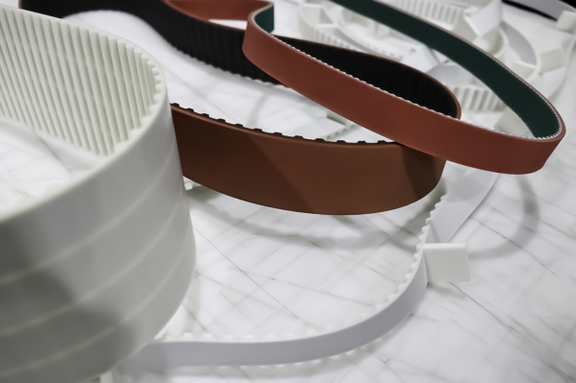

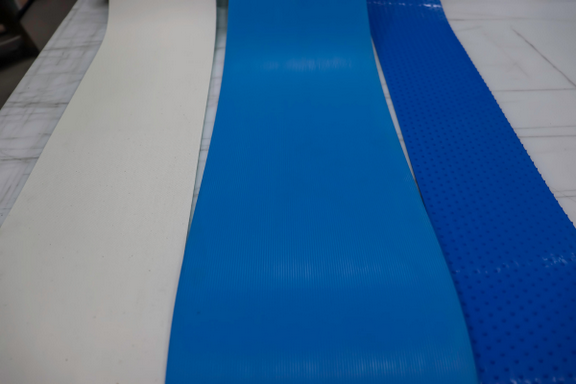

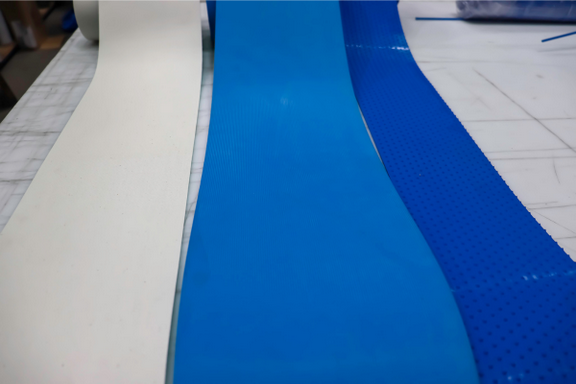

With over 25 years of experience, ENE Group specialises in delivering high-quality, bespoke conveyor belting solutions to industries across Ireland and the UK. Operating from our advanced facilities in Dublin and Banbridge, we design, manufacture, and install a wide range of conveyor belts tailored to meet the exact requirements of our clients. We also provide a full fitting service to ensure correct installation and optimal performance, as well as a dedicated breakdown service to minimise downtime and keep production running efficiently.

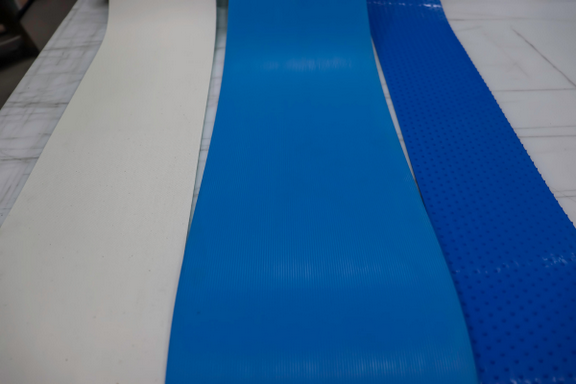

Our experienced team of fabricators and fitters work with precision and expertise to produce PU belts, PVC belts, modular belts, rubber conveyor belts, and wire mesh belts, ensuring optimal performance across various applications. From meat production and bakeries to pharmaceuticals, recycling, airports, and the paper, textile, and printing industries, our solutions are designed to handle the specific challenges of each sector.

Conveyor Belt Fitting

We understand how disruptive and costly downtime can be; that's why we complement our conveyor belting range with a comprehensive onsite fitting and servicing solution across Ireland and Northern Ireland. Our dedicated fitting service is scheduled at your convenience, minimising any disruption to your production processes. With highly skilled technicians trained extensively in conveyor belting installation, we ensure a seamless, efficient, and professional fitting experience.

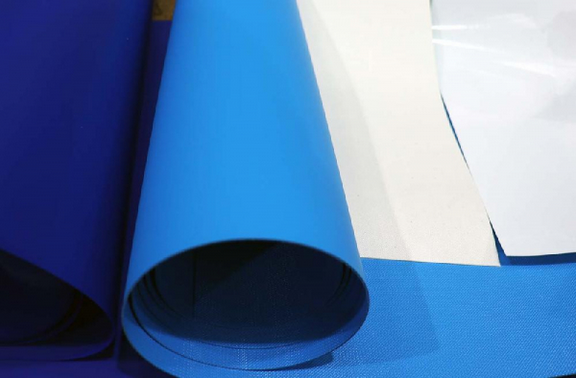

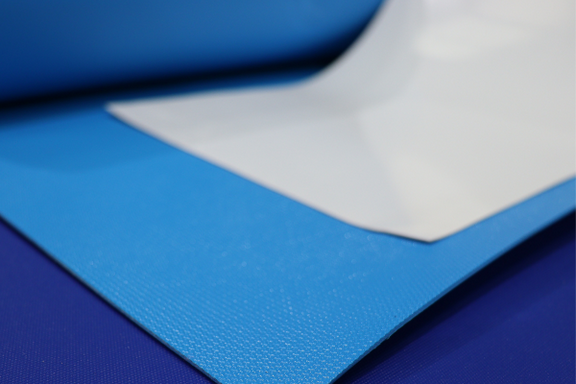

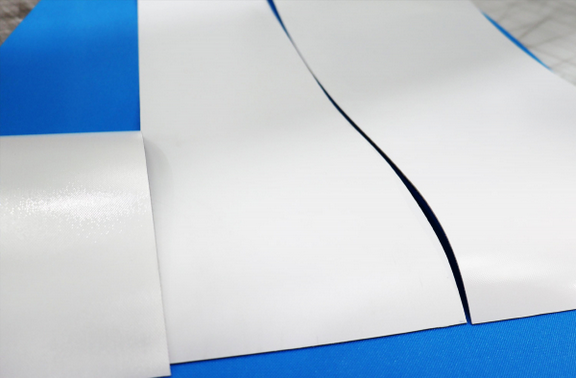

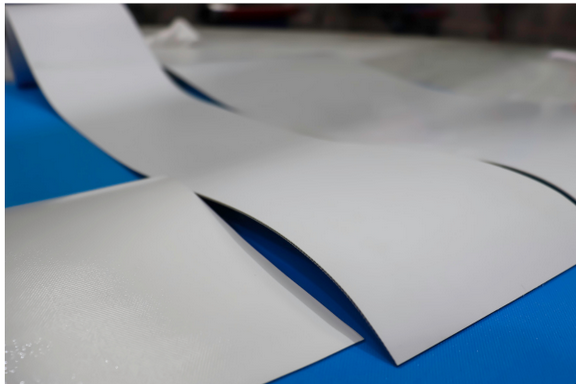

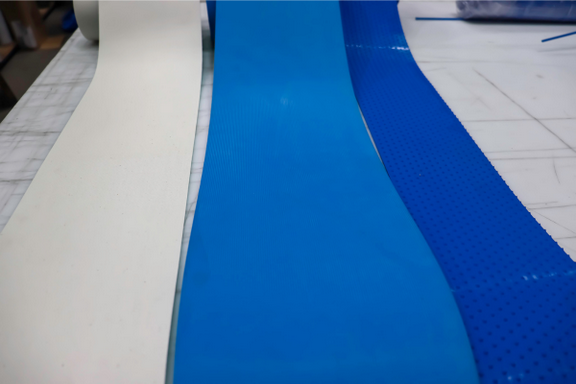

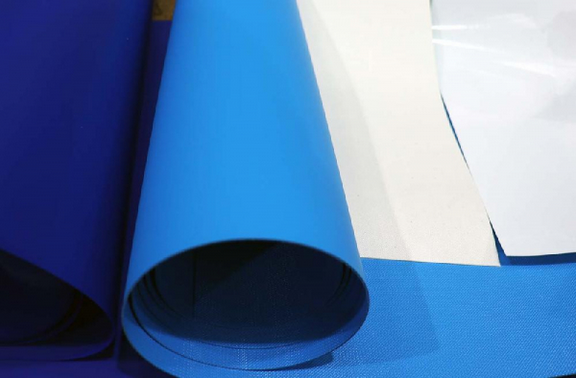

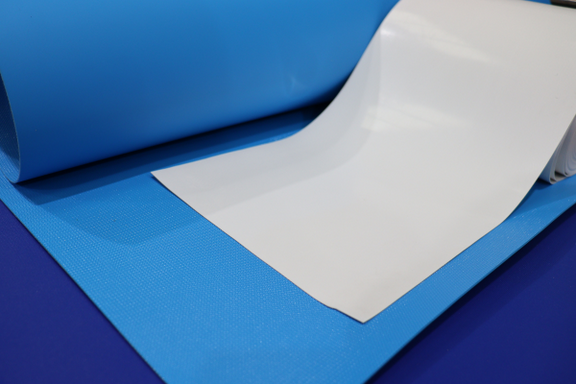

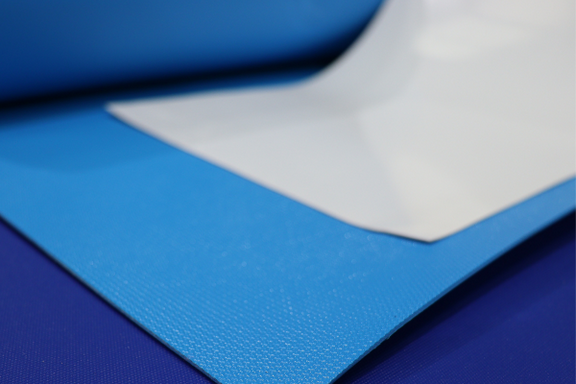

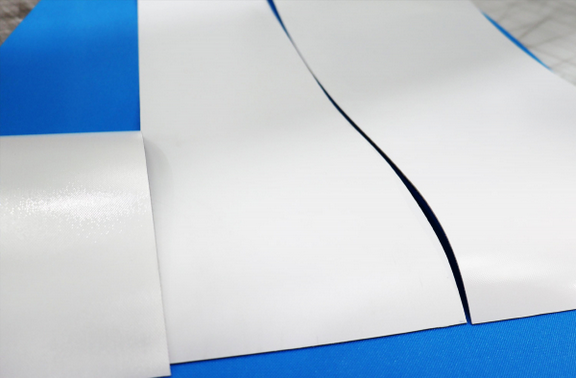

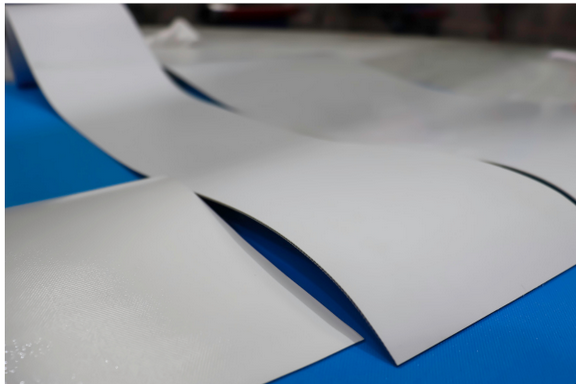

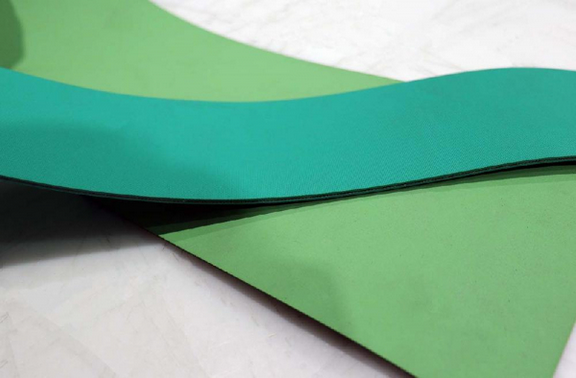

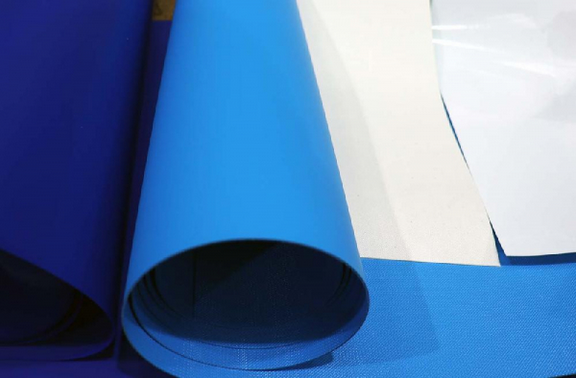

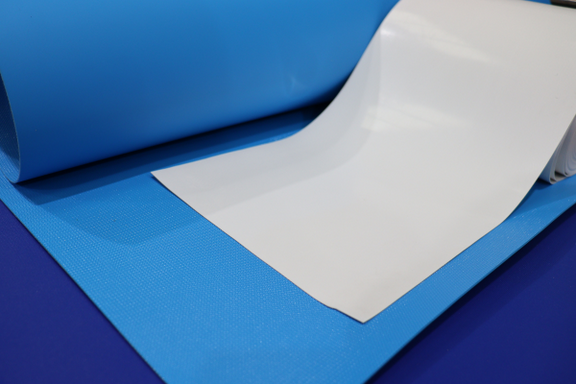

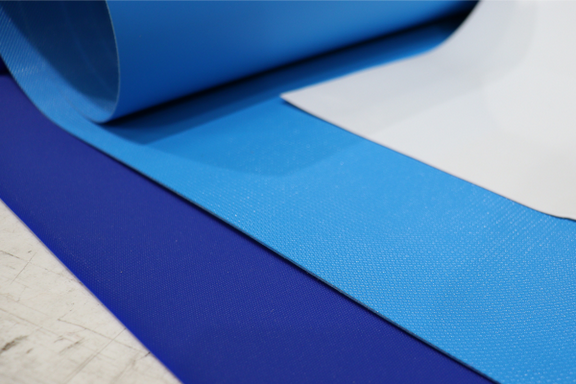

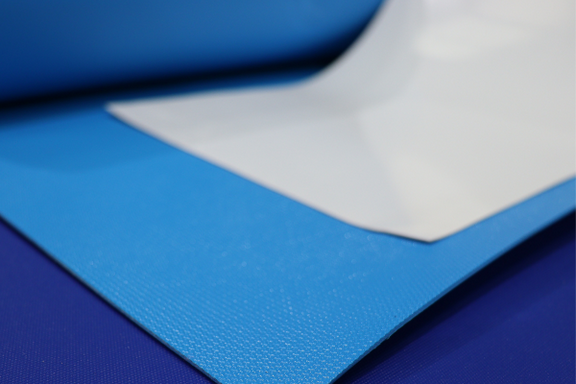

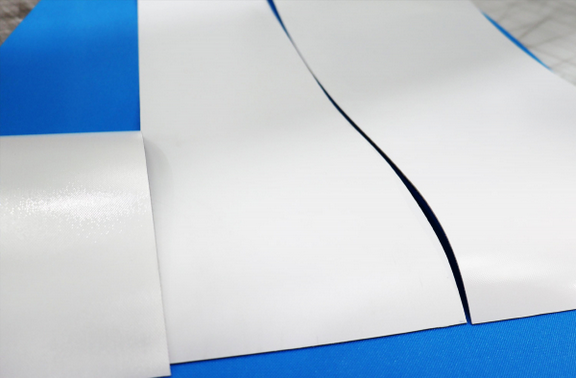

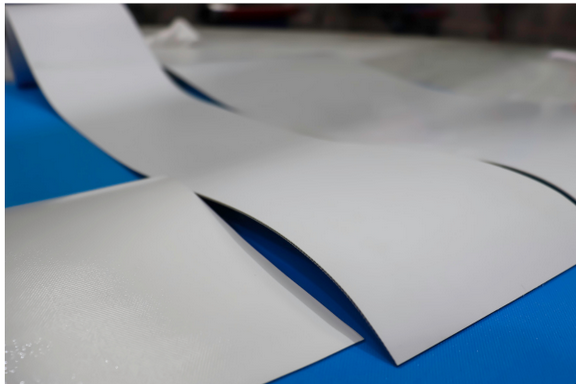

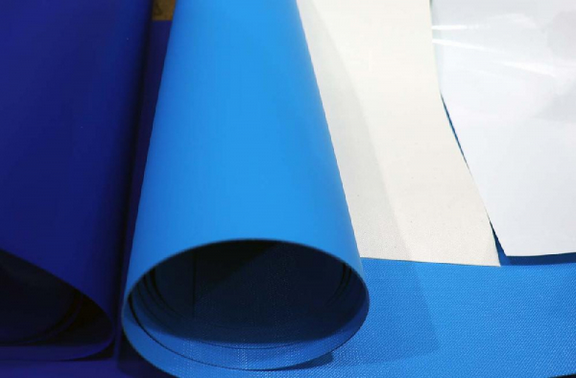

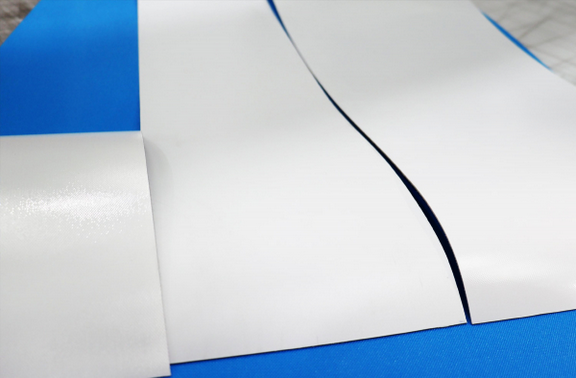

Solid PU Conveyor Belts

ENE Group supplies solid PU conveyor belts engineered for hygiene, durability, and stability in high-demand production environments. With facilities in both Northern Ireland and the Republic of Ireland, we provide fast access to belts specifically designed for industries such as meat production, dairy processing, pharmaceuticals, bakery, and fruit and vegetable handling. As the largest stockist of Gates TPU food belting in Europe, we offer a wide range of solid PU belts available directly from stock. These belts are reinforced with aramid tension members, minimising stretch and distortion while supporting precise, consistent performance across intense processing operations.

Built to outperform standard monolithic belts, our solid PU conveyor belts are ideal for maintaining hygienic, efficient transport in environments where cleanliness and reliability are critical. Suitable for cleanrooms, washdown zones, and high-volume processing lines, they are available in a variety of widths and lengths to match specific operational needs. Whether moving raw meat, dairy products, pharmaceuticals, or baked goods, these belts deliver excellent stability and a longer service life. Contact us today to learn how our solid PU belts can enhance your production line with dependable performance and tailored solutions.

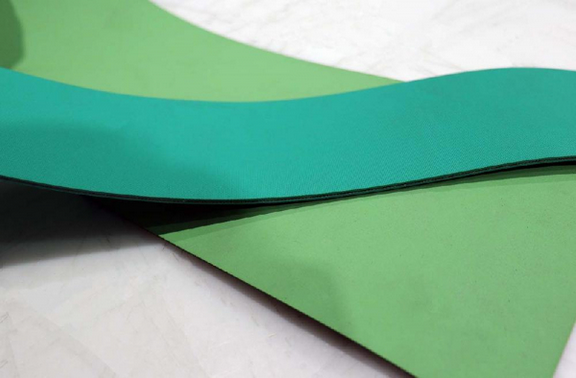

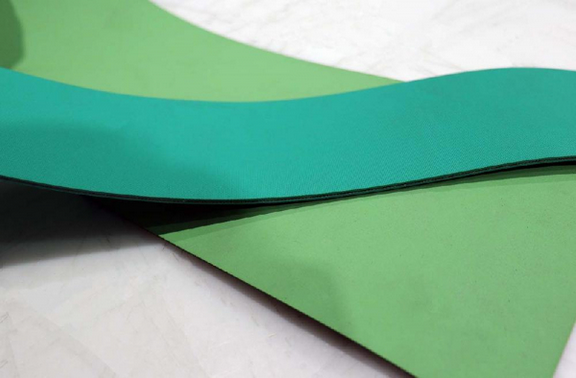

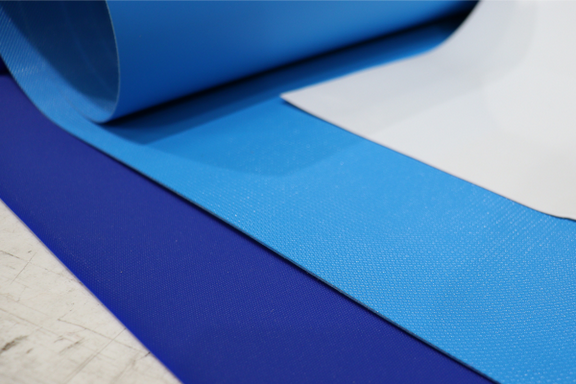

Plied Conveyor Belts

Plied conveyor belting is designed for light to medium-duty applications, providing the durability and flexibility needed for demanding industrial processes. Built to perform reliably in high-frequency use, it ensures smooth and efficient operation in sectors such as food processing and packaging. Manufactured to high standards, our belting maintains strength and stability over time, making it a dependable choice for production environments where performance matters. With locations in Northern Ireland and the Republic of Ireland, we supply high-quality belting to businesses across various industries. Contact us to discuss your requirements and find out how our plied conveyor belting can improve your production line.

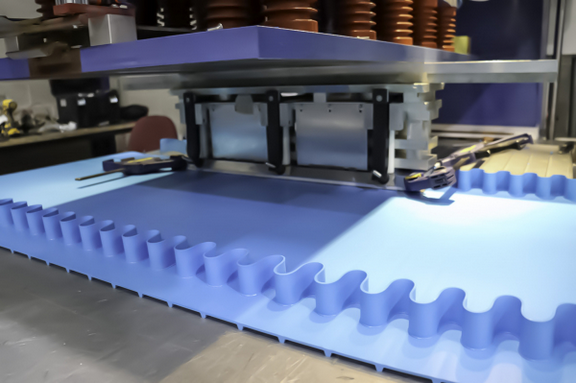

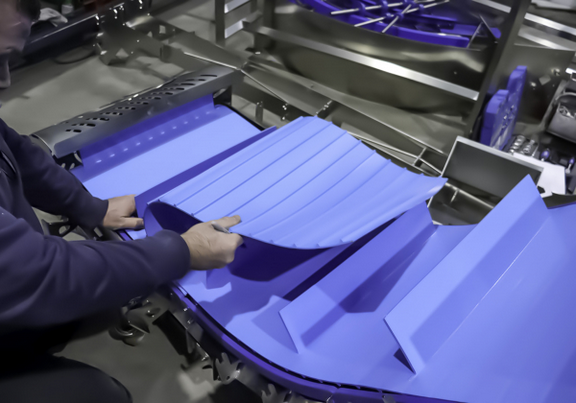

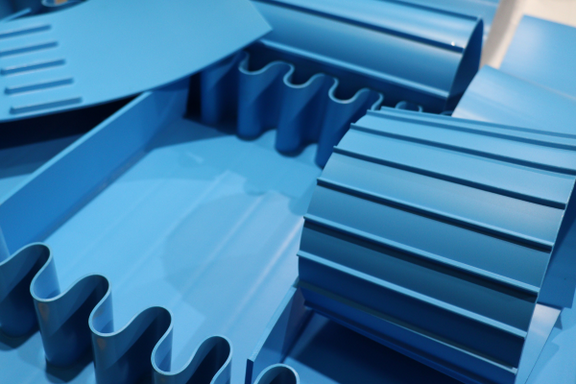

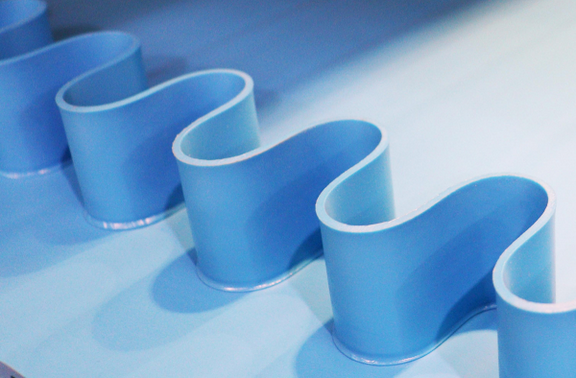

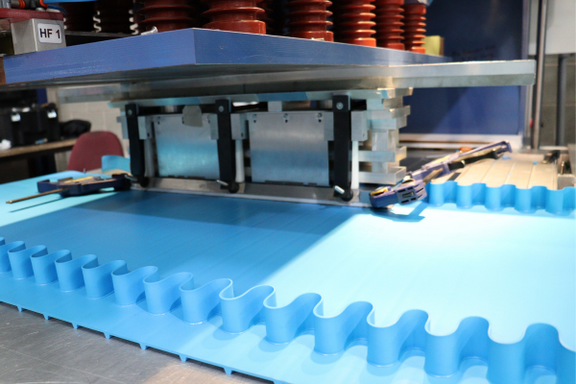

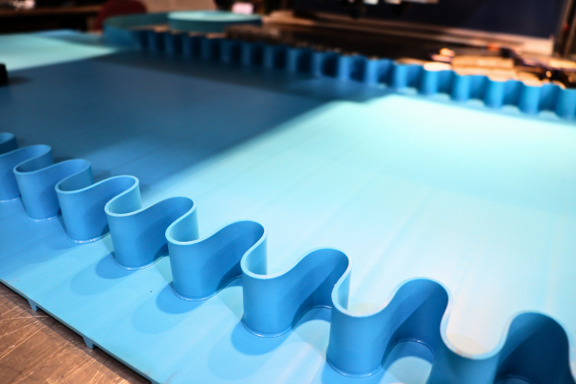

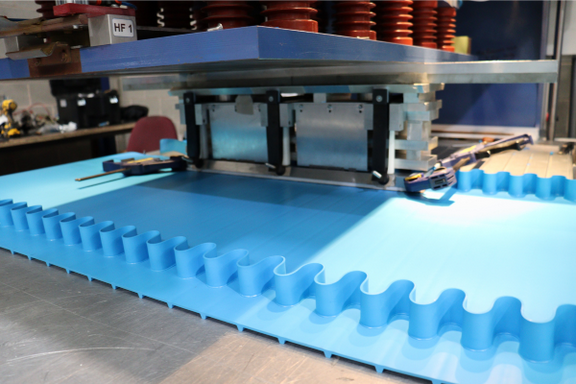

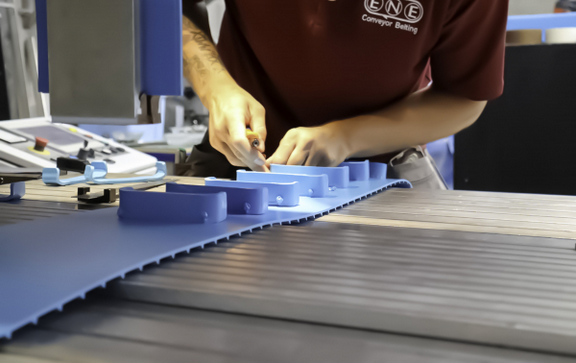

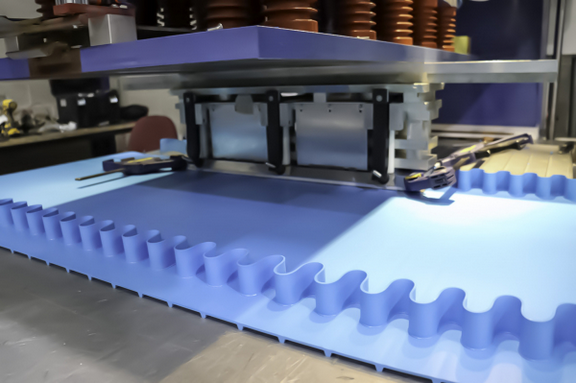

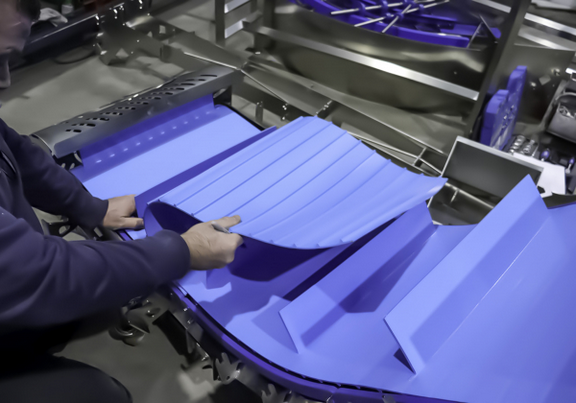

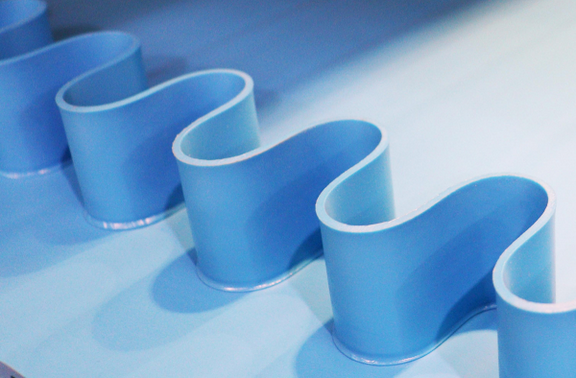

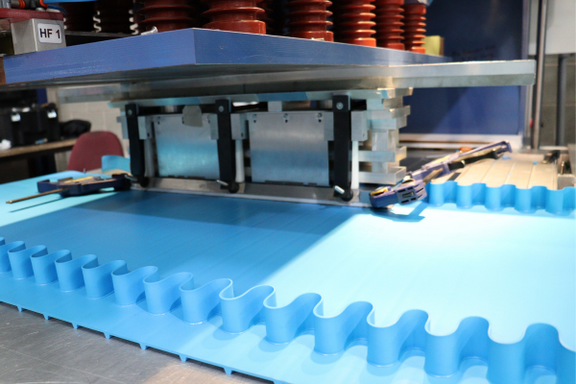

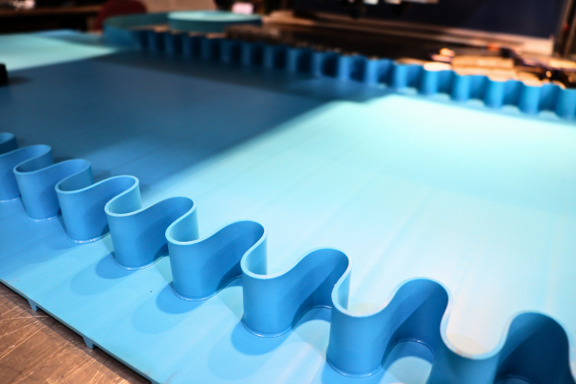

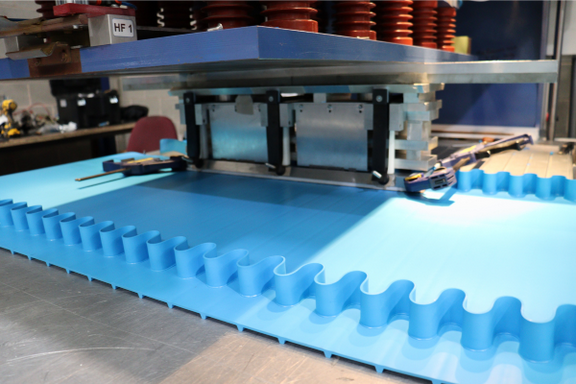

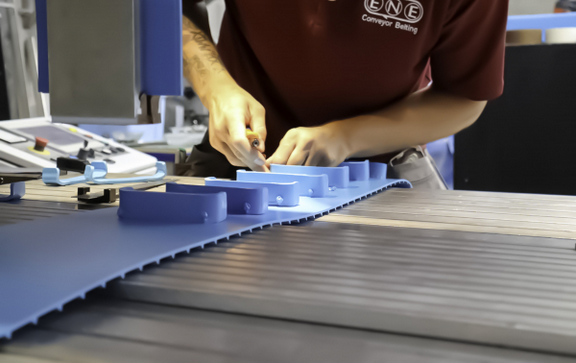

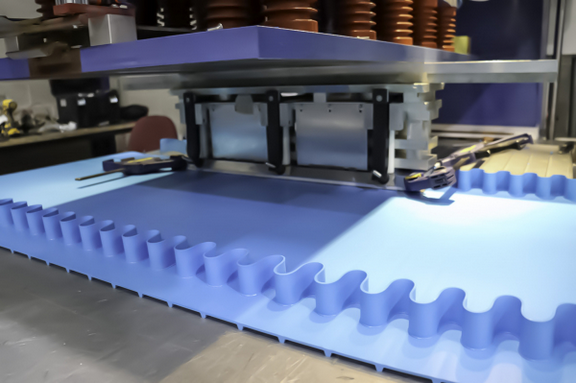

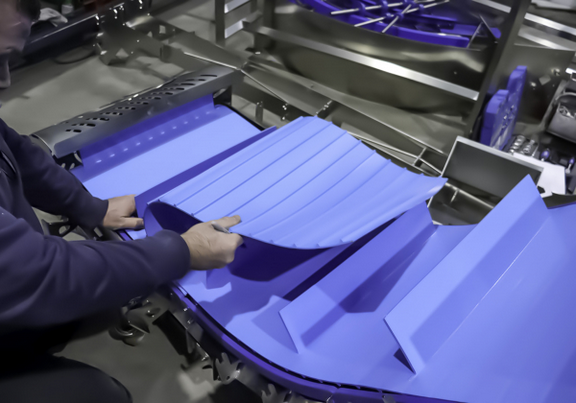

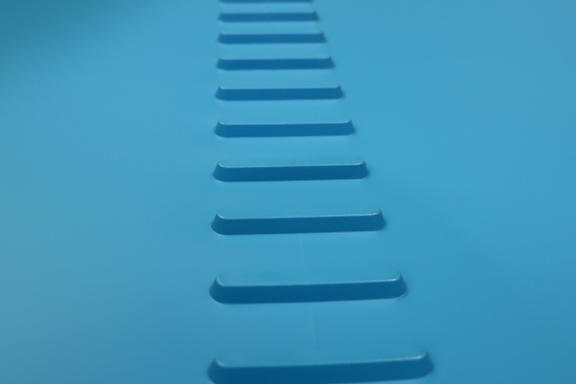

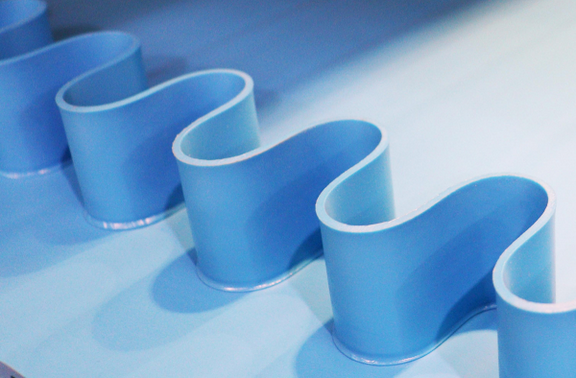

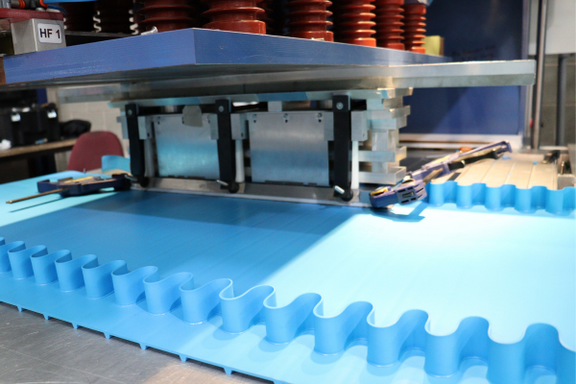

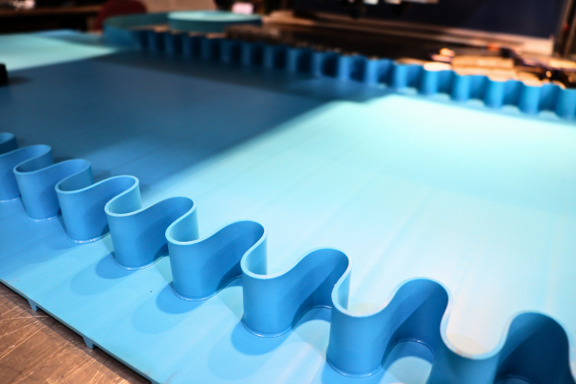

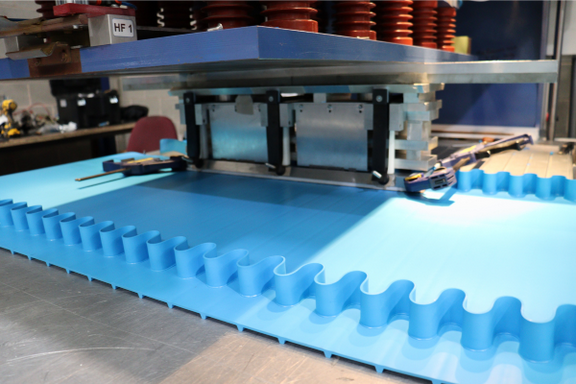

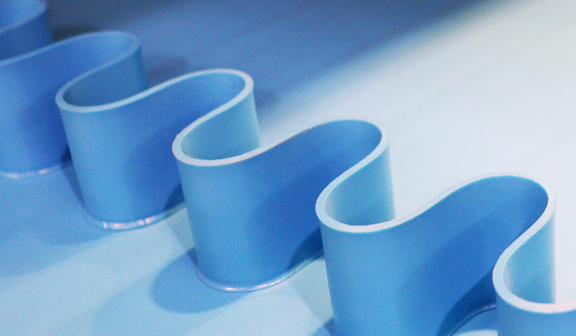

Flighted Sidewalled Conveyor Belting

Our flighted and sidewalled conveyor belts are engineered for quality, compliance, and adaptability, meeting the needs of food processing, pharmaceutical, and heavy-duty manufacturing industries. Designed for secure product movement on inclines and declines, they ensure hygienic, efficient handling of goods. With facilities in Northern Ireland and the Republic of Ireland, we provide tailored solutions to optimise your production process. Contact us today to learn more.

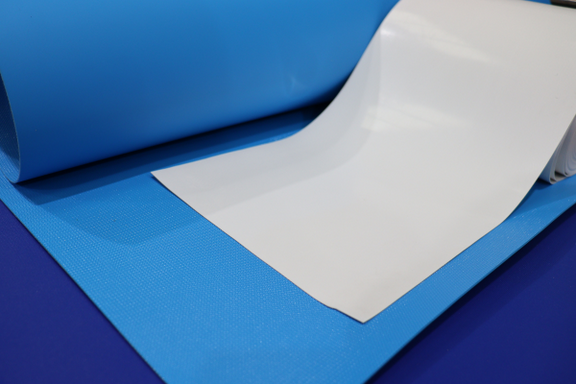

FDA Compliant Conveyor Belts

ENE Group offers a comprehensive range of FDA and HACCP-compliant conveyor belts, engineered to meet the rigorous hygiene standards of food processing and pharmaceutical applications. With facilities in Northern Ireland and the Republic of Ireland, we supply a variety of belt types including solid PU, plied PVC and PU, silicone, and modular designs. Each belt is built to withstand demanding conditions while ensuring safe and efficient product handling. Designed for frequent cleaning and reliable performance, our belts are suitable for use in food preparation, packaging, and cleanroom environments where hygiene is critical.

Ideal for industries such as meat production, bakeries, dairy processing, fruit and vegetable handling, and pharmaceuticals, our FDA-compliant conveyor belts provide durable, food-grade solutions across diverse applications. With smooth surfaces for easy cleaning, reinforced materials for durability, and customisable dimensions, they are built to support high-volume, hygiene-sensitive operations. Additional features include specialised coatings, sealed edges, and temperature-resistant options to meet specific process requirements. Contact us today to learn how our FDA-compliant conveyor belting can support your operational goals with safe, efficient performance.

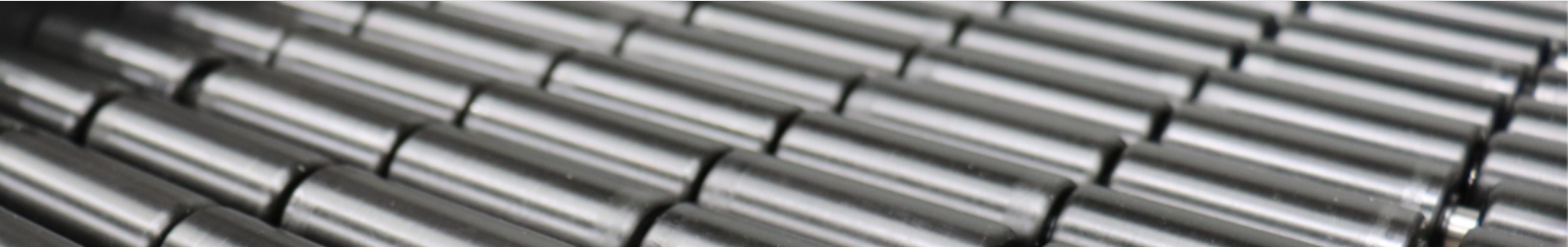

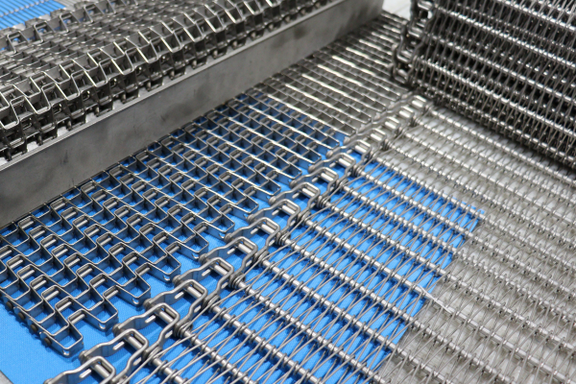

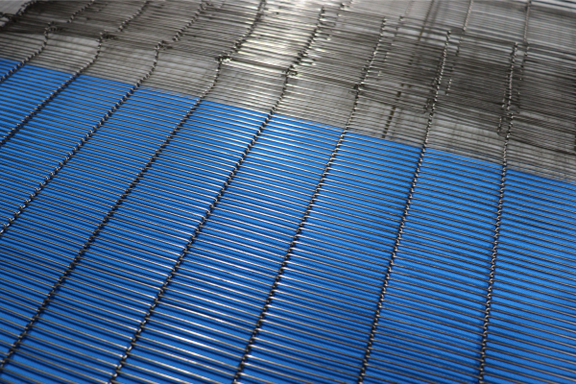

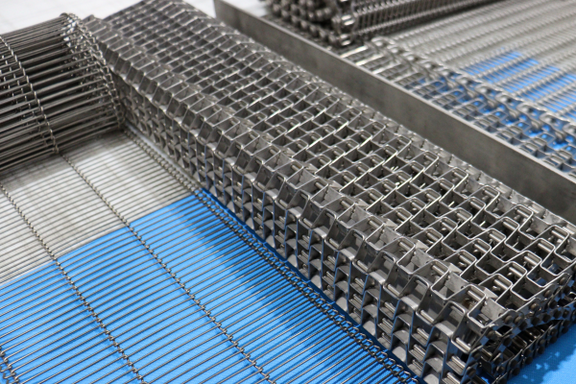

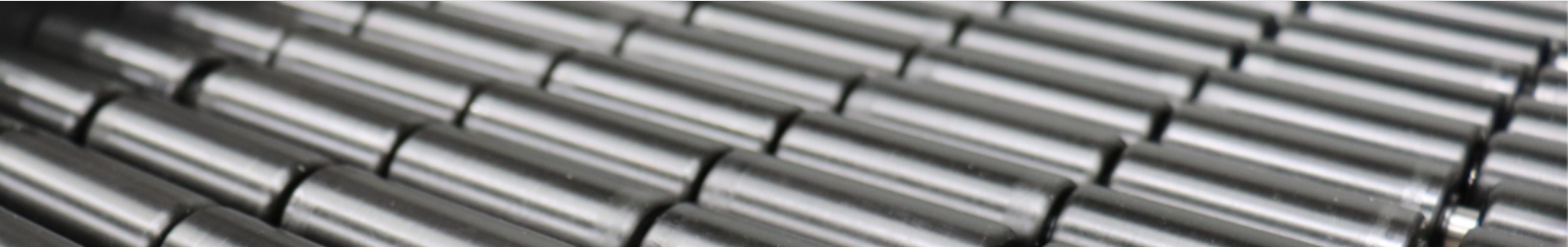

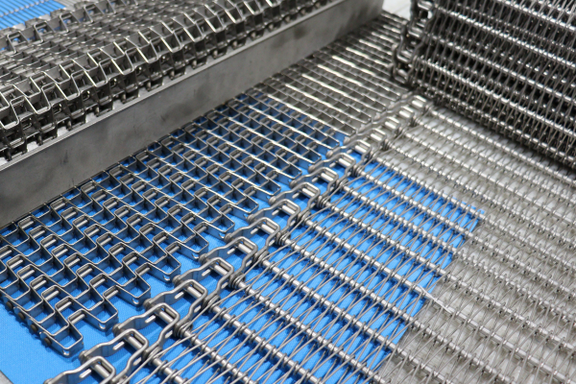

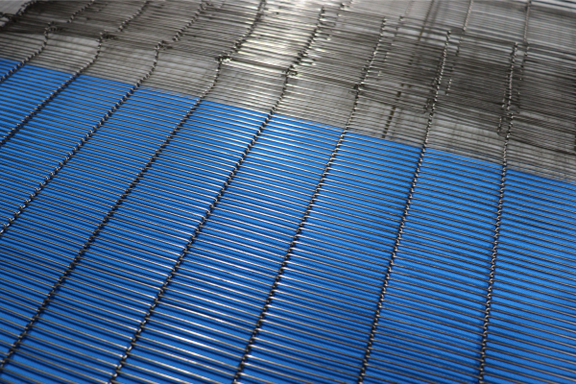

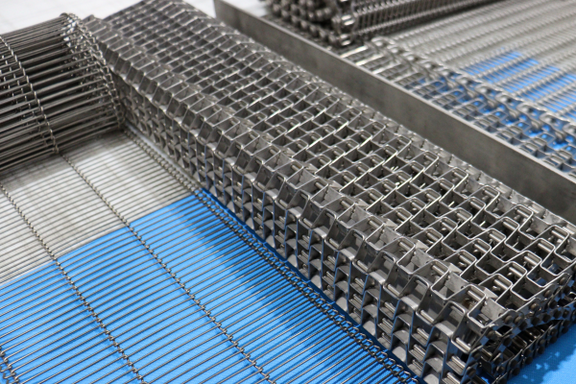

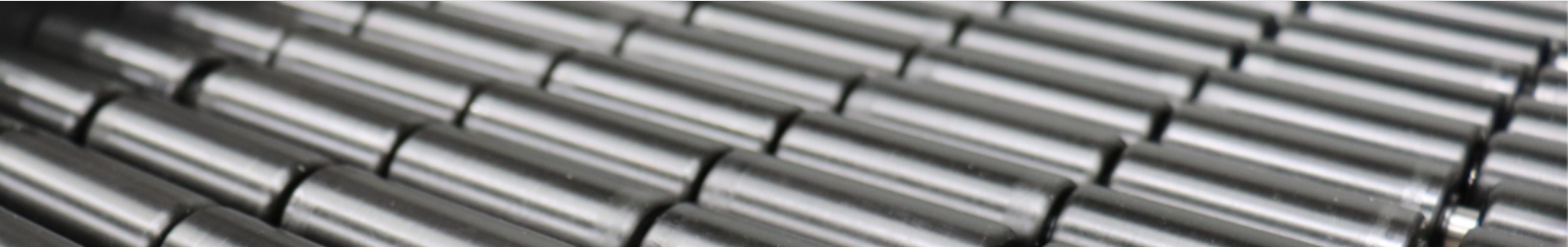

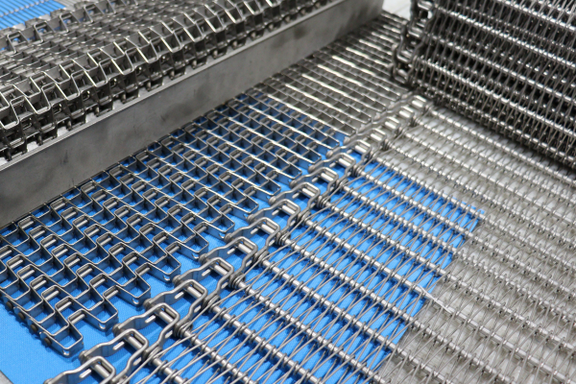

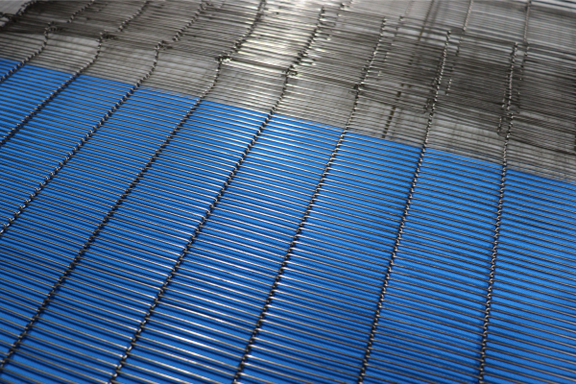

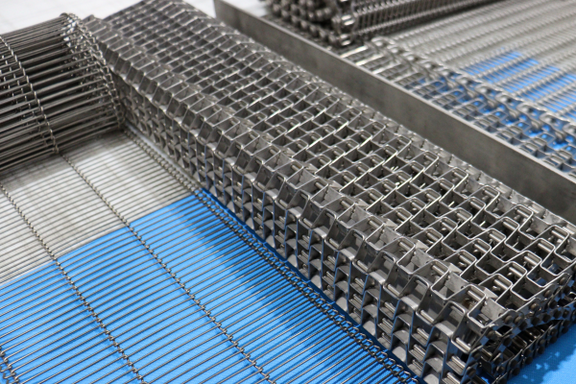

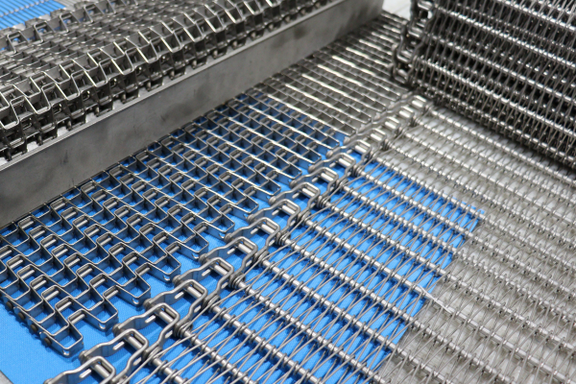

Wire Belting

ENE Group supplies high-quality wire conveyor belting engineered for durability, hygiene, and efficiency in demanding industrial environments. Available from our facilities in Northern Ireland and the Republic of Ireland, these belts are built from robust stainless steel and are suitable for a range of high-intensity applications, including food processing and manufacturing. Designed to perform under extreme temperatures, our wire belting is ideal for use in ovens, freezers, and processes requiring controlled airflow, drainage, or drying. The open mesh design promotes efficient heating, cooling, and cleaning while supporting reliable, hygienic product handling.

Our made-to-measure wire conveyor belts are tailored to meet the specific needs of industries such as meat production, bakeries, fruit and vegetable processing, convenience foods, and pharmaceuticals. They offer long-term performance in environments where temperature resistance, hygiene, and minimal maintenance are essential. Custom options include varying mesh sizes, material grades, edge guards, and drive systems to support your exact production requirements. Whether handling frozen goods, baked items, or delicate produce, our wire conveyor belting ensures consistent throughput and operational efficiency. Contact us today to discuss a solution tailored to your process.

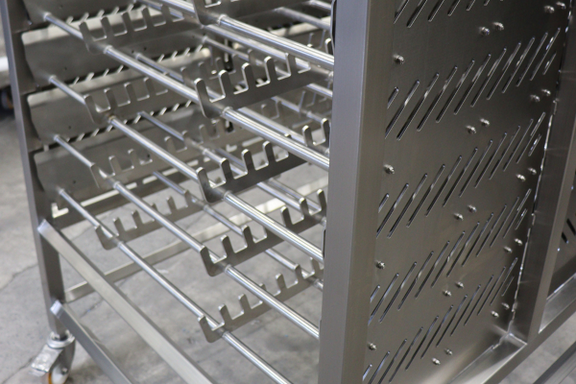

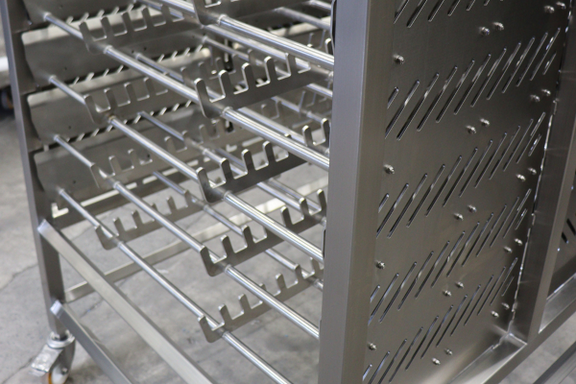

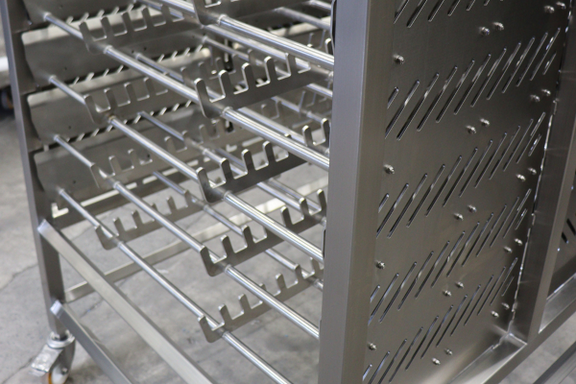

Hygiene Equipment

At ENE Engineering, we design and manufacture custom hygiene equipment tailored to meet the specific needs of hygiene-critical industries. Operating from our facilities in Northern Ireland and Norfolk, we build equipment that supports food processing, pharmaceuticals, manufacturing, healthcare, hospitality, and catering environments. Constructed from 304-grade stainless steel, our products are engineered for durability, easy cleaning, and compliance with industry hygiene standards. From sinks and wash stations to benches, shelving, and waste systems, every item is designed to streamline operations, improve efficiency, and support long-term hygiene control.

Our equipment range includes custom-built sinks, urinals, storage units, boot racks, garment washers, and more. Each product is designed with space efficiency and functionality in mind, and options such as sensor-activated taps, automated waste systems, or 316-grade stainless steel upgrades are available to meet specific requirements. Whether integrating into a cleanroom, food production area, or commercial kitchen, our hygiene solutions offer reliable performance in demanding environments. Contact us today to explore how our custom-built stainless steel equipment can support your operational goals and maintain hygiene compliance.

Bespoke Food Processing Equipment

ENE Engineering specialises in the design and manufacture of bespoke stainless steel food processing equipment tailored to your specific process and production line. With extensive experience across a wide range of applications, we have delivered custom systems for meat portioning, dough preparation, vegetable processing, sauce filling, and snack coating. Each solution is developed by our in-house engineering team, who work closely with you to understand your requirements and design equipment that meets your operational goals. Once approved, systems are manufactured in our facilities in Northern Ireland or Norfolk and rigorously tested to ensure hygiene, efficiency, and durability before dispatch.

Built from food-grade stainless steel, our bespoke equipment is designed to integrate seamlessly into existing production lines while complying with strict food safety standards. Custom options include sizing, automation features, and process-specific functionality to address unique production challenges. Whether you need to improve workflow, reduce waste, or enhance throughput, our tailored systems are built for long-term performance in demanding food environments. Contact us today to discuss a custom solution for your processing requirements.

E-Stops, Isolators, Start Stop Boxes

ENE Group supplies a comprehensive range of E-Stops, isolators, and start/stop boxes designed to meet the highest standards of safety, hygiene, and durability. Housed in stainless steel enclosures, these components are IP66-rated, corrosion-resistant, and suitable for demanding environments such as food processing, pharmaceuticals, and recycling. Built for easy cleaning and long-term use, they offer reliable performance in hygiene-sensitive areas. With high stock levels and next-day availability across Northern Ireland and the Republic of Ireland, we provide dependable solutions that enhance safety and operational efficiency.

Our safety control range includes emergency stop buttons, electrical isolators, start/stop boxes, and custom control panels. These are engineered to withstand washdowns, humid conditions, and corrosive environments, making them ideal for applications in meat processing, bakeries, produce handling, convenience food lines, and cleanroom settings. Custom options include tailored labelling, mounting configurations, indicator lights, and adjustable enclosure sizes. Whether you require basic controls or integrated safety systems, our components support compliance and control across your production line. Contact us today to find the right safety solution for your facility.

Stainless Steel Control Panels

ENE Group supplies stainless steel control panels engineered for durability, hygiene, and reliable performance in demanding industrial environments. Built from high-grade stainless steel and designed to withstand high-pressure washdowns, these panels are ideal for food processing, pharmaceutical, meat and dairy production, beverage, and automation applications. Each unit features IP-rated enclosures that protect against moisture, dust, and harsh cleaning agents, ensuring long-term operation in hygiene-critical areas. With options for motor control, safety integration, and process automation, our panels support efficient and safe control across production lines.

Designed for seamless integration, our control panels are fully customisable in layout, functionality, and mounting configuration. Available options include button, switch, and touchscreen interfaces, with configurations tailored to your operational requirements. Whether you need motor control panels, automation enclosures, or operator stations, we provide precise control solutions that reduce downtime and support hygiene compliance. With flexible IP ratings, optional stainless steel grades, and fast turnaround, our panels deliver performance and reliability where it matters most. Contact us today to discuss a tailored control panel for your application.

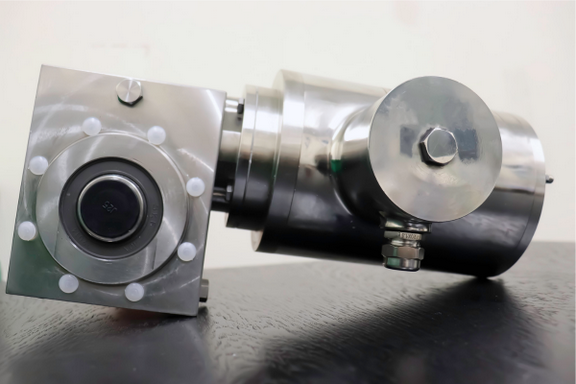

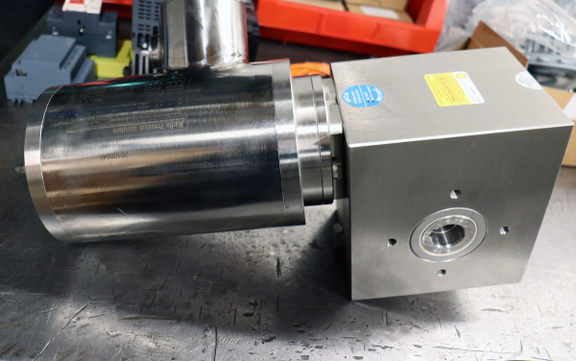

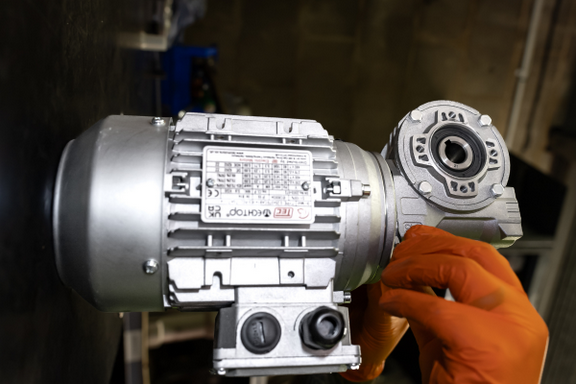

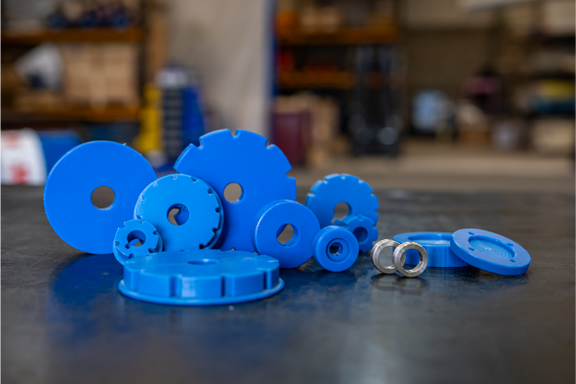

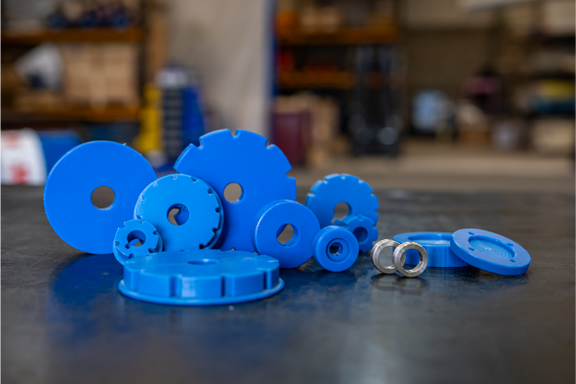

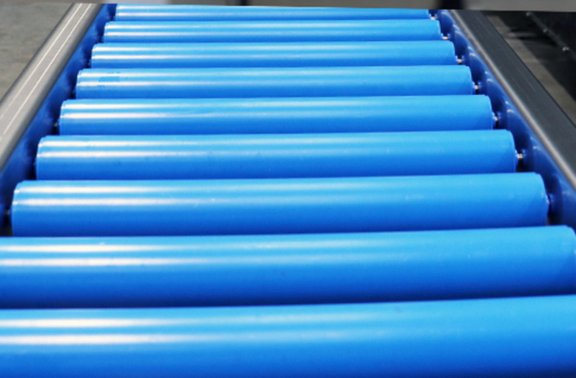

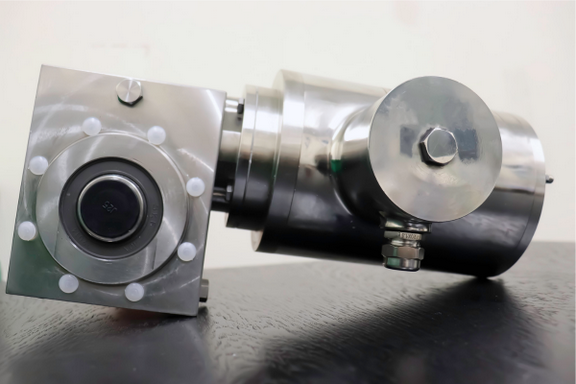

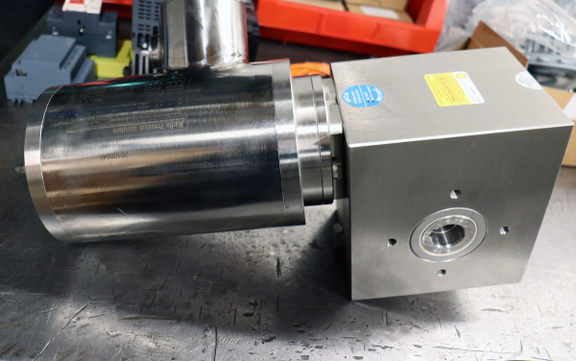

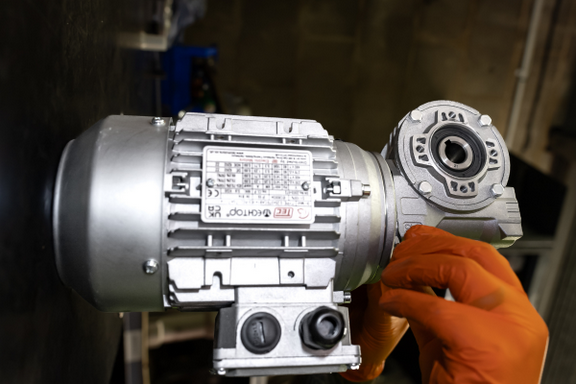

Spare Parts

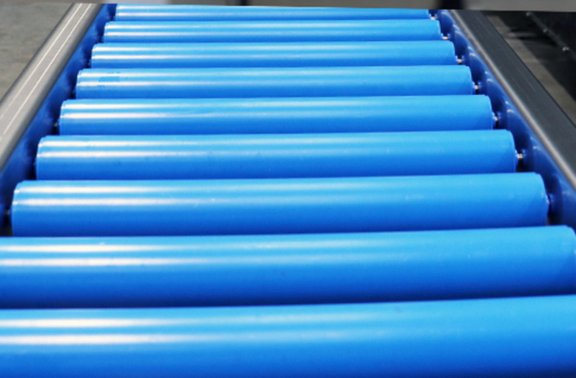

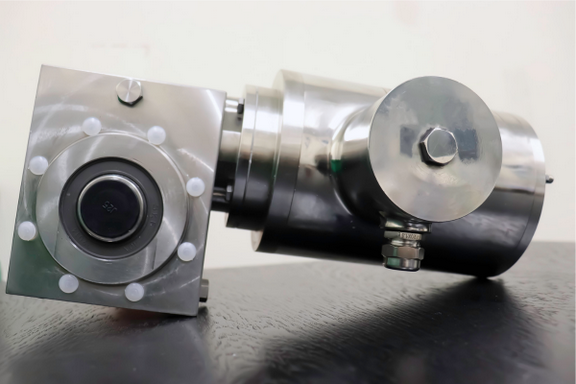

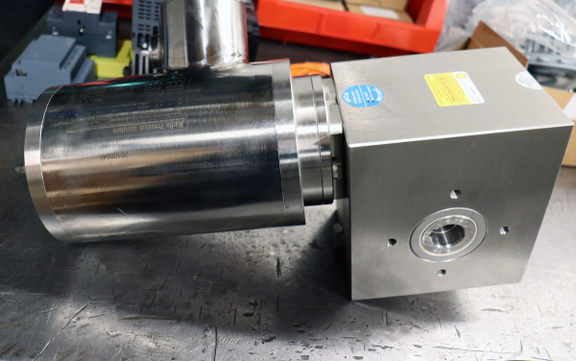

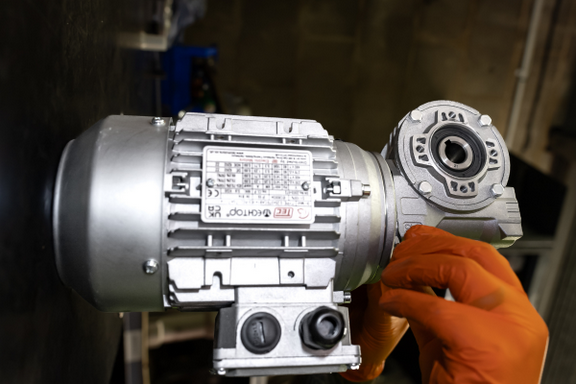

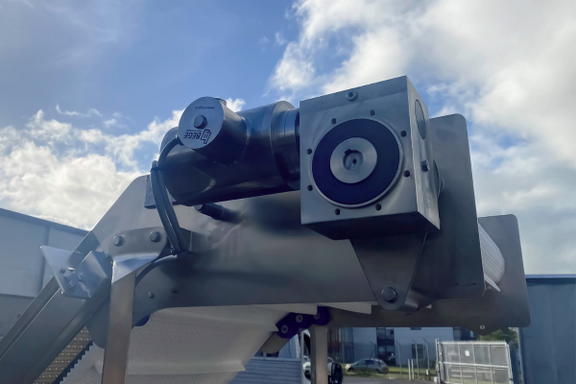

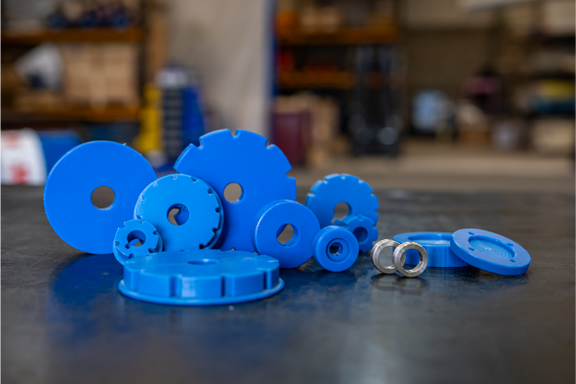

At ENE Group, we understand the challenges that downtime and breakdowns can cause. That's why we offer a wide range of high-quality conveyor spare parts to keep your systems running efficiently. With quick access to replacement parts and expert support, we minimise downtime and ensure your operations stay on track. We stock housed bearings with thermoplastic housings and stainless-steel inserts, providing corrosion-resistant solutions ideal for food-grade applications and industries like recycling and airports. These bearings deliver smooth operation and long-lasting reliability, even in harsh environments. Our conveyor components include plastic sprockets, guide rails, conveyor rollers and wear strips, which are vital for maintaining the efficiency and alignment of your conveyor systems. Manufactured from food-safe materials, they meet strict hygiene standards, making them suitable for food, beverage, and pharmaceutical processing lines.

About us

ENE Group has been designing and manufacturing premium conveyor systems for over 25 years across our facilities in Northern Ireland, Great Britain, and Ireland.

We offer comprehensive solutions, such as stainless steel conveyor systems, replacement belting, custom food processing equipment, and advanced labelling systems. Our in-house team ensures excellence throughout every phase, from design to installation, guaranteeing seamless integration and dependable performance.

We provide engineering support, spare parts, and expert guidance to customers across the UK, Ireland, and the EU. At ENE Group, our dedication to precise engineering and outstanding service ensures your operations run smoothly and efficiently.

Our Products & Services Include:

ENE Conveyor Systems

With over 25 years of expertise, ENE Group designs and manufactures custom stainless steel conveyor systems tailored to industry needs. Operating from advanced facilities in Banbridge, Northern Ireland, and King’s Lynn, UK, we offer comprehensive solutions, from design to installation and commissioning. We also provide engineering support, spare parts, and specialised belting solutions to ensure seamless production. Serving key industries including food and beverage, pharmaceuticals, meat processing, fruit and vegetable, and convenience food, our engineering team creates high-performance systems for modern production demands. With locations in Banbridge and King’s Lynn, we serve clients across the UK and Ireland.

ENE Conveyor Belting

With over 25 years of experience, ENE Group specialises in providing high-quality, custom conveyor belting solutions across Ireland and the UK. Operating from our state-of-the-art facilities in Dublin and Banbridge, we design, manufacture, and install a wide range of conveyor belts to meet client needs. We also offer full fitting services for proper installation and performance, as well as a breakdown service to minimise downtime and ensure smooth production. Our skilled fabricators and fitters produce PU, PVC, modular, rubber, and wire mesh belts, ensuring top performance for industries like food production, pharmaceuticals, recycling, airports, and more.

ENE Engineering

ENE Group specialises in designing and manufacturing custom hygienic stainless-steel equipment and food processing systems. Prioritising hygiene, our products minimise contamination risks while ensuring efficiency and durability. From our advanced facilities in the UK and Ireland, we produce a variety of hygienic equipment, including sinks, urinals, tables, benches, shelving, lockers, drains, and waste holders. We provide solutions ranging from small equipment supplies to complete factory fit-outs, catering to food processing and pharmaceutical industries. We also create specialised items like boot racks, washers, garment washers, turnstiles, and dispensers, all crafted from high-quality stainless steel to meet food safety standards and facilitate easy cleaning.

Spare Parts

At ENE Group, we recognise the impact of downtime and breakdowns, which is why we offer a comprehensive range of high-quality conveyor spare parts to keep your systems operating smoothly. With fast access to replacement parts and expert support, we help minimise downtime and maintain seamless operations. Our inventory includes housed bearings with thermoplastic housings and stainless-steel inserts, offering corrosion-resistant solutions perfect for food-grade applications and industries like recycling and airports. These bearings ensure reliable, long-lasting performance in demanding environments. Additionally, we supply essential conveyor components such as plastic sprockets, guide rails, rollers, and wear strips, all made from food-safe materials to meet stringent hygiene standards for food, beverage, and pharmaceutical processing.

For more information on any of our services, feel free to call, email, or complete the form on our website and submit it.

Images