02 July 2025 | Western Mechanical Handling UK Ltd

The importance of Transfer Equipment in streamlining Factory Production Processes

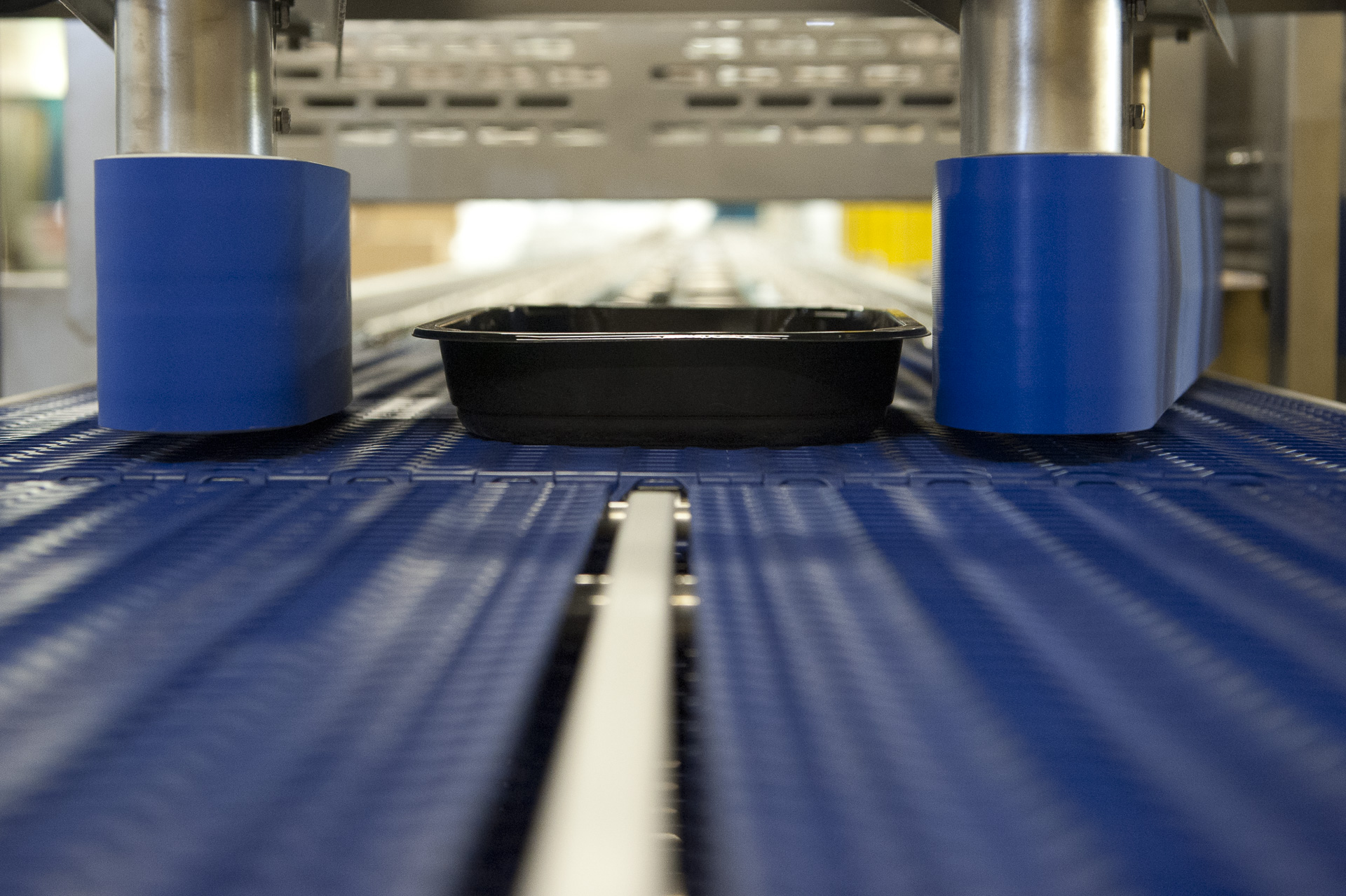

Production line efficiency in food factories depends not just on big machines like ovens and chillers, but on the often-overlooked transfer equipment between them. Well-designed conveyors and automation ensure smooth product flow, minimise waste, and adapt easily to future upgrades—making them crucial to long-term performance and profitability.

Production lines in food factories are constantly changing and evolving as technology and production requirements change. Over time this will lead to the reduction in the efficiency of a line if the transfer equipment between the major processing machines isn’t considered at each line upgrade.While capital expenditure focuses on the large pieces of equipment in the line, how product moves between these can make or break the efficient flow. It is with the help of the transfer conveyors - where products are collated, sorted and arranged - that the full capacity of your oven or freezer is achieved.

Along every production line, the product will need to be arranged differently to maximise the capacity of the equipment and the throughput of the line. At the start of your line you may have products in single file passing along your assembly line. From here it may need to be collated into arrays of 16 or 20 to fully populate the width of a travelling oven. From the oven this pattern will need to be reduced to 3 or 4 across your chiller before again reducing to single lane to feed your wrapping and packing machines.

Transfer points between pieces of machinery in your line are also critical to the success of a line. Simply pushing two pieces of equipment together can lead to product damage, product getting stuck and products tipping over and out of alignment. All this reduces your line efficiency and profitability. Careful consideration of the product being carried will influence the type of transfer; whether that be a simply inline, straight transfer, a 90-degree transfer or one using guides and pushers to help the product flow smoothly. It may seem simple to add an extra operative at a difficult transfer point but in this economic climate where labour costs are souring and labour shortages are rife, getting the transfer right with conveyoring and automation will pay for itself in a very short time.

Whenever you start to consider any upgrade to your line it is important to get a systems integrator and automation specialist involved with the discussions from an early stage. They will work with you and the suppliers or your large pieces of equipment to look at the most efficient way of helping you achieve the outcome that you want. While your oven supplier will focus purely on the oven and the chiller provider will concentrate on the chiller, a systems integrator and automation company will look at the bigger picture and will be able to develop a layout that pulls the separate pieces together to form a seamless production line. They will design and build bespoke transfer conveyors and machines that will conveyor your product safely and efficiently from end to end with minimal operator intervention.

Building a long-term relationship with your integrator can be the key to maintaining the efficiency of your line as future upgrades occur. Machine builders generally don’t like to modify other companies’ equipment so maintaining a good relationship with your original provider can pay dividends in the future as they will be much happier to modify and re-configure their own designed machines in the future, to meet your changing requirements.

In today’s competitive manufacturing environment, every detail of your production line matters—and transfer equipment is no exception. By treating these systems as integral components rather than afterthoughts, manufacturers can unlock significant gains in efficiency, product quality, and operational flexibility. Investing in tailored transfer solutions and forging strong partnerships with automation specialists not only optimises current performance but also future-proofs your production for the challenges and innovations to come.