17 October 2025 | Tascomp Ltd

Unlocking Efficiency, Clarity, and Control on the Factory Floor

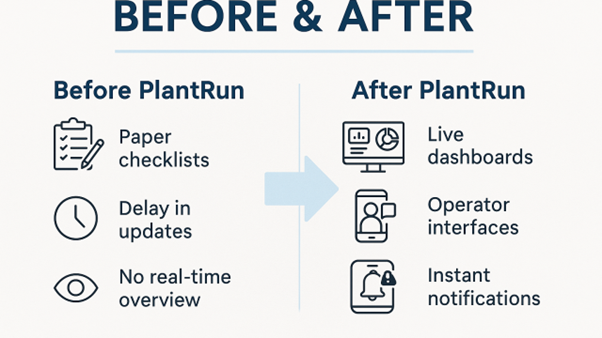

In manufacturing, small inefficiencies add up fast. Time, materials, labour, and uptime all affect profitability - yet many factories accept losses as normal simply because they lack visibility. Paper records and spreadsheets hide the real causes of downtime, leaving teams reacting instead of improving.

PlantRun changes that. It transforms raw production data into clear, actionable insights - often paying for itself within months.

Visibility Creates ROI

Every improvement starts with seeing the truth. One manufacturer believed breakdowns were their biggest issue. But once PlantRun captured live stoppage data, the real culprits emerged: setup delays, material waits, and shift-change downtime. Over a quarter of stoppages were “unknown.”

Armed with facts, the team fixed planning and process issues instead of investing in more equipment - instantly reducing wasted time and cost.

Quick Wins First

Early ROI comes from targeting the biggest and easiest improvements. Focus on:

- The top downtime causes

- Long or inconsistent setups

- High “unknown” stoppages

One packaging firm discovered label changeovers cost 18% of production time. Simple changes to staging and QA involvement delivered 16 extra productive hours per week.

PlantRun features such as downtime reason tracking, operator callouts, and live dashboards make these improvements fast and visible.

Sustaining Improvement

True ROI grows through consistent review. Weekly analysis of top downtime causes, supported by tools like Short Interval Control and OEE dashboards, helps teams act on facts - not assumptions.

Beyond Downtime

As monitoring expands to job tracking, changeovers, callout response, and paperless records, ROI compounds through less waste, clearer communication, and better planning.

PlantRun doesn’t just measure performance - it transforms it. The result is lasting control, confidence, and continuous improvement across your factory floor.

Visit plantrun.co.uk for more information