Company details for:

Anopol Ltd

70 Bordesley Street,

Birmingham,

West Midlands,

B5 5QA,

United Kingdom

Quick Links:

Products / Services

Subcontract Processing Services

The range of stainless steel fabrications and components treated by Anopol is wide and diverse. Industries using its services include food and beverages, automobile, building and construction, medical and pharmaceuticals, paper and pulp, aerospace, nuclear and electronics.

Stainless steel castings, spinnings, forgings, pressings, extrusions and welded fabrications are processed on a regular basis.

Electropolishing

Industries benefiting from the advantageous characteristics of electropolishing are numerous and continue to grow. The following are some of the technologies that have exploited electropolished features:

Aerospace (e.g. Crack detection in castings), Automotive (e.g. External wire-mesh car trim), Chemical (e.g. Polymeriser vessels), Semiconductor (e.g. Pipework and fittings for gases), Food and beverage (e.g. Hot water tanks), Hospital (e.g. Sterile furniture), Surgical (e.g. Instruments and implants), Marine (e.g. Boat handrails and deck fittings), Textile (e.g. Dye vats), Paper and Pulp (e.g. Screen cylinders), Nuclear (e.g. Plasma producing Torus), High vacuum (e.g. Vacuum chambers), Pharmaceutical (e.g. Process tanks, pipes and valves), Architectural (e.g. Lamp-posts and sculptures), Leisure (e.g. swimming pool ladders).

Pickling

Anopol has extensive pickling and passivating facilities. Additionally, Anopol can supply all the necessary equipment, including water treatment, together with the necessary chemicals to those companies wishing to carry out in-house pickling and passivation, or provide resources and trained personnel to complete onsite surface treatment for customers.

Cleaning, pickling and passivating products are available in liquid and gel / paste form.

Passivating

ANOPOL has extensive pickling and passivating facilities at its Birmingham and Bordon, Hampshire facilities. Additionally, ANOPOL can supply all the necessary equipment, including water treatment, together with the necessary chemicals, to those companies wishing to carry out their own pickling and passivation.

Cleaning, pickling and passivating products are available in liquid and paste form. ANOPOL also markets the WELDKLEEN machine, an environmentally friendly way of removing weld burn.

Special Materials

Other special metals include Titanium, Tungsten, Molybdenum, Aluminium, Cobalt Alloys, Nickel, Nickel Alloys, Copper, Copper Alloys and Zirconium

In addition to offering sub-contract processing services, plant and chemicals, ANOPOL can also supply an extensive range of pickling, passivating and general cleaning products for many materials. These are suitable for use by companies who wish to carry out in-house processing.

Chemical Products

When working with stainless steels, the surface of the material can be significantly affected in a number of ways. Rolling, forming, welding and even general handling in the workshop can result in surface contamination, which can lead to reduced corrosion resistance.

The ANOPOL range of products for Cleaning, Pickling and Passivating stainless steels removes contamination, improves corrosion resistance and can produce a clean, aesthetically attractive appearance.

In addition ANOPOL offers 2 types of Test Kits, one for checking the presence of free iron on a surface and the other for differentiating between grades 304 and 316.

All the products are suitable for use by manufacturers/fabricators for in-house or on-site application.

Plant and Equipment

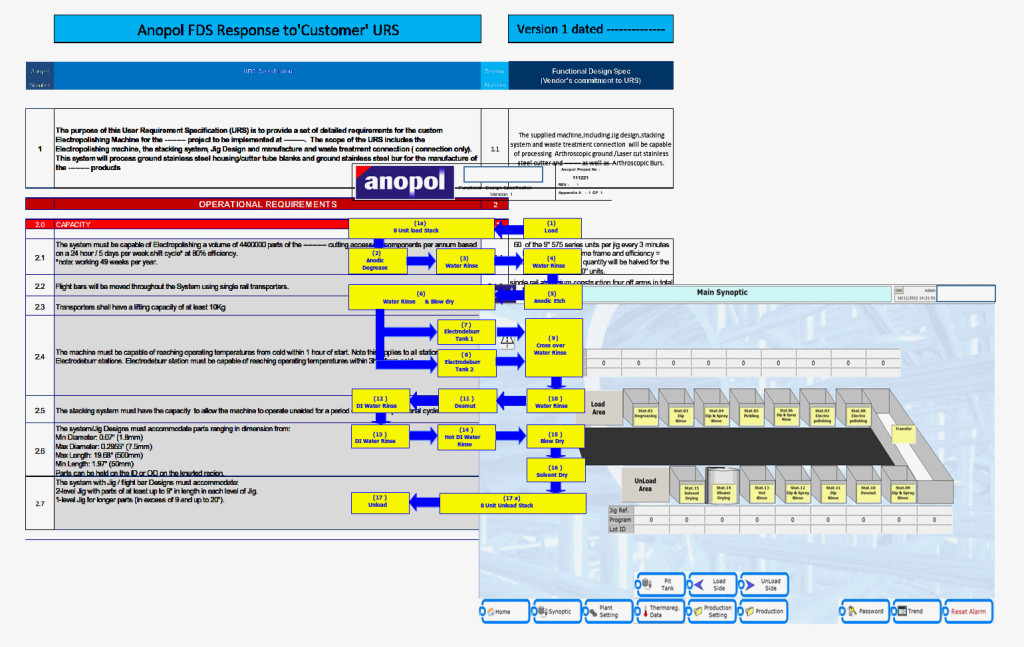

The client already uses a metal finishing process for which he now requires replacement equipment or, alternatively, he wishes to upgrade to a semi or fully automatic system.

The client has used an electroplating supply-house to produce satisfactory samples and now needs equipment in which to operate the finishing process. ANOPOL is prepared to work closely with the supply-house to arrive at the correct plant specification.

The client has a requirement for pickling, passivating or electropolishing stainless steel using processes from ANOPOL. Electropolishing treatments for other metals are also available.

Following final sample acceptance, production batch sizes, cycle times, space allocation and details of services required are considered and incorporated into the specification.

On-site Services

On-site services include technical advice, risk assessment, pre-commission cleaning, pickling and passivating of assemblies such as pipework systems. On-site spraying processes allow the pickling and passivating of large vessels and structures using only a small amount of chemicals to be carried out thus minimizing the volume of effluent requiring safe treatment and disposal.

Electropolishing of vessels on-site has included the treatment of PVC polymerizers 3.5m dia weighing 40 tons and many process and storage tanks for the food, pharmaceutical, chemical and nuclear industries. Most contracts require only product contact surfaces, usually the inside, to be electropolished allowing the vessel in itself to be used as the electropolishing processing tank.

All on-site work is carried out by trained technicians and chemists with all chemicals quality controlled by our in-house laboratory and delivered to site in UN approved containers. Effluent is collected for neutralization prior to disposal either through the site sewerage system or for return to Anopol.

Weld Cleaning

About us

We are member of the Surface Engineering Association, British Stainless Steel Association and Association of Welding Distribution. Signatories to the Supply Chain Charter for Nuclear Decommissioning. ISO.9001 & ISO.14001 approved.

Subcontract Processing Services

- In-house & on-site subcontract services for cleaning, pickling, passivating and eletropolishing of stainless steel.

- Projects carried out across the UK and Europe.

Pickling - The most cost-effective method for obtaining a clean passive surface on Stainless Steel is by immersion pickling in our own formulated solution of dilute acids. Anopol has extensive pickling and passivating facilities. Additionally, Anopol can supply all the necessary equipment, including water treatment, together with the necessary chemicals to those companies wishing to carry out in-house pickling and passivation, or provide resources and trained personnel to complete onsite surface treatment for customers. Cleaning, pickling and passivating products are available in liquid and gel / paste form.

Passivating - A clean Stainless Steel surface will generate it'sown passive oxide layer when exposed to oxygen. It is this oxide layer that gives stainless steels their corrosion resistant properties. owever it is possible to accelerate the formation of this layer by chemical passivation. ANOPOL has extensive pickling and passivating facilities at its Birmingham and Bordon, Hampshire facilities. Additionally, ANOPOL can supply all the necessary equipment, including water treatment, together with the necessary chemicals, to those companies wishing to carry out their own pickling and passivation. Cleaning, pickling and passivating products are available in liquid and paste form. ANOPOL also markets the WELDKLEEN machine, an environmentally friendly way of removing weld burn.

Chemical Products

- Anopol range of products for cleaning, pickling and passivating stainless steels.

- For removing contamination, improving corrosion resistance and providing a clean & attractive appearance.

- Anopol test kits are also available.

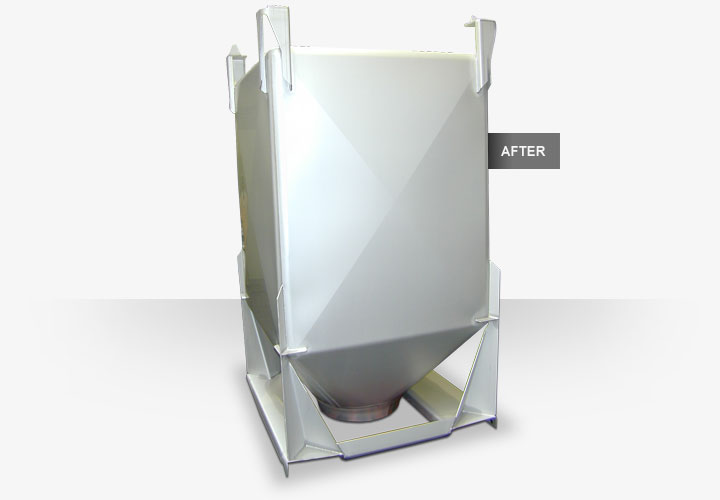

- Our equipment is designed to meet a whole range of specifications using the latest CAD techniques.

- We provide the client with plant & layout drawings & details of location & services required. For example, electricity and water.

- For preventing the corrosion of stainless steel.

- Anopol machines are suitable for a wide range of applications including ducting & flues, pipe-work systems & silos and tanks.

- We also supply smaller machines for those intricate and precise applications.

Sponsored Links

Trade Associations