Company details for:

BalTec UK Ltd

Quick Links:

Products / Services

Articulating Roller Forming

The new ELECTRIC EA30 is the world's first fully servo-driven articulating roller forming machine with three axis.

Thanks to its fully servo-driven process control, workpieces are formed with three axis, one in vertical motion downwards, one in a rotary motion, and one in an articulating (in-out) motion of the rollers. The process control software is individually programmable, allowing the machine to perform 3D profiles.

What makes the ELECTRIC EA30 so unique is the servo-controlled articulating motion, which delivers significantly higher precision and control than conventional solutions that require manual adjustment of a mechanical stop.

Last but not least, an attractive feature of the ELECTRIC EA30 is its slim design, as all three servo motors are aligned within the unit. Therefore the EA30 is well suited for integration into automated production lines with limited space or as part of a stand-alone work cell where frequent changeover of nests and programs may be necessary.

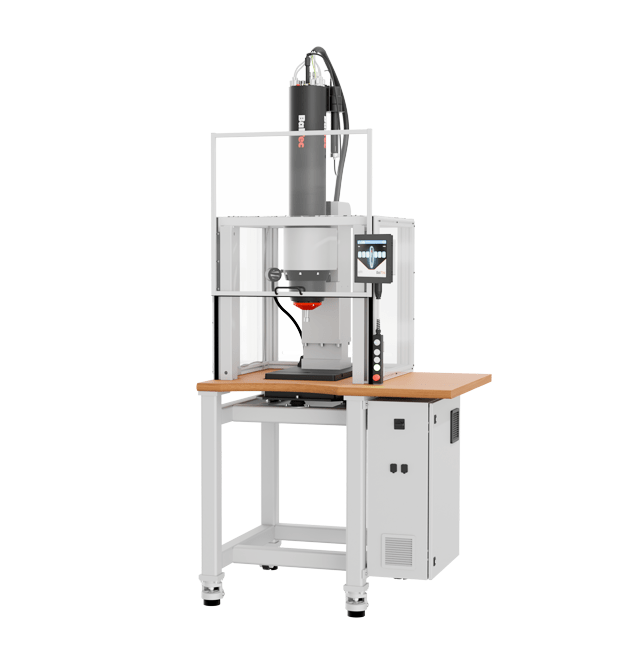

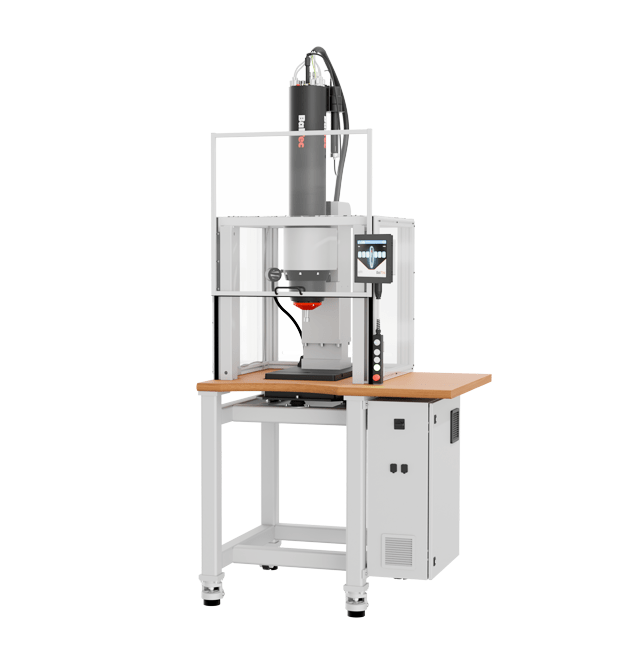

Bench Top Riveting Machines

Pedestal Riveting Machines

With Rotary Indexing Table

Double Riveting Machines

Electric Bench Top Forming Machines

Electric table riveting machines are offered as complete workstations for all three joining processes. Depending on the required force, the size of the machines differ.

Electric with C-Frame

These electric models feature a welded steel C-frame that is slim and space-efficient, making them perfect for seamless system integration. The preferred cold forming method can be chosen as needed.

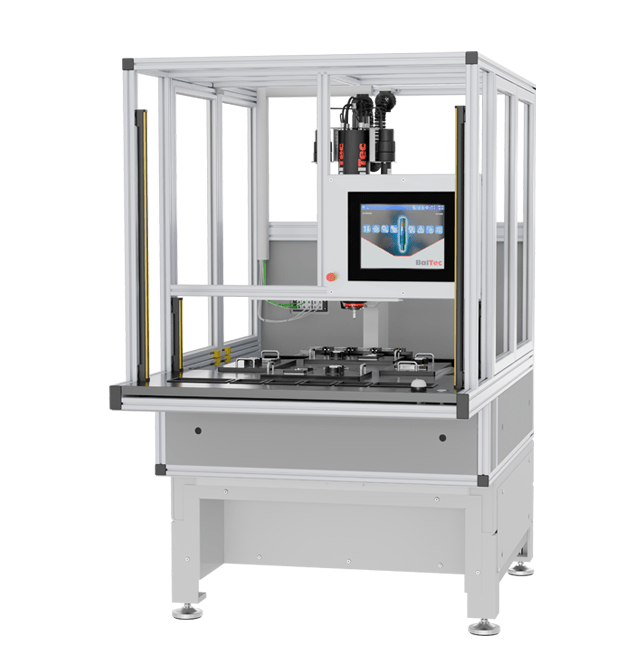

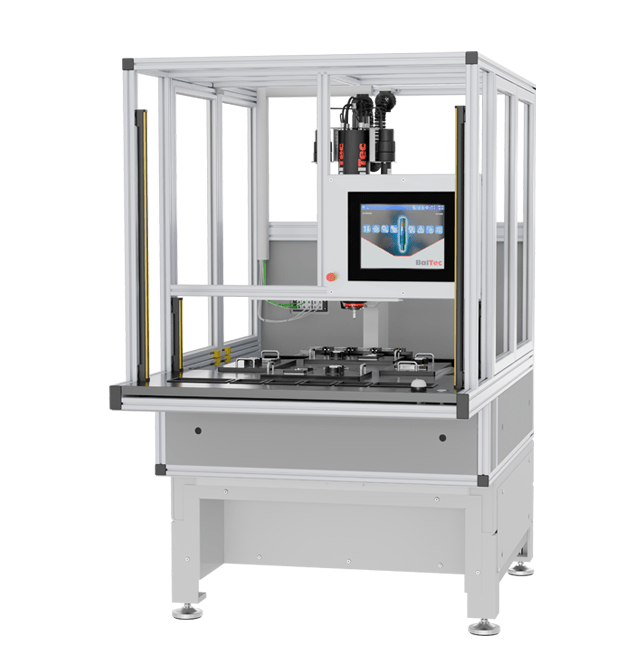

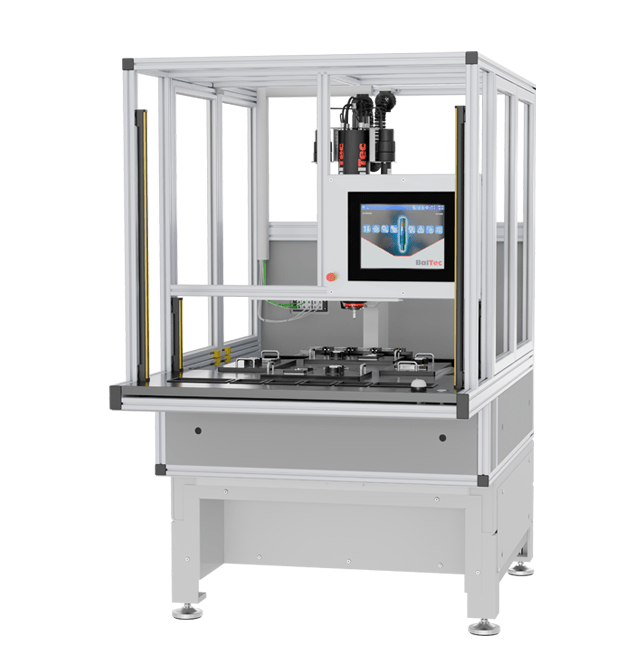

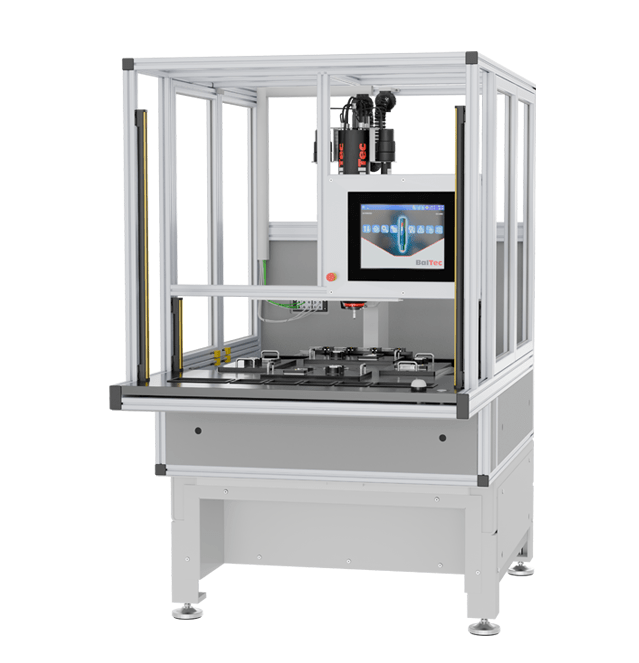

Electric Workcells

These electric servoriveting machines come as fully assembled workstations with HPPi process control included. Their safety guards feature either light curtains or lift-style doors.

Electric Customised Versions

Custom setups are available with rotary indexing tables or linear-transfer work cells. Optional features include automated part ejection and pre-inspection using OK/NOK checks or light sensors to verify correct part positioning.

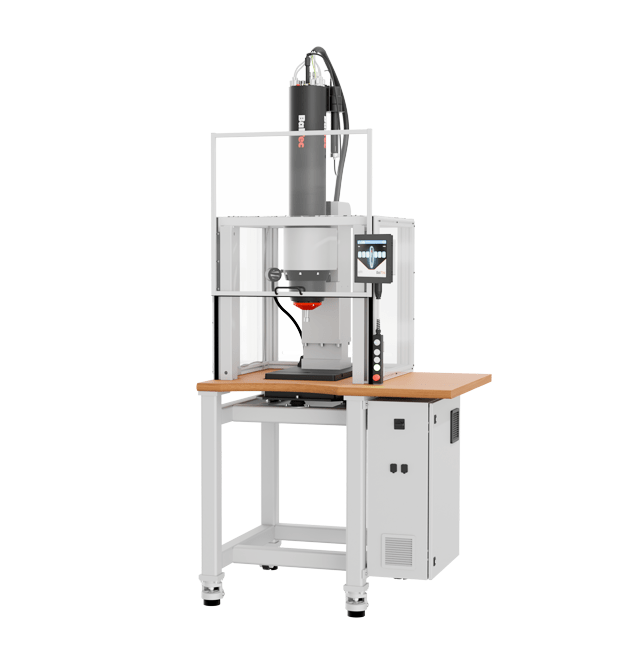

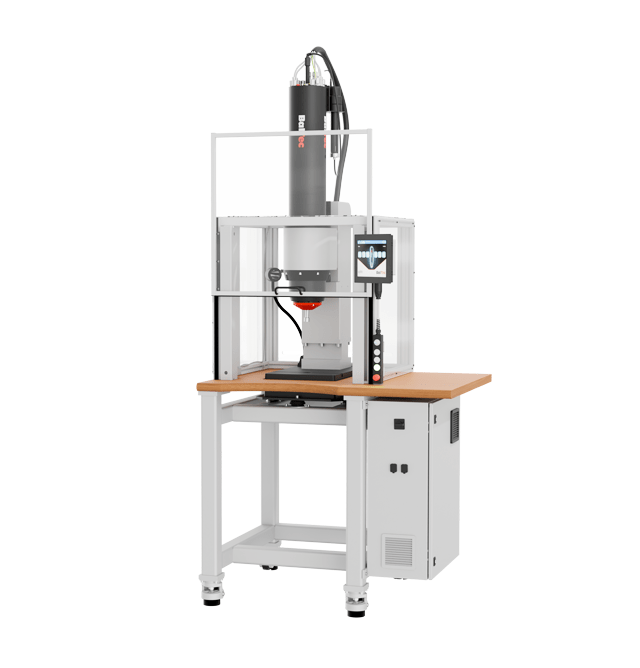

Orbital Machines with Process Control

These tabletop orbital cold forming riveting machines are ideal for standalone workstations. A protective system surrounding the process head ensures safe, CE-compliant operation. They deliver efficiency and safety while maintaining BalTec’s signature precision.

Orbital Machines with Time Based Control

These tabletop orbital cold forming riveting machines offer the same CE-compliant benefits. They feature time-based control packages and are equipped with two-hand operation controls.

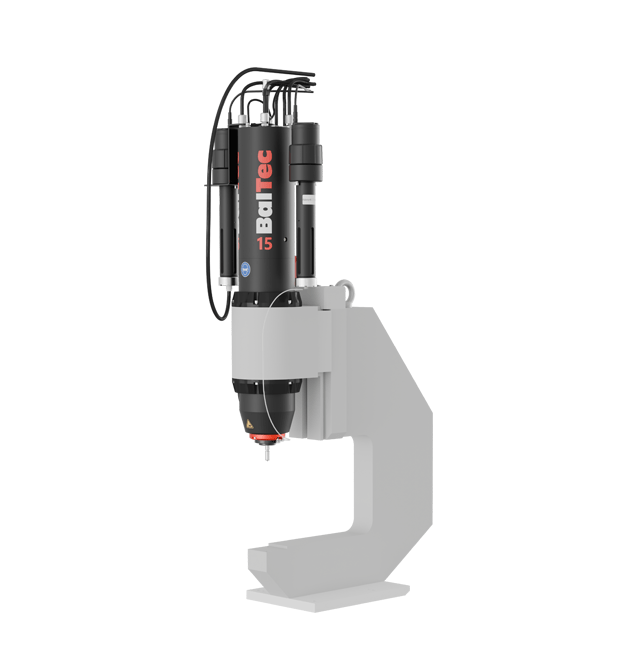

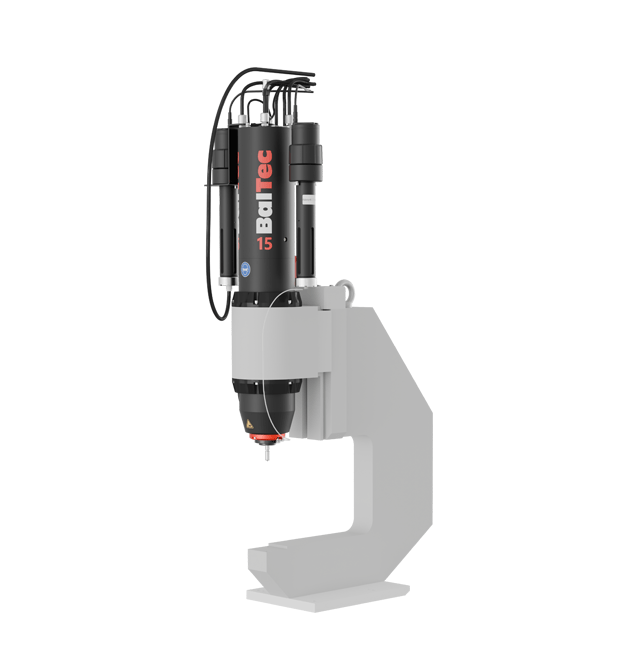

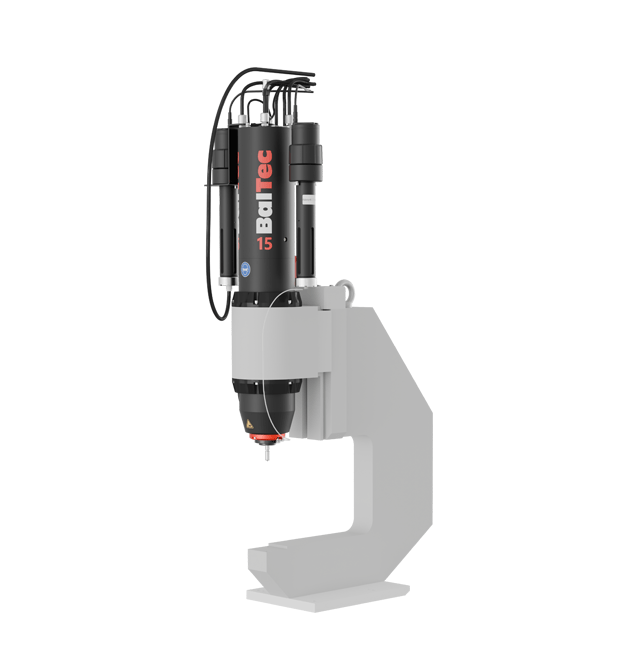

Orbital Machines for Integrators

These packages are especially bundled for integrators, who have the full construction of their production line, but are in need of reliable, precise and longlasting riveting machines including the process control, in this case the HPP.

Customised Orbital Machines

The Orbital Line can be customised with numerous upgrade options upon request. BalTec’s modular design ensures maximum flexibility, and each orbital riveting machine can be fitted with an enclosure and sliding table according to customer requirements.

CNC Cold Forming Machines

Our CNC machines and automated work cells set new benchmarks for quality, durability, and efficiency. Built for continuous operation in demanding production environments, they combine cutting-edge technology with robust construction to deliver reliable results.

The modular design of our CNC riveting machines enables flexible production processes, allowing functions to be combined and expanded to meet individual customer requirements.

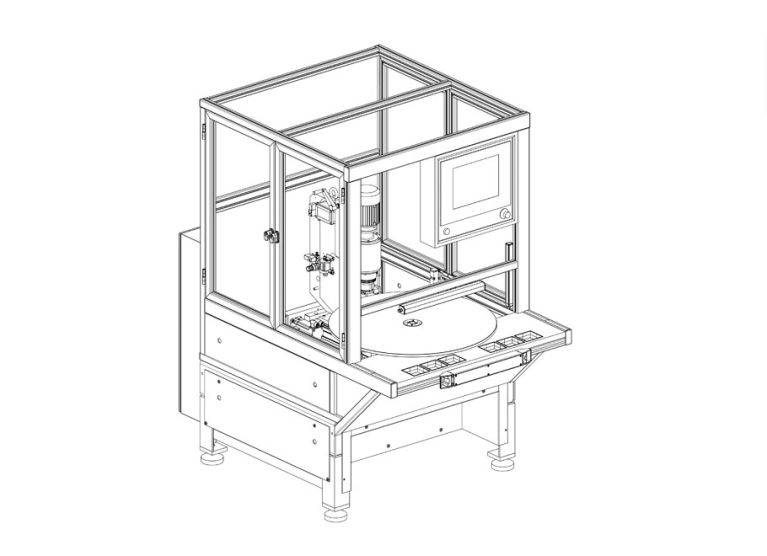

The ELECTRIC RX—a fully electric CNC radial riveting machine with a rotary indexing table—ushers in a new era of precision forming. It is the first CNC machine to offer complete numerical control across all axes, providing true CNC precision, not just monitoring. With an optional tool changer that accommodates up to four forming tools, the ELECTRIC RX can complete four forming operations in a single cycle, enhancing production speed and efficiency.

Control & Monitoring

Time Based Control with RC-30

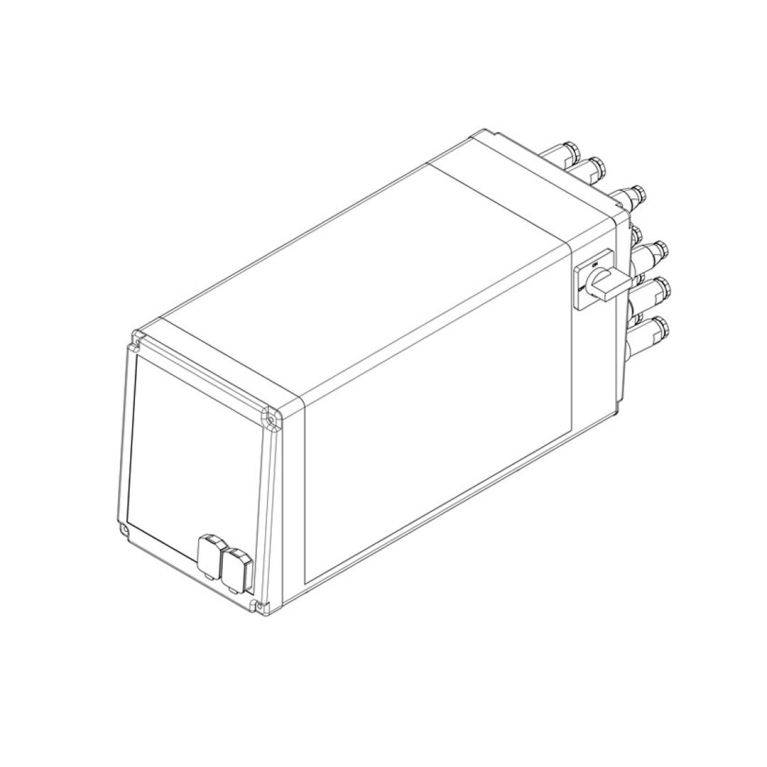

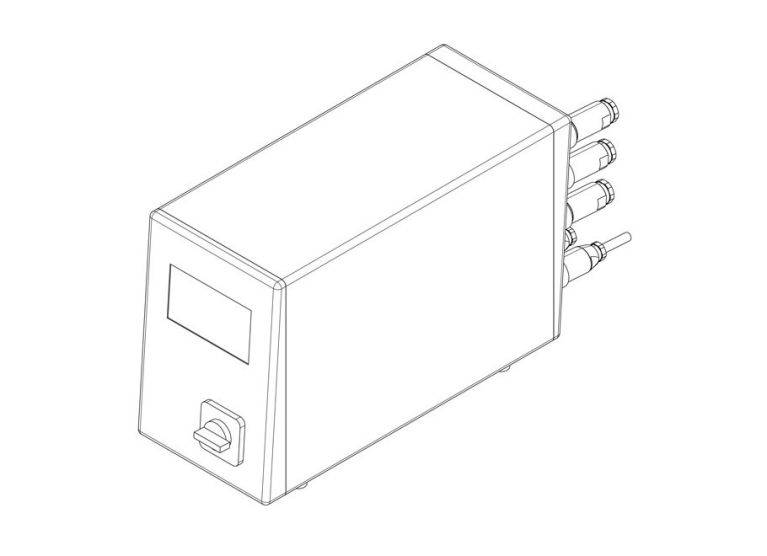

Designed for use with BalTec radial riveting machines, this modular control system is also compatible with single- or double-acting pneumatic riveting machines, hydraulic machines, NHE-E systems, rotary table machines, or setups with a sliding table.

The RC-30 control features a touchscreen, providing direct access to all information and functions.

Forming Tools

Multiple Riveting

Rivet Base Detection

Sliding Tables

Downholders

Downholders secure components in position, making them ideal for setting, compressing, or inserting parts prior to riveting or cold forming.

BalTec provides two types of downholders—equipped with either disc springs or coil springs—depending on the required force, which should be determined through testing. These downholders are also compatible with MRX multi-riveting heads.

Application Support

To identify the ideal solution for each customer, we conduct feasibility studies considering factors such as material, riveting, power, cycle time, and more.

We collaborate closely with clients to develop applications that are optimal both technically and economically.

With over 50 years of experience, BalTec engineers and technicians bring exceptional expertise, which we share with our global partners and representatives.

Consulting & Development

BalTec’s expertise lies in developing and implementing advanced riveting technology solutions—fully Industry 4.0 ready—built on over 50 years of experience and specialisation.

Our experience spans from simple riveting units to turnkey work cells with integrated machines. Our global specialists continuously create new applications tailored to customer requirements. From analysis to feasibility studies, we consider all parameters and innovate new tools, profiles, and production methods.

Engage BalTec engineers early in your project to receive expert guidance. Our skilled team will review specifications, help develop prototypes, and provide recommendations for testing before moving into full-scale production.

Repair & Spare Parts

Whether you need a new motor for your riveting machine, a replacement valve for your assembly equipment, or a set of bearings, we have the spare parts you require. Complete seal and bearing kits for all riveting machine models from the past 25 years are in stock and ready for immediate dispatch.

Refurbished Machines & Units

Explore our selection of expertly refurbished machines, ready for immediate use or integration, all offered at competitive prices. By providing fully overhauled, demo, or refurbished machines, BalTec delivers cost-effective solutions while promoting sustainability by giving equipment a second life.

Demo machines, used in technology centers or exhibitions, typically have only 10–20 hours of operation per year.

Each machine can be tailored with additional accessories to suit your needs. Contact us for a personalized offer.

About us

Founded in Pfäffikon, Switzerland, the BalTec Group manufactures joining technology machinery, with a special focus on radial riveting, orbital riveting, roller forming and pressing.

It was BalTec (then known as Bräcker, which coined the term "brackering") that pioneered radial riveting technology in 1968. As a global leader in joining technology, we encompass seven companies with over 60 direct employees and 40 sales and service partners throughout the world.

Our Products Include:

Riveting Machines

Our products find application in situations demanding top-notch connections and joints. They come in diverse configurations, providing exceptional adaptability. The fundamental component in all our machines is the core unit, responsible for producing high-quality connections using radial riveting, orbital riveting, or roller forming methods. We provide a comprehensive array of solutions and develop processes for various joining applications with rigorous quality requirements. Our ability to do so is attributed to our extensive expertise in diverse forming technologies.

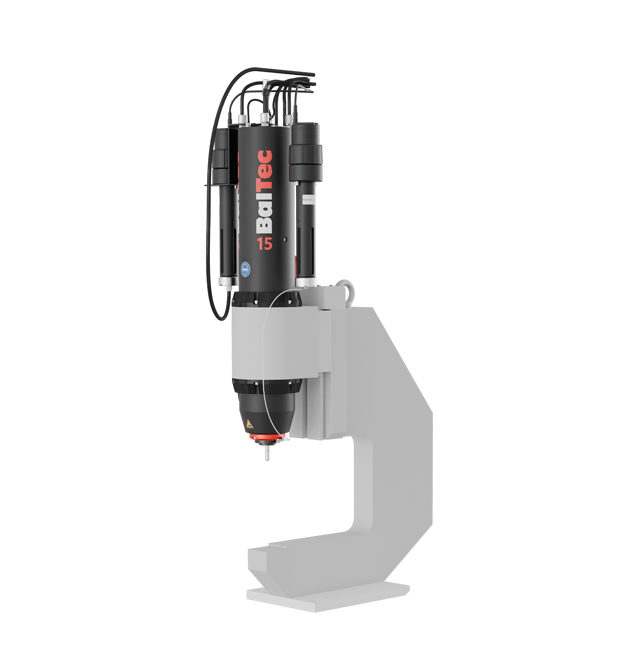

Riveting Units

BalTec riveting units are well-suited for seamless integration into automation systems, rotary indexing tables, or transfer installations, regardless of their orientation. These units offer an optimal range of capacities to ensure the efficient utilisation of their riveting capabilities. With over ten various sizes on offer, you can choose between radial and orbital riveting techniques. The selection of the appropriate riveting unit is based on the specific forming force requirements.

Work Cells

To ensure that your radial riveting machine or press operates at its peak efficiency, BalTec offers both off-the-shelf assembly equipment and tailor-made solutions designed to meet all your production needs. BalTec specialises in creating efficient workcells and has a team of experienced designers capable of guiding your assembly equipment system from its initial concept to full realisation.

Control & Monitoring

Whether it's the automotive, electronics, consumer goods, hardware, or medical technology sector, the foundation of any prosperous industrial production lies in the supervision and regulation of forming processes. BalTec has been providing their patented process control solution for more than two decades, initially designed for radial riveting and now implemented across all joining processes offered by BalTec.

Accessories

BalTec provides an extensive selection of accessories that can broaden the range of applications or serve as optional enhancements for expanding existing machinery. Explore our diverse collection of authentic BalTec accessories, all produced in our Swiss facility.

Third Party Products

By providing products from well-established third-party manufacturers, we enable you to procure everything from a single, convenient source. BalTec offers supplementary third-party products to enhance our product range and offer you comprehensive solutions from a single provider. These products are the specialty of other companies and serve as an extension of our line-up of devices and components.

What we offer

It is our firm belief that only a strong local presence can ensure BalTec's high level of quality and customer satisfaction. In both testing and service centers around the world, we provide support for plant manufacturers and customers during the process of determining the best joining technology or integrating machines. BalTec employees or trained representatives provide this close personal support.

Where we aim to go

The direction we wish to take in the future is determined by our position as a technology leader. To provide you with the best solution, BalTec refines and advances existing technologies as well as develops new possibilities. Providing solutions for challenges in joining technology is also key for BalTec, which works closely with partners and customers. We have created a new benchmark in process monitoring with the patented HPP-25 and the latest, electric product line.

We are BalTec

What is our greatest strength? The key to our success is our committed and motivated employees, many of whom have gained years of experience. A single goal drives us all together: the satisfaction of our customers.

Images