Company details for:

Carbolite Gero Ltd

Quick Links:

Products / Services

AriesPlus Temperature Controller | Carbolite

The AriesPlus touch screen controllers provide programmable control, allowing up to 99 segments to be configured as ramps, steps, or dwells, with the option to control relays.

Featuring a capacitive touch screen, the AriesPlus series offers an intuitive interface for selecting and editing program profiles, scheduling programs to run at specific dates and times, logging setpoint and actual temperature data, choosing the display language, and managing user-level security.

The controllers can store and recall up to 50 unique program profiles. Data is logged to internal memory, which can be accessed via the built-in USB port or downloaded to a PC over a network. Ethernet connectivity is included as a standard feature.

Technical Service Plans

Our customers and their applications are diverse, but they share one essential requirement: unwavering reliability. The solutions we provide are designed to deliver top-level performance, ensuring accurate and consistently repeatable outcomes.

At Verder, we recognise that our products play a vital role in your quality assurance and R&D workflows. Whether you handle large volumes of samples daily or just a select few, you depend on equipment that performs with precision every time. That’s why routine maintenance is so important — not only to resolve problems, but to proactively prevent them and keep your operations running smoothly.

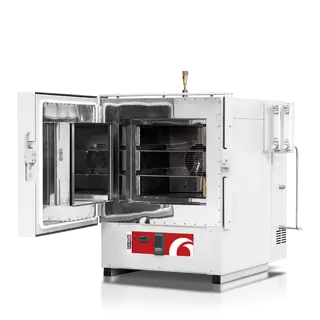

Laboratory Ovens

Carbolite produces a variety of laboratory ovens designed for everyday lab use. These models are well-suited for general laboratory processes and routine heating tasks, offering exceptional temperature consistency and meeting the safety requirements of BS EN 61010-2-010:2003.

Each oven can be customised with a range of optional features to suit specific customer needs. Available options include over-temperature protection, adjustable shelves and runners for diverse applications, digital timers, and advanced temperature control or programmable systems for precise operation.

Industrial Ovens

Carbolite produces a broad selection of industrial ovens designed for batch processing. These models can operate at temperatures up to 700°C and are available in sizes exceeding 13,000 litres. Built with durable materials and a strong construction, the ovens are well-suited for demanding, heavy-duty applications.

Each unit can be customised with various optional features, such as advanced temperature control systems and specialised loading or handling solutions to meet specific process requirements.

Clean Room Ovens

Clean room ovens are specifically engineered for use in ISO 14644-1 compliant environments. Carbolite’s clean room ovens incorporate particle-free silicone rubber door seals, completely sealed insulation, and a fully enclosed brushless fan motor to eliminate particulate contamination. Their stainless-steel interiors and smooth, gloss white epoxy exteriors are designed for easy cleaning and maintenance.

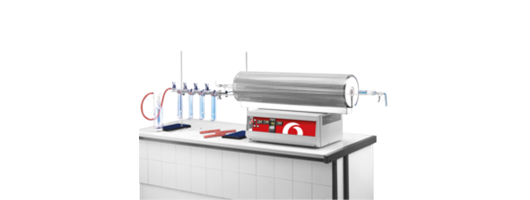

Controlled Atmosphere Oven - HTMA

The HTMA series consists of high-temperature ovens designed for operation in inert atmospheres, with maximum temperatures of up to 700°C.

They feature independent flow controls for purge and process gases, allowing efficient purging of atmospheric air before switching to lower process gas flow rates.

Gas selection can be managed manually or through an optional automatic programmable control system. Under optimal conditions, oxygen levels as low as 50 ppm can be achieved.

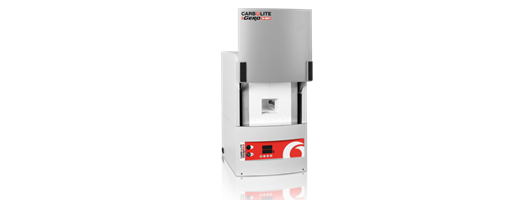

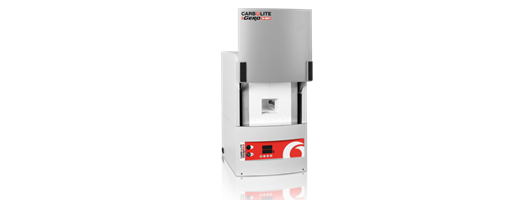

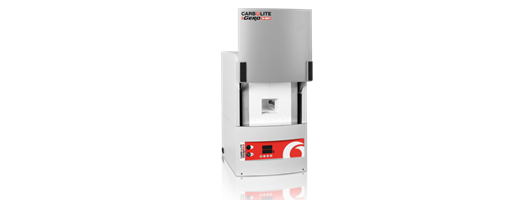

Laboratory Furnaces

Carbolite offers a comprehensive selection of chamber and muffle furnaces suitable for a wide range of laboratory applications.From compact, bench-mounted, cost-effective models to premium high-temperature furnaces, there is an option to suit every budget and requirement. The range spans from entry-level ELF models operating up to 1100°C to the laboratory-scale HTF furnaces capable of reaching 1800°C. With over eighty years of experience supplying quality furnaces worldwide, the Carbolite name has become synonymous with advanced heat technology.Whether you require a front, top, or bottom-loading furnace, Carbolite’s extensive product range ensures an appropriate standard model is available. Additionally, the company’s custom design service enables the creation of tailored solutions for virtually any application.

Industrial Furnaces

Carbolite provides a wide selection of industrial furnaces designed for batch processing. Each furnace is engineered for durability, safety, and ease of maintenance. The range includes models from compact, bench-mounted units to large, floor-standing furnaces with heating chamber capacities exceeding 3000 litres, and maximum operating temperatures of up to 1800°C.To meet specific customer requirements, Carbolite furnaces can be configured with a variety of optional features. Depending on the model, available options may include over-temperature protection, digital control systems, multi-segment programmers, and data logging capabilities. Browse the industrial furnace range below for detailed product information.

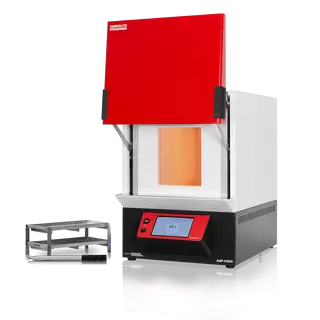

Ashing Furnaces

Carbolite’s range of ashing furnaces is designed for one of the most frequent laboratory furnace applications — heating combustible materials to examine the remaining ash residue. Since ashing and burn-off requirements vary, the range includes several furnace models specifically tailored to suit different analytical needs.

Annealing Furnaces & Ovens

Carbolite provides an extensive selection of annealing furnaces and ovens, ranging from standard models to fully customised designs. Below, you can explore suitable products categorized by operating atmosphere, along with a general overview of the available solutions.

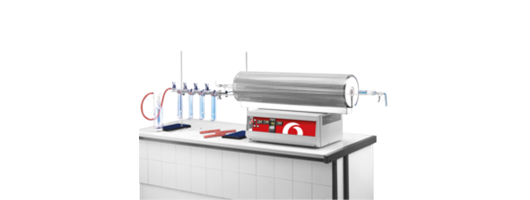

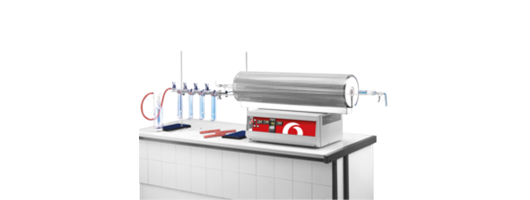

Universal Tube Furnaces

Carbolite’s tube furnaces offer maximum operating temperatures ranging from 1100°C up to 2600°C, depending on the specific model and the type of heating elements incorporated in their design.

Split Tube Furnaces

A split tube furnace is designed to open, making it simple to insert or remove work tubes and reaction vessels. Carbolite’s TS split tube furnace series features a two-part construction connected by hinges and equipped with pneumatic dampening struts to facilitate smooth and easy opening.

Rotary Tube Furnaces

Rotary furnaces are well-suited for physicochemical processing.

The TSO rotary tube furnace is ideal for laboratory use, enabling the processing of material batches. Developed in collaboration with Imperial College of Science & Technology in London, it allows samples to be heated and mixed simultaneously within a controlled atmosphere.

The TSR rotary tube furnace also heats and mixes materials in a controlled atmosphere, with the material continuously moving through the work tube. It features three heating zones, adjustable rotation speed, a tilting mechanism, and a removable work tube. Both ceramic and metal work tubes are available, and the TSR can be equipped with feeders and inert gas systems for specialised applications.

TG Gradient Tube Furnace Range

These compact split tube furnaces are engineered to create a temperature gradient along the length of the heated zones. They utilise free-radiating wire elements embedded within the furnace insulation, offering flexibility: with the use of tube adapters, a single furnace can accommodate a range of tube diameters.

The furnace is constructed in two hinged halves, with pneumatic dampening struts at each end for smooth opening. This split design simplifies the insertion and removal of work tubes or vessels, such as reactors with end flanges, which would be difficult to handle in a standard, non-split furnace.

The TG2 model features a 25 mm unheated zone between two 200 mm heated zones, while the TG3 has two 75 mm unheated zones separating three 150 mm heated zones. Each heated zone is independently controlled with its own thermocouple and temperature controller.

Accessories & Configurations

Carbolite offers a broad selection of work tube accessories for its tube furnaces.

To ensure the appropriate accessories are provided, please indicate the furnace model (horizontal or vertical), work tube dimensions (inner diameter, outer diameter, and length), and the intended operating temperature. If you are unsure which accessories best suit your application, our application specialists are available to provide guidance.

Vacuum Chamber Furnaces

At Carbolite Ltd, we are a leading manufacturer of vacuum chamber furnaces, providing high-performance solutions for precision heating applications in controlled environments. We design our vacuum furnaces to deliver exceptional temperature uniformity, reliable operation, and precise control over atmospheric conditions, making them ideal for processes such as degassing, sintering, brazing, and heat treatment of sensitive materials. Built with robust construction and advanced technology, our vacuum chamber furnaces ensure safety, efficiency, and reproducibility, meeting the exacting demands of modern laboratories and industrial applications.

Vacuum Hood Furnaces

At Carbolite Ltd, we design and manufacture vacuum hood furnaces, providing reliable and efficient solutions for high-temperature processes in controlled atmospheres. We engineer our furnaces to combine the benefits of a vacuum environment with effective fume extraction, making them ideal for applications such as material processing, sintering, and heat treatment where both contamination control and operator safety are critical. Our vacuum hood furnaces are built for durability, precise temperature control, and ease of use, ensuring that we deliver consistent, high-quality results for laboratory and industrial operations.

Vacuum Bottom Loader Furnaces

At Carbolite Ltd, we design and manufacture vacuum bottom loader furnaces, offering advanced solutions for high-temperature processes that require controlled atmospheres and safe, efficient handling of materials. Our bottom loader design allows for easy loading and unloading of heavy or bulky workpieces while maintaining the integrity of the vacuum environment, making these furnaces ideal for applications such as brazing, sintering, degassing, and heat treatment of sensitive or reactive materials. We focus on precision temperature control, robust construction, and user-friendly operation to ensure consistent, high-quality results for both laboratory and industrial applications.

Vacuum Laboratory Furnaces

At Carbolite Ltd, we design and supply vacuum laboratory furnaces, providing precise and reliable solutions for high-temperature processes in controlled environments. Our laboratory vacuum furnaces are ideal for applications such as degassing, sintering, brazing, and heat treatment of delicate or reactive materials, where exact temperature control and atmospheric integrity are critical. We focus on delivering robust construction, user-friendly operation, and exceptional temperature uniformity, ensuring safety, efficiency, and reproducible results for research, development, and small-scale industrial applications.

Vacuum Tube Furnaces

At Carbolite Ltd, we design and manufacture vacuum tube furnaces, offering high-precision solutions for controlled-atmosphere processing of materials. Our vacuum tube furnaces are ideal for applications such as sintering, degassing, brazing, and heat treatment, where maintaining a clean, contaminant-free environment is essential. We build our furnaces for durability, precise temperature control, and ease of use, ensuring consistent performance and reproducible results. With a focus on safety, efficiency, and flexibility, our vacuum tube furnaces meet the demanding requirements of both laboratory research and industrial processes.

Asphalt Binder Analyser - ABA

The ABA 7/35B is designed to determine the asphalt binder content in hot mix asphalt (HMA) using the loss on ignition method, in line with AASHTO T 308-10, ASTM D6307-19, and BS EN 12697-39:2020. It features an integrated microprocessor-controlled weighing and calculation system, which can be configured to accommodate variations of the standard asphalt binder test method. Test results can be accessed both in printed form and via software. A high-temperature afterburner reduces the emission of harmful fumes, and the asphalt binder analyzer comes complete with two sets of sample baskets.

MTT - Carbon14-Tritium Furnaces

This equipment employs catalyst-assisted combustion to provide a clean and precise method for extracting carbon-14 and organically bound tritium, also known as “fixed tritium,” from materials such as concrete, steel, graphite, and “free water.” A catalyst ensures the complete combustion of all thermal decomposition products, which are then collected for liquid scintillation analysis. This method offers more reliable combustion than traditional “wet oxidation” techniques and prevents colored contamination of scintillation media from botanical samples. Computer control allows for remote operation of single or multiple units, even in hazardous environments.

Coal & Coke Test Equipment

Over the years, the range of coal and coke tests performed in furnaces and ovens has expanded, and Carbolite has developed furnaces tailored to meet the specific requirements of each new standard.

As a result, Carbolite equipment is often chosen as the reference standard in coal laboratories, inspection agencies, power plants, and steelworks worldwide.

Our range supports a variety of international coal, coke, and iron ore testing methods, including ISO, ASTM, EN, BS, and DIN standards. Please refer to the Standards Overview Table to identify the appropriate furnace for a specific standard.

If you have questions about a particular test method, our application specialists are available to provide guidance.

Custom Designed Furnaces & Ovens

Even with one of the most diverse and comprehensive ranges of furnaces and ovens on the market, there are times when a standard model cannot fully meet a user’s specific needs. This is where the benefit of working directly with the manufacturer becomes evident—particularly with a company like Carbolite, which has extensive expertise and experience.

We can easily provide quotes for modifications or fully custom-built furnaces and ovens. These may range from simple adjustments, such as making a standard product slightly larger or smaller, or increasing its maximum temperature, to more complex designs required for specific test methods or compliance with standards such as AMS 2750G or Nadcap for heat treatment.

In these cases, Carbolite has the skills and experience to adapt our standard designs or engineer bespoke solutions to ensure the required levels of compliance. Below are a few examples of the types of furnace and oven modifications we can provide.

301 Standard Controller

The 301 PID furnace controller features a large display positioned behind a smooth, easy-to-clean membrane and provides a single ramp to the set point.

It also includes a 99-hour process timer, which can be set for a delayed start or used as a countdown timer during the process.

About us

At Carbolite , we are proud to be the UK’s leading manufacturer of high-performance heat treatment technology. With over 85 years of engineering expertise, we design and build premium laboratory and industrial ovens and furnaces that are trusted by research laboratories, pilot plants, and manufacturing facilities across the UK and around the world.

Our commitment to innovation, precision, and reliability has made Carbolite a name synonymous with excellence in heat treatment. From 30 °C to 3000 °C, our solutions are engineered to meet the most demanding applications across a wide range of industries - including aerospace, automotive, ceramics, glass, chemistry, steel, energy, food, electronics, and materials research.

Here at Carbolite, our experience in heat treatment has allowed for high-quality innovations to be utilised in research laboratories, pilot plants, and manufacturing sites across the UK and beyond. We offer one of the most comprehensive and advanced product ranges in the industry. Our portfolio includes laboratory ovens, clean room ovens, industrial ovens, atmosphere-controlled ovens, ashing furnaces, annealing furnaces, split tube furnaces, vacuum furnaces, precious metal furnaces, soldering furnaces, crystal growth furnaces, dental furnaces, and many more.

Our operations span two centres of excellence: our headquarters and manufacturing facility in Hope Valley, UK, and our specialist high-temperature site in Neuhausen, Germany. While our UK site focuses on ovens and furnaces up to 1800 °C, our Neuhausen facility is dedicated to advanced systems for vacuum and modified atmosphere applications, enabling heat treatment processes up to an impressive 3000 °C. Together, these sites allow us to deliver a complete spectrum of heat treatment solutions.

Carbolite has built a strong and lasting reputation for professional engineering expertise and a customer-first approach. We pride ourselves on delivering not just products, but complete solutions - tailored to meet the specific needs of each client. From initial consultation to after-sales support, we are committed to providing an exceptional customer experience at every stage.

At Carbolite, we’re not just heating materials - we’re enabling progress.

Images

Videos

Articles / Press Releases

Brochures

Reviews

Trade Associations