Company details for:

Colwall Conveyor Systems

Unit C, Leamore Close,

Leamore Industrial Estate,

Bloxwich,

Walsall,

West Midlands,

WS2 7NL,

United Kingdom

Quick Links:

Products / Services

Bespoke Conveying Solutions

Slat & Modular Plastic Belt

Diverter, Combiner & Merge Systems

We have many years of experience in merging, diverting, and combining some of the most difficult products. We also have the ability to test your product during the proposal process to confirm the best method in which to handle your product. The basic premise of merging, diverting, and combining is to create lanes of slugged back to back product of a predefined length then merge or divert lines of slugged product into a single or multiple lane. The lanes are controlled using a product stop and a photocells to ensure accuracy of flow.

Other modules for redirecting pallet or carton loads include:-

- Chain Transfers and Pneumatic Pushers

- Turning Units and Ball Tables

- Turntables and Transfer Cars

Various parameters of product identification prior to diverting can be employed such as Bar code reading, RF tags, product size, colour, count, weight, etc.

Belt Conveyors - Horizontal & Inclined

CCS belt conveyors are designed to be modular in construction to support prompt and short delivery periods without compromising quality. Where customers have a specific application or are operating in difficult environmental conditions, bespoke belt conveyors can be tailored accordingly with to specific widths, lengths, finishes with fixed or variable drive to suit.

Belt Conveyors are used to convey a great variety of products including loose loads, small or fragile goods, a combination of unit sizes, sacks and parcels along horizontal, declining or inclining paths. Integrated controls can be designed and manufactured by CCS control engineers, fitted and tested to provide complete handling solutions from one source and are available with accessories such as side and directional guides, product hoppers, optional belt finishes, etc.

Elevators & Lowerators

Elevators can be purchased as stand alone equipment or can be fully integrated into an existing package handling system Other types of elevator/lowerators are available and can also be supplied for boxes, pallets etc including:-

- S Bend Elevators

- Continuous Platform Elevators

- Reciprocating Platform Elevators

- Spiral Elevators

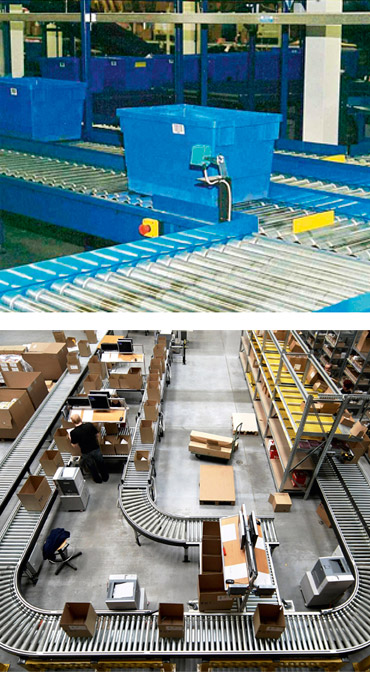

Powered Roller & Accumulation Systems

The modular design allows for cost effective integration of units to create highly efficient and adaptable handling systems to transport and accumulate cartons, totes, and other palletised products for off-load, release to other work stations, order picking or into a sortation conveyor systems. From simple light duty lineshaft driven systems through to heavy duty or chain driven conveyors for handling a wide range of products up to 1500kg.

Colwall Conveyor Systems design and manufacture the following conveyor modules:-

- Lineshaft - Light, Medium, Heavy Duty

- Motorised Roller Conveyor

- 24 volt Zero Line Pressure Roller Conveyor

- Belt Under Roller Conveyor

- Pallet Conveyor

In the more sophisticated conveyor solutions, there is often a demand for individual flow control and tracking of items, as well as minimum pressure contact or zero-pressure contact accumulation. Non-contact, zero pressure accumulation conveyors are the ideal solution, especially where delicate or varying shapes and sizes of product are to be queued to avoid damage or jamming of products on the conveyor.

If you need assistance in product selection best suited to your application, we can use our expert knowledge to ensure you make the right decision.

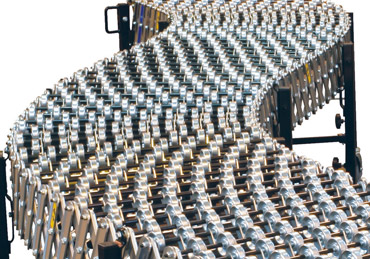

Gravity Roller & Skatewheel

Pallet Conveyor Systems

Gravity Roller - designed for free running of pallets, these gravity operated roller conveyors provide a relatively low cost method of pallet storage and transportation. Available in mild or stainless steel, the conveyors can be supplied in various widths, lengths, roller diameters and pitches to suit individual applications. Braked rollers can also be supplied to slow pallets down on decline applications.

Powered Roller - CCS offer a wide range of stainless steel or painted mild steel pallet conveyor products to create customised pallet handling systems for semi or automatically loading/unloading and accumulation. These can be based on modular designs to provide a simple and cost effective installation or alternatively, a bespoke solution can be proposed for the handling of pallets or tote bins.

Pallet conveyor systems can incorporate:

- Accumulation Roller Conveyors

- Steel Chain Conveyors

- Pallet transfers and turntables

- Pallet Dispensers/Stackers

- Pallet lifts

A full range of powered roller and chain conveyors are available together with all necessary ancillary equipment such as weigh stations, scissor lifts, work stations etc and can be supplied with full controls and software, project management, installation and technical support to optimise a customer's specific requirements.

Feasability, Design & Layout Services

Our extensive knowledge of the automated material handling industry and in-house experience enables CCS to design, manufacture, install and provide final commissioning of conveyor systems for most application. Whether it is for a complete integrated conveyor system or individual conveyor modules to integrate with packaging equipment, refurbishment or modification to your existing conveyor system, CCS can provide an ideal handling solution.

CCS can supply cost effective standard conveyor products or design, manufacture and install innovative bespoke equipment which can be provided either as stand-alone products or as a part of a standard system.

Full Turnkey Project Services

No two materials handling requirements are identical and that is why our conveyors come in a wide range of shapes, sizes and finishes designed to suit a variety of industries and specific applications. These range from standard off-the-shelf based systems to unique bespoke designs to meet your exact needs and provide the best solution for your business.

At CCS we are able to identify the optimum solution to meet your needs and provide turnkey solutions to meet your handling requirements and financial budgets. Our team of highly experienced design and project engineers is on hand to discuss, design and specify the appropriate equipment to ensure project parameters are met.

Automation & Control

Each system takes into account the customer requirements and their site standards by selecting the appropriate design philosophy and components.

We offer:

- Fully automated PLC control systems

- Control panels

- Software

Installation & Commissioning

CCS offer a full mechanical and electrical installation service through its team of experienced team of installation and service engineers. This extends through installation, commissioning and service/maintenance contract if required.

All conveyors and conveying systems come fully backed up with full documentation - as built layouts, electrical hardware drawings, software, operating and spares manuals. Training can be provided on larger projects.

After Sales Services

It is important that customers protect their investment in equipment and materials handling systems by ensuring regular and scheduled maintenance. At CCS, we offer a high level of expertise in both electrical and mechanical services including maintenance advice, spare parts supply or site service in order to ensure systems operate trouble free, without the costly disruption created by downtime.

We can offer

- Scheduled maintenance contracts

- On site relocation and commissioning

- Electrical programming and trouble shooting

Steel Fabrication Division

About us

Sponsored Links

Articles / Press Releases

Trade Associations