Company details for:

McCarthy Environmental Ltd

Quick Links:

Products / Services

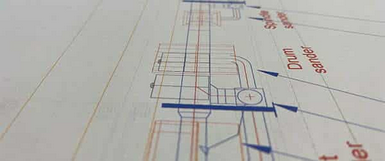

LEV System Design Consultancy

We offer comprehensive Local Exhaust Ventilation (LEV) design consultancy, guiding projects from initial concept to fully specified, compliant system designs. Whether you need a centralised system or a single extraction point, our custom solutions include detailed 2D and 3D modelling for precise planning and competitive tendering.

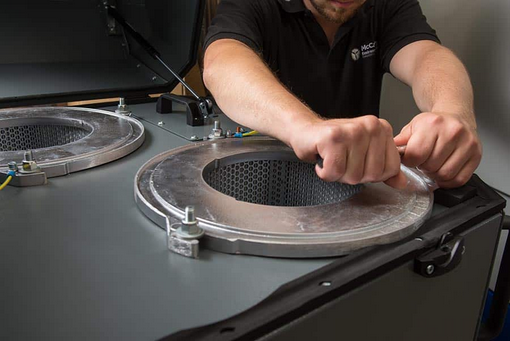

Installation & Commissioning

Our in-house installation teams carry out LEV system installations to the highest standards. All engineers are fully trained, certified in the necessary disciplines, and follow safe working practices while ensuring equipment and ductwork comply with current regulations.

LEV Electrical Interfacing

LEV interfacing installations offer a cost-effective solution to lower energy use and CO₂ emissions from Local Exhaust Ventilation, helping achieve sustainability targets while also minimising excessive workplace noise.

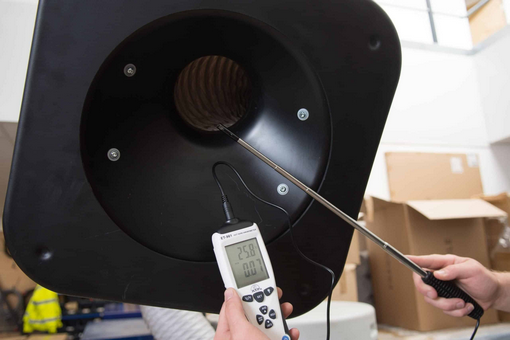

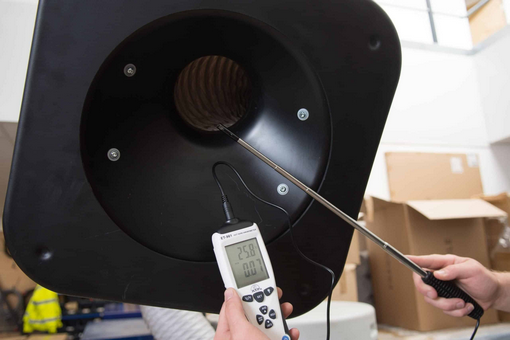

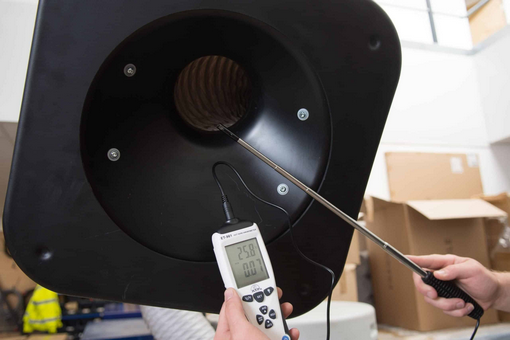

LEV Testing

We offer a comprehensive nationwide COSHH/LEV testing and inspection service in line with HSG258 guidelines, ensuring all your extraction and LEV systems operate efficiently, function correctly, and remain fully compliant.

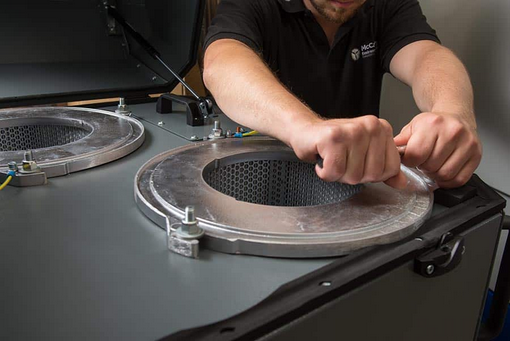

Service & Maintenance

Have you thought about a Service Contract? Equipment breakdowns can be costly, and to ensure smooth operation, regular maintenance is essential to identify and prevent potential issues before they occur.

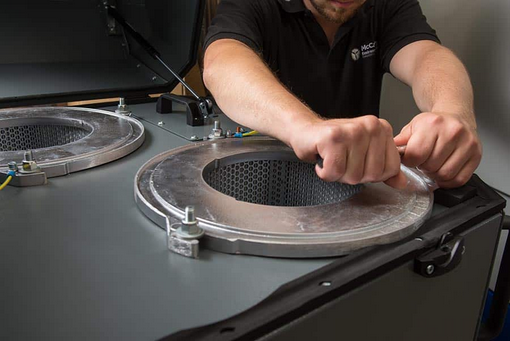

Spares & Consumables

Need Spares?

Check out what McCarthy Environmental can provide.

The filter is the core of any extractor. A damaged, worn, or improperly fitted filter can allow dust to bypass, defeating its purpose, while a blocked filter reduces airflow and compromises control of emitted substances.

BOHS Endorsed LEV Training Centre

The McCarthy Environmental Centre of Excellence, located at our Swan Valley headquarters, is unique in the region and provides a variety of LEV (local exhaust ventilation) and Occupational Hygiene courses.

Extraction Systems & Units

Under the COSHH Regulations 2002 (as amended), employers are legally required to protect employees by preventing or controlling exposure to any workplace contaminants classified as substances hazardous to health.

Dust Extraction

Many industries and processes produce dusts considered hazardous to health. It is well established that exposure to these dusts can cause a range of health problems, so they must be prevented or properly controlled in accordance with the COSHH Regulations 2002 (as amended).

Fume Extraction

Our fume extraction (LEV) systems are engineered to efficiently manage and reduce exposure to hazardous fumes, vapours, gases, smoke, and aerosolised solids.

Oil Mist Extraction

The COSHH Regulations 2002 (as amended) mandate that exposure to metalworking fluids—whether by inhalation, ingestion, or skin contact—must be prevented where possible, or, if prevention isn’t feasible, effectively controlled.

Industrial Vacuum Systems

Industrial vacuum systems are available in a wide range of types and sizes, serving numerous industries including food production, CNC machining, general construction, and many others.

Absolent A•erity Range

Our flexible design allows for customised solutions tailored to specific requirements. Depending on airflow and particle load, units can be adjusted or converted, handling 500–40,000 m³/h of airflow and particle loads from 70 mg/m³ to 10 mg/m³. Each system is modular, with a main unit configured based on flow and particle load, and additional sub-units can be added or removed as future needs arise. All units feature IE5-class EC motors for optimized energy efficiency and safer operation.

Absolent A•line Range

With A•line, you get a versatile, adaptable filter suited to your specific needs. It works equally well for small, demanding machines or those producing a moderate amount of oil mist in the workshop. A•line is future-ready—changes in coolant, cutting speed, or pressure won’t affect its performance. Plus, it features intelligent monitoring equipment that delivers the right amount of airflow exactly where and when it’s needed.

Absolent A•smoke Range

When running CNC machines at high speeds or with high coolant pressure, or during die casting or hardening, the machines can produce thick oil smoke made of tiny particles. These particles can penetrate surfaces and even enter the bloodstream. A similar issue occurs with minimal quantity lubrication (MQL). To effectively remove this type of pollution, a robust filter like A•smoke is essential.

AirBench BD Downdraught Bench

The Airbench BD is a self-contained blow-down station designed for workplaces needing to remove coolant mist, swarf, and other contaminants. The suction system is operated via a foot pedal, which controls the compressed air gun, allowing the user to manually dislodge debris. A polycarbonate screen prevents mist and droplets from escaping.

Two models are available: the BD500 (500mm width) and BD1000 (1000mm width). Both operate solely using a compressed air source, requiring no electrical power.

Airbench FN – Heavy Duty Downdraught Benches

The Airbench FN series are heavy-duty downdraught benches with a fully ventilated top surface. They can be supplied with custom filter configurations to suit specific needs, and the filters are easily accessible via a hinged front panel. Each bench includes a pressure loss gauge to monitor filter condition, with optional speed control available.

To ensure the benches meet your specific workplace requirements, please contact us before purchasing at 01604 635333 or enquiries@mccarthy-environmental.co.uk

AirBench FP – Higher Surface Loadings Downdraught Bench

The Airbench FP series consists of five heavy-duty downdraught benches, specially designed for industrial workplace use.

Airbench FPK – Downdraught Bench with Kneespace

The Airbench FPK series of heavy-duty downdraught benches are designed for both dust and fume applications and are ideal for tasks where the user is seated for extended periods. Available in five standard sizes, the benches feature a perforated top for easy access to filters for removal and maintenance, and a pressure loss gauge allows operators to monitor filter condition efficiently.

User control options range from a simple on/off switch for single units to centrally controlled or timed operation, with the ability to daisy-chain multiple units. The top surface is almost fully ventilated, ensuring consistent extraction quality across the entire bench for efficient work.

To ensure the benches meet your specific workplace requirements, please contact us before purchasing at 01604 635333 or enquiries@mccarthy-environmental.co.uk

Airbench FPW/FPT – Welding & Grinding Downdraught Bench

The Airbench FPW and FPT series are heavy-duty downdraught benches, with two models specifically designed for grinding and welding fume applications. Both feature a spark trap design and a three-stage filter system, extending filter life by ensuring the final filter is protected from sparks and other contaminants.

AirBench FX – ATEX Rated Downdraught Bench

The Airbench FX series features three downdraught ATEX-rated benches, ideal for use in areas classified as potentially explosive under DSEAR regulations. The FX series is specifically designed for handling dust-only applications.

AirBench RP – Self-Cleaning System Downdraught Bench

The Airbench RP series of downdraught benches is ideal for applications generating high volumes of non-explosive dust, particularly stone dust. The benches feature on-demand compressed air filter cleaning and are available in various sizes and configurations to meet specific requirements.

Airbench VertEX Cross-Draught Extraction Systems

The Airbench VertEx cross-draught extraction series consists of modular wall units, starting with a single 1200×600 module that can be expanded to create walk-in dust and fume extraction booths of any size. Suitable for sanding, grinding, and fume applications, these modules can serve as the foundation for a full extraction booth. When combined with VP or VertEx VA units, the modular booth becomes a complete dust extraction system, featuring high-efficiency EC fans and a pressure gauge.

DENA 26 CY Cyclone Dust Extractor

Cyclone dust extractors can achieve abatement efficiencies of 85%–95% and are ideal for dust with a specific weight over 300 kg/m³. They are particularly effective for coarser particles, handling dust larger than 10 µm for weights of 1000–1500 kg/m³, and over 50 µm for dust around 500 kg/m³.

DENA AT-JET

The mobile AT1-JET filter is the most compact model in the range, handling airflow up to 1,450 m³/h. It is available with or without an extraction arm and comes standard with an automatic cartridge cleaning system using compressed air jets.

About us

With more than 25 years of experience, McCarthy Environmental Ltd, headquartered in Northampton, has earned a strong reputation as a nationwide expert in air pollution control solutions for industrial, educational, and commercial environments.

We design, install, and commission a variety of dust, fume, and ventilation systems tailored to your specific needs, with all our system designers fully qualified to BOHS P602 standards.

Our installation teams are highly trained and fully certified to ensure safe work on customer sites, and the company maintains CHAS accreditation.

Our Product & Services Include:

LEV System Design

We offer comprehensive LEV design consultation packages, covering everything from initial concept to final design and specifications, including 2D and 3D modelling, allowing you to competitively tender your project.

LEV Products

We collaborate with a range of LEV manufacturers to provide the ideal solution for your dust, fume, or oil mist applications, including ATEX, W3, and HEPA options.

LEV Installation

Our in-house installation teams handle LEV system installations to the highest standards, with engineers fully trained and certified in all necessary disciplines to ensure safe working practices.

LEV Testing

We provide LEV system testing to ensure compliance with COSHH Regulation 9, carried out by our fully qualified and experienced engineers on all LEV systems and equipment.

LEV Servicing & Maintenance

A service contract can help extend the lifespan of your LEV system. Regular maintenance prevents avoidable failures and increases the chances that your system remains fully operational and compliant.

LEV Awareness

Delivered by BOHS-qualified staff either at our Northampton training facility or on-site, LEV awareness training equips participants with a clear understanding of the key aspects of LEV systems.

Based at our Northampton headquarters, McCarthy Environmental Ltd provides a complete range of services, including the design, supply, installation, and commissioning of LEV systems, occupational hygiene monitoring (personal air and noise assessments), scheduled maintenance, emergency repairs, and spare parts supply and fitting. Partnering with leading manufacturers such as ESTA, DUSTCONTROL, Nederman, BOFA, Filtermist, Airbench, Absolent, and Kemper, alongside our bespoke manufacturing capability, we deliver cost-effective turnkey solutions for all dust and fume extraction needs.

Our LEV test engineers are trained to the latest BOHS P601 standards as mandated by the HSE, enabling them to carry out Local Exhaust Ventilation (LEV) testing. This ensures that both new and existing systems continue to operate at optimal performance to protect your workforce.

Contact us to discuss your LEV requirements—our experienced and qualified team is ready to assist.

Images

Reviews

Trade Associations