Company details for:

Specialist Coatings GB Ltd

PO Box 148,

Ninfield,

Battle,

East Sussex,

TN33 3BS,

United Kingdom

Quick Links:

Products / Services

Water Tank Lining

Brewery Tank Lining

Bund Lining

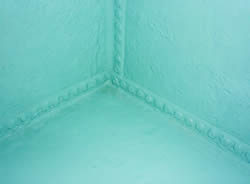

We have wide range of chemical resistant and flexible lining materials at our disposal including lining materials that are chemical resistant, UV light stable, easy clean, anti-slip and even a range of ultra fast hardening polyurea materials that are completely elastmeric and flexible for treating areas that are located on unstable surfaces such as loose shale and which can be walked upon within minutes following application.

Material Sales

Specialist Resin Floors

About us

Specialist Coatings services include cold water tank refurbishment, potable water tank lining, chemical tank & bund lining, fuel storage tank lining, plant hygienic coatings, black water tank lining, swimming pool lining, water treatment tank lining, high temperature coatings, wooden fermentation vat lining, tank lining repairs, steam condensate return tank lining, effluent tank lining, food grade epoxy lining, brewery tank lining and acid tank lining.

SCGB offer a comprehensive service for the on-site lining for all types of industrial storage and process tanks. We are able to carry out a range of different surface preparation treatments prior to applying the new lining system. We have lining materials suitable for potable water and food contact applications. We have materials suitable for a wide range of chemical and temperature environments.

Specialist Coatings have a range of materials can be applied to a wide range of different substrates including mild steel, stainless steel, fibreglass and concrete. We have materials that can even be applied underwater. We have materials applied to damp concrete surfaces and to very new “Green” concrete.

We even have a dust-free Nu-Tank potable water lining tank system with a 48hr return to service. We have our own QA and Inspection service to check the condition of tank linings, including the coating thickness and micro-porosity.

Drawing on years of international experience in corrosion prevention, we offer a specialised, comprehensive service for the on-site lining for all types of industrial storage and process tanks, no matter how big or small.

Applying an internal lining to a tank in-situ is always more cost-effective than replacing the tank and is certainly more environmentally friendly. At SCGB we understand, however, that the ongoing purity of the contained product itself is your first and foremost priority.

By adding neutral linings to the internal surfaces of your vessel, we are able to guarantee the safe containment of your product with zero contamination.

To ensure the maximum lifespan of our service to you, our range of impervious internal linings bond permanently to mild and stainless steel, fibreglass and all types of concrete. This guarantees that the lining will last the lifetime of the vessel.

Incorporating the latest technology in corrosion prevention, we can offer you the most time-efficient solution to any storage vessel problem, with the minimum amount of disruption. We use materials and techniques suitable for a wide range of chemical and temperature environments, including underwater applications; we even have a dust-free Nu-Tank potable water lining tank system with a 48 hour return to service.

Our tank lining materials are normally based on epoxy resins, vinyl ester resins, biphenyl ester resins, MIO, fibreglass laminates and glass flake technology.

In addition to this, we also supply our own QA and inspection service checking the condition of new and existing tank linings, including the coating thickness and micro-porosity.

Although many bulk storage tanks are now located within a secondary containment bunded area, many have been constructed from materials that are not resistant to the chemicals that are being stored in the tanks or vessels located within them. In many situations the concrete is porous.

At SCGB we offer a service of secondary containment bund lining solutions. These are resistant to a wide range of chemical products used in industry, including aggressive and harsh chemical environments as well as relatively inert chemicals.

With time-efficiency and convenience at heart, we also have a range of ultra-fast hardening polyurea materials that are completely elastmeric and flexible for treating areas that are located on unstable surfaces such as loose shale. These areas can be walked upon within minutes following application.

It is essential that all liquid materials are stored correctly and safely and in the event of spillage or an accident, aggressive and harsh chemicals will be contained in the catchment area and recovered with the minimum of losses.

These measures are particularly important when considering that the Environment Agency and Europe are taking an ever closer watch regarding the Control of Major Accident Hazard prevention (COMAH) and in the event of an incident of the effect it would have on the environment.

Our secondary containment linings are normally based on epoxy resins, vinyl ester resins, biphenyl ester resins, fibreglass laminates and glass flake technology.

We also supply our own QA and inspection service checking the condition of new and existing bund linings, including the coating thickness and micro-porosity.