Company details for:

TLM Laser

Quick Links:

Products / Services

Laser Cladding

https://tlm-laser.com/laser-systems/laser-cladding/

Laser Cleaning

Cleaning using lasers is precise, fast and mess free. The dry and contact free process does not damage the underlying substrate and eliminates the use of hazardous and expensive consumables such as chemicals or blasting media.

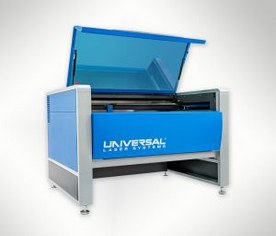

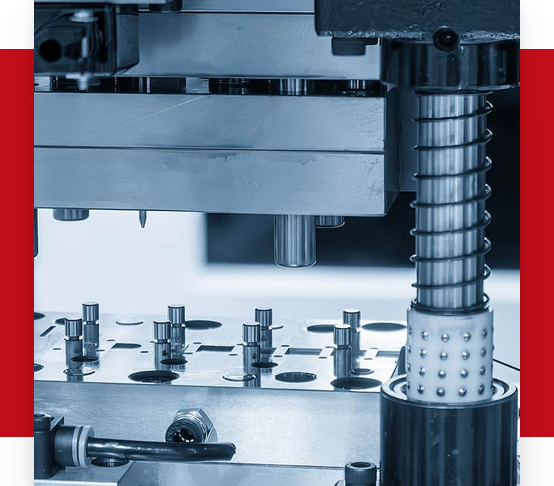

Laser Cutting

Laser cutting is a highly precise method used to cut a broad range of materials, including metals, plastics, wood, paper, cardboard, leather, and rubber. The technique involves using a laser to melt, burn, or vaporise the material, resulting in smooth, high-quality finishes.

Laser Hardening

Laser hardening is a precise, contact-free heat treatment process that enhances surface hardness and wear resistance of metals. By focusing laser energy on specific areas, this method creates a targeted hardened layer, improving durability and extending the service life of components.

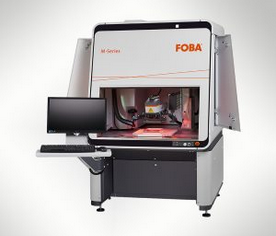

Laser Marking & Engraving

Using lasers for marking and engraving provides a permanent and high-contrast solution ideal for traceability, branding, and compliance. This precise, non-contact process works on various materials and is perfect for industries requiring reliable, detailed identification.

Laser Metal 3D Printing

3D metal printing technology is revolutionising manufacturing with its capacity for creating highly detailed and complex metal components. This additive manufacturing technology is celebrated for its precision, safety, and efficiency in handling various metals.

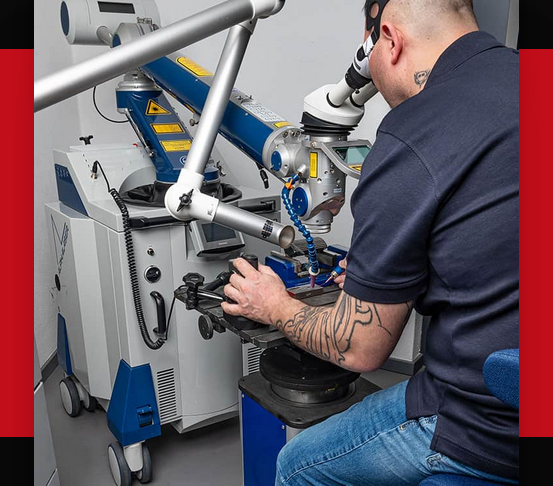

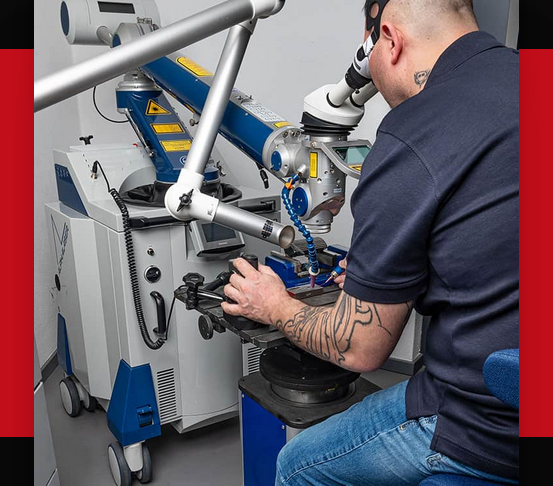

Laser Welding

Laser welding is a precise, high-efficiency joining process ideal for various industries and materials. With pinpoint accuracy, it delivers durable, high-quality welds, minimising heat distortion and ensuring consistent results for even the most complex applications.

Packaging & Converting Laser Systems

In the fast-paced world of packaging and converting, precision, speed, and adaptability are essential for meeting modern production demands. Laser systems have transformed the industry by offering contactless cutting, scoring, perforating, and marking solutions tailored for a wide range of packaging materials. TLM Laser, in partnership with LasX Industries, provides cutting-edge laser systems designed for enhanced productivity, material efficiency, and design flexibility in packaging and converting applications.

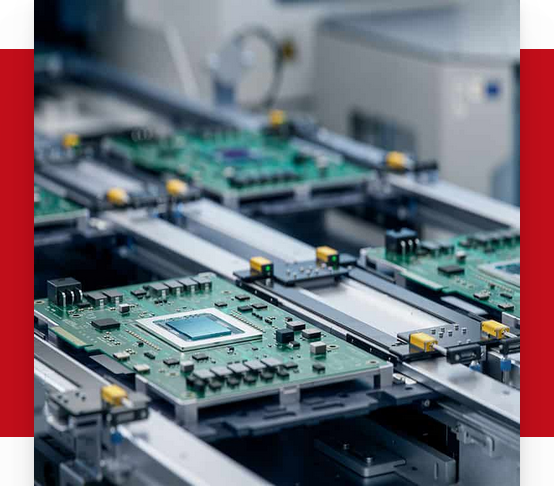

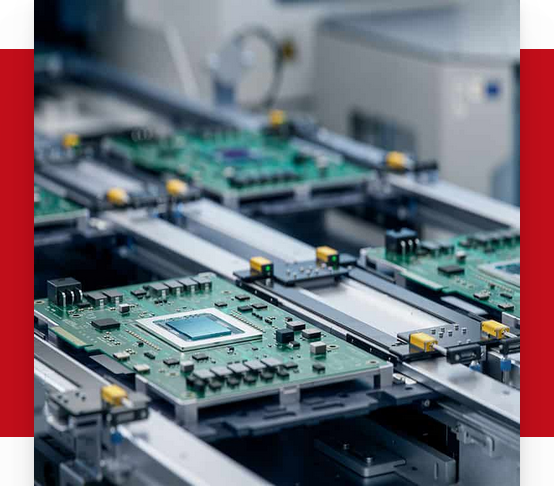

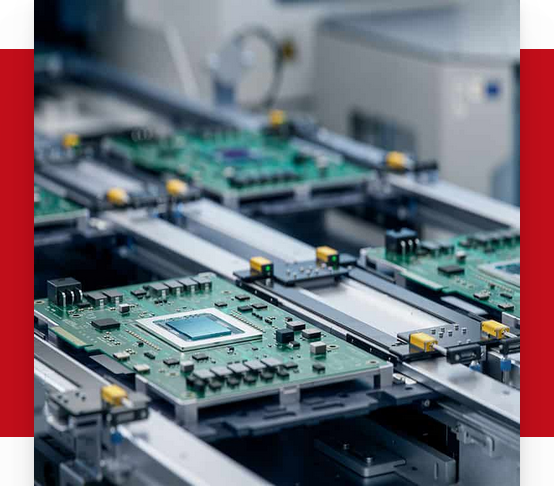

Semiconductor Processing Laser Systems

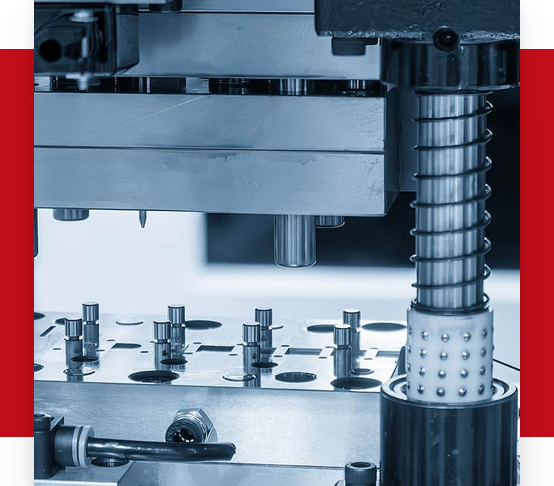

Semiconductor manufacturing demands exceptional precision, consistency, and traceability throughout the production cycle. Laser-based semiconductor processing systems provide unmatched accuracy for critical applications such as wafer marking and wafer sorting, which are essential for efficient production and quality control in the semiconductor industry. TLM Laser, in partnership with InnoLas Semiconductor, offers industry-leading solutions designed to meet the rigorous demands of this advanced sector.

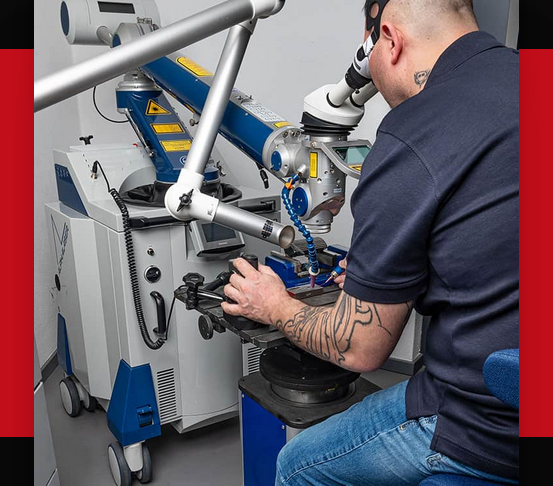

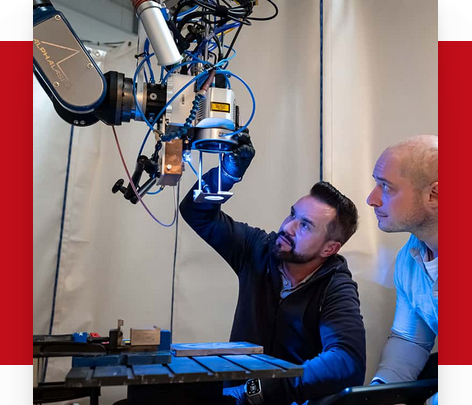

Laser Servicing & Maintenance

At TLM Laser, we understand the importance of reliable laser systems in maintaining productivity and meeting deadlines. That’s why we offer tailored servicing and maintenance solutions to ensure your systems operate at peak efficiency, minimising downtime and preventing unexpected breakdowns.

Laser Training

Empower your workforce with TLM Laser’s comprehensive laser training programmes. Our expert-led courses cover everything from laser safety protocols to advanced maintenance techniques, equipping your team to maximise machine uptime and efficiency. By building in-house expertise, you’ll reduce reliance on external technicians, slashing repair costs and boosting productivity.

Technical Support

At TLM Laser, we pride ourselves on delivering industry-leading technical support for a wide range of laser systems. With decades of experience, our team of expert engineers ensures your systems operate at peak performance, minimising downtime and protecting your production.

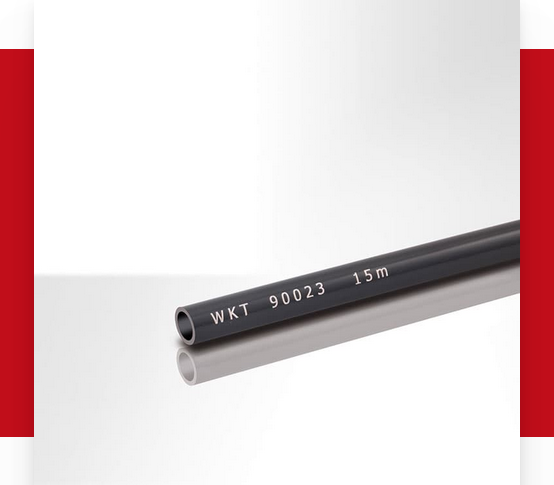

Laser Spares & Consumables

TLM Laser offers an extensive range of spare parts and consumables for all major laser systems. With fast access to high-quality products, we minimise production interruptions and maximise system reliability.

Laser Processing for Metals

From precision marking to high-strength welding and deep engraving, laser processing offers a non-contact, high-contrast solution for metals. Improve traceability, durability, and production efficiency with TLM’s advanced laser systems.

Laser Processing for Plastics

Achieve permanent, high-contrast marking, clean cuts, and strong, particulate-free welds with laser systems optimised for plastics. TLM’s solutions are ideal for industries demanding precision and compliance, such as medical and automotive.

Laser Processing for Films & Foils

Cut, kiss-cut, or mark delicate films and foils without causing distortion or burn marks. Laser processing delivers clean, burr-free edges and fine detailing, making it perfect for packaging, electronics, and graphic applications.

Laser Processing for Textiles

Enhance speed and design freedom with laser cutting and marking for textiles. Produce complex patterns, seamless cuts, and custom designs while maintaining material integrity — ideal for fashion, automotive, and industrial fabrics.

Laser Processing for Semiconductors

Precision is everything in semiconductor manufacturing. Laser systems offer reliable marking and wafer sorting solutions with micron-level accuracy, supporting cleanroom environments and strict industry standards.

Laser Processing for Organics

Laser processing is a natural fit for organic materials like paper, cardboard, wood, and leather. Cut, mark, or engrave with precision while maintaining the integrity and appearance of each unique surface.

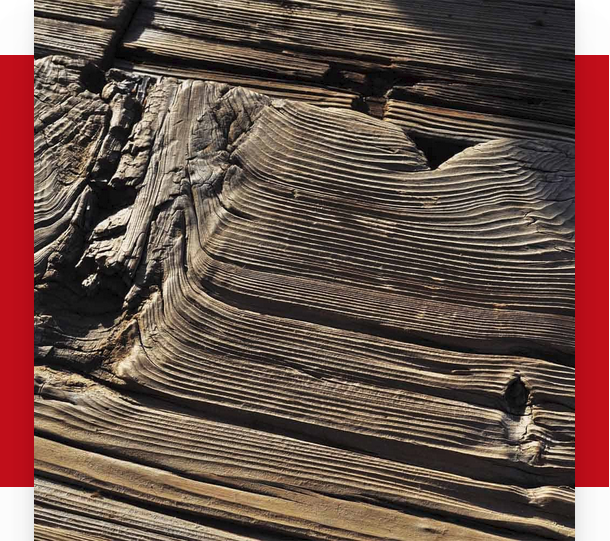

Laser Processing for Wood

From intricate engraving to clean-edge cutting and surface cleaning, laser systems handle wood with precision and care. Create custom designs, signage, or remove contaminants without damaging the material.

Laser Processing for Stone

Restore, clean, or prep stone surfaces using non-contact laser cleaning. Remove coatings, pollutants, or residues without harsh chemicals or abrasive methods, maintaining the natural integrity of the stone.

Laser Processing for Rubber

Cut, engrave, or mark rubber materials with sharp precision and clean edges. Laser systems offer high-speed processing for seals, gaskets, and custom components, all without fraying or tool wear.

Laser Processing for Leather

Perfectly suited for cutting and decorative marking, laser processing allows for detailed patterns and intricate designs on leather, enhancing quality while reducing waste in fashion, accessories, and interior design.

Laser Processing for Glass

Laser marking for glass enables permanent, high-contrast marks without compromising strength or clarity. Achieve decorative designs, data codes, or branding while maintaining the smooth, flawless surface.

Laser Processing for Cardboard

Laser cutting and marking provide clean, accurate edges and fine detailing on cardboard, ideal for custom packaging, displays, and prototyping. Achieve high-speed results with zero tool wear and minimal waste.

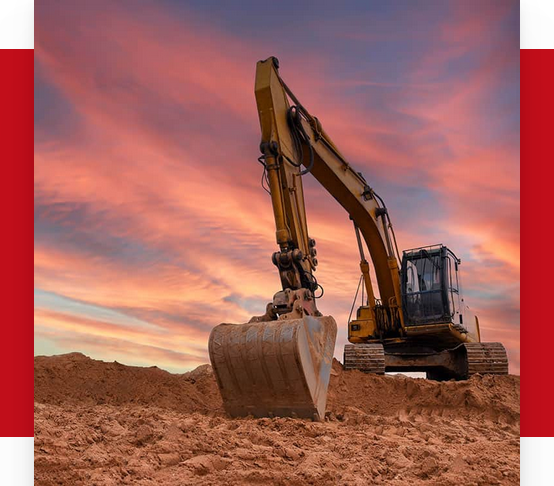

About us

TLM Laser is the top provider of advanced industrial laser systems in the UK and Ireland, offering a wide range of solutions including marking, welding, cleaning, cutting, and other applications designed to improve production efficiency and performance.

Established in January 2006, TLM Laser began with a mission to deliver outstanding laser service and maintenance throughout the UK. Evolving from a specialist service provider, we’ve become a trusted supplier for manufacturers, offering a full range of laser systems from top global technology brands.

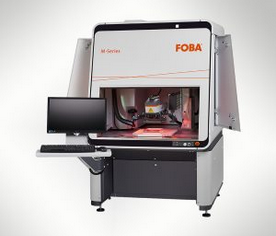

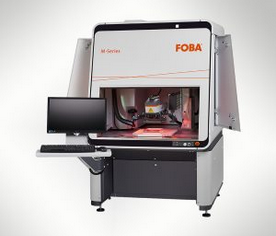

We offer a broad selection of industrial laser systems, including solutions for marking, welding, cutting, cleaning, cladding, and 3D metal printing. As the UK and Ireland distributor for leading global brands like FOBA, InnoLas, Alpha Laser, and IPG Photonics, we serve a wide range of manufacturing needs.

Our Laser Systems Include:

Laser Cladding

Laser cladding is a high-precision surface engineering technique that improves component durability and extends service life. It involves applying a metallic coating to a base material using a laser, delivering excellent wear resistance, corrosion protection, and effective repair solutions across industries.

Laser Cleaning

Laser cleaning is a precise, efficient, and clean method that removes contaminants without damaging the underlying surface. This dry, non-contact process eliminates the need for harmful or costly consumables like chemicals and abrasive media.

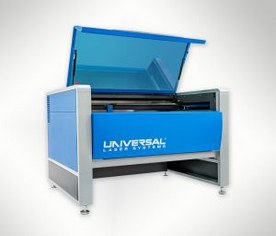

Laser Cutting

Laser cutting is an accurate and versatile technique used to slice through various materials such as metal, plastic, wood, paper, cardboard, leather, and rubber. It works by melting, burning, or vaporising the material with a laser beam, producing clean, high-quality edges and finishes.

Laser Hardening

Laser hardening is an accurate, non-contact heat treatment technique that increases the surface hardness and wear resistance of metal parts. By directing laser energy to specific areas, it forms a hardened layer that boosts durability and extends the lifespan of components.

Laser Marking & Engraving

Laser marking and engraving offer a permanent, high-contrast solution ideal for traceability, branding, and regulatory compliance. This accurate, non-contact method is compatible with a wide range of materials, making it ideal for industries needing precise and dependable identification.

Laser Metal 3D Printing

3D metal printing is transforming manufacturing by enabling the creation of intricate and detailed metal components. This additive manufacturing technology is praised for its precision, safety, and efficiency in working with a wide range of metals.

… And more.

At TLM Laser, we don’t just provide equipment; we adopt a solutions-focused approach, collaborating closely with clients to address their production challenges and offer customized laser solutions. With extensive industry experience and technical expertise, we deliver comprehensive solutions that enhance productivity, efficiency, and compliance.Our dedication to exceptional service has gained the trust of top manufacturers throughout the UK and Ireland. Whether assisting small precision workshops or large industrial plants, we remain committed to reducing downtime, optimising performance, and providing reliable, dependable service.

At TLM Laser, our drive for innovation inspires us to transform precision and efficiency in manufacturing and engineering across the UK and Ireland. Using cutting-edge laser technology, we provide not only machines but also comprehensive, tailored solutions designed to improve your operational performance.

Images