Company details for:

Wrightfield Ltd

Quick Links:

Products / Services

Bespoke & Custom Conveyors

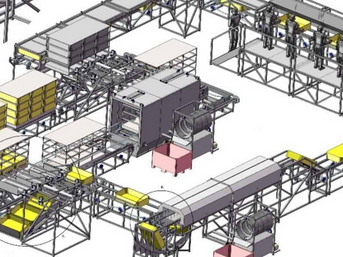

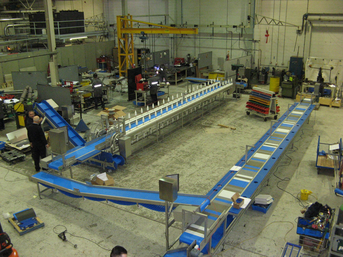

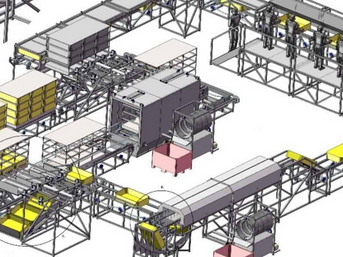

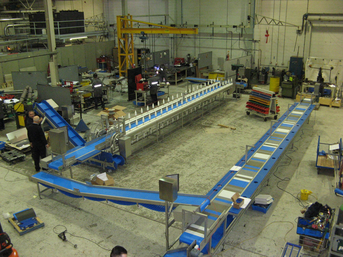

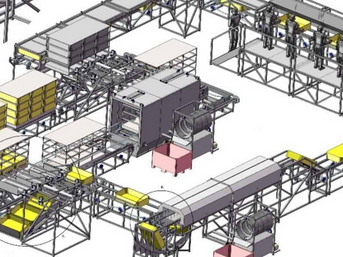

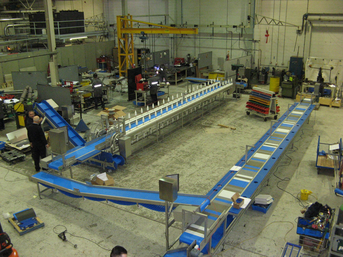

We custom design and manufacture bespoke conveyors to suit individual requirements. All bespoke conveyors are manufactured in-house at our modern UK factory.

Our approach to conveyor design is based around fully understanding the needs and operating requirements of a clients production. All bespoke designs will be presented to the customer for approval & sign-off before manufacture commences. All bespoke conveyor solutions are project managed from the initial enquiry to final commissioning. This allows you to check what stage your conveyor is at throughout the process with our professional yet friendly technical engineers

Our expertise has been built up over thirty years and our aim is to design and manufacture conveyor systems that will provide reliable performance and improve productivity.

Bi-Directional Conveyor

For conveyor belt applications that require bi-directional operation Wrightfield offers a wide range of general and food grade conveyor options. Adjacent lanes on the conveyor surface run in opposite directions while still being driven off the same line shaft.

Decline Belt Conveyors

Decline Belt Conveyors ( also called De-Elevators) are a practical and affordable solution to the declined transfer and conveyance of products and have been the mainstay of Wrightfield’s business for the last 30 years.

Many applications for conveyors require the installation to take product between two set points. These points however are rarely in line or at the same height, or even in the same room. In order to accommodate the wide ranges of process machinery required for the manufacture of any given product; many twists and turns are inevitable throughout a factory layout. This is where Wrightfield can help.

Dedicated project engineers will visit the site and thoroughly survey and discuss the exact requirements of the conveyor solution needed.

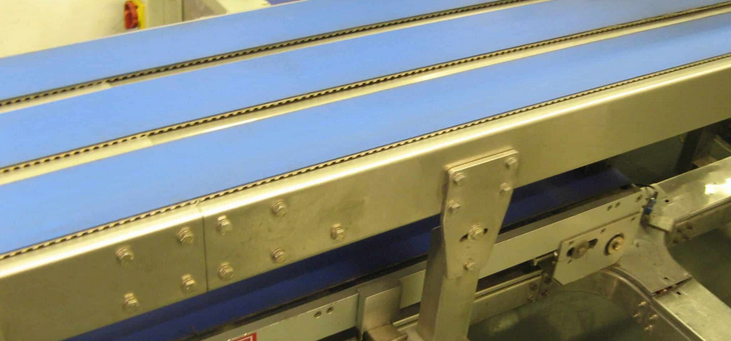

Flat Belt Conveyor

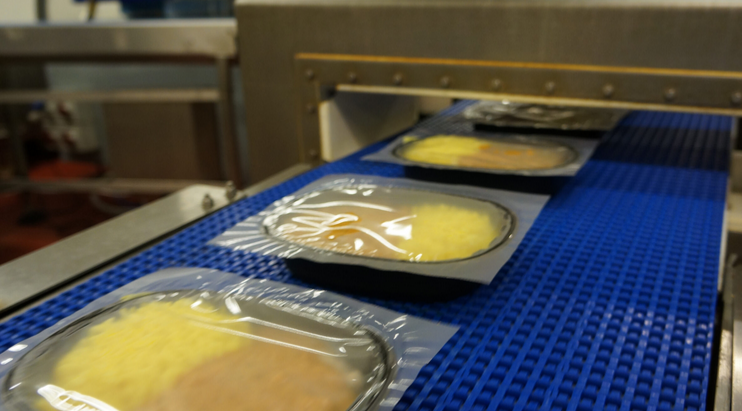

Flat belt conveyors are widely used in the majority of conveyor technology applications. In fact, they are the most common type of conveyor system, primarily used for moving products through various processes.

For instance, the belts used on flat belt conveyors can include modular, PU, or Thermodrive varieties, depending on the application.

Additionally, these conveyors can be equipped with end drives or underslung drives to enable tight transfers, especially for small products.

Moreover, the belts can be customized in various widths, up to 1500mm, and can be designed in any length, ranging from just a few centimeters to hundreds of meters, offering great flexibility in their application.

Inclined Belt Conveyors

Inclined Belt Conveyors ( also called Elevators) are a practical and affordable solution to the inclined transfer and conveyance of product and have been the mainstay of Wrightfield’s business for the last 30 years.

Many applications for conveyors require the installation to take product between two set points. These points however are rarely in line or at the same height, or even in the same room. In order to accommodate the wide ranges of process machinery required for the manufacture of any given product; many twists and turns are inevitable throughout a factory layout. This is where Wrightfield can help.

Dedicated project engineers will visit the site and thoroughly survey and discuss the exact requirements of the conveyor solution needed.

Multi Lane Conveyor

These units are used to effectively combine the product flow from multiple lanes into an organised stream that will avoid overflow or products to pile up. Wrightfield custom design and custom build lane merging conveyors to site specific requirements

Multi lane conveyor systems with a merge stream offers multiple lanes moving into one without multiple servos

Multi-lane conveyor systems are a highly efficient solution for various industries, offering several structural advantages that enhance productivity, flexibility, and space utilisation.

Pallet Conveyor

When moving drums, bales, cages etc or large/heavy pallets, chain driven rollers and chain conveyors are often used.

Wrightfield supply a wide range of pallet conveyor products to create customised pallet handling systems. These are used for moving anything from empty single pallets up to pallets with 2 ton loads in simple transit or accumulation modes and can also be utilised for feeds to and from palletisers, wrappers, hooders, strappers, etc.

Radius Conveyor (Curved Conveyor)

Radius conveyors are also known as

- Curved Conveyors,

- 90 degree,

- 180 degree,

- Horseshoe,

- S conveyors

- Zero target radius belt

- Curved conveyor belt

- Offset conveyor belt

Wrightfield offer a range of radius conveyors which may require only a few degrees of off-set to allow a conveyor to fit into an existing system, through to 90 degrees. This can be incorporated into a swan neck conveyor, or a full 360 degree carousel as part of a central stand alone system or integrating to a turn key package.

Radius conveyor side members can be manufactured from stainless steel or High Molecular Weight Polyethylene (HWMPE ). If required in food applications these can incorporate quick belt removal for ease of clean down. This allows all elements of the conveyor to be cleaned, without the need for special tools.

Modular Belt

The advantages of Modular Belt Conveyors

One of the major advantages of modular belt conveyors is that they can move your product through inclines as well as round bends and corners. Combine this with the advantage of only requiring one drive unit and modular belt conveyors become a very cost effective solution.

Modular Belt Conveyors can withstand a temperature range from-50° C to 90° C ( if you require an operating temperature outside of these parameters please call our engineering team on 01379 872800). They will work perfectly in dry, damp or wet conditions and do not suffer from tracking problems. Modular Belts can be easily removed, this minimises the impact on production down time for maintenance or cleaning. Another advantage of modular belts is that they are particularly quiet in operation.

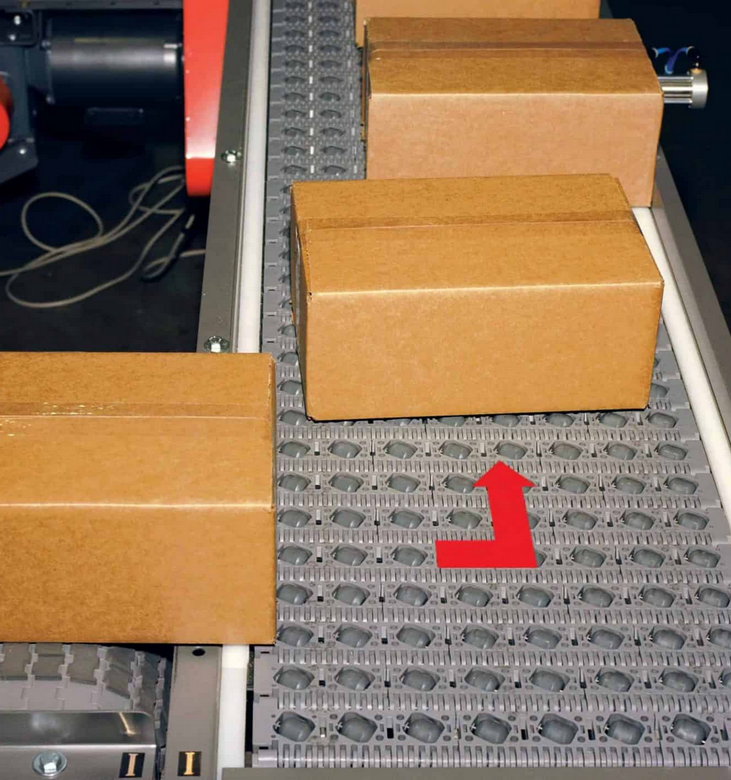

Activated Roller Belt

Intralox’s patented Activated Roller Belt™ (ARB™) technology enables increased flexibility, high throughput, reduced footprint, gentle product handling, and simplified controls. Wrightfield have been designing and manufacturing conveyor systems using Intralox belts for more than 15 years, incorporating in systems that sort, merge, turn, and singulate across a wide range of food processing industries.

Active Integrated Motion (AIM)

The AIM technology has a simple design, but the improvements it delivers for cleanability and worker experience are dramatic

Active Integrated Motion sorting, switching, and merging equipment is designed to perform in multiple environments, including washdown, to promote cleanability and line flexibility and reduce dependence on labour.

With AIM technology, you can increase throughput, protect product integrity through gentler handling, and decrease safety concerns and risks.

ThermoDrive®

Benefits of ThermoDrive

- ThermoDrive tensionless belt system provides reliable, predictable drive performance

- Reduced costs with unparalleled belt life and minimal component wear

- ThermoDrive technology combines flat, homogeneous thermoplastic material, and the positive drive feature of modular plastic belting with a unique, patented drive engagement solution.

- The unique tensionless belt system eliminates the costs and complexities of a tensioned belt system.

- ThermoDrive® technology is specifically designed for direct food contact applications

- ThermoDrive’s open access design allows cleaning in place resulting in a dramatic decrease in sanitation time and costs

Wire Belt Conveyors

At a glance…Wire belt conveyors offer a range of advantages, particularly in food processing environments where hygiene is crucial. First, their open design allows for better airflow, which enhances drying and cooling processes. Additionally, unlike plastic belts, wire belts are highly resistant to extreme temperatures, making them suitable for a variety of applications.

Moreover, stainless steel wire belting is more resilient against wear and tear, meaning it lasts longer under heavy use. As a result, facilities can experience reduced maintenance costs over time. Finally, wire belt conveyors are easier to clean, ensuring compliance with strict sanitation standards. If you are looking for trusted suppliers of wire belt conveyors, choose Wrightfield.

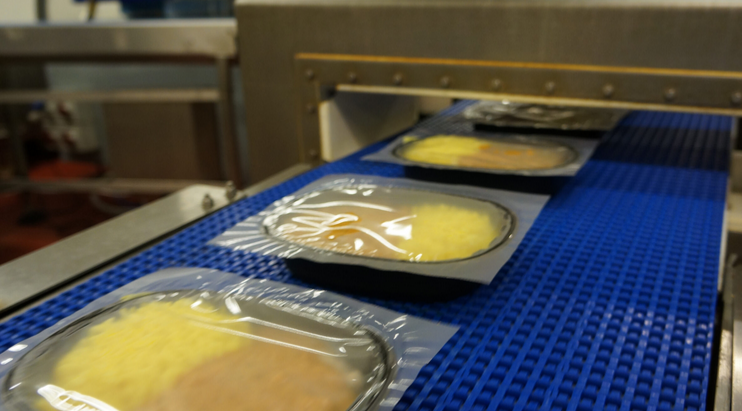

Polycord Conveyor

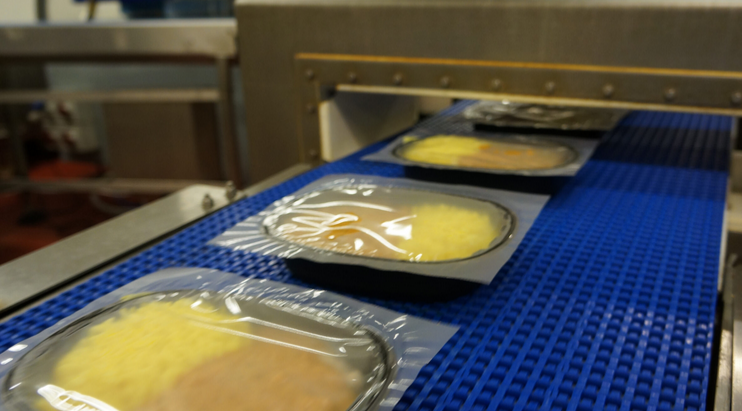

Wrightfield Polycord Conveyor systems have been used in the following

- Food processing from ready meals to meat preparation and meat production

- Food packaging with fresh fruit going into tubs or burgers into pre packs

- Dairy

- Confectionery

- Bakery and snacks from doughnuts to biscuits,

- Prepared food, ready meals, food processing,

- Meat processing – where we have extensive capabilities in all elements of meat

For more information regarding our range of stainless Polycord belt conveyors please contact us via the contact from below or simply give us a call

PU Belt Conveyors

Wrightfield PVC/PU Belt Conveyors have been used in the following

- Beverage in bottling plants

- Nutritional Supplements,

- Food processing from ready meals to meat preparation and meat production

- Food packaging wit fresh fruit going into tubs or burgers into pre packs

- Dairy,

- Confectionery,

- Bakery and snacks from doughnuts to biscuits,

- Prepared food, ready meals, food processing,

- Meat processing – where we have extensive capabilities in all elements of meat

For more information regarding our range of PVC/PU belt conveyors please contact us via the contact from below or simply give us a call

Slat Conveyor

Slat chain conveyor belt systems are a type of conveying technology that uses a chain-driven loop of slats to move product from one end to another. A motor drives the chain, which causes it to cycle just as belt conveyors do. Instead of a rubber belt, this conveyor type uses slats connected to a chain, providing a rigid, flat surface for every item on the conveyor. This makes slat conveyors ideal for irregular shaped products that cannot / are unsuitable to be used on rollers or belts .

Slats are typically made from metal or engineering plastic, which allows slat conveyors to function in high weight, hazardous, and high-temperature environments. Another major advantage is that the slats can be built with unique shapes to hold / locate items, giving them more use-cases than most conveyors. Slat conveyors can be manufactured to your exact requirements to match your speed and size needs, and can have optional side railings fitted to help guide materials through the conveyor system.

Automation

Wrightfield has designed, engineered and installed a wide range of Automated Conveyor Solutions to address multiple conveying needs. These include: moving, scanning, weighing, dimensioning, diverting, routing, merging, incline, declines, bends, accumulating, printing, labelling of goods for production and processing operations.

From simple unpowered gravity roller conveyors to complex conveyor systems, which can be dynamically controlled by integrated Software Systems, Wrightfield provides a full turnkey service to meet all conveyor system requirements.

Wrightfield manufacture conveyors from Stainless Steel 304/316 or Aluminium Construction to meet any specific technical or aesthetic requirement.

Integration

Bespoke conveyor integration is of paramount importance and can assist with streamlining processes, offering large savings across production. The new equipment you select needs to be the right choice to fit into your space and work effectively with your other processing and production equipment including existing conveyors.

Working with an expert partner like Wrightfield ensures you have the expertise required to assess your current equipment and help choose or design the new conveyor to fit in and work effectively. Custom design is possible and often the best solution to ensure the conveyors integration within your factory are setup to work in the optimal condition for your business.

Multiple Conveyors

With automation becoming an ever-growing element within production processes we can help you automate and improve your throughputs and operating efficiency.

Wrightfield multiple conveyor systems are used for all manner of products from food, pharmaceuticals, automotive, packaging and consumer products. We have designed and manufactured complete multi-conveyor centralised product handling systems, including flat bed and incline belt conveyors mounted with separators to take products from multiple machines to centralised locations

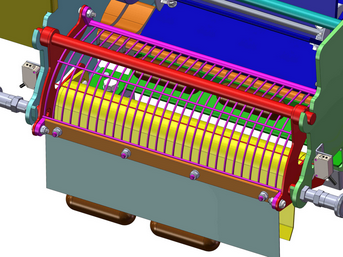

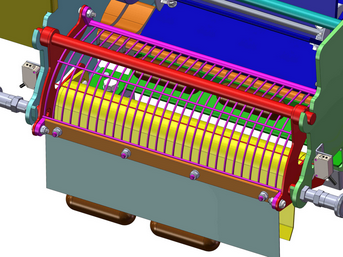

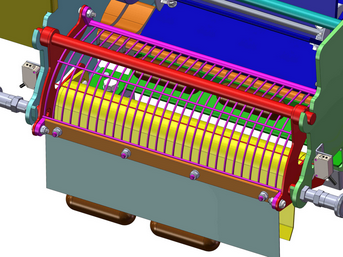

Meat Processing Press

The Wrightfield Meat press machine is the result of accumulative knowledge and hands-on experience gained over many years from within the bacon industry. Further to this, we continuously tap into the enormous wealth of knowledge that exists out there in the bacon processing plants today and to that end we welcome and encourage feed-back from our customers.

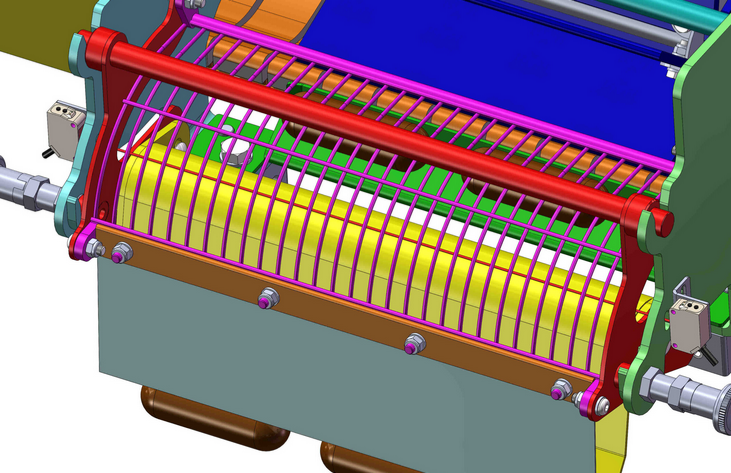

Breading & Coating Machines

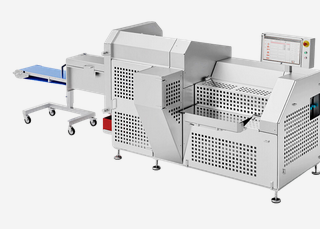

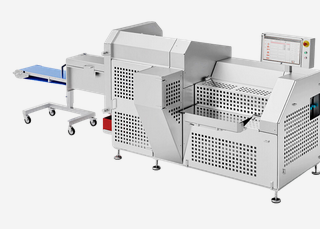

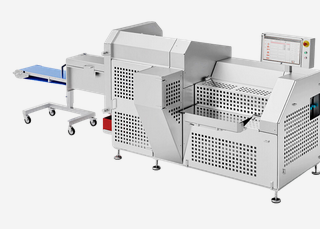

Wrightfield are the exclusive distributor of the all new Combi Coater from Symotab for UK & Ireland

The Combi Coater is a multi purpose dry coating machine

Coating can be applied in normal flatbed mode and in drum mode. The same machine will run pre-dust as well as a great variety of crumb

This makes Combi Coater the perfect machine before and after the wet coater in any convenience line.

In a flexible production line, machine configurations may need to be changed more then once a day. Replacing a flatbed machine with a drum-breader usually takes a fair bit of time and is a number one cause for damaged belts. Adjusting machine positions to create the perfect change over is also a silent cost adding to downtime.

Industrial Food Slicer & Dicer Machines

Wrightfield is proud to offer a comprehensive range of high-performance industrial food slicer and dicer machines from MHS, now available across the UK and Ireland. With decades of engineering expertise and a deep understanding of the food processing industry, we provide cutting-edge solutions designed to deliver precision, speed, and reliability in high-volume operations.

From high-speed slicers and dicers to advanced portioning systems, MHS machines cater to a variety of applications, including meat, cheese, and plant-based products. Backed by Wrightfield’s dedicated support and technical know-how, we are committed to optimizing your production processes and ensuring minimal waste, maximum yield, and exceptional slicing accuracy. Explore our range today to find the perfect solution for your business.

Live Bird Handling Systems

Live Bird Handling System – Pro Load and Modules

The modular Wrightfield Live Bird Handling System provides animal-welfare friendly conditions for loading and transporting birds. The system meets industry demands for:-

- Line speed

- Hygiene

- Durability

- Cleaning

The Wrightfield Live Bird Handling System is modular and offers solutions for all production capacities and levels of automation.

Live birds are generally transported by truck and carried in either stainless steel containers or crates. Transporting live birds in both containers as well as crates, is subject to strict governmental regulations. The number of birds transported varies according to these regulations, but also depends on climate and size of crate or container. Wrightfield offers efficient systems for module transportation.

With the Wrightfield Pro Load and module system the birds are separated by horizontal divisions only, allowing more air to circulate and reducing stress related damage to the birds.

The demands of production facilities and circumstances vary from plant to plant. Wrightfield manufacture every system to meet these specific requirements.

For more information on the Poultry Processing Expertise Provided by Wrightfield call our Engineering Team on 01379 872800

Deboning Line

Meat

Wrightfield’s highly efficient deboning systems support the meat processing industry in achieving the right quality product and to satisfy the growing demand for deboned meat.

Poultry

Wrightfield’s highly efficient deboning systems support the poultry processing industry in achieving the right quality product and to satisfy the growing demand for deboned poultry meat.

Packing & Trimming

Wrightfield design, manufacture and install conveyors for both empty trays and full trays for trimmings and subsequent packing.

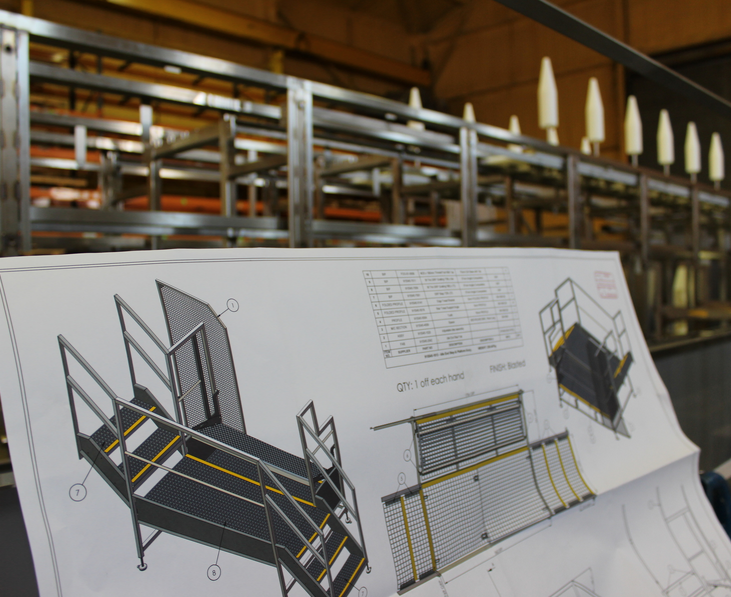

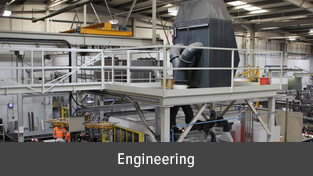

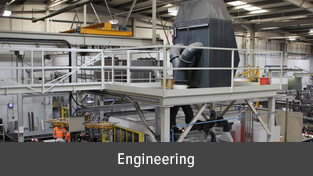

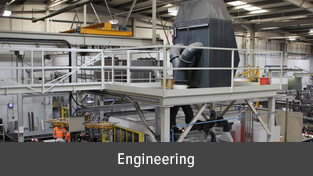

Bespoke Equipment & Design

Wrightfield are specialists in the design and build of stainless and mild steel access structures. One of our key product lines is the design and installation of bespoke platforms, gantries or walkways for any purpose or application. Be it a control station, elevated work zone, inspection area or even a bridge over a production line, a Wrightfield system can get you there.

Our platforms, gantries and walkways are individually designed to fit into or weave though any given area or workspace, under or over other machinery, or to allow access to any height for any operation.

All Wrightfield constructions are made to the highest build quality standards with safety in mind at all times. Heavy duty fully welded hand and side rails, kick plates, and the use of entirely non slip punched metal footplates are standard build practice.

For more information on Access and Guarding call our Engineering Team on 01379 872800

About us

Wrightfield Ltd is a specialist engineering firm with more than 30 years of experience in the food manufacturing and processing sector, specialising in the design, production, and installation of food conveyor systems and tailored solutions.

Wrightfield’s strong reputation in the food processing industry is founded on long-standing partnerships with clients and suppliers. Guided by our “Better by Design” philosophy, we continuously innovate by integrating the latest technologies from our partners to develop highly efficient solutions that boost our clients’ productivity and profitability.

Our 40,000 sq. ft. facility serves as the hub for in-house design, project planning, and manufacturing. Utilising advanced 3D modelling software, our design team develops conveyor system layouts, while our manufacturing plant features some of the UK’s most advanced machinery. Coupled with our extensive food industry experience, this guarantees top-quality service and results for our clients at every stage.

Our Conveyor Range Includes:

Various Conveyor Types

Our in-house design team and skilled engineers have been creating and producing custom conveyors for food industry applications for more than twenty years.

Various Conveyor Belt Types

For conveyor belt systems needing bi-directional operation, Wrightfield provides a variety of options where adjacent lanes move in opposite directions, all powered by a single line shaft.

Conveyor Systems

A decline belt conveyor is designed for moving products downward. Wrightfield customises these conveyors to match the specific product by varying flight heights and pitches, and offers options with either PU or plastic modular belts.

Our Equipment Range Includes:

Meat Press Machines

The Wrightfield meat press is designed to shape and form products according to customer specifications, while prioritising the maximisation of pressing yields.

Breading & Coating Machines

The Combi Coater is a versatile coating machine, and Wrightfield is the exclusive distributor for Symotab in the UK and Ireland.

Live Bird Handling Machines

The modular Wrightfield Live Bird Handling System offers humane conditions for loading and transporting birds, while meeting industry standards for line speed, hygiene, durability, and ease of cleaning.

Dicer & Slicer Machines

Wrightfield is the exclusive reseller for MHS Schneidetechnik GmbH in the UK and Ireland. Explore their range of food slicers tailored to fulfil your slicing and portioning needs.

Deboning Machines

An efficient deboning and trimming process is key to maximising yields while ensuring smooth operation with minimal downtime and reduced operational expenses.

… And more.

With over 30 years of manufacturing experience, Wrightfield is a recognized leader in food conveyor systems, also providing custom solutions for pharmaceutical and other high-volume industries. We focus on designing, manufacturing, and installing high-quality machinery and bespoke conveyor systems for food processing, pharmaceuticals, bakery, ready meals, poultry, and fish sectors.

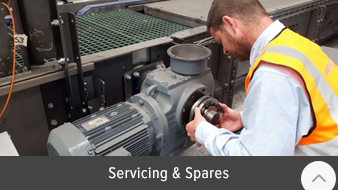

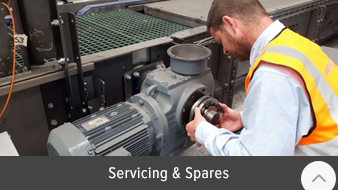

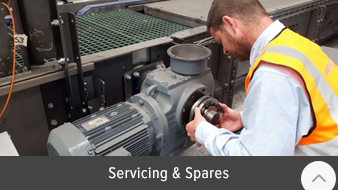

Our 40,000 sq. ft. facility in the UK is equipped with state-of-the-art machinery and the latest 3D modeling software to enable precise manufacturing. We provide comprehensive services including engineering, structural solutions, EN1090 compliance, and continued support with maintenance and spare parts, ensuring top-quality service from project planning to commissioning throughout the UK and Ireland.

Kindly fill out the contact form on our website, and we will respond to you promptly.

Images

Articles / Press Releases

Brochures

Reviews

Trade Associations