Company details for:

Wrightform Ltd

Quick Links:

Products / Services

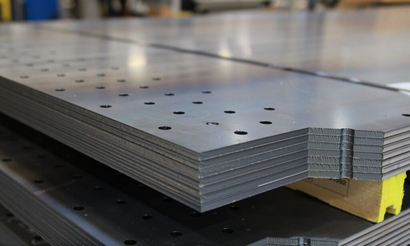

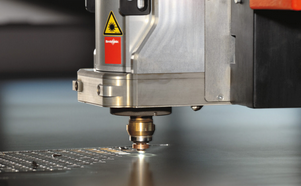

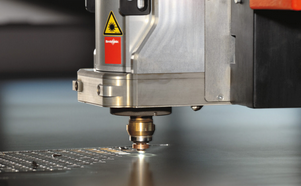

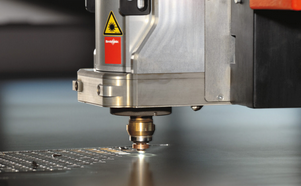

Laser Cutting Services

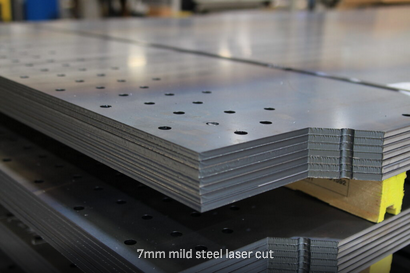

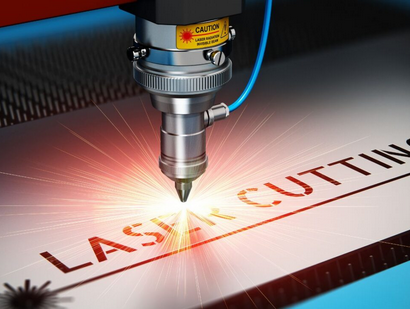

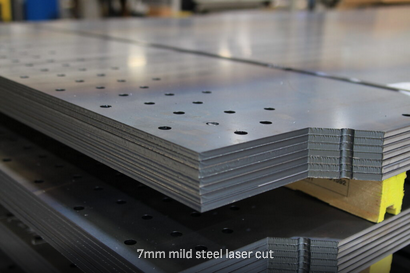

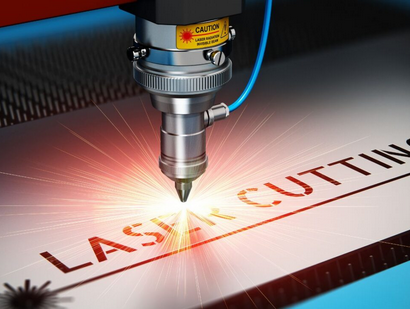

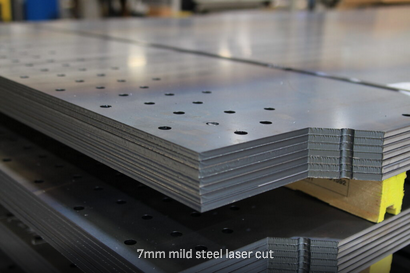

Laser cutting is a versatile manufacturing process widely used in the production of various products such as beams, columns, pipes, tubing, and sheet metal. At Wrightform our emphasis is always on quality and the lasers we operate reflect this ethos.

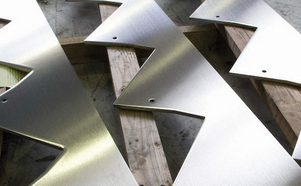

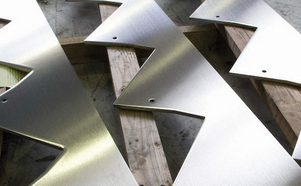

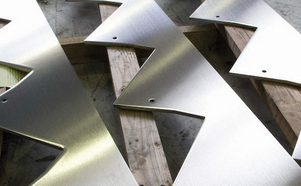

Folding | Forming | Bending

Wrightform operate a range of press brakes from high speed 40 tonne 1 metre to high capacity 320 tonne 4 metre.

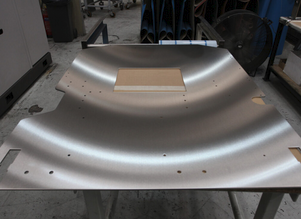

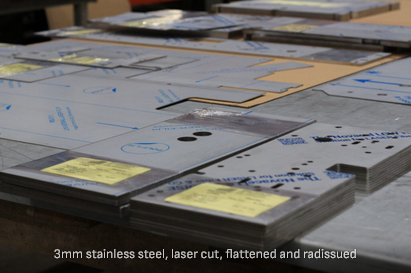

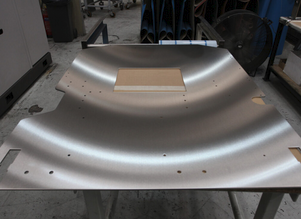

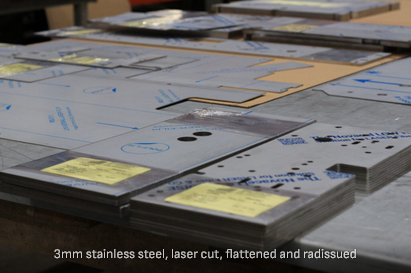

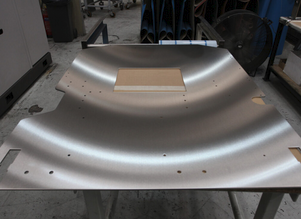

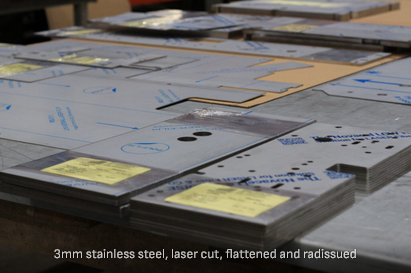

Metal Flattening Service

At Wrightform, we understand sheet metal flattening, parts levelling and fabrication. Especially, the fact that a flat piece of metal will perform better than a bowed one.

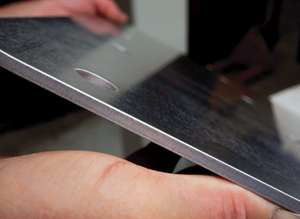

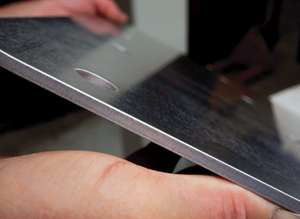

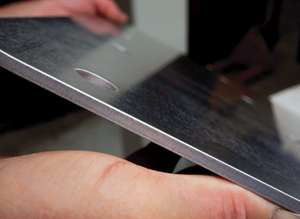

Edge Rounding | Radiusing | Surface Finishing

While laser profiling leaves components virtually burr free, some small burrs and sharp edges still remain, which pose a handling risk.

Dull Polishing

Producing a unidirectional grained or satin decorative finish to the faces of stainless steel parts up to 1300mm wide.

If you require your profiles to be grained or given a decorative finish Wrightform can achieve this by utilising our Timesaver Grindmaster machine.

Metal surface finishing plays a pivotal role in enhancing the visual appeal of metal products across various industries. Whether it’s steel, stainless steel, aluminum, or copper, selecting the appropriate finish can transform sheet metal components, imparting a polished and professional appearance. This aesthetic enhancement is particularly crucial in industries where visual appeal matters, such as architecture and interior design.

Electro-Chemical Marking & Laser Etching

A permanent process for high resolution part marking on stainless steel parts.

Customer designs are quickly and easily converted to a printable stencil in house resulting in an easy to see, permanent, black oxide mark.For Surface marking and visualisation Wrightform are happy to laser etch your profiles whilst in the cutting process.

Metal fabrication Service

Wrightform offer a full metal fabrication and machining service.

At Wrightform, we offer a full-service metal fabrication service, that covers every stage of metal production, from initial design to final assembly. This typically includes laser cutting, bending, forming, radiusing, flattening, machining, welding and finishing processes, and custom engineering solutions tailored to client needs. Contact our sales team for a competitive quotation.

Vibratory Finishing Service | Rumbling

Wrightform now offer deburr, polish and superfinish.

In line with continued product improvement Wrightform have recently made a new addition of the PDJ VIBRO bowl Vibratory finishing machine, utilising both ceramic and polyester media we can remove burrs from multiple small parts leaving them with a matt finish whilst still maintaining cost effectiveness.

We use various media to deburr, smooth and polish hard metals, as well as plastic media for softer metals, such as aluminium and brass. This machine offers a superior vibratory finishing service and uses high abrasive efficiency and great surface finishing.

Certified EN1090-2

Wrightform continue to be certified to EN1090 execution class 2. EN 1090-2 stands as a European standard outlining the prerequisites for producing structural steelwork, encompassing bolting and welding procedures. Forming part of a suite of European standards, it’s crafted to regulate the fabrication and assembly of steel and aluminium structures. Compliance with BS EN 1090-2 necessitates designers, manufacturers and subcontractors to stipulate the extent of quality control throughout the fabrication processes.

About us

Wrightform Ltd supplies top-quality metal products, components, and precision sheet metal fabrications to a wide range of UK industries, including manufacturers and contractors. As a skilled subcontractor, we offer reliable, tailored solutions that enhance or extend your in-house capabilities. Let’s talk.

With over 20 years of expertise in laser cutting and subcontract engineering, Wrightform delivers precision, quality, and reliable turnaround. From single prototypes to large-scale production, we offer in-house design and fast delivery via our fleet in East Anglia and trusted UK-wide carriers.

Supported by a full suite of advanced machinery, Wrightform offers cutting, folding, deburring, polishing, rumbling, and flattening services—all completed in-house and delivered using our own fleet of covered vehicles.

Our Services Include:

Laser Cutting Services

Laser cutting is a flexible manufacturing method commonly used to produce items like beams, columns, pipes, tubing, and sheet metal. At Wrightform, we prioritise quality in every job—reflected in the high-performance lasers we operate.

Folding | Forming | Bending

Wrightform runs a variety of press brakes, ranging from fast 40-tonne, 1-metre machines to powerful 320-tonne, 4-metre units, allowing for precise and flexible metal forming.

Metal Flattening Service

At Wrightform, we specialise in sheet metal flattening, part levelling, and fabrication—recognising that a properly flattened component consistently outperforms one that’s bowed or uneven.

Edge Rounding | Radiusing | Surface Finishing

Although laser profiling produces components that are nearly burr-free, minor burrs and sharp edges can still be present, creating potential handling hazards.

Dull Polishing

Creating a satin or unidirectional grained decorative finish on stainless steel surfaces, accommodating parts up to 1300mm in width.

… And more.

Founded more than twenty years ago, Wrightform has consistently expanded its business by staying ahead of the competition through continuous investment in technology..

Wrightform recently expanded its facility by 6,500 square feet to house a new 15KW fiber laser equipped with automated sheet feeding. Other recent equipment upgrades include a press brake with robotic automation, a rumbling machine, and possibly the largest metal flattening machine commercially available in the country.

If you have any questions, require a quote for a new project, or wish to arrange a guided tour of our facility, please get in touch with us.

Images

Articles / Press Releases

Reviews

Trade Associations