25 September 2025 | Interface Force Measurements Ltd

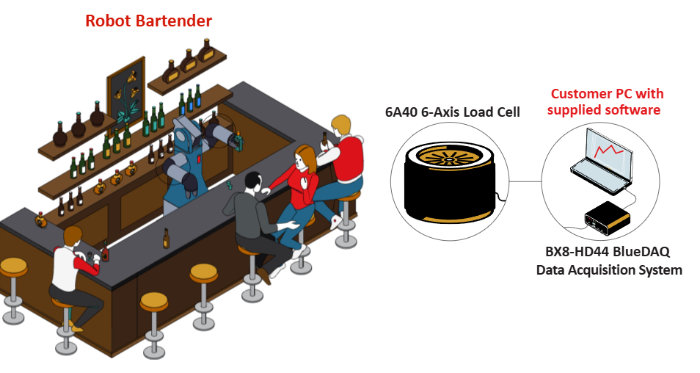

Robotic bartender

Can a robotic bartender meet demand at high-volume events and festivals?

Every drink is poured with exact precision, resulting in 100% consistency and eliminating errors due to manual preparation.

How can a robot pour drinks with precision?

Interface’s 6A40 6-Axis Load Cell measure force and torque along several directions simultaneously—vital for accurate drink preparation under dynamic conditions. The testing results can be logged, displayed, and measured when connected to Interface’s BX8-HD44 BlueDAQ Series Data Acquisition System with included BlueDAQ software.

How to measure the force needed by a robotic bartender

Thanks to our products, every drink is poured with exact precision, resulting in 100% consistency and eliminating errors due to manual preparation.

What products are available for measuring robotic force?

6A40 6-Axis Load Cell

BX8-HD44 BlueDAQ Series Data Acquisition System with included BlueDAQ software

Customer’s robotic bartender arm and control system

How do load cells collect data from force and torque measurements?

The 6A40 6-Axis Load Cell is installed at the head of the robotic bartender arm.

For data collection of force and torque measurements, the 6A40 6-Axis Load Cell interfaces with the BX8-HD44 BlueDAQ Series Data Acquisition System.

The customer connected the BX8’s analogue outputs to their control system. The customer is able to log, display, and graph these measurements. The results are sent to the customer’s control system via analogue or digital output.

FAQs on robotic bartender

Q: What problem does a robotic bartender address?

A: It helps venues, event planners, and hospitality operators serve drinks faster and more consistently—especially during high-volume events such as weddings, festivals, corporate gatherings—by automating pouring and shaking to reduce human error, spillage, and variability.

Q: What are the key challenges in getting a robotic bartender to work well?

A: Key challenges include detecting subtle shifts in force and torque during shaking and pouring (to avoid spillage), ensuring consistency across many drinks in dynamic conditions, and integrating accurate measurement into the control systems.

Q: What solution does Interface provide in this case?

A: Interface uses its 6A40 6-Axis Load Cell to measure force and torque in multiple directions simultaneously, paired with their BX8-HD44 BlueDAQ Data Acquisition System (including software). These allow the robotic system to log, display, graph, and feed back measurements to the control system to improve precision.

Q: How is the 6-Axis Load Cell used in the robotic bartender setup?

A: The load cell is installed at the head of the robotic arm. It feeds data to the Data Acquisition System which then provides analog (or digital) outputs to the robotic controller. The system can monitor force/torque in real time, detect deviations, and correct shaking/pouring motions.

Q: What is the outcome of using this measurement & control system?

A: The result is high precision in drink pouring, 100% consistency, and the elimination of manual-preparation errors.

Q: What materials / components are required for this solution?

A: The necessary components are:

6A40 6-Axis Load Cell Interface

BX8-HD44 BlueDAQ Series Data Acquisition System with BlueDAQ software Interface

The robotic bartender arm and its control system (customer’s existing hardware)

Q: Can the system handle dynamic conditions (e.g., movement, vibration)?

A: Yes — the multi-axis load cell measures force and torque along several axes which helps detect shifts even in dynamic or varying conditions. This allows for maintaining precision and avoiding spillage.

Q: How does data from the system get used?

A: The system logs, displays, and graphs measurements. It sends output (analog or digital) to the robotic control system so that control adjustments can be made based on the measured force/torque data.

Q: Is this solution customisable?

A: Yes. The customer uses their own robotic arm and control system, integrating the Interface measurement hardware. The measurements and control outputs can be adapted to their specific pouring / shaking routines.