12 November 2025 | Interface Force Measurements Ltd

Optimising Cheese Weighing on Packaging Lines

A leading cheese production company wants to optimise its packaging lines for a well-known soft-ripened cheese while maintaining the highest product quality, while meeting strict food industry regulations. The company needs a weighing solution that can integrate into an existing line, offer high accuracy at high speeds, and withstand the demanding hygiene requirements of dairy environments.

What solutions are there for weighing food products on production lines?

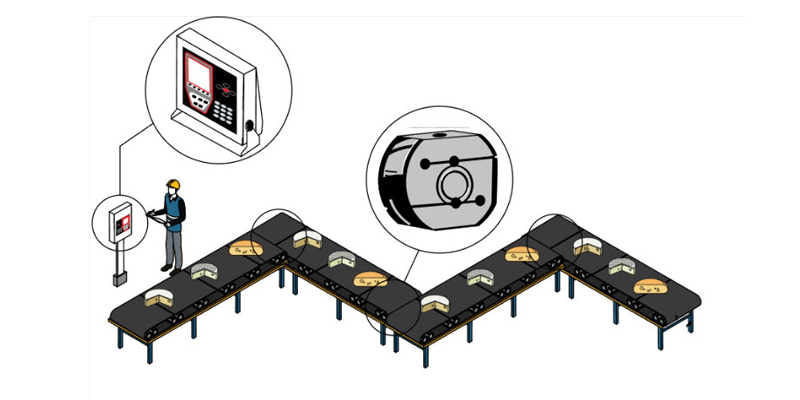

Incorporating our WSSB Welded Stainless Steel S-Beam Load Cells into different parts of the line deliver precise and accurate weighing results. The load cell is IP68 environmentally protected, and integrated into the line’s checkweigher to monitor product weight. When connected to the 920i Programmable Weight Indicator and Controller, will give the customer real time results of the weight of the cheese being processed. The 920i Programmable Weight Indicator and Controller can read up to four scale channels in real-time.

How can load cells improve a food packaging line efficiency?

Using our WSSB Welded Stainless Steel S-Beam Load Cells significantly improved the packaging line’s efficiency, enabling high-speed operations without compromising accuracy.

What materials were used for cheese weighing?

WSSB Welded Stainless Steel S-Beam Load Cells

920i Programmable Weight Indicator and Controller

How did the cheese weighing solution work?

The WSSB Welded Stainless Steel S-Beam Load Cells are installed at the checkweighing points of the customer’s production line belt. As cheese transports across the belts, the WSSBs will measure its weight in real-time.

Weighing results are sent to the 920i Programmable Weight Indicator and Controller, where it can read all of the load cells simultaneously and in real-time.