Company details for:

A1 Extraction Systems Ltd

Unit 20,

Wentworth Road,

Heathfield Industrial Estate,

Newton Abbot,

Devon,

TQ12 6TL,

United Kingdom

Quick Links:

Products / Services

Services Provided

Complete design, manufacture, installation, maintenance and spares service as follows:

- Industrial dust and fume extraction. For all dusts and fumes.

- Industrial Ventilation.

- COSHH Local Exhaust Ventilation test surveys.

- System Maintenance. See below.

- Consultancy – Environment Protection Act – Health & Safety – System Carbon Efficiency.

- Suppliers of: Ducting, rigid and flexible, replacement filters, grilles, fans, mobile welding arms, dust collector and rotary valves. Special fabrications. Spares for all extraction equipment.

Maintenance Work

- Dust collectors – filter replacement, cleaning mechanism servicing, refurbishment.

- Rotary valve – motor, gearbox, rotor, bearings and blade replacement.

- Fans – replacement of faulty fan impellers, drive belts, motors, bearings, casings.

- Ductwork – replacement of damaged and worn out duct, unblocking and hatch fitting.

Dust & Fume Installations

We have installed extractors for the following applications.

If your application is not on the list below we would be very interested in quoting and extending the list.

- Acetone

- Acid fume

- Alcohol

- Aluminium

- Ammonia

- Animal feed

- Bitumen fume

- Brick dust

- Bronze dust

- Carbon Black

- Carbon Dioxide

- Carbon Fibre

- Caustic

- Cement

- Ceramic

- Cooking fume

- Coolant mist

- Custard fume

- Degreasant fume

- Dog Food

- Dung

- Engine exhaust fume

- Ferrous dusts

- Fettling dust

- Fish care products

- Foundry dust

- Glass

- Glue

- Gold

- Granite dust

- GRP dust

- Hay

- Horse hair

- Hydrogen gas

- Ink solvent

- Isocyanate

- Isopropyl Alcohol

- Kiln

- Lambs wool

- Lead

- MDF

- Oil Mist

- Paint spray

- Paper

- Photographic laboratory

- Pigment dust

- Plasma cutting

- Plastic

- Pottery dust

- Rubber crumb

- Rubber Smoke

- Sawdust

- Screen printing

- Shot Blast

- Silicate

- Soldering

- Solvent

- Spark erosion

- Steam

- Styrene

- Sugar powders

- Titanium

- Trichloroethylene

- Volatile Organic Compounds

- Water spray

- Wax fume

- Welding

- Wood wa

Industries & Establishments Worked In – So Far

- Airport fire stations

- Animal feed factories

- Boatyards

- Boat builders

- Brick works

- Carpentry shops

- Carpet factories

- Cheese factories

- Chewing gum manufacturing

- Colleges

- Dockyards

- Electronics

- Engineering works

- Food factories

- Foundries

- Furniture manufacturers

- Investment casting

- Joinery shops

- Laboratories

- Marine industry

- MOD establishments

- Motor vehicle workshops

- Municipal waste

- Museums

- Optoelectronics

- Plastic industry

- Powder coating

- Printers

- Prisons

- Quarries

- Rubber recycling

- Rubber extrusion

- Schools

- Stone masons

- Tyre remould factories

- Universities

- Vending machine manufactures

- Wood waste recycling

- Window manufacturers

Other Installations Include

Common installation work carried out other than dust & fume extraction.

- Compressor ducts – summer warm air discharge winter warm air to factory

- General ventilation – fans in roofs for factory cooling and air changes

- Office ventilation – where offices are inside an industrial building

- Warm air ducting – from industrial heaters for spot heating or spray booth makeup air

- Ventilation ducting for workforce or process cooling

- Clean room ventilation

- Air control curtains over doorways to prevent heat loss

- Air control curtains within factories to aid process heat control

- Factory canteen cooker canopies and extraction

- Acoustic attenuation

PPEU4 Filter

Pleated panel filter G4 and F6 efficiency.

Standard sizes: 600 x 600 x 50, 600h x 300 x 50

Typical uses: Pre filter to higher efficiency filters, Air handling unit filter. Spray room intake filter, process air filter, air conditioning unit filter etc.

Standard sizes in stock. Other sizes to order.

GP Filters

Glass fibre panel filter G2 efficiency.

Standard sizes: 600 x 600 x 50, 600 x 300 x 50, 630 x 500 x 50, 450 x 450 x 50Typical uses: Coarse pre filter for medium efficiency filters, compressor cooling air filter etc.Standard sizes in stock. Other sizes to order.

Pocket Filters

Filter pockets mounted on a header frame G4 – F6 efficiency.

Standard sizes:

Typical uses: Air handling unit filters.

Made to order.

Mini Pleat Filters

Rigid Minipleat filter F6-F8 efficiency.

Standard size: 600 x 600 x 300

Typical uses: Replacement for pocket filter, secondary filter

In Stock.

HEPA Filters

High efficiency particle arrester H10-13 efficiency.

Standard sizes: 600 x 600 x 300, 600 x 300 x 300

Typical uses: Secondary filter to dust collectors, clean room filters, hazardous dust filter.

Standard sizes in stock. Other sizes to order.

PST Filter

PST290 filter roll G4

Standard size: 20m x 2m x 20mm

Uses: Spray room supply air filter, industrial process filter, pre filter etc.

In Stock.

Paint Stop Filters

Fibreglass filter roll G2 efficiency

Standard size: 20 m x 2 m x 100 mm, 20 m x 1 m x 100 mm.

Uses: Spray booth filter, process filter, high dust holding pre filter.

In Stock.

Andrae Filter

Cardboard dry back spray booth filter.

Standard size: 9.2 m x 920 mm

Uses: Dry back spray booth filter.

In Stock

Paint Stop Fibreglass Filter Roll

Fibreglass filter roll G2 efficiency

Standard size: 20 m x 2 m x 100 mm, 20 m x 1 m x 100 mm.

Uses: Spray booth filter, process filter, high dust holding pre filter.

In Stock.

TA500 Filters

Filter roll F5 efficiency.

Standard size: 20m x 2 m x 25 mm

Uses: Spray room supply air filter, pre filter to high efficiency filters etc.

In Stock

Ducting & Flex

Ducting & Flex content coming shortly.

Spares Etc.

Give us a call to discuss your requirements and find out how we can help.

01626 832007

LEV Surveying Experience

- Our Survey Engineers have had a total of over 90 years of LEV surveying experience.

- Our engineers regularly design and project manage the installation of complete LEV systems.

- A full understanding of the design of LEV systems is key in the diagnostic process when systems do not perform as they should.

- Our engineers have specialist knowledge of all filter types, cyclone separators and DSEAR/ATEX regulations.

Survey Contents

A typical LEV record would include the following:

- A1 Extraction Ltd, contact details.

- Name &: address of Company responsible for the plant

- Location of the LEV plant

- Description of the LEV plant

- Person responsible for LEV plant

- Date of test, previous test and next test date.

- Process/ substance controlled

- Number of extract points to be used at one time

- Examiner name and signature

- Test equipment used and calibration date.

- Fan details and rotation check.

- Dust collector / filter details

- Dust collector/ filter condition.

- Dust collector cleaning mechanism description and condition

- Filter differential pressure

- Dust particulate reading where filtered air is returned to the workshop.

- Explosion relief condition (if applicable)

- Comments on system design and condition of hoods, ducting etc.

- Airflows, duct velocities, duct sizes, air volumes and face velocities where required.

- Test conditions, combinations of dampers open.

- Assessment of system effectiveness.

- Recommendations to improve performance if required.

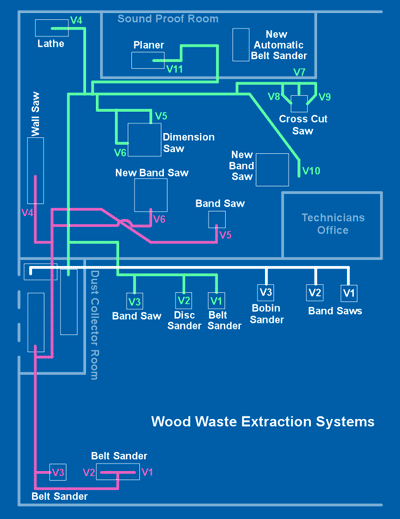

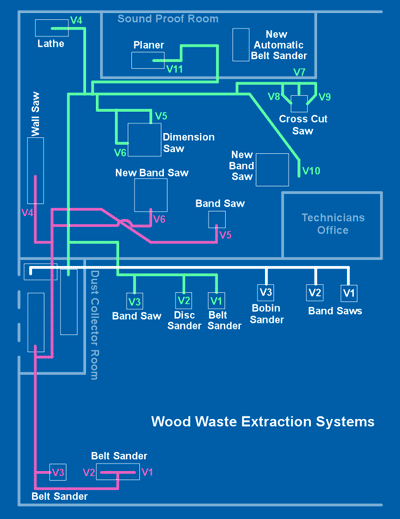

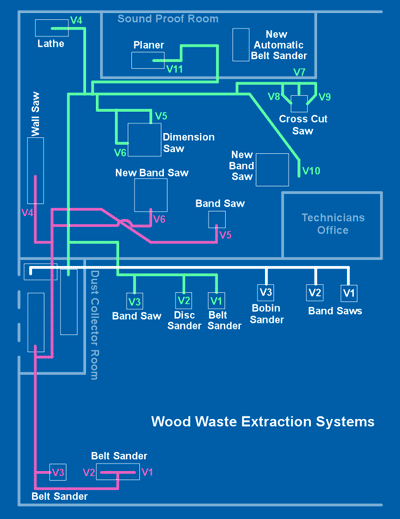

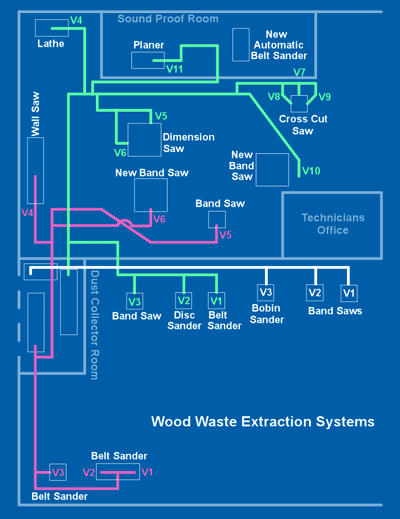

- Plant layout schematic showing test points.

Equipment Used

- In the course of our LEV surveys we use analogue TA2 anemometers, digital pressure meters, dust lamps and smoke testers.

- A digital particle sampler is used for return air sampling where necessary.

- All our meters are calibrated annually and are checked between calibrations by comparing their readings to the latest calibrated meter. In this way a meter that has become less accurate, is soon identified and is recalibrated.

- Pitot tubes and digital pressure meters are used where highly accurate airflow measurements are required. For example when calibrating production plant and for test equipment.

About us

A1 Extraction Systems Ltd – The UK’s Leading Dust and Fume Extraction Experts

At A1 Extraction Systems Ltd, we are proud to be the UK’s leading provider of industrial dust and fume extraction systems. With decades of industry experience and a dedicated team of engineers, designers, and health and safety consultants, we deliver high-performance extraction solutions that ensure cleaner, safer, and compliant work environments.

We provide end-to-end services, including system design, in-house manufacturing, professional installation, routine maintenance, spare parts supply, and COSHH Local Exhaust Ventilation (LEV) testing and surveys. Our commitment to quality, safety, and customer service makes us the trusted choice across multiple sectors—including manufacturing, engineering, woodworking, pharmaceuticals, food production, and more.

Our Comprehensive Services

Industrial Dust & Fume Extraction System Design

We specialise in the bespoke design of dust and fume extraction systems tailored to your facility’s layout, processes, and hazards. Our design team works closely with you to assess your operational needs, identify risks, and engineer an efficient extraction solution.

- Airflow & system pressure calculations

- Custom hood and ductwork layout (rigid or flexible)

- Correct filter selection and ventilation planning

- Bespoke design of dust collectors and fans, ranging from 200m3/h to 172,000m3/h

- Compliance with HSE guidelines and COSHH regulations

Each system is designed to maximise air quality, energy efficiency, and regulatory compliance.

Professional Installation Services

With decades of installation experience across a wide range of industries, our engineers provide:

- Full LEV installation and commissioning

- Ductwork routing and connection

- Fan, filter, and collector assembly

- Electrical setup and control systems integration

- On-site testing to ensure functionality and compliance

All installations are carried out by CSCS-certified professionals and adhere to the highest standards of health and safety. Whether you're building a new facility or upgrading existing extraction systems, we ensure minimal disruption and fast turnaround.

Spare Parts & Accessories

A1 Extraction Systems Ltd stocks a wide range of genuine spare parts and accessories compatible with most industrial extraction systems, fans, and filtration units. Whether for planned maintenance or emergency repairs, we supply:

- Replacement filters (standard, bag, HEPA, activated carbon)

- Centrifugal, bifurcated and axial extractor fans

- Flexible and rigid ducting

- Mobile welding extraction arms

- Grilles, hoods, and canopies

- Rotary valves, motors, and impellers

- Mounting kits and connectors

We understand how important uptime is for your business. That’s why we offer fast nationwide delivery and expert advice on part compatibility and installation.

LEV Testing & COSHH Surveys

We are specialists in Local Exhaust Ventilation (LEV) testing and inspection, helping you meet your obligations under the Control of Substances Hazardous to Health (COSHH) regulations.

Our LEV services include:

- Initial system assessments and risk analysis

- HSG258-compliant testing and certification

- Visual inspection of hoods, ducts, filters, and fans

- Airflow measurements and pressure drop testing

- Detailed reports and action plans for improvements

- Annual re-testing and service reminders

Whether you're due for a routine check or need a full compliance review, our LEV engineers provide nationwide coverage and flexible scheduling.

📞 For a no-obligation quote, call us on 01626 832007 today.

📞 Get in Touch – Let’s Talk About Your Extraction Needs

Whether you're starting a new project, upgrading existing systems, or looking for help with LEV testing, spare parts, or regulatory compliance, we’re here to help.

🧾 Request a Free Consultation or Quote Today

📞 Call us now on: 01626 832007

📧 Email: enquiries@a1extraction.co.uk

We’re happy to discuss your requirements, answer technical questions, or arrange a site visit anywhere in the UK.

Images