Company details for:

Aqua Dynamics Ltd

Unit E2,

Watlington Industrial Estate,

Cuxham Road,

Watlington,

Oxfordshire,

OX49 5LU,

United Kingdom

Quick Links:

Products / Services

Bespoke Water Jet Cutting

Precision Water Jet Cutting Machinery

Versatile Water Jet Cutting Services

Sustainable Water Jet Systems

Quality Water Profile Cutting

CNC Waterjet Cutting

Accurate Waterjet Profiling

Ultra High Pressure Water Jetting

Waterjet Machines: OMAX 55100

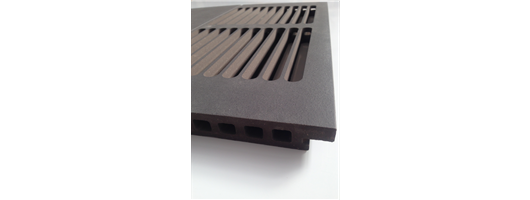

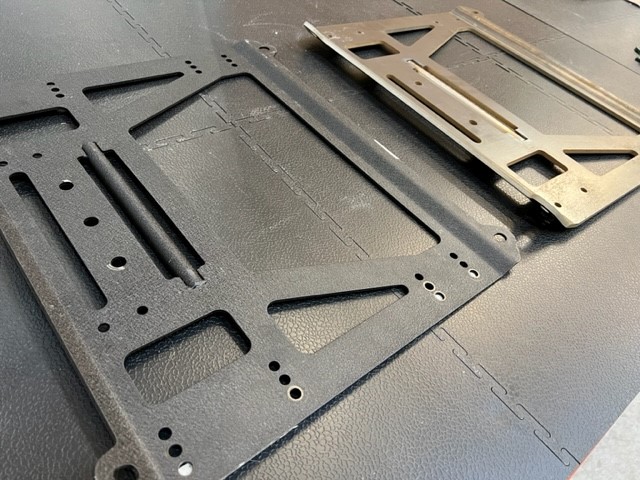

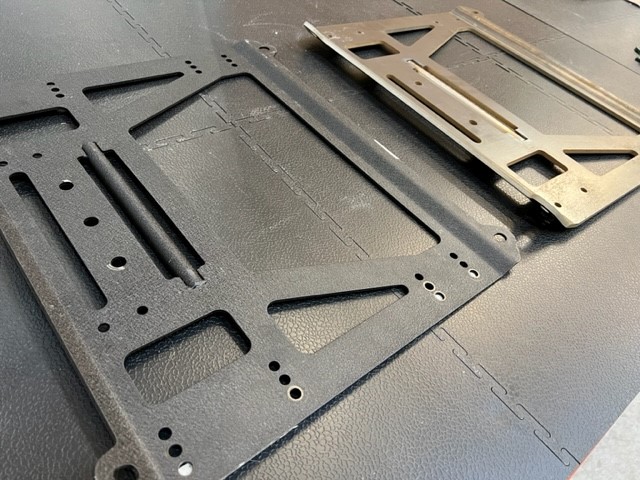

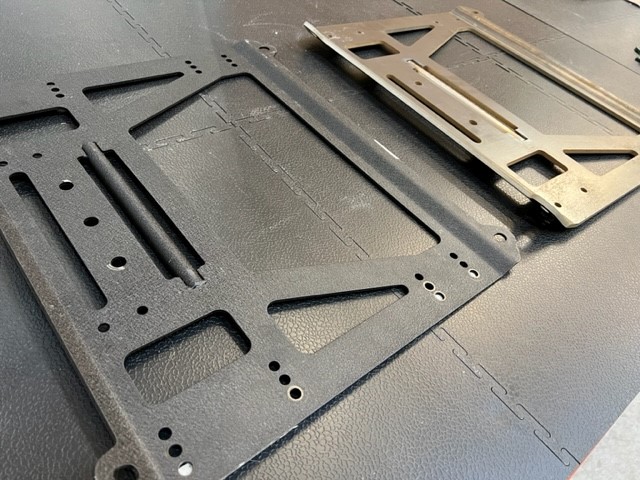

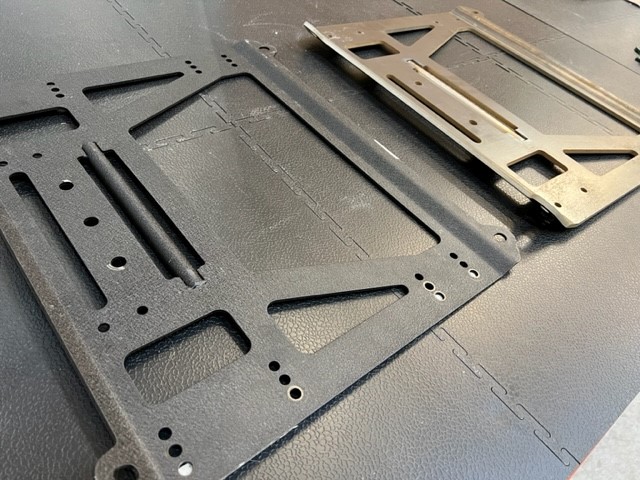

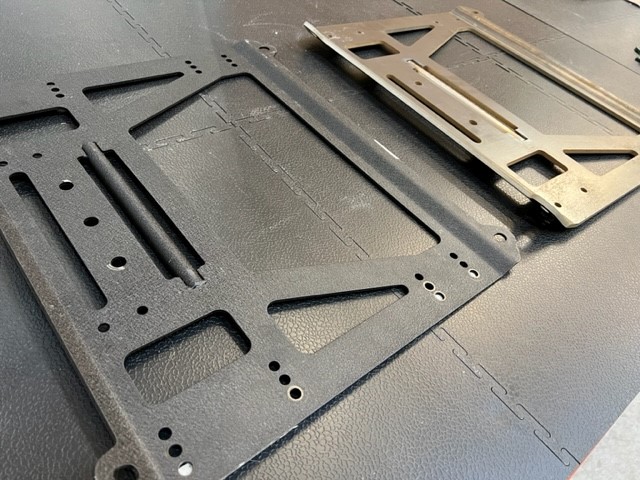

Even the hardest materials will benefit from stacking, but there will always be a situation where it is not convenient; certain composites will cut better as a single sheet but many of these materials are also not at all suited to the Laser process in the first place.

OMAX 55100

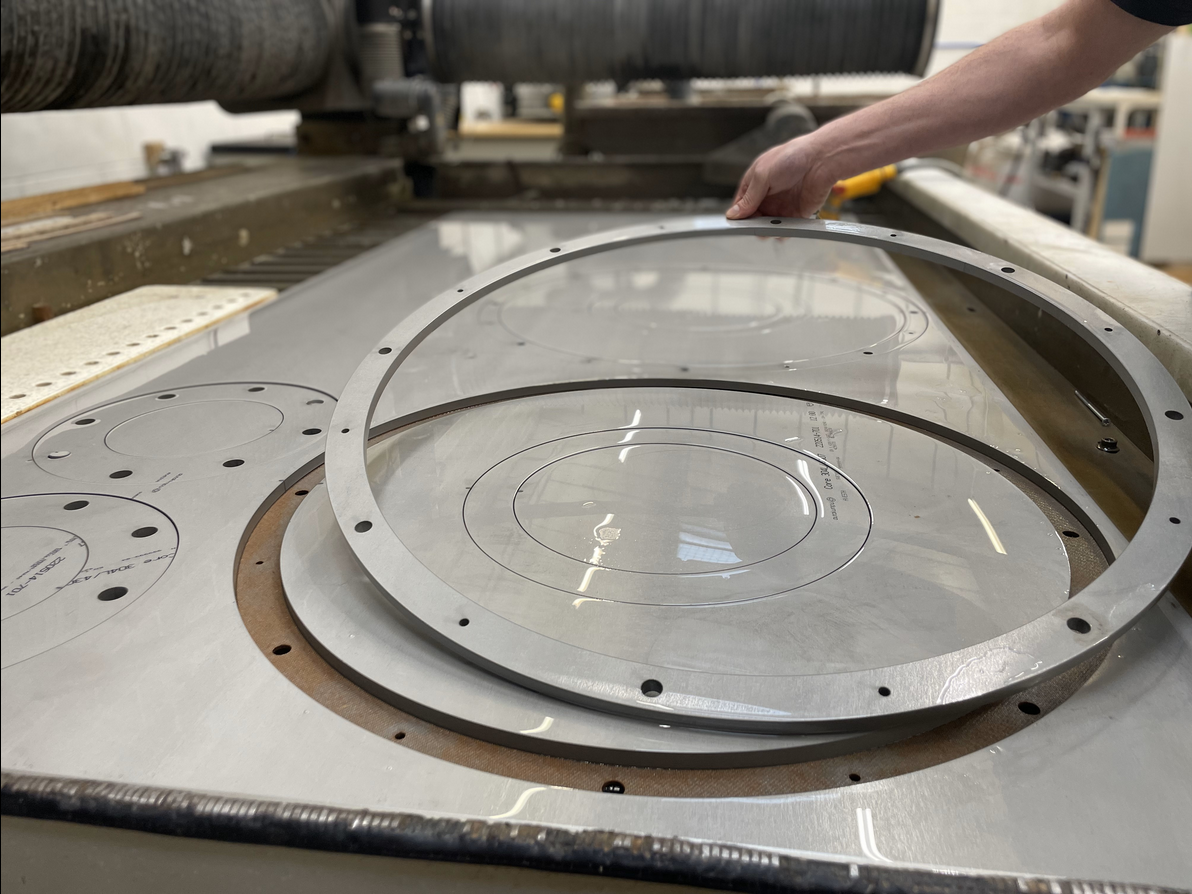

Table size of 10'6" x 5'5" (3200mm x 1650mm)

A cantiliver Y-axis on a bridge X-axis, with a motorized z-axis allows for material loading from 3 x open sides

A work envelope offering an X-Y cutting travel of 8'4" x 4'7" (2540mm x 1397mm)

Waterjet Machines: OMAX 5555

Even the hardest materials will benefit from stacking, but there will always be a situation where it is not convenient; certain composites will cut better as a single sheet but many of these materials are also not at all suited to the Laser process in the first place.

OMAX 5555

Table size of 6'8" x 5'5" (2032mm x 1650mm)

A cantiliver Y-axis on a bridge X-axis, with a motorized z-axis allows for material loading from 3 x open sides

A work envelope offering an X-Y cutting travel of 4'7" x 4'7" (1397mm x 1397mm)

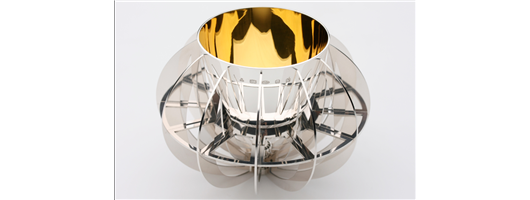

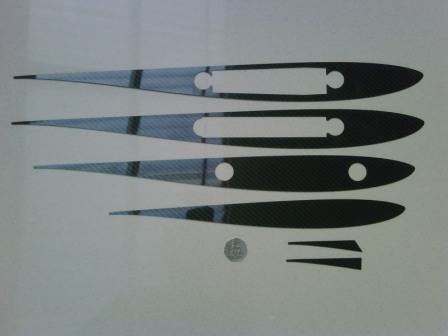

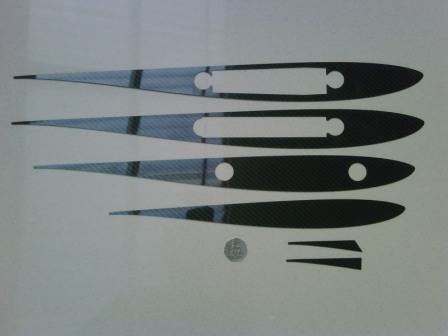

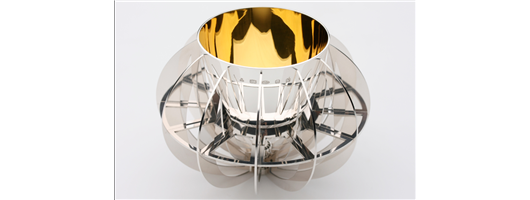

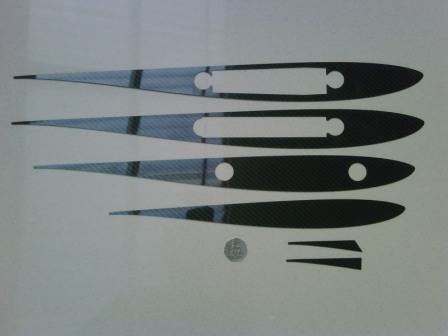

Waterjet Cutting Carbon Fibre

We offer unparalleled precision cutting service in carbon fibre across all industries.

About us

Established in 2007, Aqua Dynamics Ltd is a family-run business providing intelligent, precise & sustainable waterjet cutting solutions for all materials. As a company, we strive to provide the very best quality service and finish.

With a foundation built on a passion for engineering and a commitment to quality, we are dedicated to transforming ideas into reality through precision and craftsmanship. Our journey began with a vision to provide exceptional service across diverse industries, and we have consistently delivered on this promise by leveraging cutting-edge technology and expertise. As a family-run business, we value integrity, trust, and collaboration, ensuring that every project not only meets but exceeds client expectations. We are driven by a relentless pursuit of perfection, pushing the boundaries of what is possible and delivering unparalleled success in every endeavour. Our commitment to efficiency, flexibility, and exceptional value underpins our operations, as we continue to forge strong relationships and solidify our position as leaders in the CNC waterjet cutting industry.

Aqua Dynamics uses the latest Omax technology to ensure accuracy, efficiency, and top-notch results. Cutting materials with waterjets involves shooting a fine stream of water at high velocity and pressure through the material you want to cut, or mixing water with an abrasive garnet particle.

Industries

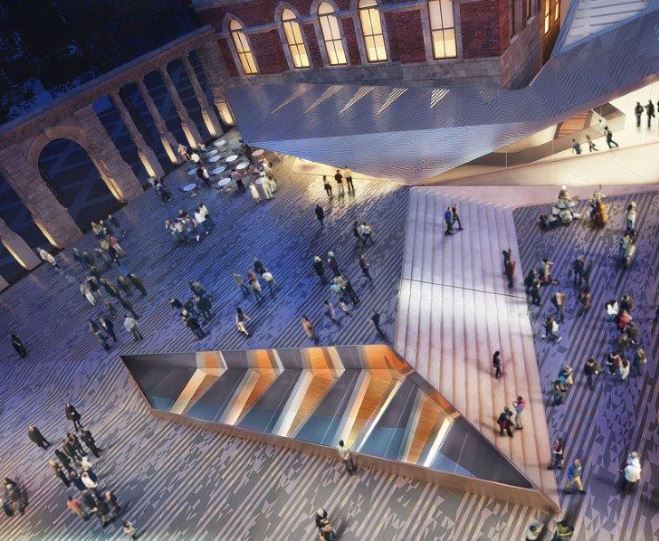

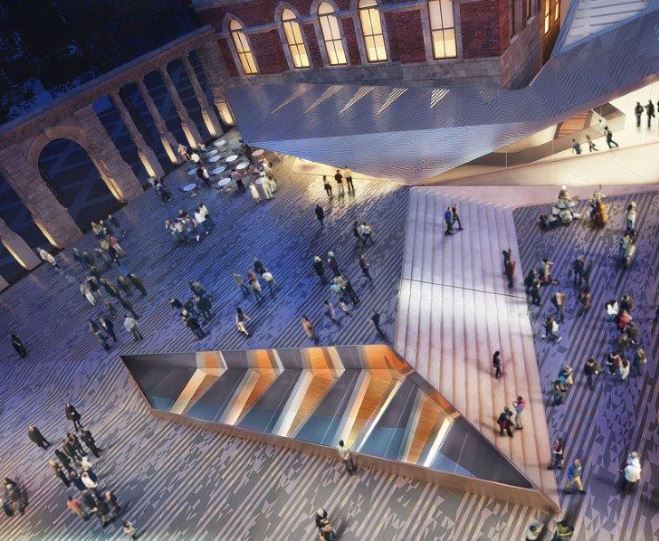

Aqua Dynamics works within a multitude of industries with its environmentally friendly Omax waterjet cutting process. We are involved in a wide range of construction and infrastructure projects as well as in the aerospace, architecture, automotive, manufacturing, and health industries. With our ISO 9001:2015 certification, you can be confident that our services are of the highest quality.

Industries We Service Include:

- Automotive/ F1

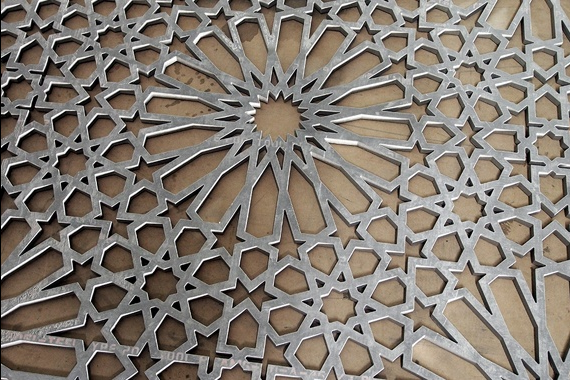

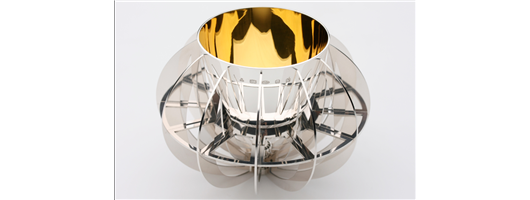

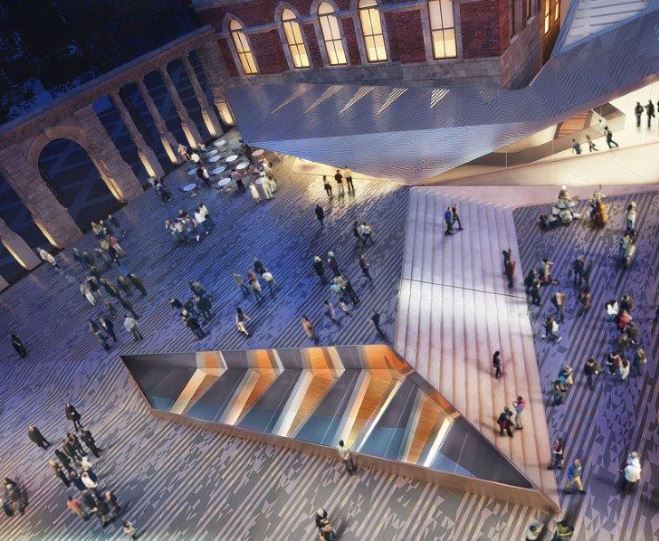

- Architecture & Design

- Construction

- Film

- Oil and Gas

- Ceramics and Marbles

- Stone Masonry

- Sign Manufacturing

- Prototyping

- Defence Engineering

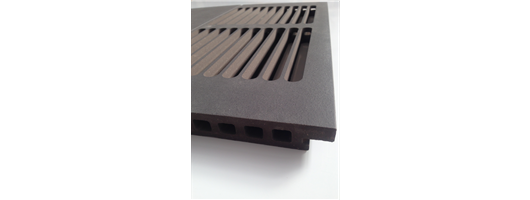

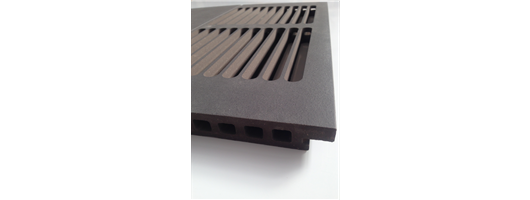

A waterjet process has a competitive advantage over a laser process. Almost anything can be cut with one of our Abrasive Waterjet machines, including aluminium, brass, bronze, copper, stainless steel, titanium, tungsten, carbon fiber, Kevlar, composites, fiberglass, ceramics, glass, granite, marble, and many more.

In addition to being environmentally friendly, this approach to engineering allows for complex designs to be achieved in all materials.

Aqua Dynamics Ltd, based in Watlington Oxfordshire, is a leader in the CNC waterjet cutting industry, offering its services on a national scale. Our business is dedicated to providing a comprehensive range of services, including cutting services, engineering solutions, consultancy and design, prototyping, CAD design, and product development. We pride ourselves on delivering bespoke services tailored to the specific needs of each client, ensuring that every project is handled with the utmost care and attention to detail.

What truly sets Aqua Dynamics Ltd apart is our team of highly skilled engineers, each specialising in CNC waterjet technology. Our team’s precision and commitment to quality are evident in every project we undertake. As a long-established, family-run business with over 18 years of dedication, we apply the same level of care and attention to every project, regardless of its size. This dedication to excellence is a cornerstone of our reputation and success.

Inquiries are welcome, large or small batches are catered for and lead-times are flexible. Acceptable file formats include dxf, dwg, pdf or hand drawn and dimensioned designs.

Images

Videos

Articles / Press Releases

Reviews

Trade Associations