Company details for:

Aycliffe Filtration Ltd

Quick Links:

Products / Services

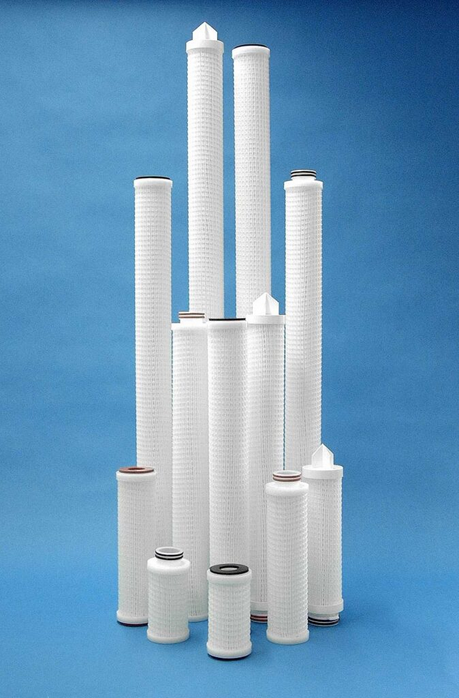

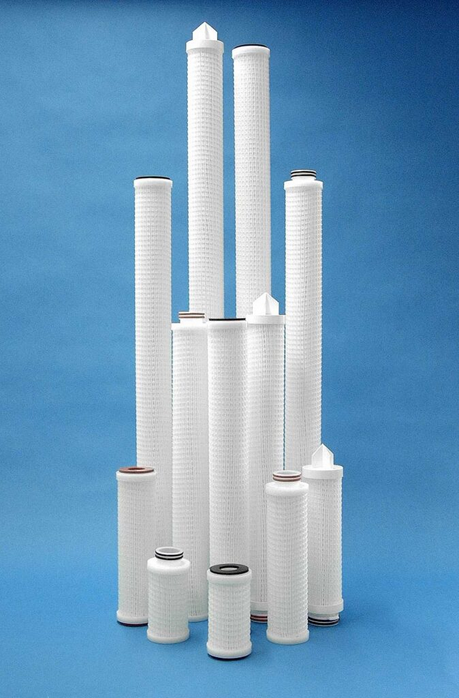

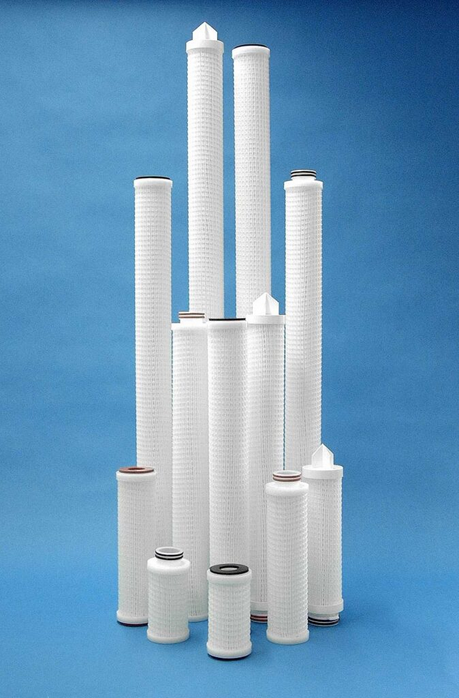

Pleated Cartridges

AFL manufactures and supplies pleated cartridges in a full range of media including polyester, polypropylene, glass fibre, polyethersulfone and nylon.

Pleated filters from AFL offer excellent filtration properties in absolute and nominal efficiency grades to suit your application.

Pleating allows the filtration media to be tightly packed inside the cartridge, dramatically increasing available surface area while maintaining high dirt holding and low-pressure drops.

Pleated filter cartridges are used effectively against the cryptosporidium parasite, found in some water supplies, which is known to cause respiratory and gastrointestinal illnesses. They are often used in the beverage industry.

In the oil and gas sector, the fully thermally bonded construction of pleated cartridges offers safe operation and optimum performance.

An outer support cage provides product strength and rigidity, protecting the pleat pack to ensure media integrity. The inner support core allows end caps to be thermally bonded to the cartridge for security and strength. Thermal bonding means no adhesives are used and ensures no leaching into the filter stream.

AFL cartridges are manufactured in the UK from FDA-compliant materials.

For superior performance, AFL offers a premier glass fibre pleated cartridge. This features a pleat pack constructed from borosilicate laboratory-grade glass fibre for high purity. Applications for this premier glass fibre pleated cartridge include potable water, cyst reduction, air and gas filtration and beverage clarification.

Cartridges can be supplied in a range of micron sizes, lengths, end-cap configurations and operating temperatures and we are happy to work with you to help find the correct combination of materials for the solution you need.

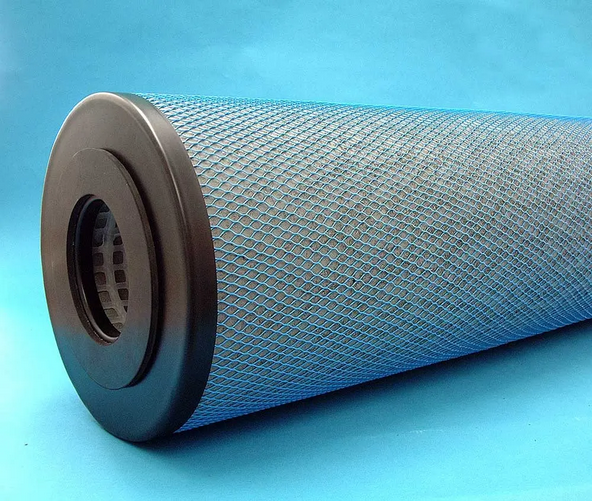

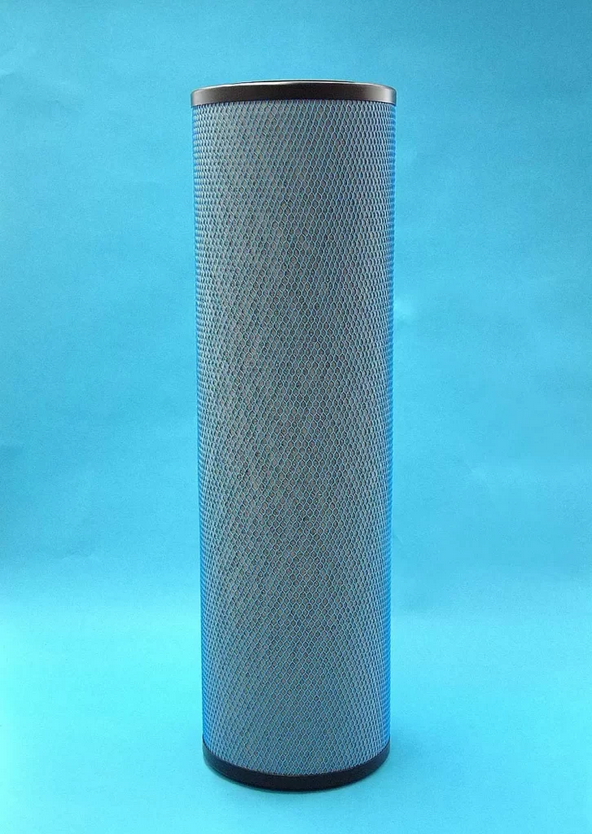

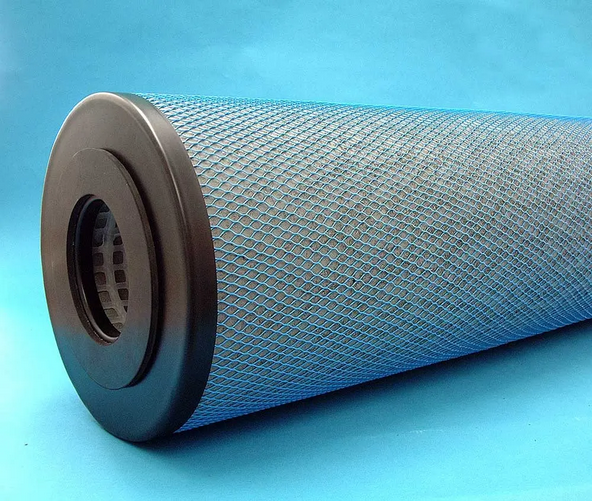

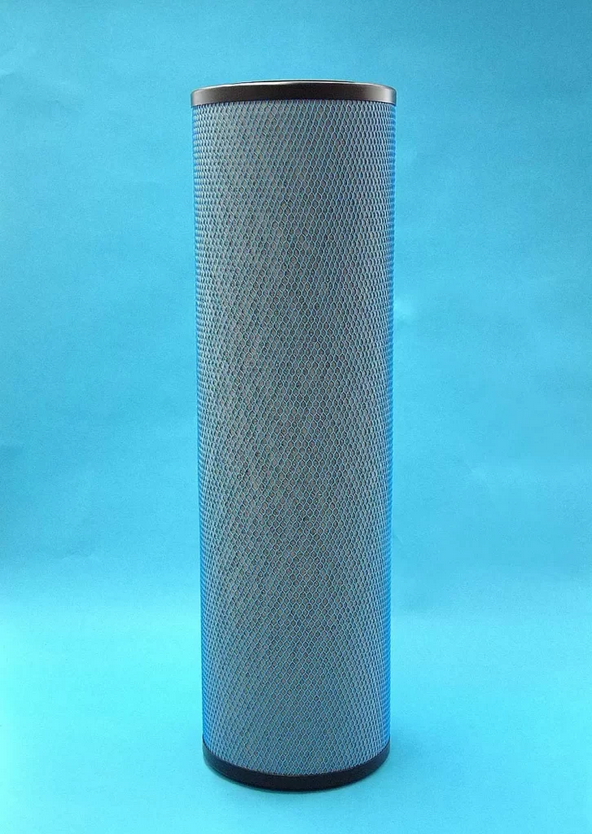

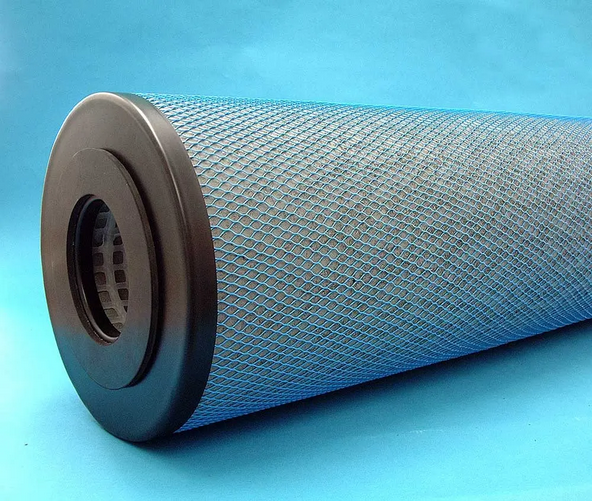

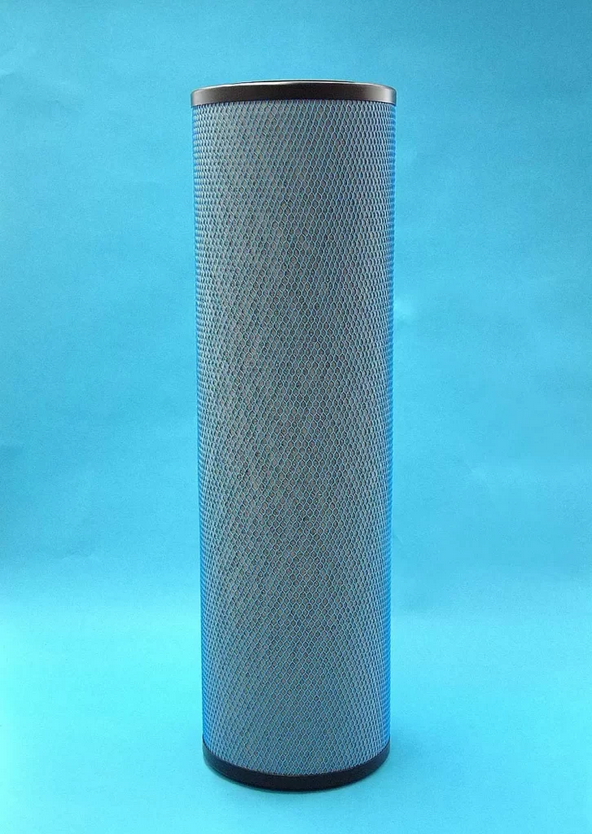

Carbon Cartridges

AFL manufactures carbon cartridges for filtering potable, industrial and process waters using different types of activated carbon.

The primary functions of activated carbon are the removal of chlorine, volatile organic compounds (VOCs), chlorinated hydrocarbons and organic impurities whilst acting as a mechanical filter for particulate reduction.

The cartridges are made in 70mm and 117mm diameters and finished with a range of end caps.

AFL can provide cartridges made to customer specification with alternative diameters and lengths and will assist in any cartridge development that may be required.

If you are looking for a bespoke product or would like assistance with your particular application please contact us.

Multimedia Cartridges

AFL’s multimedia cartridges combine different media in one filter, saving on housings and cost.

Our most popular multimedia cartridge features a wound polypropylene first stage to capture sediment and other impurities before water passes through a core filled with granular activated carbon (GAC) for dechlorination and removal of odour and bad taste. This cartridge is offered in a wide range of micron ratings from 0.5 to 50, lengths up to 40” and with multiple end-cap options.

Other combinations are available, including wound polypropylene over ENVirol™ oil removal media to remove sediment and hydrocarbons in a single cartridge.

Water Treatment

Hard water is good to drink and good for health but causes limescale to build up on metal surfaces, damaging heating and hot water systems. Over time, limescale blocks pipes, taps and shower heads and damages washing machines and dishwashers.

TAC (template assisted crystalisation) cartridges are the proven alternative to using water softeners to protect against limescale build-up.

AFL also offers resin media cartridges to target specific unwanted elements. These include softening resin cartridges; scale inhibitors; deionising cartridges, including a colour change option; heavy metal removal cartridges; and cartridges for iron removal and pH correction.

Filter Housings

AFL supplies plastic filter housings that have been manufactured to suit the most rigorous applications, give good performance and are simple to install and use while offering the best value for money.

AFL also offers a wide range of single and multi-cartridge standard and bespoke stainless steel and surface-coated metal vessels to suit many applications and requirements.

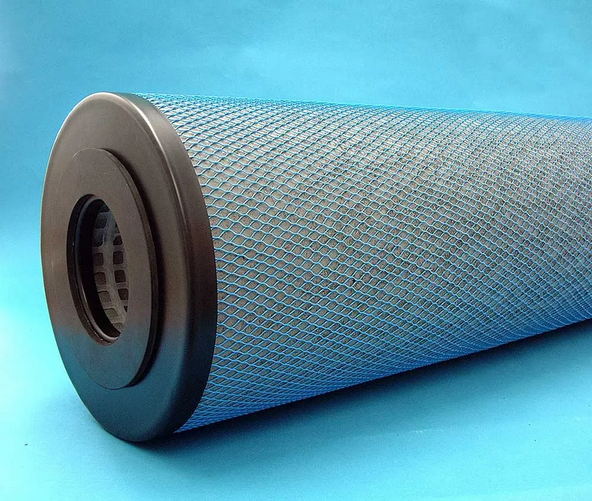

Oil Removal

ENVirol™ − the efficient and economical oil removal cartridge range from AFL

ENVirol™ is AFL’s efficient and economical oil removal cartridge range which effectively takes total oils from oilfield-produced and industrial waters.

The range now includes ENVirol™ Original, ENVirol™ Plus and ENVirol™ Block.

The polishing out of trace hydrocarbons from partially processed water prior to discharge has always proved a difficult and costly exercise. Emulsions and the dissolved fraction can now be economically removed using ENVirol™ filter cartridges as a polishing phase after existing oil removal technologies.

The ENVirol™ media is surface-modified substrate composed of selected fibres which are chemically modified to have a high affinity to forming a powerful electro-chemical bond with hydrocarbons.

ENVirol™ has been designed to provide high efficiency and take up of all types of hydrocarbon with exceptional holding capacity.

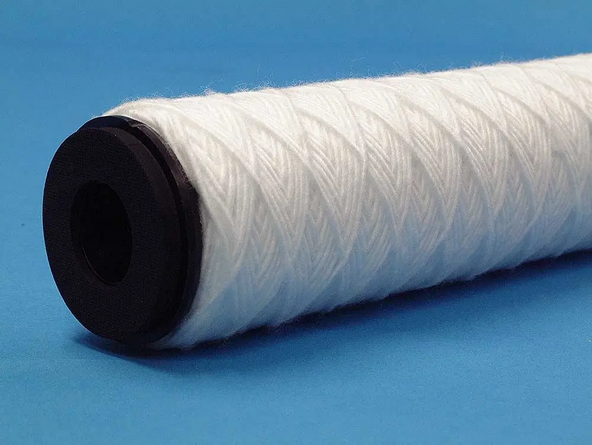

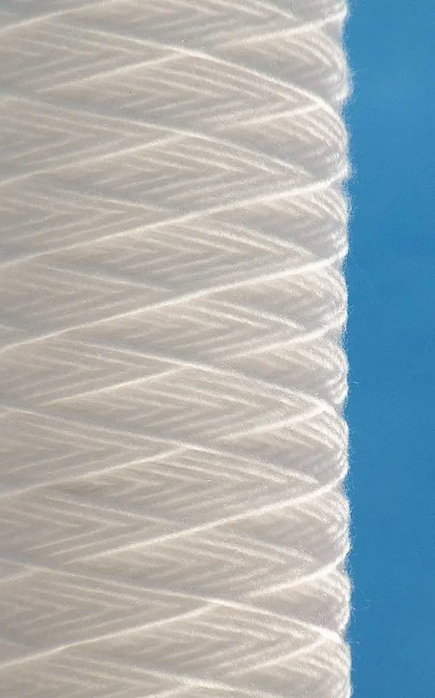

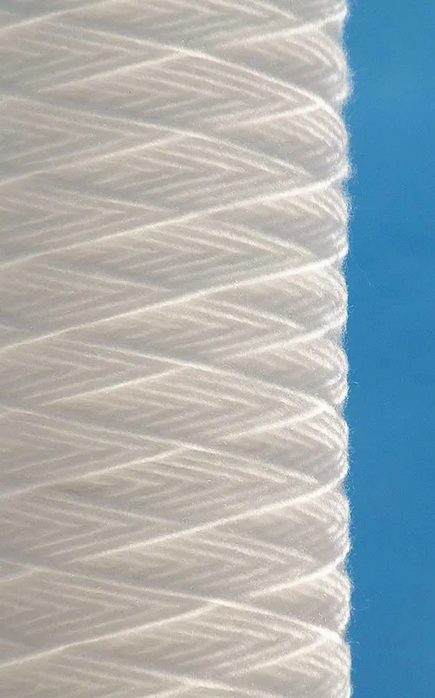

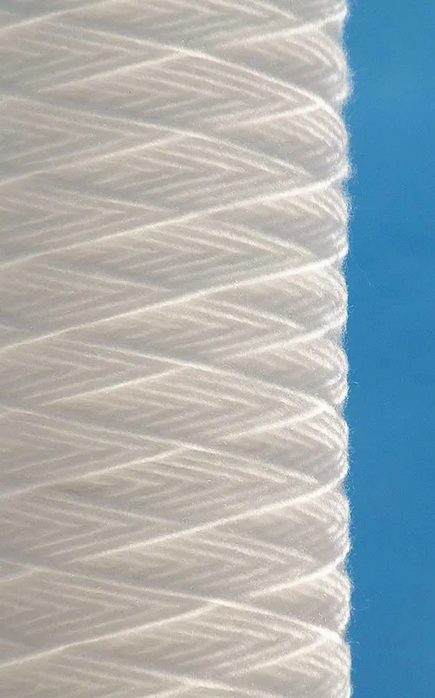

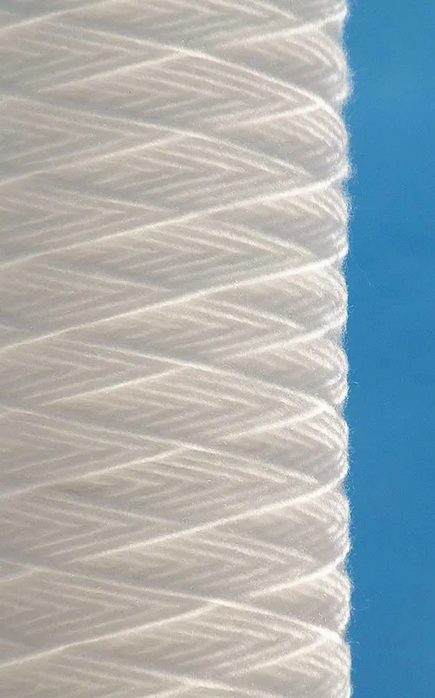

String Wound

String wound filter cartridges – high dirt-holding capacity and a longer life.

AFL spiral string wound filter cartridges provide an excellent economical solution to particulate removal for a broad range of industries.

Manufactured in the UK, AFL’s precision wound cartridges are available in a comprehensive range of micron ratings (from 0.5 to 200), yarns, core lengths and diameters. These cartridges have high dirt-holding capacity, accommodate high flow rates and offer fewer cartridge change-outs.

Precision winding patterns on our computer-controlled machines eliminate product variation and ensure accurate filtration ratings and high retention.

Various fibres and cores offer compatibility with a broad range of chemicals and high temperature applications.

For higher efficiency we offer dual wound cartridges featuring two wind patterns. A more open pre-filtration section removes larger particles, while a tighter final filter section provides removal of smaller particulates.

AFL string wound cartridges are suitable for filtering liquids, compressed air and gases. They are available in standard 2½” and 4½” (BB-style) cartridge diameter configurations and other diameters.

Our lead time is one to two weeks.

About us

Aycliffe Filtration Ltd (AFL) is a well-established UK manufacturer and supplier of filtration products, offering a wide range of standard and bespoke string wound, oil removal, pleated, and carbon cartridges tailored to meet specific customer needs. Based in Darlington and founded in 2009, AFL benefits from over 25 years of manufacturing expertise, making it a leading European provider of premium process filtration products. The company serves major industries such as oil and gas, industrial filtration, oil removal, and water treatment.

AFL’s product range includes UK-made Pleated Cartridges in various media types, including polyester, polypropylene, glass fibre, polyethersulfone, and nylon. These cartridges provide high dirt-holding capacity, low pressure drop, and durability, suitable for water, beverage, and oil and gas applications. They are FDA-compliant and thermally bonded to ensure strength without adhesive leaching. A premier borosilicate glass fibre version is available for potable water, cyst reduction, air and gas filtration, and beverage clarification, with multiple micron sizes, lengths, and configurations.

The company also manufactures activated Carbon Cartridges designed for potable, industrial, and process water filtration to remove chlorine, VOCs, chlorinated hydrocarbons, organic impurities, and particulates. These are offered in standard diameters with customisable sizes and end caps, with full support for bespoke product development. AFL’s multimedia cartridges combine filtration media in a single unit—commonly a wound polypropylene sediment filter paired with a granular activated carbon core for dechlorination and odour removal—available in various micron ratings and sizes. Other options include combinations for simultaneous sediment and hydrocarbon removal.

AFL’s ENVirol™ Oil Removal Cartridges—comprising Original, Plus, and Block versions—offer an efficient and economical solution to remove total oils from oilfield and industrial waters. Designed for polishing trace hydrocarbons after primary removal processes, they target emulsions and dissolved fractions with surface-modified fibres that bind hydrocarbons electrochemically, providing high efficiency and exceptional capacity.

The company’s UK-made Spiral String Wound Cartridges offer a cost-effective particulate filtration solution with high dirt-holding capacity, long life, and chemical and temperature resistance. Available in micron ratings from 0.5 to 200 and various yarns, lengths, and diameters, they support high flow rates and fewer replacements. Precision computer-controlled winding ensures consistent quality, and dual wound designs enable staged filtration. These cartridges are suitable for liquids, compressed air, and gases, offered in standard and BB-style sizes, with a typical lead time of one to two weeks.

All AFL products are manufactured on-site to BS EN 9001:2015 standards, ensuring quality and reliability. The extensive range also includes water treatment products and polypropylene and stainless steel filter housings. AFL maintains a large inventory of standard cartridges and housings while delivering tailored solutions for unique applications. Leveraging deep industry expertise, AFL designs and supplies high-performance filtration systems to meet diverse customer requirements.

For more information or assistance, please contact a member of our team who will be happy to help.

Images

Trade Associations