Company details for:

biplas Medical Ltd

Quick Links:

Products / Services

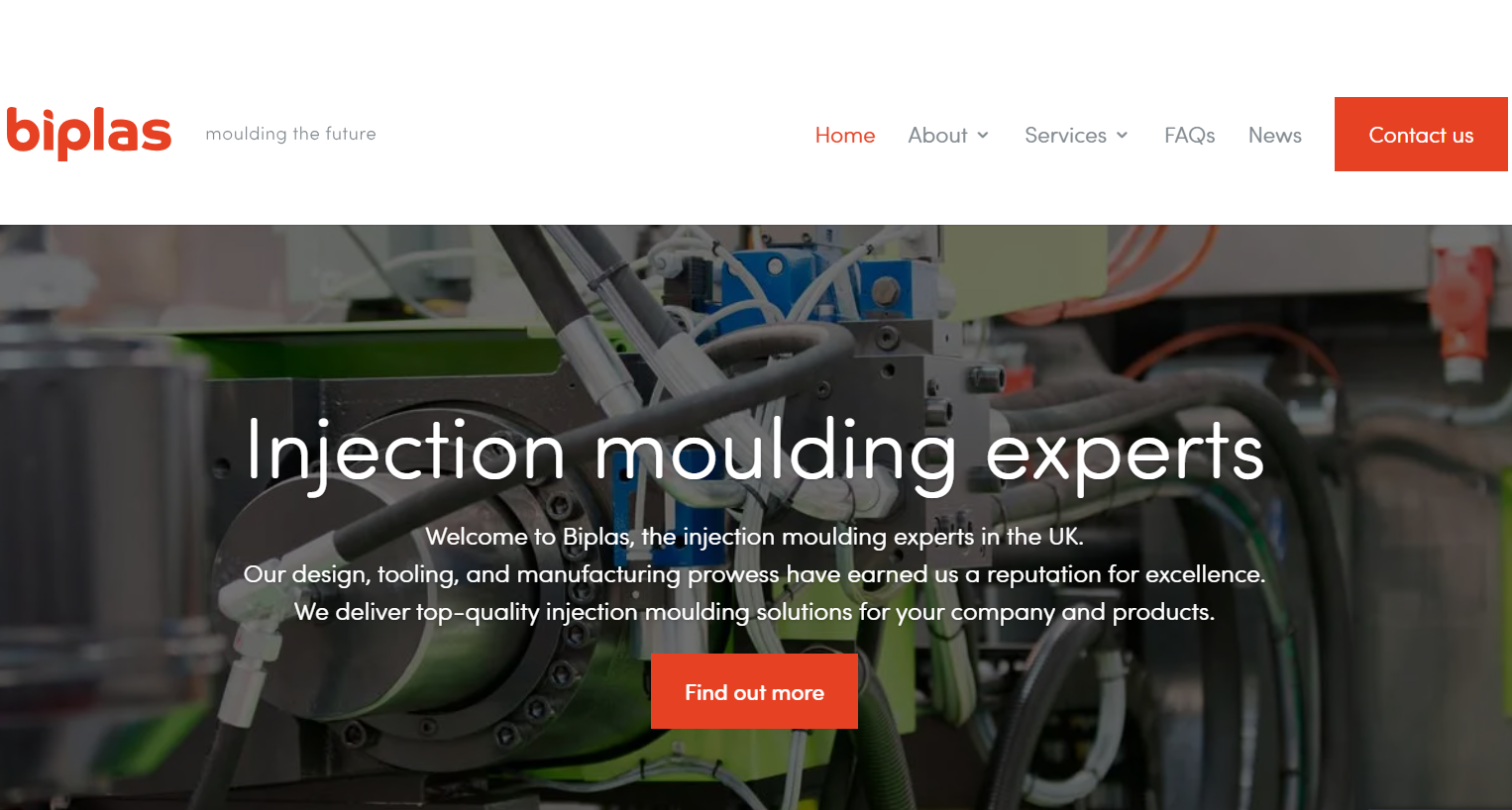

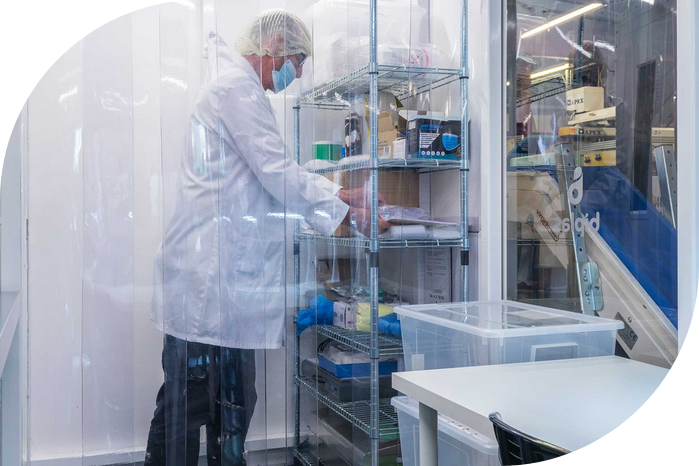

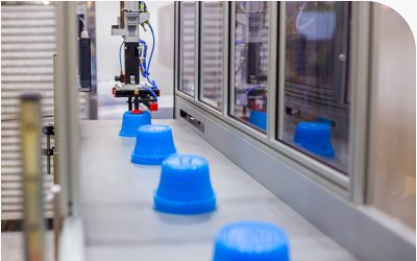

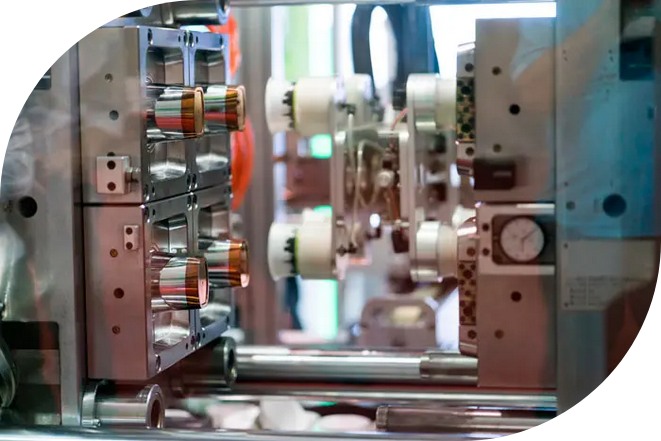

Cleanroom Moulding

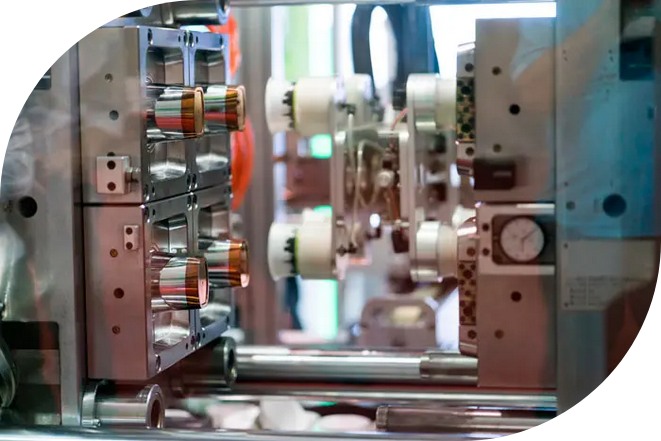

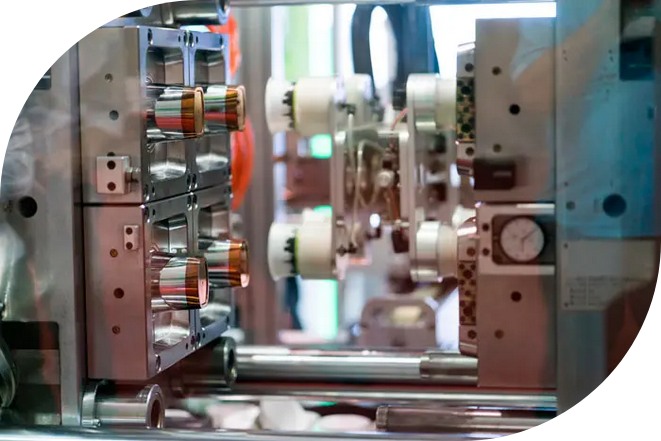

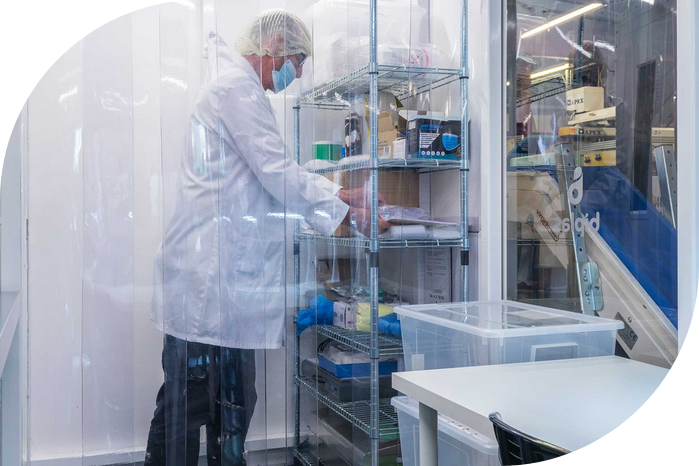

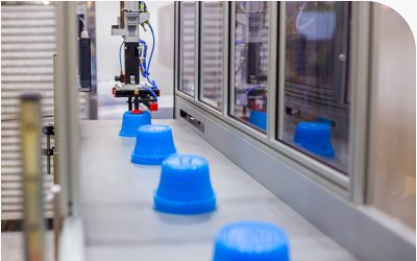

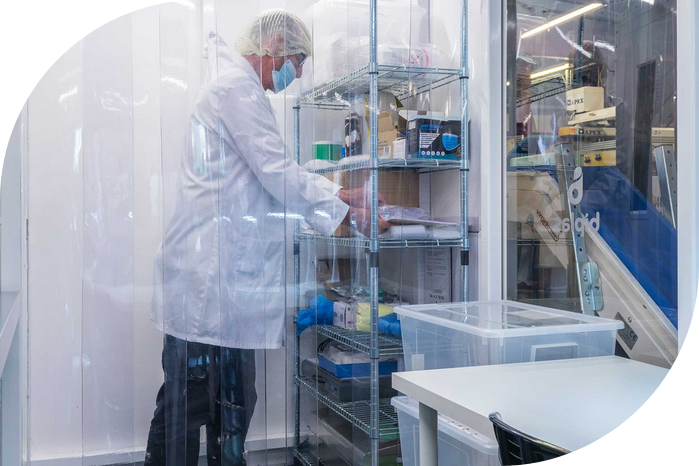

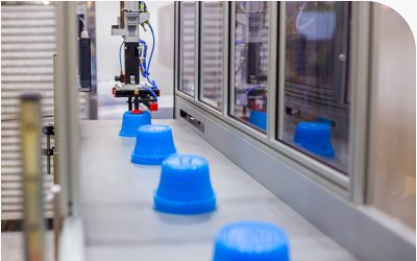

Our flexible cleanroom moulding protocol allows automatic moulded components to be manufactured in a Class 5 environment. Our facilities mean we have the capability to create medical devices in a sterile environment.

Sterile Medical Plastic Injection Moulding

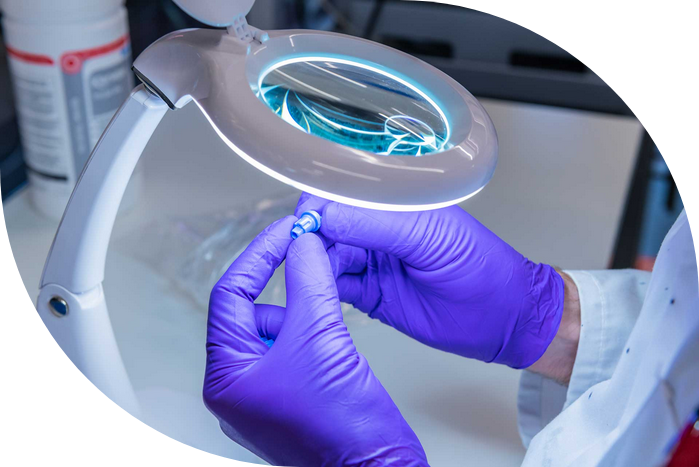

Our sterile medical plastic injection moulding facilities allow us to produce approved and validated products made with specific materials and requirements in mind. Careful manufacturing processes allow us to keep a sterile class 5 and class 7 environment for your medical devices and biotech packaging needs.

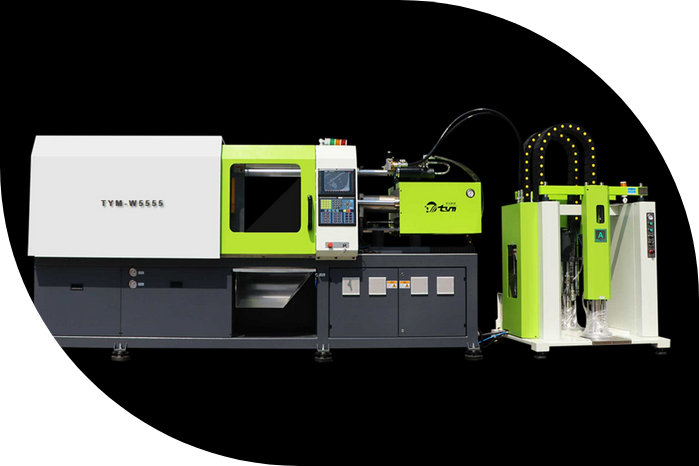

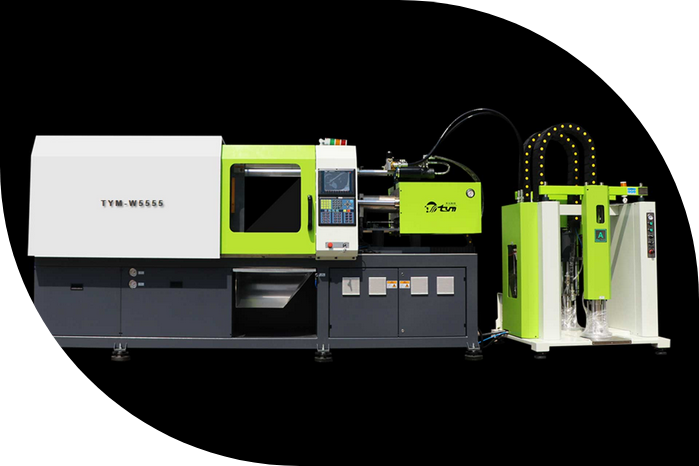

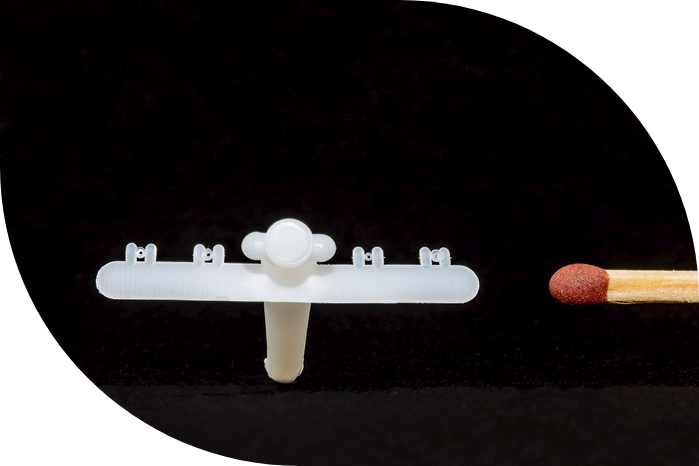

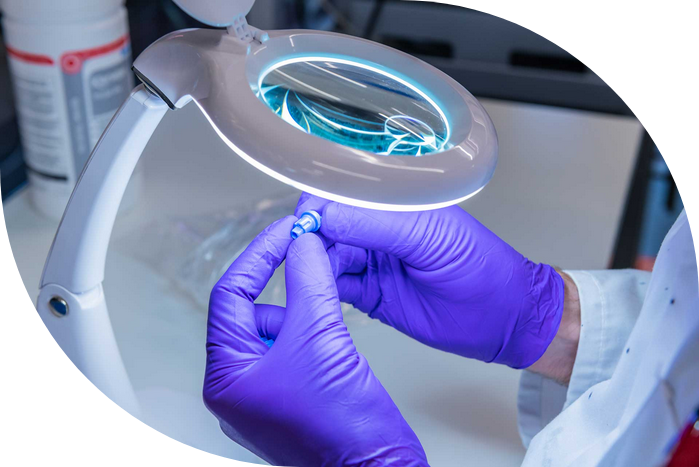

Micro Moulding Services

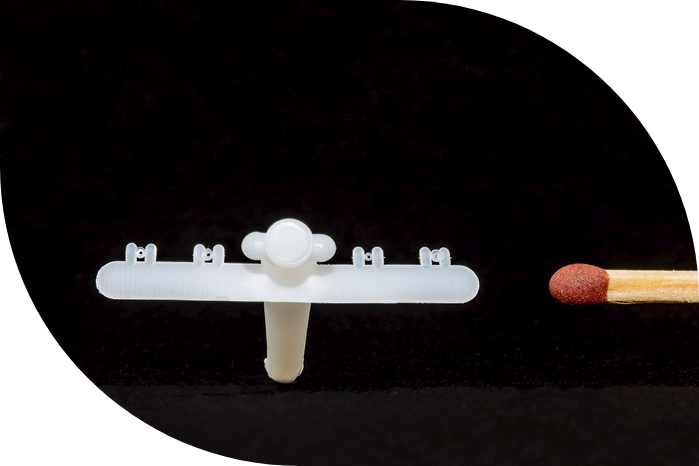

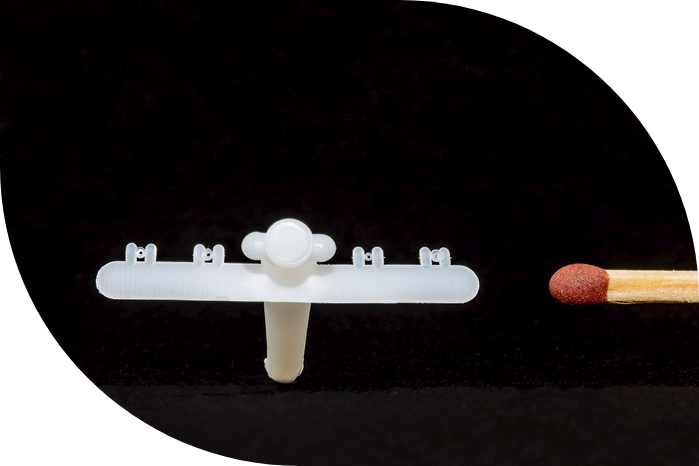

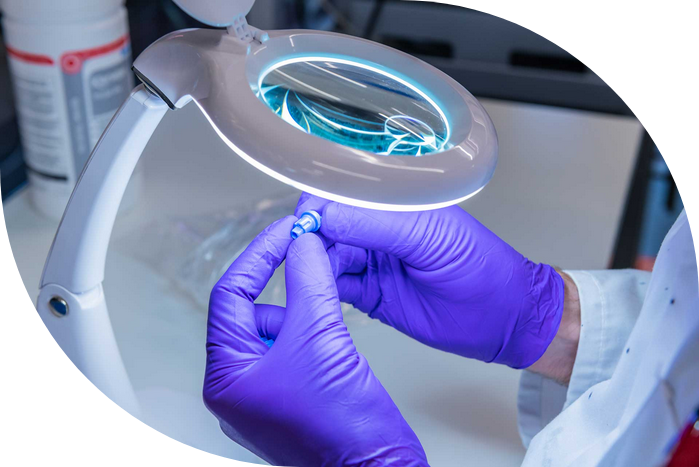

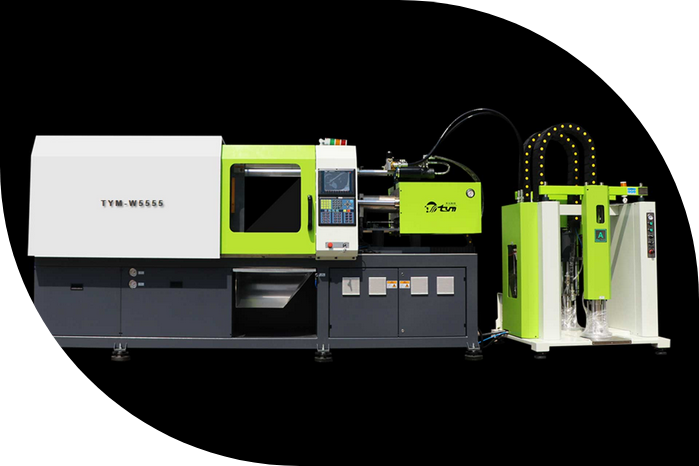

Micro injection moulding, a cutting-edge process at Biplas, enables the production of extremely small and high-precision thermoplastic components with tolerances in the micron range. With over 40 years of expertise, Biplas has developed the capability to mould sections as thin as 0.1mm, catering to industries requiring micro-sized parts, such as medical devices and electronics. Our advanced machinery, including the Babyplast 10/12, and Class 5 Cleanroom facilities ensure the production of high-quality, precise components for specialised applications.

Biplas’s micro moulding services are pivotal in advancing medical technology, exemplified by our recent project to develop micro-moulded components for use in human veins to aid in cancer treatment. Our commitment to innovation is reflected in our ability to produce parts with wall sections as thin as 0.03mm, meeting stringent quality and cleanliness standards. By leveraging state-of-the-art equipment and extensive experience, Biplas continues to push the boundaries of micro injection moulding, providing tailored solutions to meet the evolving demands of various high-tech industries.

PEEK & LCP Micro Moulding Specialists

High-Performance Micro Moulding with PEEK & LCP

At Biplas, we specialise in precision micro moulding using high-performance polymers, with a particular focus on PEEK (Polyether Ether Ketone) and LCP (Liquid Crystal Polymer). These advanced materials enable us to produce ultra-small, high-precision components for demanding industries, including medical, electronics, aerospace, and automotive.

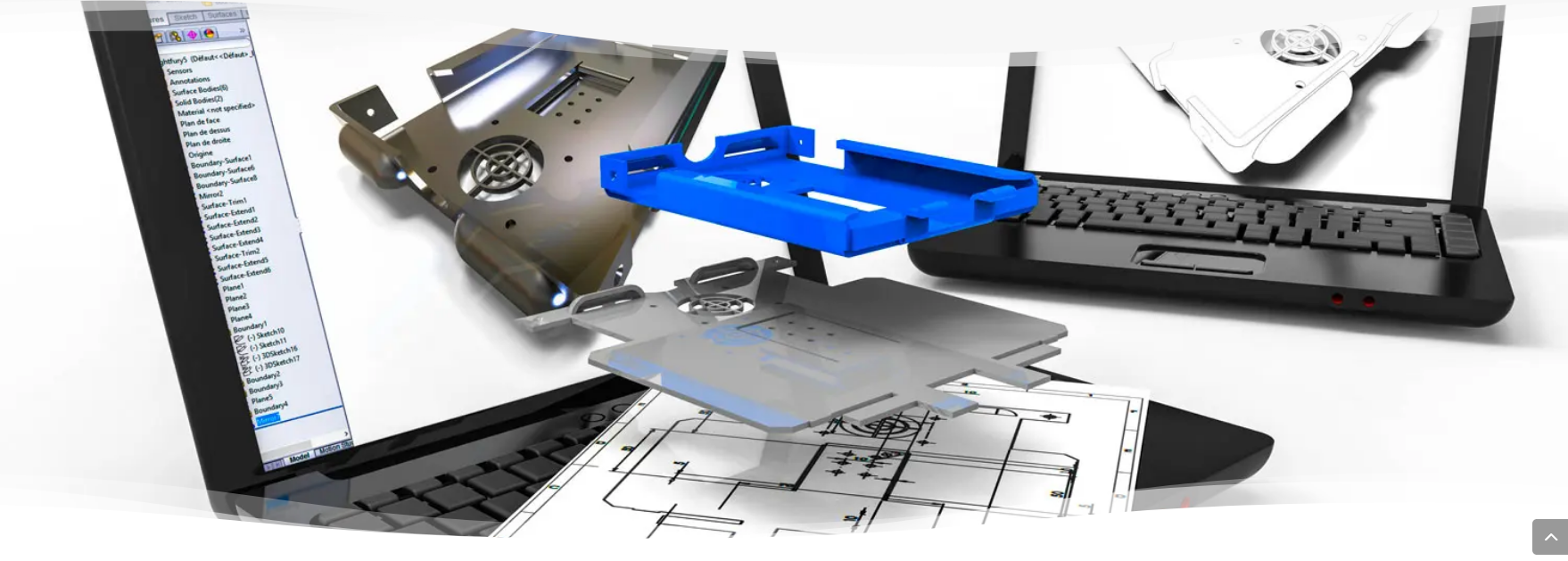

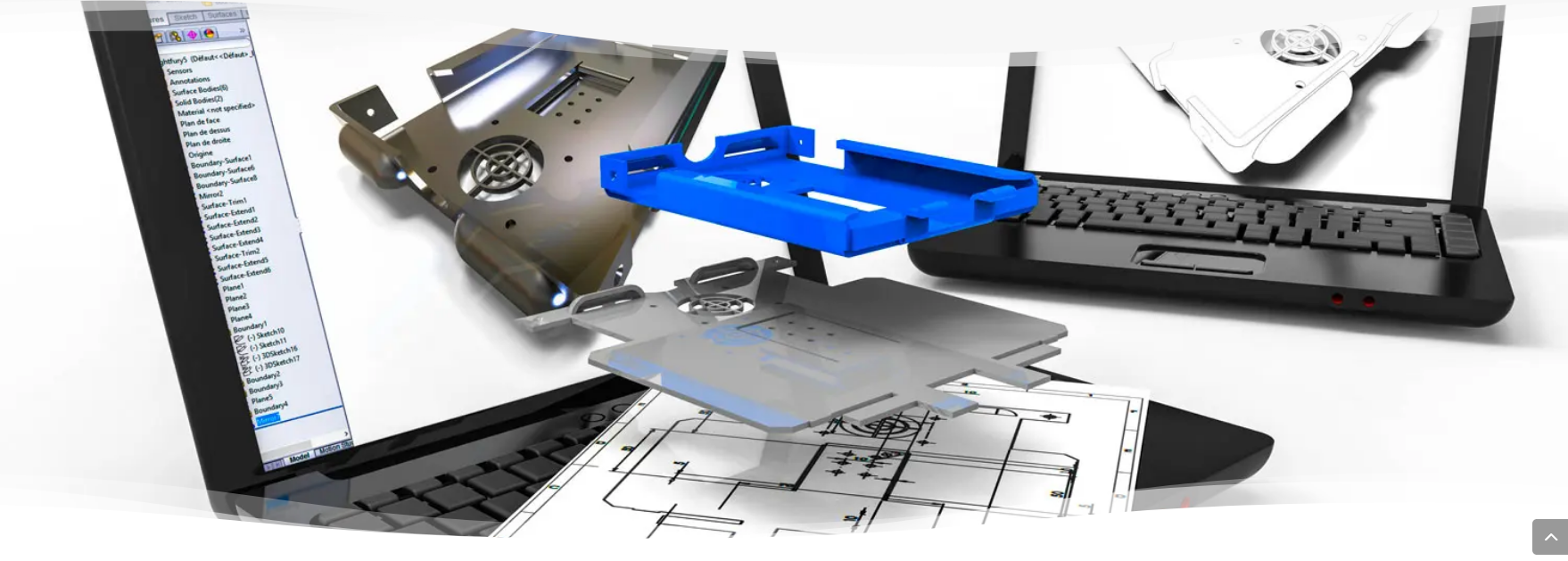

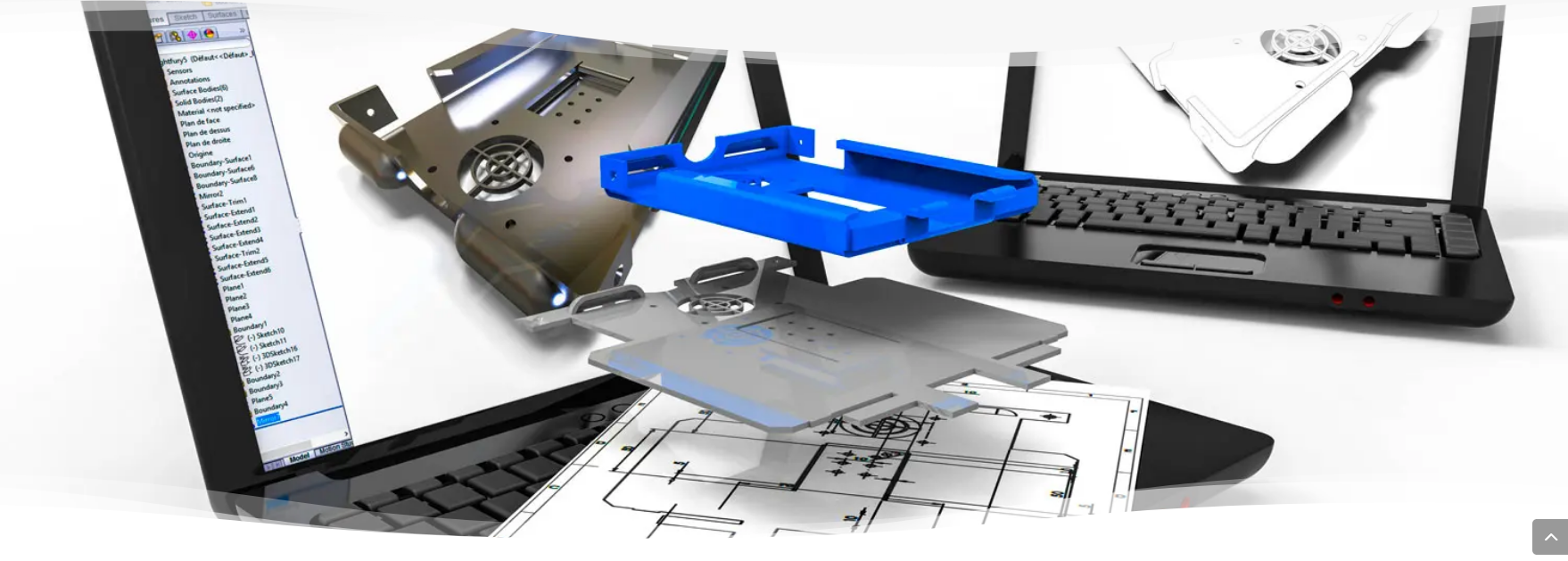

Injection Moulding Design

Years of experience in injection moulding design. Designing and developing products in various sectors and demanding industries.

Biplas product design and innovation team. With over 40 years experience of design and development in demanding industries.

In the world of injection moulding, design is key to success. At Biplas, we have a team of highly skilled designers who have years of experience in injection moulding design. They are experts in developing innovative and creative solutions that meet the specific requirements of our clients. Our designers work closely with our clients to ensure that every detail is taken into consideration, from the initial concept to the final product. We use the latest software and technologies to create 3D models and simulations that allow us to test and refine our designs before moving on to production. This ensures that the final product is of the highest quality, meets all requirements, and is cost-effective to produce. Our injection moulding design services are tailored to meet the needs of our clients, from small start-ups to large corporations. Contact us today to learn more about how our injection moulding design capabilities can help you bring your ideas to life.

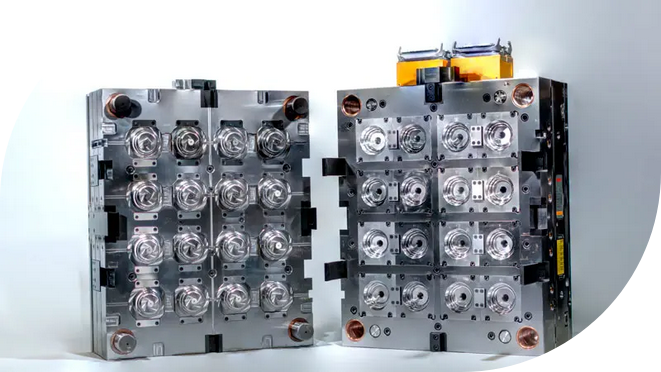

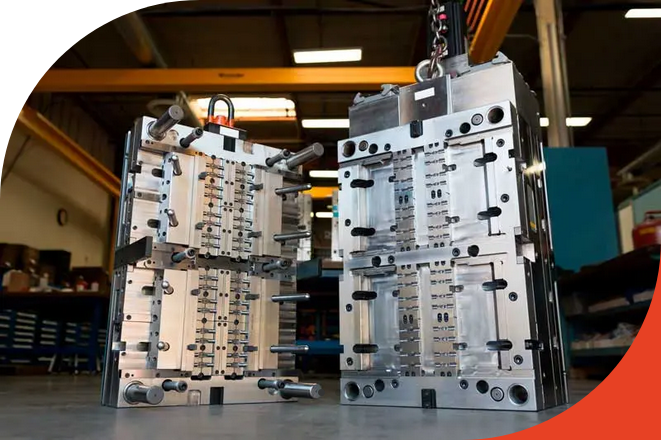

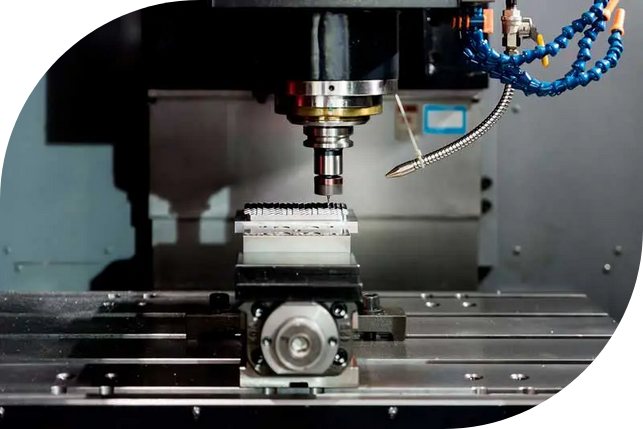

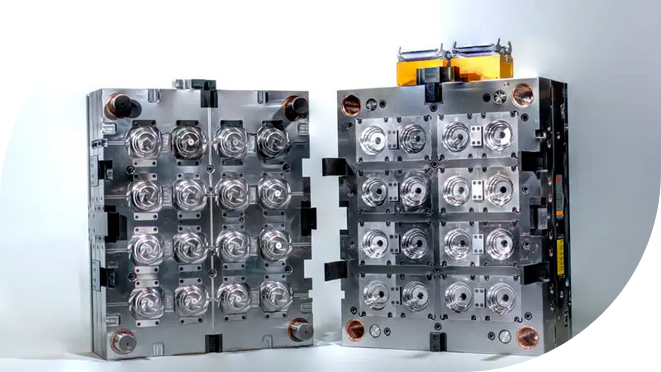

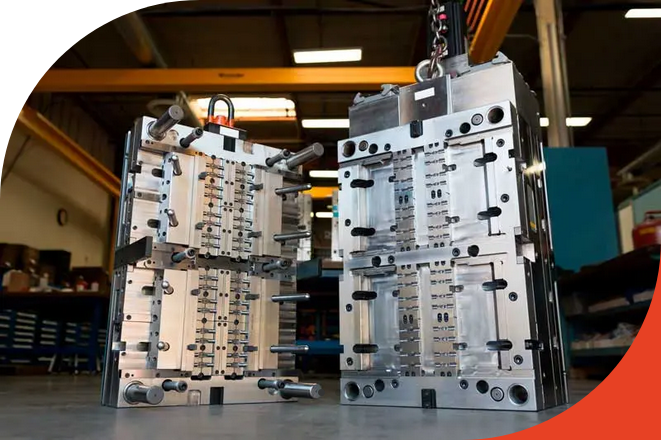

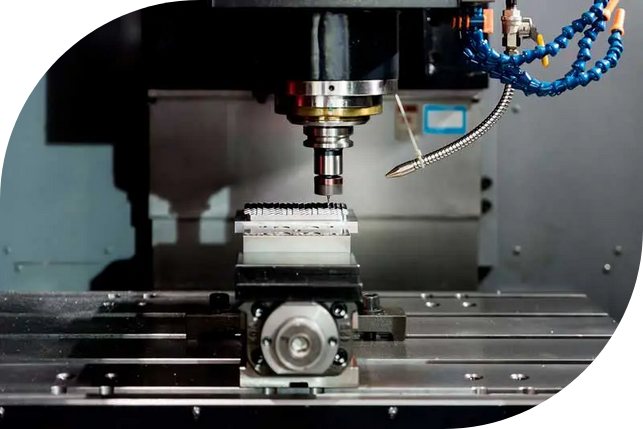

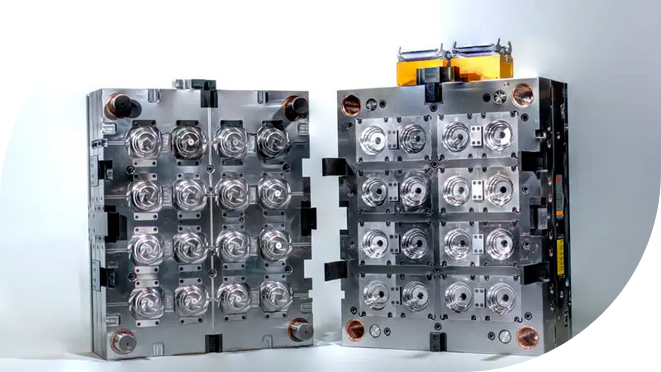

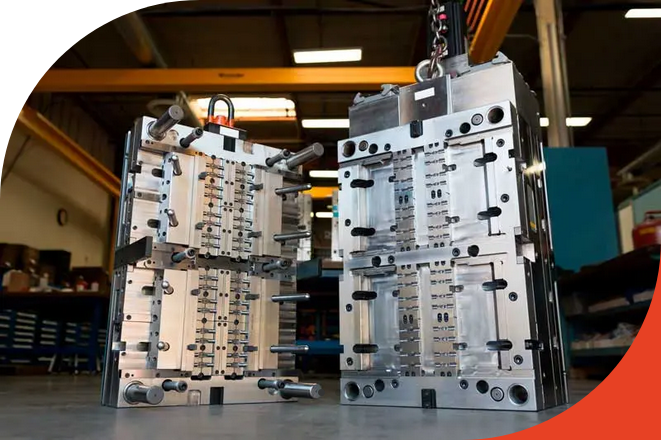

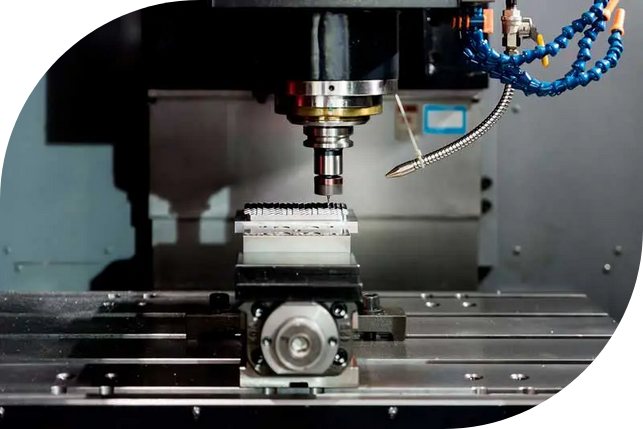

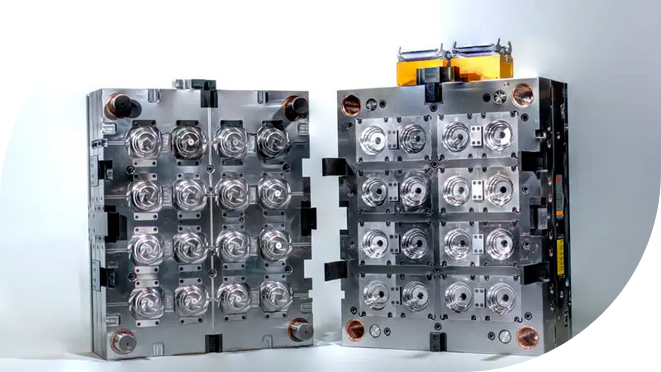

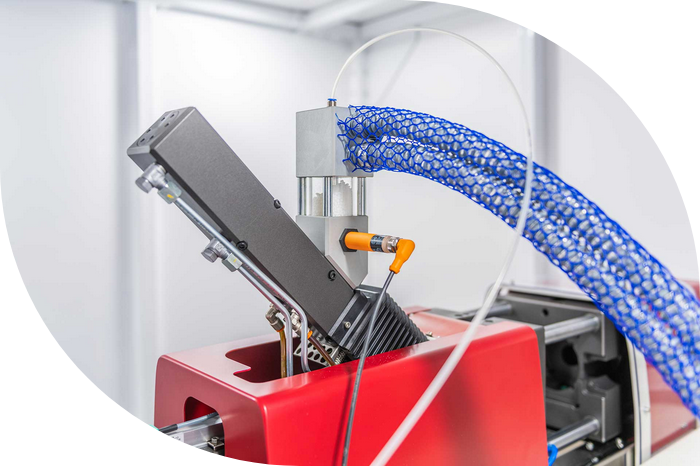

Injection Moulding Tooling

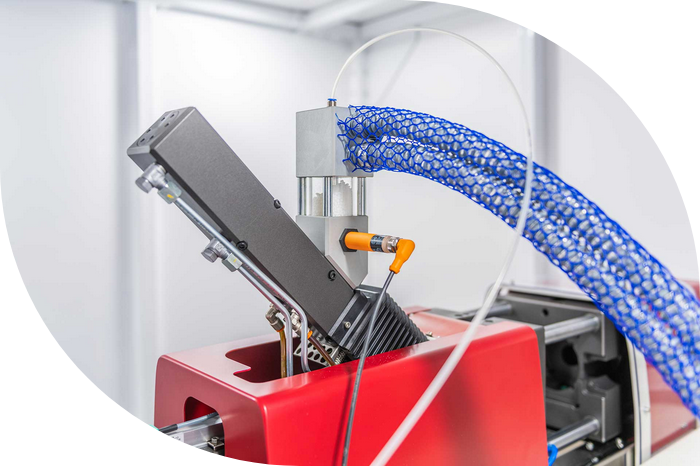

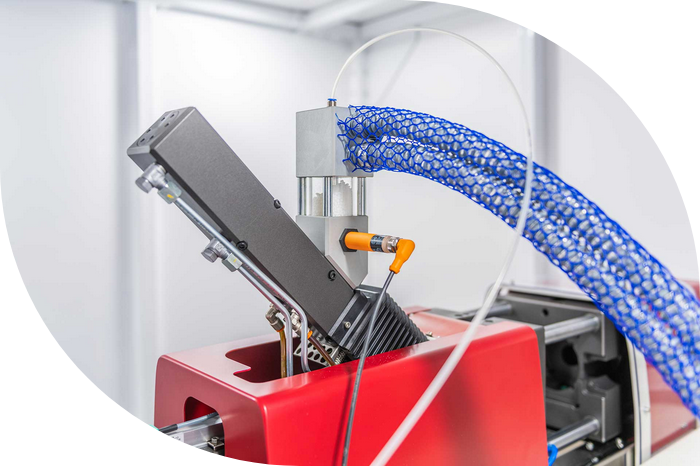

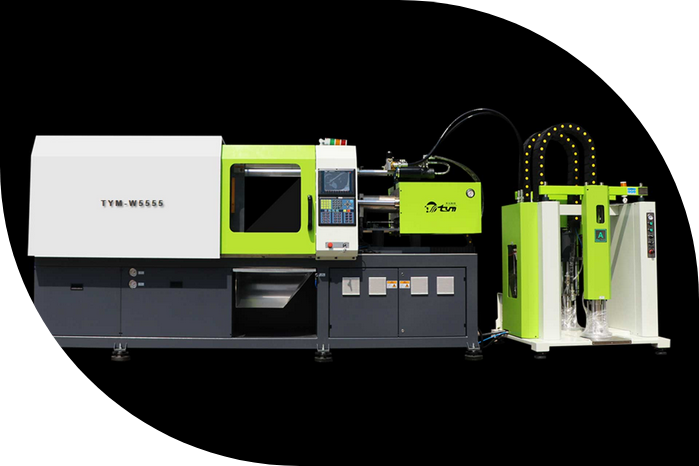

Effective injection mould tooling using the latest high speed machines for milling and spark erosion.

Biplas in-house toolroom and China toolroom enables us to offer competitive tooling using the latest high speed CNC machines for milling and spark erosion. Tool steel from aluminium single impression prototype through to P20 and fully hardened multi cavity tools with valve gate hot runner systems.

Liquid Silicone Moulding Specialists

High-Precision Liquid Silicone Moulding

At Biplas, we specialise in Liquid Silicone Rubber (LSR) moulding, delivering high-quality, precision-moulded silicone components for industries that demand durability, flexibility, and biocompatibility. Our advanced moulding techniques ensure consistency, reliability, and exceptional material performance for a wide range of applications.

Why Choose Liquid Silicone Moulding?

Liquid Silicone Rubber is an ideal material for injection moulding due to its outstanding thermal stability, chemical resistance, and flexibility. It is widely used in applications where high performance, precision, and biocompatibility are required.

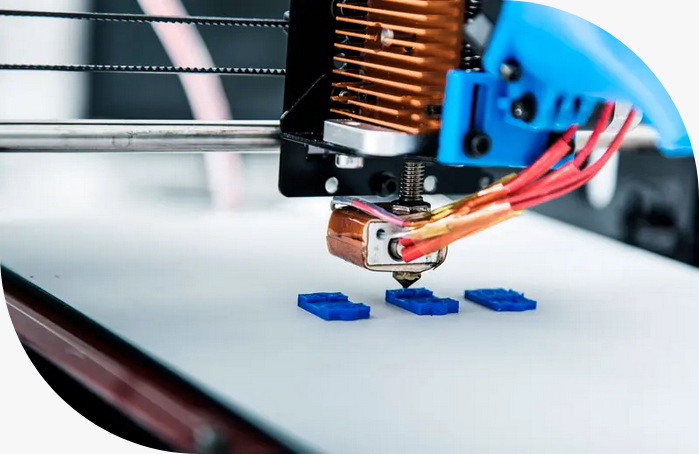

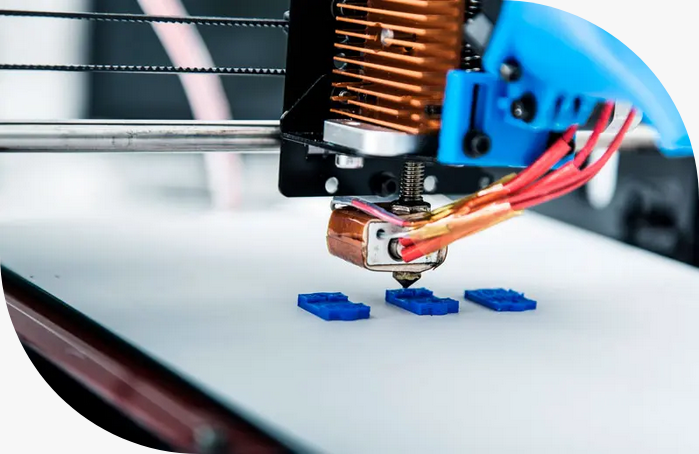

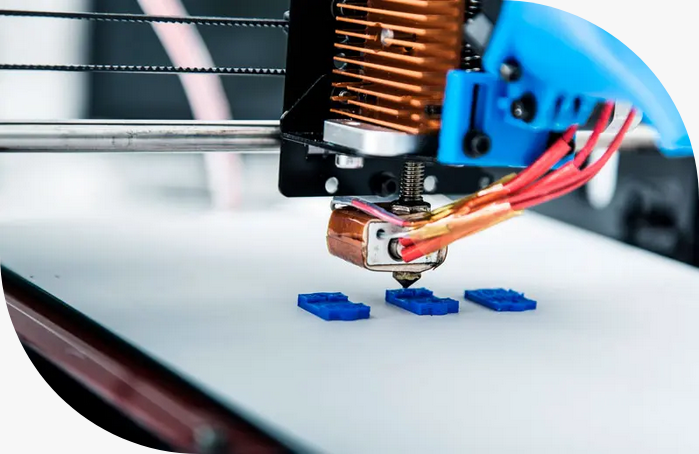

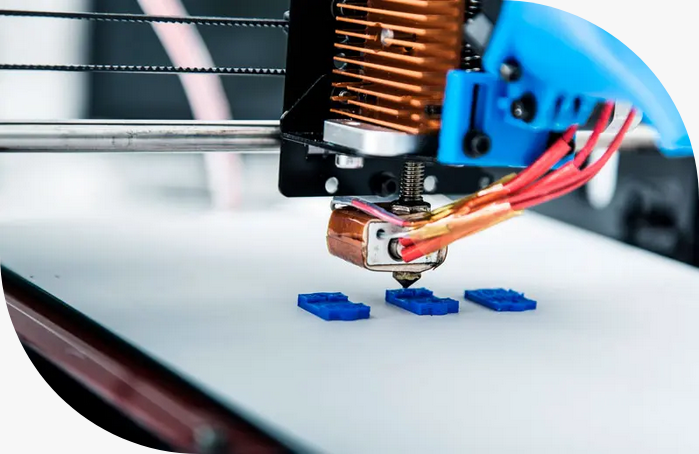

3D Printing

We have knowledge of the latest material developments and their applications. Our printing partner has the very latest equipment to achieve cost and time benefits.

We are developing 3D printed injection mould tooling for moulding in the specified production moulding material. This enables testing before cutting production tooling.

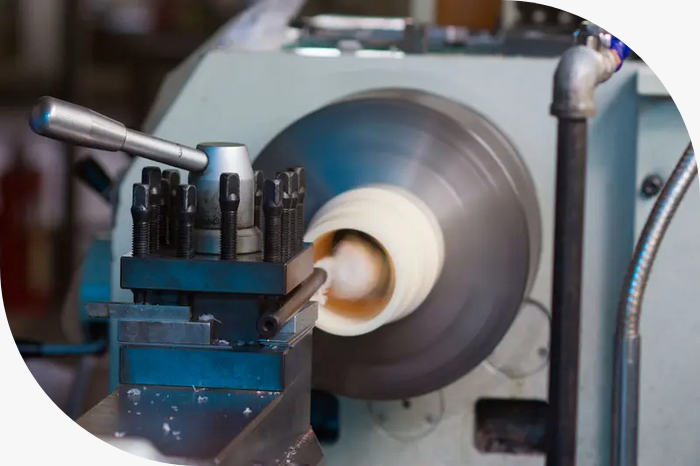

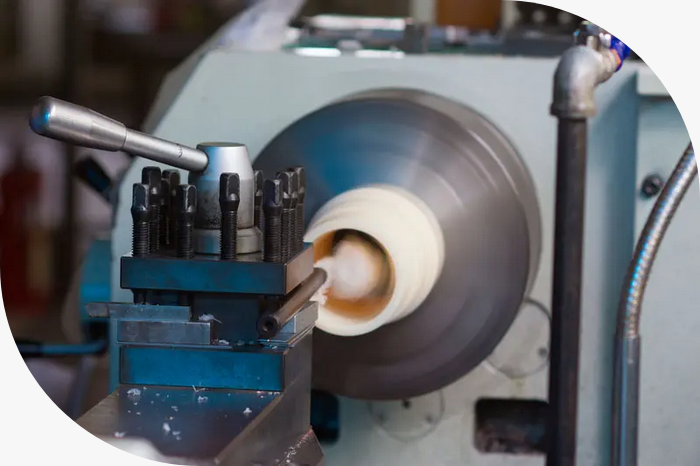

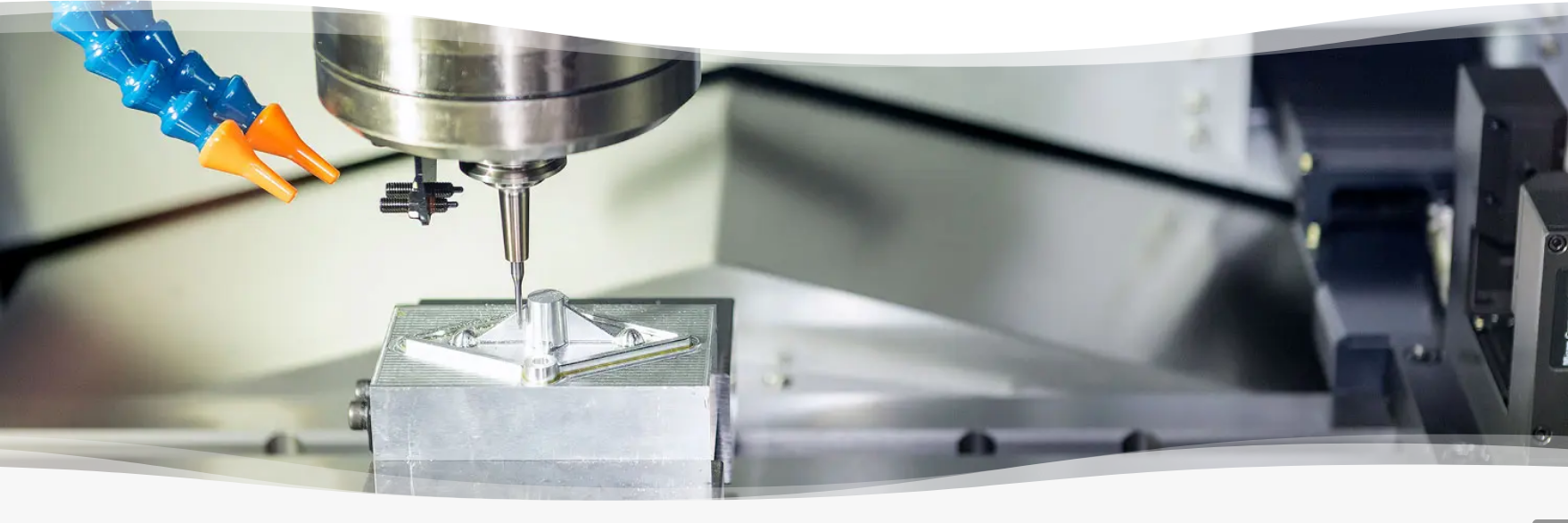

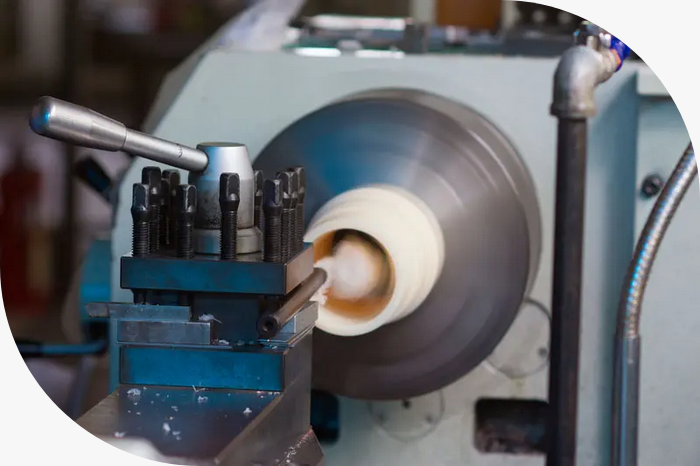

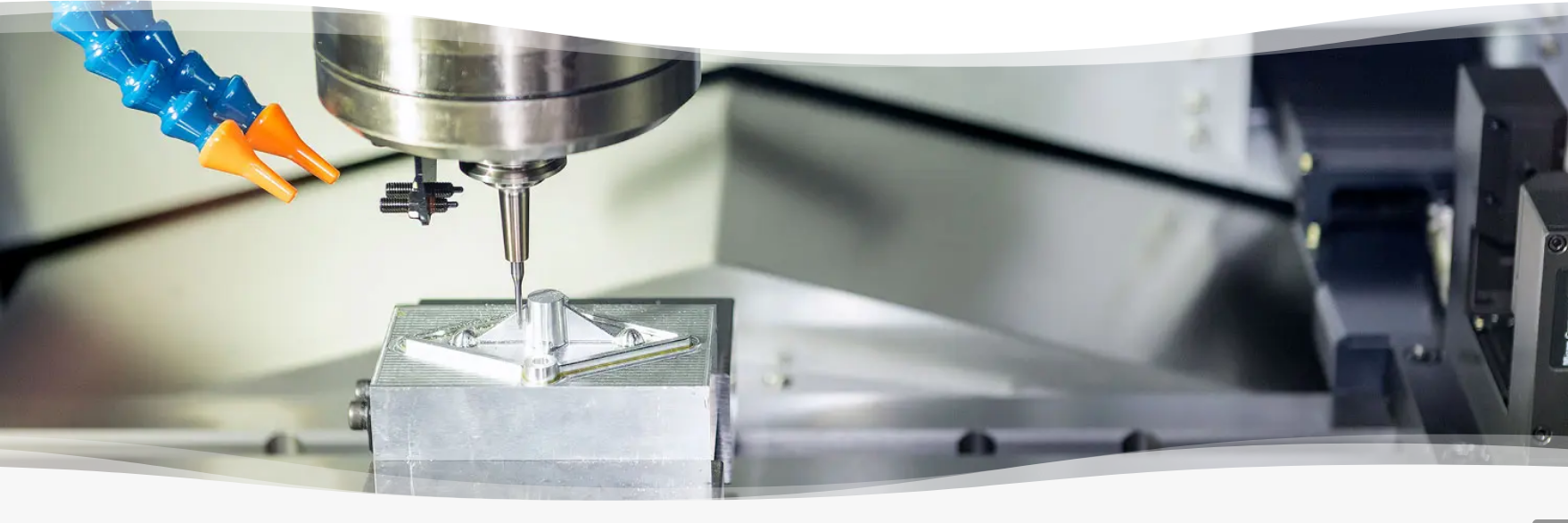

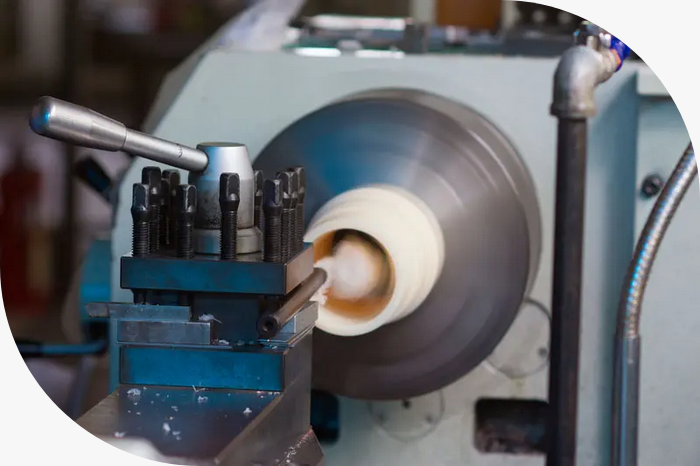

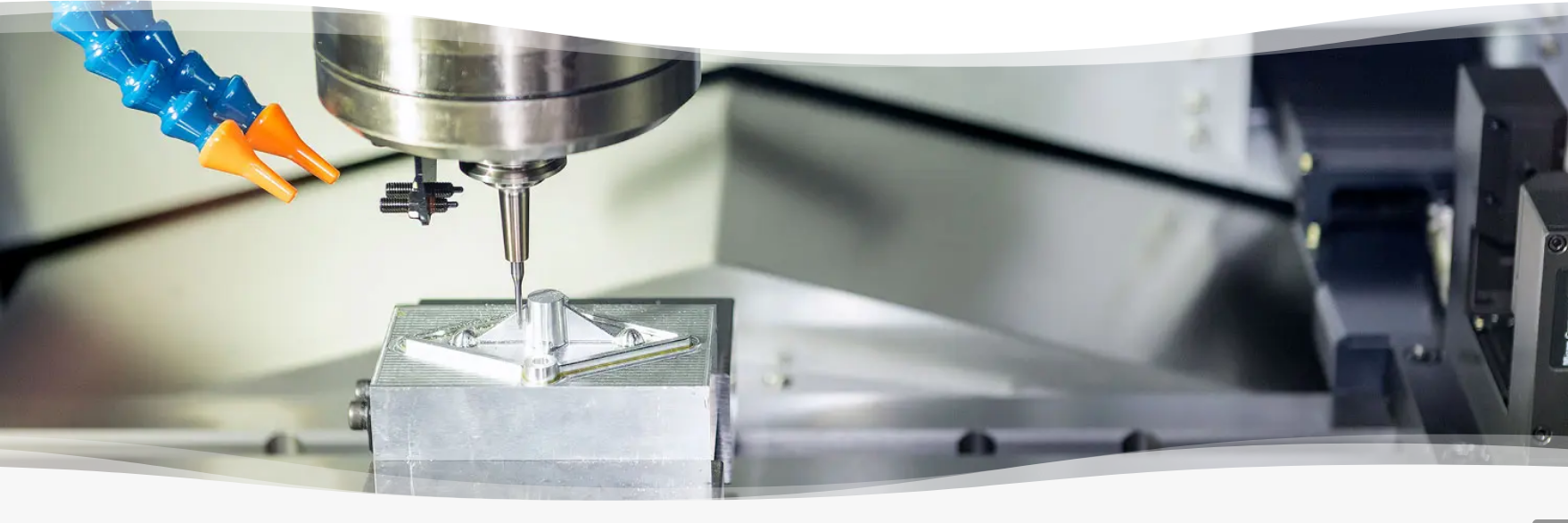

Machining Plastics

Precision machine plastics to enable technical plastic components for small production runs without the need for tooling.

Our CNC machining can achieve tolerances up to +/-0.02mm.

We have experience of machining a wide range of engineering grade materials.

Additional Services

Additional Services Include:

Ultrasonic Welding

Insert Moulding

Assembly & Packing

Let us know your requirements and we can offer you free advice and quoting. No matter which service, we can offer our professional advice and insight. For help with your next plastics product manufacture, get in touch with our in house manufacturing experts.

About us

biplas Medical Ltd is a forward-thinking UK company specialising in design, tooling, and manufacturing for complex, high-precision industries. We’re known for our expertise in technical and medical injection moulding, component and mould design, and close-tolerance plastic machining. Our focus on quality and customer satisfaction distinguishes us from others in the field.

We support your entire manufacturing journey—from initial design to final production. With expertise in technical and medical injection moulding, component and mould design, and precision plastic machining, we deliver exceptional quality and meticulous attention to detail.

We’re with you every step of the way, guiding your manufacturing process from concept to completion. Our strengths include technical and medical injection moulding, precision plastic machining, and expert design of components and moulds—all delivered with exceptional quality and care.

Our Services Include:

Cleanroom Moulding

Our adaptable cleanroom moulding process enables the production of automated moulded components within a Class 5 sterile environment, allowing us to manufacture medical devices to strict hygiene and cleanliness standards.

Sterile Medical Plastic Injection Moulding

Our medical-grade plastic injection moulding facilities are designed to produce validated, compliant products using specified materials. With controlled Class 5 and Class 7 cleanroom environments, we ensure sterile conditions for medical devices and biotech packaging.

Micro Moulding Services

At biplas, our advanced micro injection moulding process allows us to create ultra-small, high-precision thermoplastic components with micron-level tolerances. With over 40 years of experience, we can mould parts as thin as 0.1mm, serving sectors like medical and electronics. Using specialised equipment like the Babyplast 10/12 and operating in Class 5 cleanroom conditions, we deliver exact, high-quality components for demanding applications.

PEEK & LCP Micro Moulding Specialists

biplas specialises in precision micro moulding using advanced polymers, notably PEEK (Polyether Ether Ketone) and LCP (Liquid Crystal Polymer). These high-performance materials allow us to manufacture ultra-small, accurate components for industries such as medical, aerospace, electronics, and automotive.

… And more

Based in the UK and serving global markets, our injection moulding solutions support a wide range of industries—from automotive and healthcare to food contact and defence. Every product we deliver is tailored to meet your unique specifications.

From initial design to final moulding, we provide expert support at every stage of the process. Offering guidance throughout, biplas ensures the best results for your product, delivering tailored manufacturing solutions step by step to meet your needs perfectly.

Get in touch with biplas for all your design, tooling, and manufacturing requirements.

Images

Trade Associations