Company details for:

Bunting Magnetics

Quick Links:

Products / Services

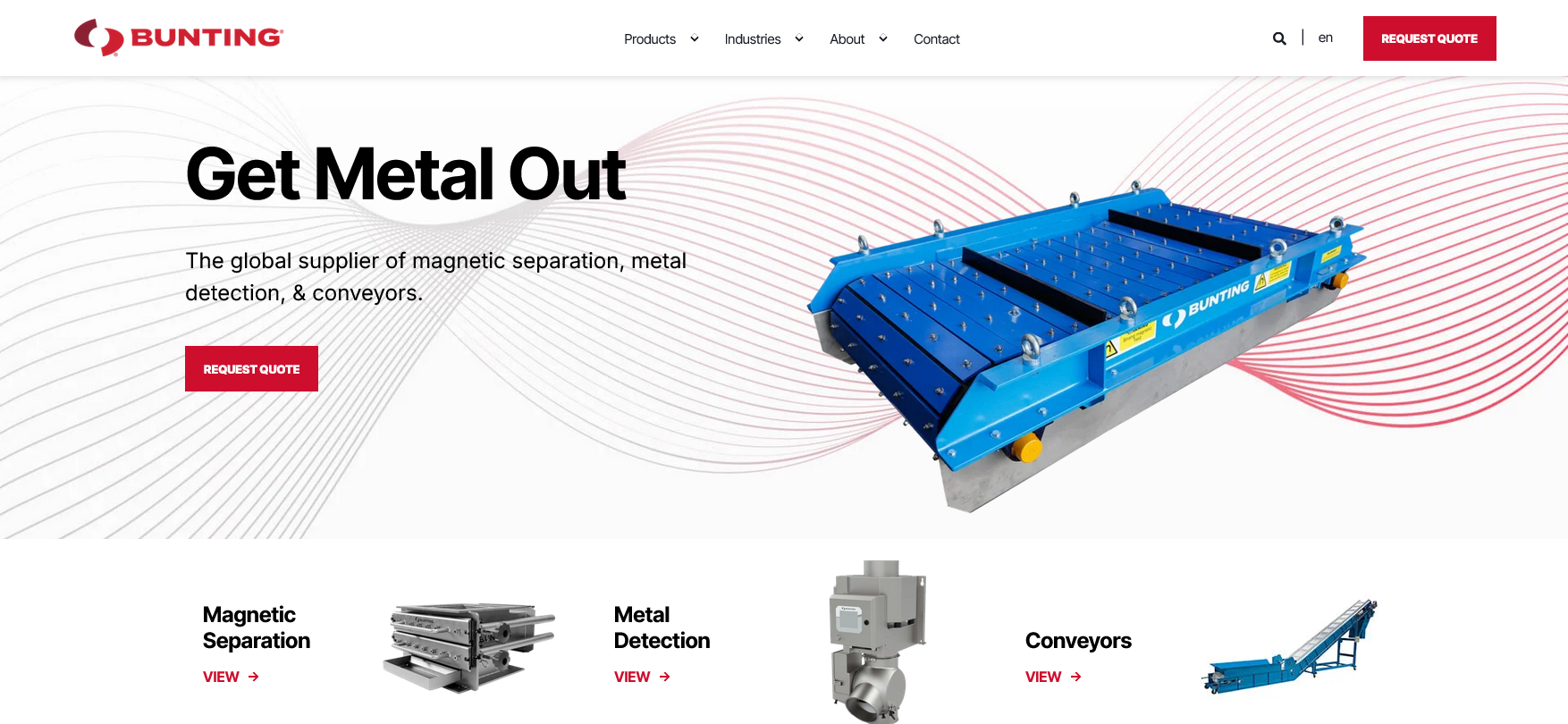

Magnetic Separators

Bunting® is a leading provider of magnetic separation solutions designed to remove ferrous contaminants, safeguarding both your processing systems and end customers. Our custom separators deliver superior product purity, reduce equipment wear, and maintain peak operational efficiency.

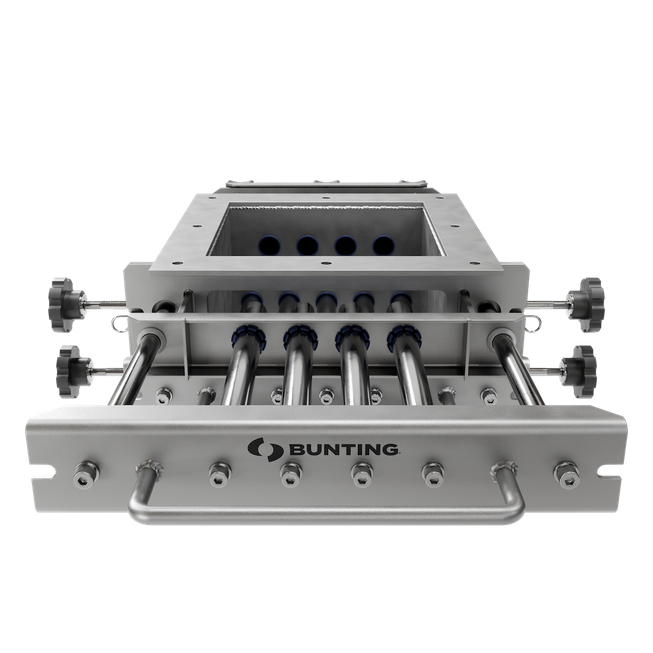

Drawer Filter Magnets

Bunting’s drawer filter magnets deliver high-performance magnetic separation for dry, free-flowing materials across industries including plastics, food, pharmaceuticals, recycling, and bulk powders. Engineered for efficient ferrous removal, they enhance product quality, safeguard equipment, and optimize process efficiency.

Drum Magnets

Drum magnets provide robust magnetic separation, effectively extracting ferrous metals from non-magnetic materials. Commonly used in recycling, mineral processing, and food production, they help maintain product quality and prevent equipment damage from metal contamination.

Inline Magnets

Removes ferrous contaminants from pneumatic and gravity-fed systems while maintaining optimal material flow.

Metal Detection

Metal Detection Products.

Gravity Fall Metal Detectors

Gravity free-fall metal detectors are engineered for precise detection and removal of ferrous and non-ferrous metal contaminants from bulk materials such as powders, granules, and grains. As product flows freely through the detection coil, any contaminated material is automatically diverted using a rapid-response reject flap or valve.

Pneumatic Metal Detectors / Separators

Bunting’s pneumatic metal detectors and separators provide reliable detection and removal of metal contaminants from materials transported through vacuum or pressure pneumatic conveying lines. Designed for accuracy in both industrial and food-grade environments, they maintain product purity and safeguard downstream equipment in applications such as flour, spices, plastic pellets, and regrind.

Conveyor Metal Detector

Tunnel Metal Detectors deliver high-sensitivity detection of ferrous, non-ferrous, and stainless steel contaminants in a wide variety of conveyed products. Offered in one-piece models for food processing and two-piece designs for industrial use, they integrate seamlessly into production lines to maintain product integrity, protect equipment, and meet quality standards.

Industrial Conveyors

Bunting designs and manufactures a comprehensive range of industrial conveyors for moving, feeding, and discharging materials in applications such as scrap handling, recycling, stamping, metalworking, and general manufacturing. From transferring aluminum cans to feeding shredders or handling sharp steel parts, Bunting conveyors deliver dependable performance, long-lasting durability, and precise magnetic control.

Our conveyor lineup includes both magnetic and non-magnetic models, each custom-built to integrate seamlessly with existing production systems.

Feeder & Discharge Conveyors

Engineered to deliver material to shredders and transport it post-processing, these conveyors efficiently handle heavy, abrasive, and irregular scrap.

MagSlide® Magnetic Conveyors

Fully enclosed magnetic conveyors, perfect for transporting sharp, oily, or abrasive ferrous parts and chips with no carryover and low maintenance requirements.

Dragslide™ Conveyors

Enclosed drag conveyors engineered for secure, leak-free handling of small or wet components.

Printing Cylinders & Shafts

Bunting Magnetics is a trusted provider of high-quality printing cylinders and shafts, engineered to meet the precise demands of the printing and converting industries. Our durable, precision-manufactured cylinders and shafts ensure smooth, consistent operation while maintaining exact tolerances for optimal print quality. Designed for reliability and long service life, Bunting’s solutions support a wide range of printing applications, helping businesses enhance productivity, protect equipment, and achieve superior finished products.

2-Piece Can Decorators

Bunting Magnetics offers precision-engineered 2-Piece Can Decorators, designed to deliver consistent, high-quality printing on two-piece cans for the food, beverage, and packaging industries. Built for reliability and efficiency, these decorators ensure accurate registration, vibrant graphics, and smooth operation while minimising downtime. Bunting’s 2-Piece Can Decorators help manufacturers maintain superior product quality, protect equipment, and optimise production performance across a wide range of can sizes and materials.

Aerosol & Tube Printing

Bunting Magnetics provides advanced aerosol and tube printing solutions, designed to deliver precise, high-quality graphics on cylindrical containers for the personal care, cosmetic, and industrial markets. Our printing systems ensure consistent registration, vibrant colors, and efficient production, helping manufacturers maintain superior product appearance while minimising downtime. Engineered for reliability and versatility, Bunting’s aerosol and tube printing equipment supports a wide range of materials and sizes, enhancing productivity and protecting equipment throughout the printing process.

Plastic Containers Printing

Bunting Magnetics offers specialised printing solutions for plastic containers, delivering precise, high-quality graphics across a wide range of shapes and sizes. Our systems ensure accurate registration, vibrant colors, and consistent results, helping manufacturers achieve superior product presentation while maintaining efficient production. Designed for reliability and ease of integration, Bunting’s plastic container printing equipment enhances productivity, protects machinery, and supports a variety of industries including food, beverage, cosmetics, and household products.

Buy In-Stock Magnets Online

Bunting is a worldwide leader in designing, manufacturing, and supplying advanced magnetic separation, metal detection, and conveyor systems. For more than 60 years, we’ve collaborated with industries across the globe, providing custom-engineered solutions tailored to each facility’s specific needs and challenges.

Magnet Manufacturing, Sourcing & Assemblies

Bunting Magnetics specialises in magnet manufacturing, sourcing, and assembly, providing high-quality magnetic components for a wide range of industrial applications. Our expertise spans custom magnet design, precision manufacturing, and complete assembly solutions, ensuring each product meets exact specifications and performance requirements. Trusted by industries worldwide, Bunting delivers reliable magnetic solutions that enhance equipment efficiency, protect systems, and support a variety of applications across manufacturing, processing, and material handling.

Compression Bonded Magnets

Avoid delays, export restrictions, and supply chain uncertainties with Magnet Applications. We manufacture Compression Bonded Neodymium Magnets in the U.S., ensuring reliable domestic supply and shorter lead times. With over 40 years of experience, more than one billion bonded magnets produced, and 6–12+ month stocking agreements, we provide dependable solutions for your production needs.

Magnetising Equipment

The strength of Bonded Neodymium Magnets depends on the magnetiser used. Without the proper equipment, their full potential cannot be achieved. That’s why we not only manufacture magnets but also engineer the magnetisers that activate them. By controlling both magnets and magnetisers in-house, we guarantee consistent performance and reliable magnetisation.

Permanent Magnet Solutions

Magnet Applications provides precision-engineered permanent magnets and assemblies, with dependable production facilities in the U.S. and U.K. We support customers through long-term stocking agreements to ensure supply chain stability and offer expertise across material selection and full-scale manufacturing.

About us

Bunting Magnetics is a global manufacturer of magnetic separation and metal detection equipment, with engineering and production facilities in the UK and USA.

The Redditch facility, formerly Master Magnets, continues a strong heritage in magnetic separation and metal recovery, now operating as part of the Bunting Group.

Since 1959, Bunting has built a worldwide reputation for designing and manufacturing high-performance separation and detection solutions that protect equipment, maintain product purity, and recover valuable materials.

Magnetic Separation Equipment

Bunting designs and builds an extensive range of magnetic separators for both dry and wet processing applications. Equipment includes:

Overband Magnets for continuous ferrous metal removal

Drum Magnets for separation of larger ferrous contaminants

High-Intensity Rare Earth Roll and Drum Separators for fine particle separation

Pulley and Plate Magnets for conveyor systems

Eddy Current Separators for non-ferrous metal recovery

Each separator is engineered for maximum separation efficiency, ensuring clean product flow and reduced equipment wear across industries such as recycling, mining, plastics, food processing, and ceramics.

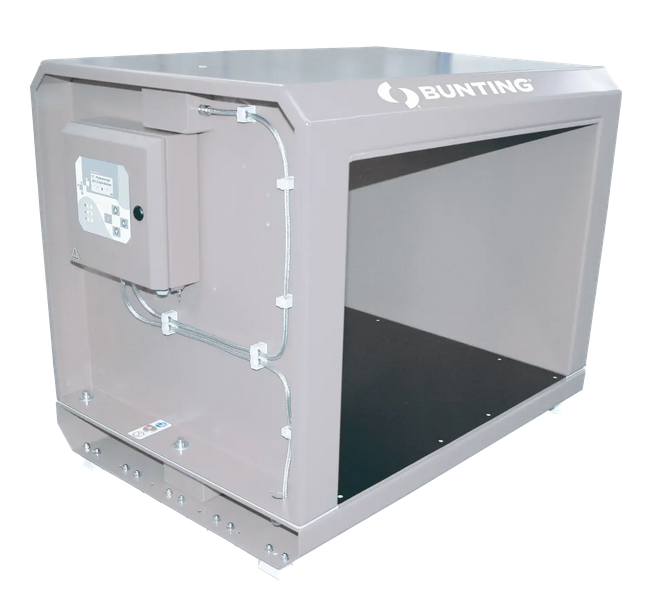

Metal Detection Equipment

Bunting metal detectors are designed to identify and remove metallic contaminants from bulk materials and packaged goods. The range includes:

Conveyor Metal Detectors for continuous production lines

Gravity-Fed Metal Detectors for powders and granular materials

Pneumatic Pipeline Detectors for vacuum or pressure conveying systems

Free-Fall Detectors for food and pharmaceutical applications

These systems are built to integrate seamlessly into existing processing lines, helping manufacturers meet quality assurance standards and protect downstream equipment.

Expertise & Support

Bunting provides complete design, testing, and service support from its dedicated laboratories and test centers. Each project benefits from in-house magnetic simulation and product testing, ensuring the right solution for every application.

With a global service network, Bunting supports customers from initial consultation to installation and maintenance, helping businesses achieve consistent, reliable metal separation and detection performance.

Bunting Magnetics continues to lead in magnetic separation and metal detection technology, providing proven solutions that enhance efficiency, protect production lines, and ensure the highest standards of product quality.

Images