Company details for:

JEB Precision Ltd

Quick Links:

Products / Services

Precision Machining

For over 40 years JEB Precision Ltd have been supplying a quality, reliable and cost effective subcontract machining solution for diverse applications used internationally.

With continual investments in the latest systems, machining technology and the training of engineers, we have what it takes to meet all your outsourcing needs under one reliable roof.

Precision Electromechanical Assembly

To complement our machining facilities, J.E.B. Precision also offer clean assembly services. Manufactured components are cleaned and assembled with bought out / free issue parts to customer’s Bill of Material in a clean environment.

We have many years experience in the supply of component sub-assemblies to the scientific instrument sector. Our machining and clean room assembly facilities are setup for delivering regular monthly call offs or to Kanban (JIT) requirement. Components are cleaned in our 7 stage aqueous ultrasonic system.

CNC Turning & Milling

At JEB Precision Ltd, we have embraced and are equipped with the latest CNC machining technology. Our modern precision engineering facility has a comprehensive CNC turning and milling section, which includes:

CNC Turning9 CNC lathes (Turning centres), with bar fed capacity of up to 50 mm diameter, including live tooling capabilities. Larger CNC turning capacity is offered on our robust CMZ lathes offering a maximum billet size of 12” diameter .

CNC Milling JEB’s milling section embraces the latest 5 axis machining technology, enabling us to machine complex parts in one operation. At the forefront of this technology, we offer simultaneous 5 axis machining, with a high specification Deckel Maho Gildermeister DMU 40 Evo machining centre.

Wire Erosion

In complimenting our extensive CNC turning and milling facility, we offer expertise in wire EDM machining, with Agie Cut 20 wire erosion technology.

Our team of highly skilled engineers have the experience and aptitude needed to produce highly complex components to the most exacting standards.

TIG Welding

J.E.B Precision have over 25 years experience of fine detail TIG welding. We carry out TIG welding for a large variety of customers in the Scientific Instrument sector producing Feedthrough Flanges, Vacuum Housings, Manifolds, Bellow Assemblies, Viewports, Tailpieces, Elbows and many other components for Ultra High Vacuum (UHV) applications.

We operate a Leybold Oerlikon Phoenix L300i vacuum leak detection system to verify weld integrity with the capability to leak check down to 1 x 10-12 mbar L/S.

Where required components are electropolished and cleaned ready for immediate integration into customer product.

We also offer TIG welding to other many other sectors, producing small precise fabrications for equipment used in various industries including pharmaceutical, medical, food technology, dairy and semiconductor equipment.

Vacuum Leak Checking

We have many years experience of Helium Vacuum Leak detection. We operate a Leybold Oerlikon Phoenix L300i vacuum leak detection system with the capability to leak check down to 1 x 10-12 mbar L/S.

We utilise our helium leak detection system for verifying weld integrity on welded fabrications as well as determining o ring or gold ring seal integrity on non welded vacuum enclosures and complete assembled vacuum systems.

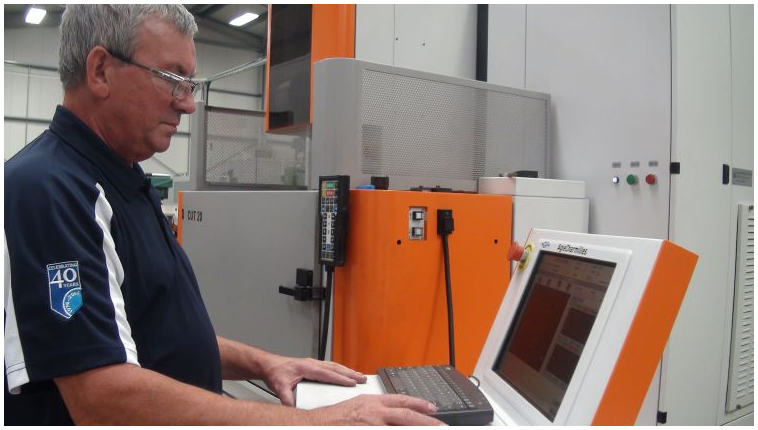

Quality Assurance

J.E.B. Precision operate a Quality Management System approved to ISO 9001:2015. A critical feature of which is the production routing which defines the sequence of manufacturing operations and inspection criteria for a specific batch.

The same document is used to record the results of inspection operations as well as material certification where material traceability is required. These documents are archived on site, thus maintaining a complete history for each batch produced.

About us

Established in January 1974, JEB Precision Ltd has grown steadily by maintaining an uncompromising focus on quality and a company-wide ‘right first time’ mindset. We proudly provide comprehensive subcontract CNC machining services across the UK.

As a subcontract manufacturer, we produce precision-machined components and assemblies in low to medium volumes, with higher quantities delivered monthly to suit customer needs. Our parts are crafted from a wide variety of materials, including stainless steel, non-ferrous metals, and engineering polymers.

We clean and assemble our manufactured components with purchased parts, providing customers with a single, reliable source of supply and removing the challenges linked to managing multiple suppliers.

Our Services Include:

Precision Machining

For more than 40 years, JEB Precision Ltd has delivered dependable, high-quality, and cost-effective subcontract machining solutions for a wide range of global applications. Ongoing investment in advanced systems, cutting-edge technology, and engineer training ensures we can meet all your outsourcing requirements in one trusted location.

Precision Electromechanical Assembly

In addition to our machining capabilities, J.E.B. Precision provides clean assembly services. Components are thoroughly cleaned and assembled using purchased or customer-supplied parts, following the customer's Bill of Materials, all within a controlled clean environment.

CNC Turning & Milling

JEB Precision Ltd utilises the latest CNC machining technology, operating from a state-of-the-art engineering facility that features a fully equipped CNC turning and milling department.

Wire Erosion

In addition to our advanced CNC turning and milling capabilities, we provide specialist wire EDM machining using Agie Cut 20 wire erosion technology.

TIG Welding

With more than 25 years of expertise in precision TIG welding, JEB Precision serves a wide range of clients in the Scientific Instrument sector. We produce components such as feedthrough flanges, vacuum housings, manifolds, bellows assemblies, viewports, tailpieces, elbows, and more for UHV applications.

… And more

Kindly reach out to us by submitting a message through the contact form on our website.

Videos

Trade Associations