Company details for:

Oberlin Filter Ltd

Unit 2,

Hurworth Road,

Aycliffe Business Park,

Newton Aycliffe,

Durham,

DL5 6UD,

United Kingdom

Quick Links:

Products / Services

Oberlin Filter Ltd at MACH2020

The Olimin8r

For our 2nd year displaying at MACH we shall be bringing the Brand New Creation for all CNC filtration, The Olimin8r!

On the stand we will be have the machine fully running so you can see just how important #cleanliquidsdrysolids are to Oberlin Filter Ltd.

Let us show you just how easy and cost effective filtration can be.

Visit us at MACH2020

20TH - 24TH April 2020

The NEC, Birmingham

Stand 6-733

Coolant Filtration

> High performance media and depth filtration typically delivers less than 10 ppm solids above 10 microns

> Lengthens coolant life 5-10 times

> Filters have flow rates ranging from 15gpm - 2,000gpm

> Optional, cleanable, semi-permanent belts available for certain applications

> Better surface finish

> Less wheel loading/burn

> Better part size control

> Less heat build up

> Less tool wear

> Dress wheels less

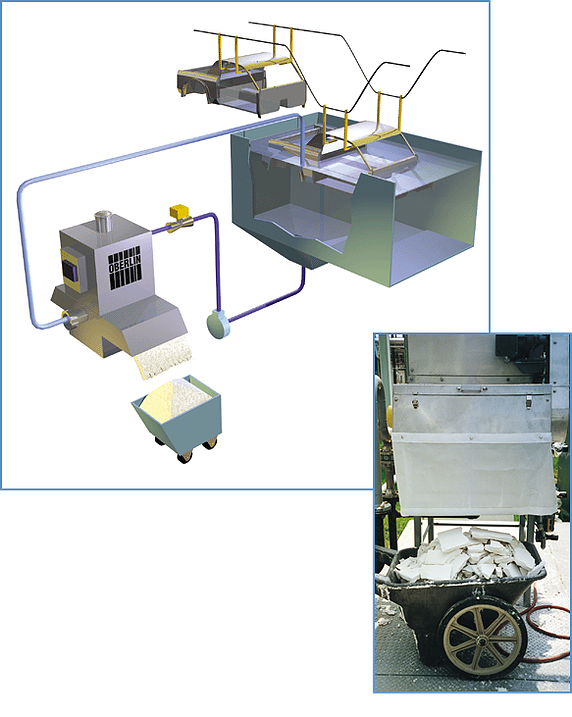

The filtered solids automatically discharge in an extremely dry cake

> Filter cakes over 90% solids by weight in typical steel grinding.

> Discharges a dry cake with less coolant loss.

> Oberlin’s thicker cakes trap far more metal fines then paper alone.

> Greatly improving the cleanliness of the coolant.

Central Filtration Systems for Coolants

Oberlin Filter Company makes fully automatic coolant filtration systems ranging from 20 gpm to 6,000gpm. These systems are designed to support a single machine like a gear grinder, or an entire shop. The larger, central systems will usually have sumps at each machine to pump back dirty coolant to the dirty tank. The larger systems also tend to have redundant filter pumps and clean pumps to minimize downtime. The Oberlin Filter is simple in design resulting in a reliable uptime availability range of 99%. A large portion of our customer base are repeat customers which speaks for itself in regards to Oberlin's Filter users expecting the performance and reliability of our filtration systems.

We will customize the design to fit your space requirements. We will use your preferred PLC’s and screens. Or you can use our standard designs and controls for more cost effective packages.

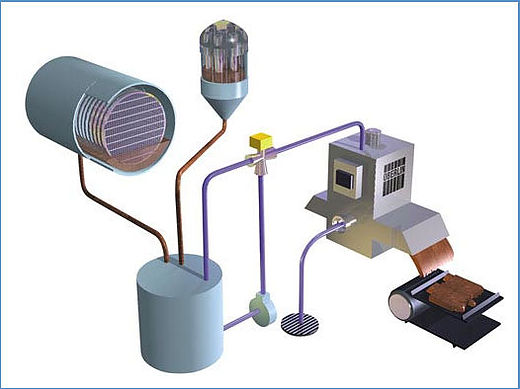

Hot Oil Filtration Food Processing

The Oberlin Hot Oil Filter is the top-performing filter for fryers and roasters and is used by the world's largest food manufacturers. The filter’s ability to filter down to 1 micron keeps frying oil in good condition indefinitely. There will be no need to discard the frying oil ever again.

The Oberlin Filter is a continuously operating pressure filter that pumps the polluted frying oil under pressure through a non-woven disposable filter media. Sinking, suspended and floating sediment are all filtered. The sediment is therefore removed before it starts to affect the oil, slowing down the oil breakdown and extending its life.

The completely automatic Oberlin Filter operates online for continuous filtration for fryers in the 300 gallon − 2000+ gallon range. The filter can also be used in a batch treatment system on an as needed basis. The 1 micron filtration removes FFAs and solids/fines and crumbs for a continual supply of clean oil. The removed solids are automatically discharged in a dry cake.

Phosphate Bath Filtration

> Chemical Usage Savings

> Extremely Reliable

> Cleaner Bath Allows More Efficient Heat Transfer Reducing Overall Energy Costs

> Fewer Reject / Reworked Parts Decrease Production Downtime

> Cost effective for 200 gallon baths

> Typically < 100mgl solids in phosphate bath

> Silicon free construction

> No clarifiers to clean

> No presses to manually open, clean and re-seal

Chemical Processing

> Easy access

> Self flushing options

> CIP options

> Internal surfaces can be polished

High Solids/High Temp/High Corrosion

> High Solids: If solids dewater easily, automatic indexing pressure filter a good choice for up to 50ft3 of solids /hour

> High Temperature: Applications up to 260 °F. Platens can be heated to prevent freezing

>High Corrosion: Filter external structures can be made entirely of 316 SS.

>Wetted parts can be high Nickel alloy stainless steel like SMO254, C276..

> Crystallizers

> Wet Scrubber

> Reactor Separations/Cleanouts

> Radioactive Processing

Sulfur Recovery

Industries & Applications

> Landfill Gas

> Coal Gasification Plants

> Claus Tailgas Cleanup

> Refinery Desulfurization

> Water Treatment Facilities

> Geothermal Plants

> Offshore Platforms

> FPSO

> Chemical Plants

> Lean Amine

> Rich Amine

Oberlin Filter Maritime Scrubber Systems

> 100 % Water Filtration − Eliminates need for secondary dirty water collection/storage

> Dry Solids Discharge of Non-Hazardous & Easily Disposable Dry Filter Cake

> Extremely Clean Water Filtrate allows easy discharge back to Body of Water

> Enables the vessel to burn a high Sulphur less expensive fuel while adhering / exceeding the environmental level regulations of cleanliness of water discharged back into the environment

> Simple Integration with Client’s Scrubber

> Worldwide Support

Pharmaceutical

We are introducing the Oberlin Filter for pharmaceutical applications. The filter is food grade quality with a sanitary design. The filter is completely automatic and can remove 99.99% of solid particles down to 1 microns in size. The filter can be used as a pretreatment for water and to treat wastewater. The filtered wastewater can be reused or recycled within the plant. It will also meet the sewage discharge limits for easy disposal. The removed solids are dry with no further dewatering necessary. Its fully automatic features and simple design deliver both dry solids and clean water without operator contact, minimizing exposure to hazardous materials.

Liquid-Solid Separations for Pharmaceutical Manufacturing

> High Solids

>High Product Quality

> High Risk Specification

> Food Grade Quality

> Sanitary Design

> Quality at Low Cost

> Minimal Attention

Water Treatment

Oberlin Filter provides systems that are solutions to the water issues of the industrial world as they serve to decontaminate and maintain a clean water supply. We have the capability to treat a wide range of water and wastewater applications. We design, engineer and provide the necessary process equipment for systems ranging from removing contaminants and toxins from water to solids dewatering. We treat extreme wastewater such as chemical destruction programs and low level radiation removal. The processed water is clean enough for reuse or discharge. We operate in challenging applications with high solids, high corrosion and high temperatures.

Often our client’s priority is clean water and dry solids − and we can do it!

Oberlin Filter got its start manufacturing an automatic filtering device for solids-liquid separations and over the past 50 years has improved on the filter design and added treatment systems support making the company into an industry leader in water treatment. Because water is the basis of our business we have long been a conservation and reclamation filtration technology leader.

Toxic Water Cleanup

Groundwater Chemical Contamination Cleanup

The Oberlin Filter technology has proved to be a crucial instrument in cleaning toxic water that gravely affects human health. Here’s example where the Oberlin Filter was an integral part in cleaning up a community’s water supply that was contaminated by industrial waste. A large industrial company used a chemical called perfluorooctanoic acid − abbreviated as PFOA or C8 in it’s manufacturing process. The PFOA contaminated the nearby area's drinking water. The Oberlin Filter technology paired with a carbon bed filter successfully cleaned up the water supply and made it economical to do so.

Chemical Weapons Destruction Program : Bluegrass Army Depot

The Blue Grass Army Depot has been storing chemical weapons since 1944 in Richmond Kentucky. The facility has been home to over 500 tons of chemical weaponry ranging from mustard gas to VX nerve agent. In the process of destroying these weapons, toxic wastewater is produced. Oberlin Filter removed a mixture of chemicals from this wastewater including nitrates, organic salts and aluminum hydroxide preventing irreparable harm to the environment.

Semiconductor & Solar Wastewater

Oberlin Filter provides solutions to the word’s largest semiconductor and solar manufacturers wastewater issues. They produce wastewater contaminated with silicon fines, Gallium Arsenide and other heavy metals. Oberlin Filter provides filter systems that remove these substances to meet sewage discharge limits. The filtered water is extremely clean and can be recycled and reused within the plant. The effectiveness of the Oberlin Filter allows for a one step filtration process that delivers clean water and dry solids for many applications in these fields.

One of the world’s largest semiconductor manufacturer’s plants was producing such an enormous volume of wastewater that it was overburdening the sewer with silicon fines. We provided a filtration system that cleaned the water so it could be safely discharged into the sewers or be reused. The Oberlin Filter reduced the solids from >500 ppm to <1 ppm. The water clarity went from >1000 NTU to <1 NTU. We are now an integrated part of this manufacture’s semiconductor chip making process.

Brine Filtration - ZLD in Power Plants

In ZLD the Oberlin Filter is used in the last process step where we take boiling salt and mineral slurries from a crystallizer evaporator, remove the salt solids and return the water brine back to the crystallizer. Typically the salts are NaCl, Na2SO4, CaSO4. This is a high temp, high solids, highly corrosive application where Oberlin has gained the reputation as the go to company when extreme filtration is required.

List of CA Power Plants with Oberlin Filters

> PG&E Colusa Generation Station - Maxwell, CA

> SMUD Utility - Sacramento, CA

> Turlock Irrigation District - Turlock, CA

> Gemma Power - Hot Springs, CA

> Russell City Energy - Russell City, CA

> Burbank Power and Water - Burbank, CA

> City of Roseville - Roseville, CA

> Gilroy/Calpine - Gilroy, CA

Sludge Dewatering

Sludge is a major economic and environmental concern. Sludge refers to the residual, semi-solid material waste produced by industrial wastewater or municipal water treatment processes. Large primary filters remove vast amounts of solids from large volumes of water. Sludge dewatering is the further separation process of solids from these waters. This is commonly the final step for cleaning wastewater from industries and water treatment plants. Sludge usually has a very high water percentage content that can be reclaimed through dewatering. The need for reduction of high liquid content sludge is becoming more evident as the volume of generated wastewater solids increases and becomes a growing concern to local municipalities and industry. The Oberlin Filter’s ability to remove 99.9% of solids from water leaving a dry cake makes it very effective in dewatering sludge. The filtered water is clean enough to be sent to municipal treatment facilities or to be recycled for reuse with industrial operations. The removed solids are extremely dry and acceptable for the landfill all while saving money in disposal costs.

A widely used sludge dewatering aid is Diatomaceous Earth. Diatomaceous Earth (DE) is the processed version of the skeletal remains of single celled plants called diatoms. It is used as a filter aid in various processes resulting in a large amount of wet slurry.

The Oberlin Filter is used as an excellent dewatering piece of equipment that enables the process of reclaiming the majority of liquid in the slurry leaving a Dry Cake ofDiatomaceous Earth. (Also known as Diatomite Sludge)

Water Technology

Since 1964, the Oberlin Filter Company has applied the Automatic Pressure Filter to solve many of our customers’ Water-Solid separation problems and reach the strict requirements of the Clean Water Act. Its fully automatic features and simple design deliver both dry solids and clean water without operator contact which minimizes exposure to hazardous materials.

The Oberlin Filter can filter solids down to 1 micron in size with capacities of a single filter of 2.8 million gallons of water a day, making it one of the top liquid solid separation filters in the world. Our filter is used throughout the wastewater, chemical, pharmaceutical, automotive, metal finishing, food and beverage industries. New advances in our technology now allow the filter to be controlled, monitored and supported remotely. Our completely integrated operation includes lab, design and engineering, prototyping, manufacturing with total quality control, startup and testing. Oberlin Filter supplies complete system packages and we offer continuing technical support to ensure that you are getting optimal results for your water filtration.

Laboratory Testing

The first step to evaluating a client’s separation application is to conduct preliminary tests at our facility on samples provided by the client. This initial testing will determine as a minimum the:

> Filter flux rate

> Filtrate cleanliness

> Cake moisture

> Media options

This testing is done free but we request the client to pay for the sample shipping costs to Oberlin Filter. Extensive bench tests or special analytics may require additional charges.

To help understand the best approach for each individual application, customers can send a sample of the fluid, and, if possible, a sample of the solids generated.

Requirements for Sample Sizes:

> Five gallons of dirty fluid taken from the process to serve as a representative sample of the fluid that would run through the filter

> One quart of concentrated sludge/solids in a separate container (if possible)

Filter Field Testing

In these situations Oberlin Filter Company offers our smaller commercial automatic pressure filters on a rental basis.

For Chemical/Process Water we can supply standalone filters or supply a temporary process system that may include feed tank, pumps and necessary chemical additions.

We also have a limited number of small (0.3 sq.ft. area) manual filters available for on-site testing. They duplicate the filter operation, need 90 psi air supply, but need an operator to control sequencing

Filter Paper & Parts

For 50 years Oberlin Filter Company has recognized the importance of a quality filter paper and media regardless of the style of filter whether it's the Oberlin Pressure Filter, a vacuum or gravity filter. The Oberlin Filter Paper and Media Department prides itself on providing only quality, 1st tier filtration grade filter paper at competitive prices for all sizes of Oberlin Filter models. In addition we also carry an extensive line of various gravity & vacuum filter paper as well.

> 100 % FDA Approved Safe Material Available in varying sizes & micron mesh sizes

> Spunbond Polypropylene ( 0.5 OSY - 2.0 OSY Weights )

> 100% Polyester Materials ( 0.5 OSY - 2.0 OSY Weights) - Flatbond Polyester & Lofted Felts

> Heavy Meltblown Polypropylene for Fine Filtration

> Specialty Composite Material (Spunbond & Meltblown Blends)

> DuPont Tyvek Sololfo for 1-2 micron Ultra Fine Filtration

> Cellulose/Rayon Based Gravity Filter Paper

About us

We are a family owned and operated business. Three generations of our family have worked hard to build filters and treatment systems that are dependable, reliable and get the job done. Our founder, Wayne Oberlin, started Oberlin Filter by making one filter at a time. His son, Tom Oberlin, developed and expanded our filtration technology making Oberlin Filter a global leader in liquid solid separation. This attention to detail and tenacity of spirit has enabled Oberlin Filter to grow into an international company that still calls Waukesha, WI home.

We are an engineering company. Our engineers are your project managers and are responsible to you for the filter’s satisfactory operation. They supervise your order from initial design stage, through production and startup. They are always available for support.

We have a global presence. We have manufacturing plants in England and Germany that provide sales, design, manufacturing and service support throughout Europe. We have service agents placed throughout the world. There are Oberlin pressure filters operating in over 30 countries throughout the world.

We are active in four major markets: Metal Working Fluids for grinding and machining, Food applications primarily in hot frying oil and specialty oils, Chemical Separations and Industrial Water Treatment. Industrial water treatment covers a wide range of applications with almost all of them unique to the client. We enjoy strong working relationships with GE and their many divisions, Veoliawater, DuPont, and a major semi-conductor manufacturer in their silicon wafer cutting processes.