Company details for:

Quality Plated Plastics

Quick Links:

Products / Services

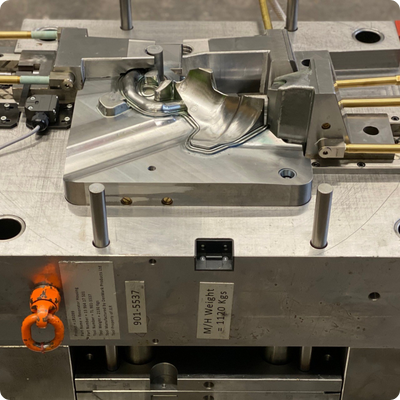

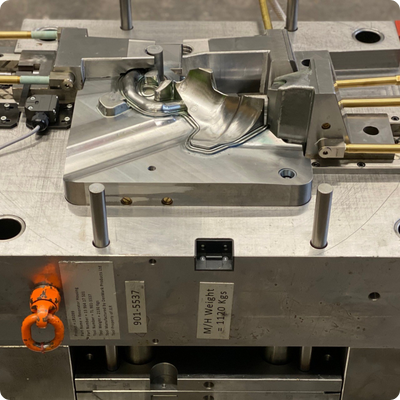

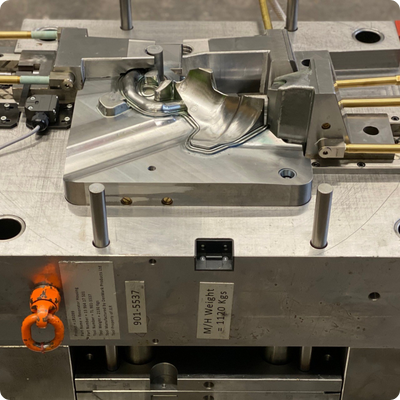

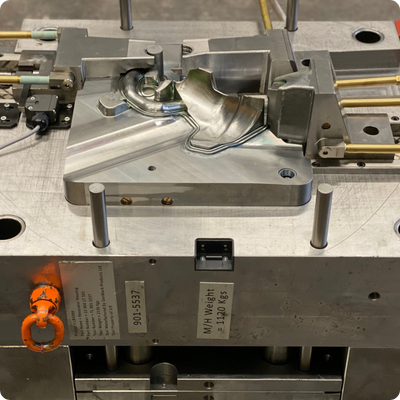

Tooling & Engineering in Birmingham

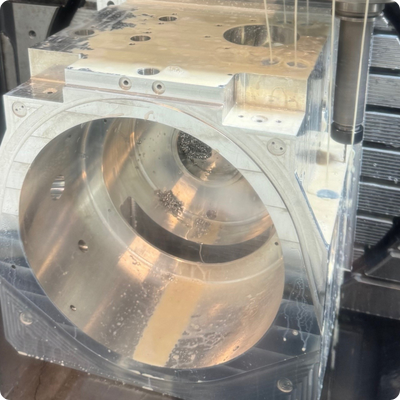

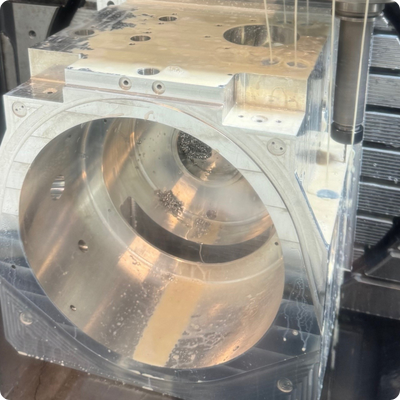

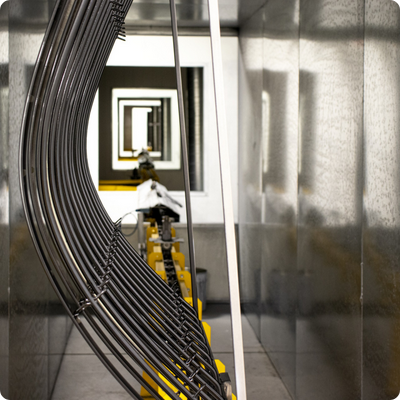

QPP have expanded their engineering services, offering UK and LCC tool manufacturing. This is all project managed from our facilities in Birmingham and Telford. All tools come with a UK tooling warranty.

- UK Tool Manufacturing - Up to 5T

- LCC Tool Manufacturing - Up to 15T

- DFM

- Tool Modification and Repairs

- Jigs & FixturesCNC Machining

Toolmaking in Birmingham

We offer our clients a tailored service to suit their budget and lead time requirements, all backed up with a UK tooling warranty.

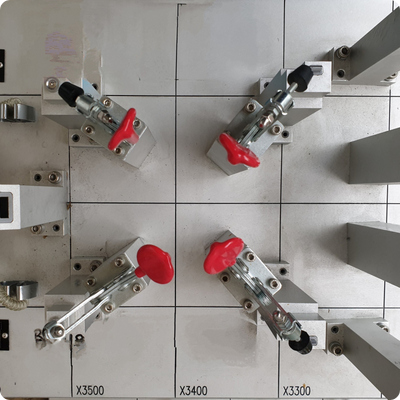

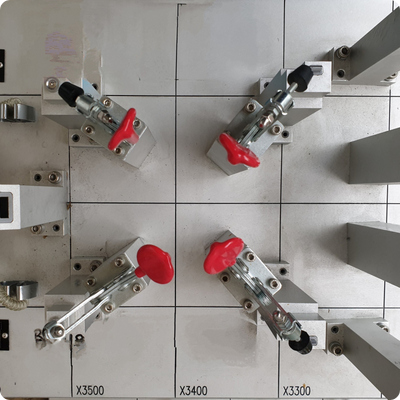

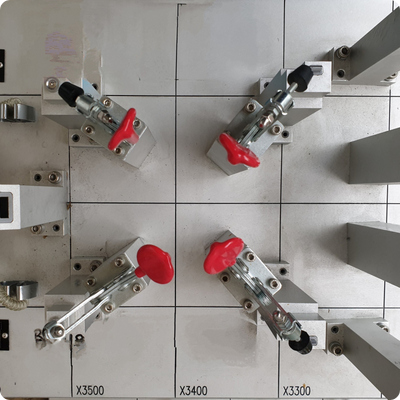

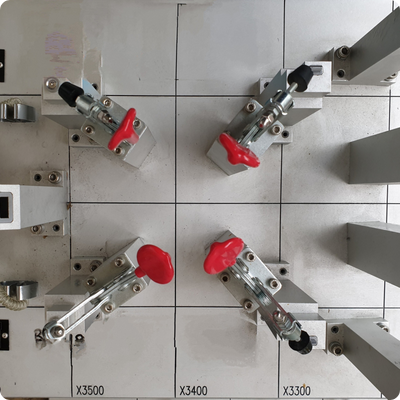

Jigs & Fixtures

UK and LCC manufactured Jigs and Fixtures. Supporting our customers GD&T requirements plus and associated assembly fixtures.

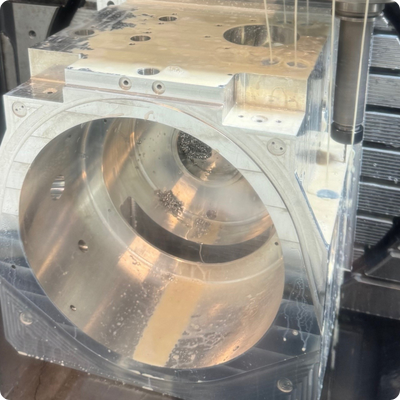

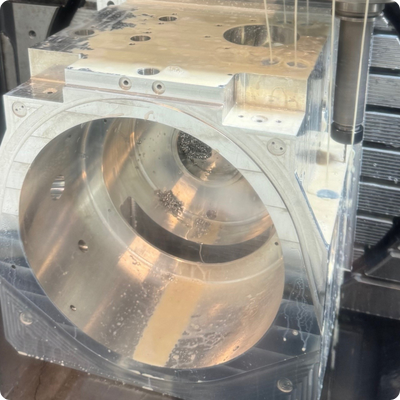

CNC Machining

3-5 Axis CNC Machining Services from one off to batch production requirements.

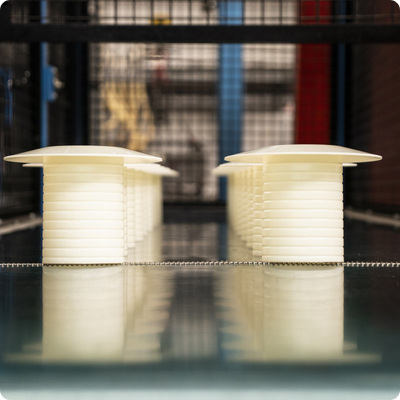

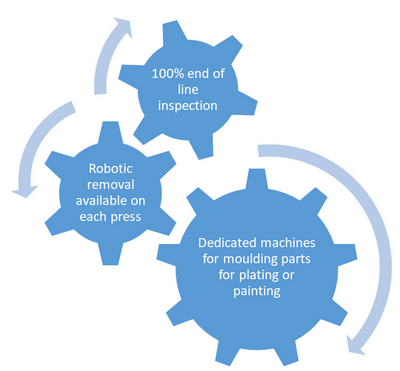

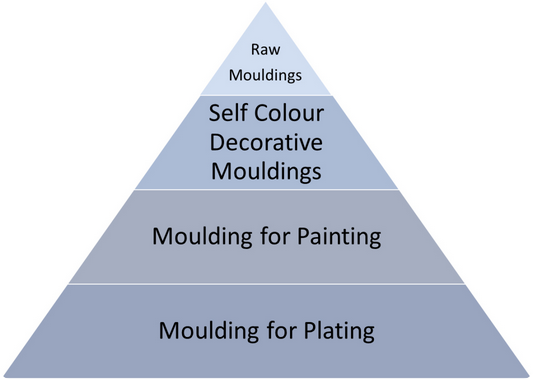

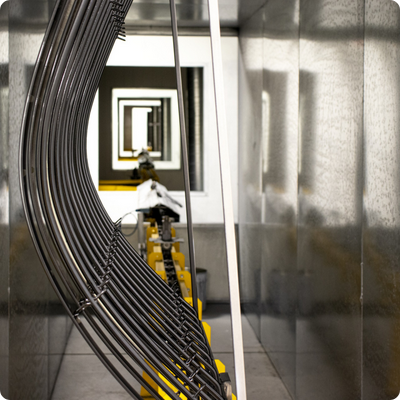

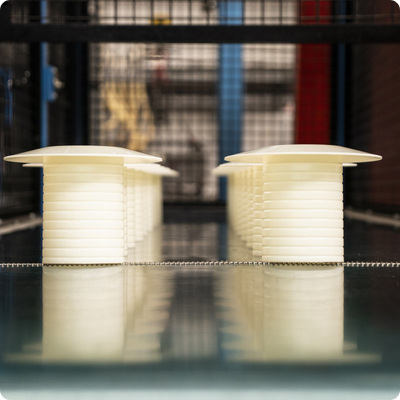

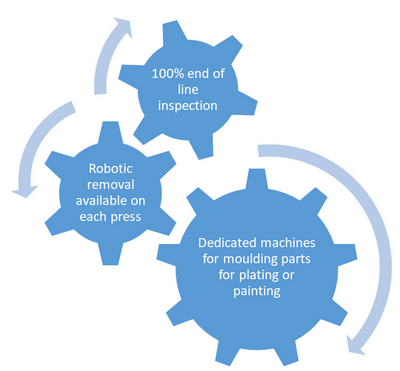

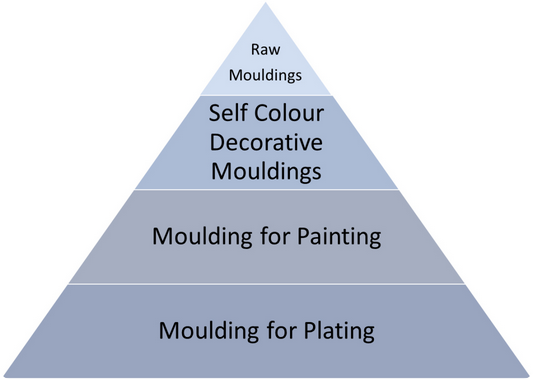

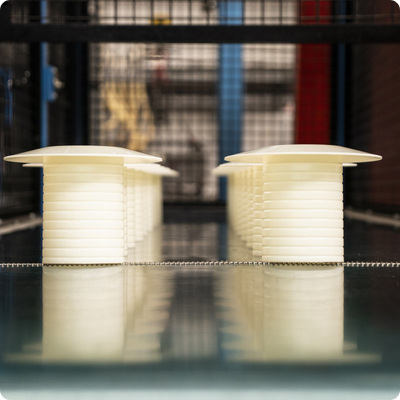

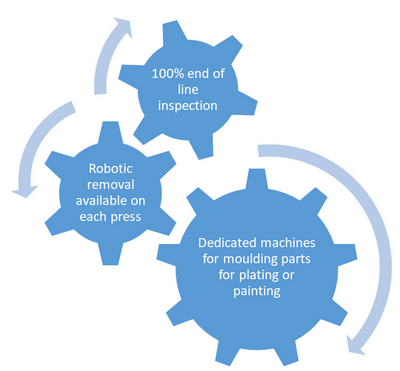

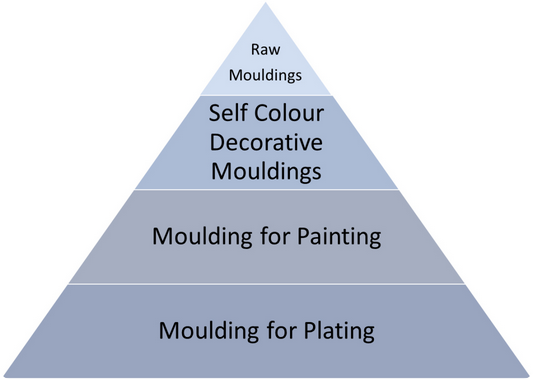

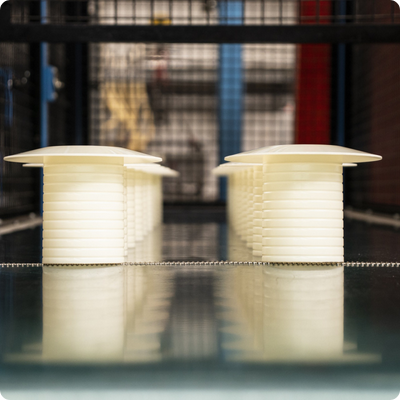

QPP Moulding Facility

In 2015 QPP recognised the benefits of controlling the mouldings coming into our facility. Moulding defects and contamination from other materials has a major impact on the outcome and quality of the plating on plastic.

Our in-house moulding facility if fitted with moulding machines specially designed with plating in plastics in mind with specific ABS & ABS/PC barrels to deliver the material in the best condition for plating.

But we do not only mould ABS & ABS PC for plating. Our skilled team produce parts that are to the highest standard to painting and for mould only applications in a range of materials

Mouldshop Machines On-Site

We have the following sized moulding machines available on-site for your products

55T

80T

130T

180T

210T

250T

400T

500T

800T

1100T

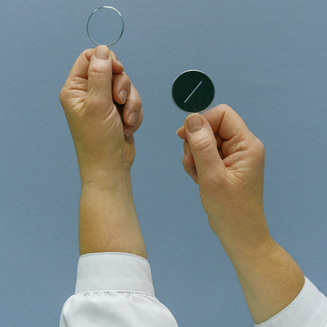

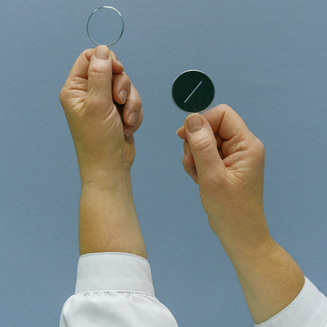

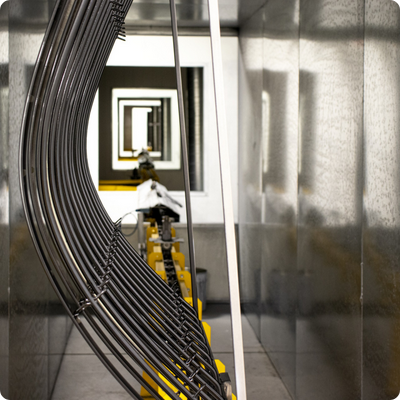

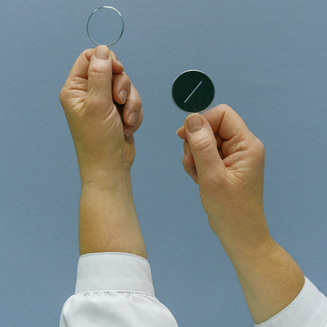

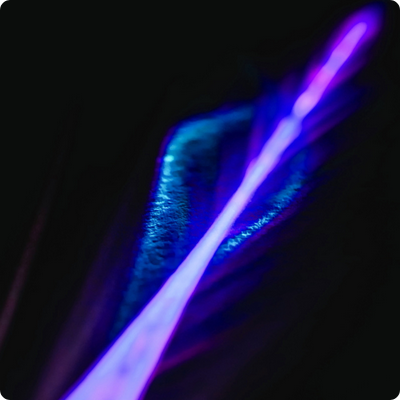

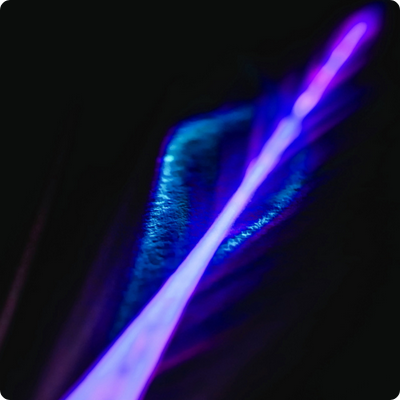

Electroplating - Chrome Facility

Often chosen for its decorative appearance and wear resistance plating on plastic can be used for a wide variety of applications due to the fact it is available in various aesthetic finishes. It offers good is corrosion and wear resistant and is lightweight when compared with its metal alternatives.

The procedure for “Plating on Plastic” consists of a highly complex chemical & electro-chemical process, during which the components go though total immersion in numerous tanks of solution. This includes etching the surface of the mouldings, at a molecular level, to chemically deposit a conductive coating, prior to building up a layer of Copper and Nickel before the final decorative finish.

Painted Finishes

Learn about our Paint facility and multi finish coatings processes.

Reduce Your Logistical Loops

Here at QPP we not only mould and apply finishes to your products, we are a completed product faciity.

We have an array of additional services that will save you time and money against further transportation loops.

For immediate information please contact us directly.

Direct Printing

At Quality Plated Plastics, we provide expert direct printing services, delivering high-resolution, long-lasting graphics and text directly onto plated plastic components. Our process is ideal for complex shapes and high-spec applications, ensuring precise alignment and a flawless finish. We serve industries such as automotive, aerospace, and electronics, offering direct printing solutions that combine durability with aesthetic appeal. Whether it’s custom designs, branding, or functional markings, we meet the most demanding quality standards with consistency and care.

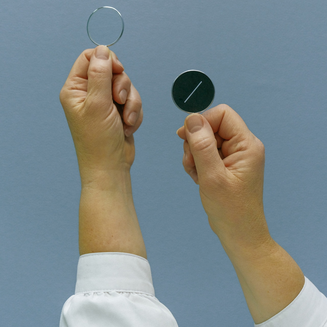

Laser Etching

At Quality Plated Plastics, we specialise in high-precision laser etching services, delivering detailed and durable marking solutions on a wide range of plastic components. With a strong focus on quality and consistency, we serve industries that demand high-specification finishes, including automotive, aerospace, and consumer electronics. Our laser etching process produces permanent, clean, and accurate markings—ideal for logos, symbols, or functional detailing—while preserving the integrity of the plated surface.

Assembly

At Quality Plated Plastics, we offer a comprehensive assembly service, expertly integrating plated components into final products with precision and care. Our skilled team handles a wide range of assembly needs, from straightforward fittings to complex, multi-part builds, supporting key industries like automotive and electronics. By combining our high-quality plating with seamless assembly, we provide a streamlined solution that saves production time and ensures consistent, reliable performance in every finished product.

Our Capabilities

At QPP we have an experienced team of Quality Engineers to support both our customers and our production. The team can support with all aspects of your quality requirements from PPAP / BEON Submissions using established APQP process to Internal & External Audits.

About us

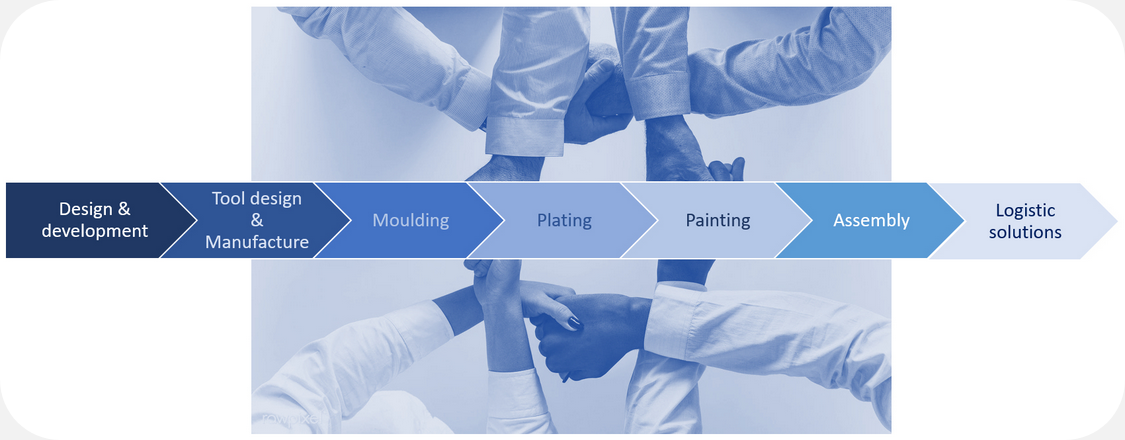

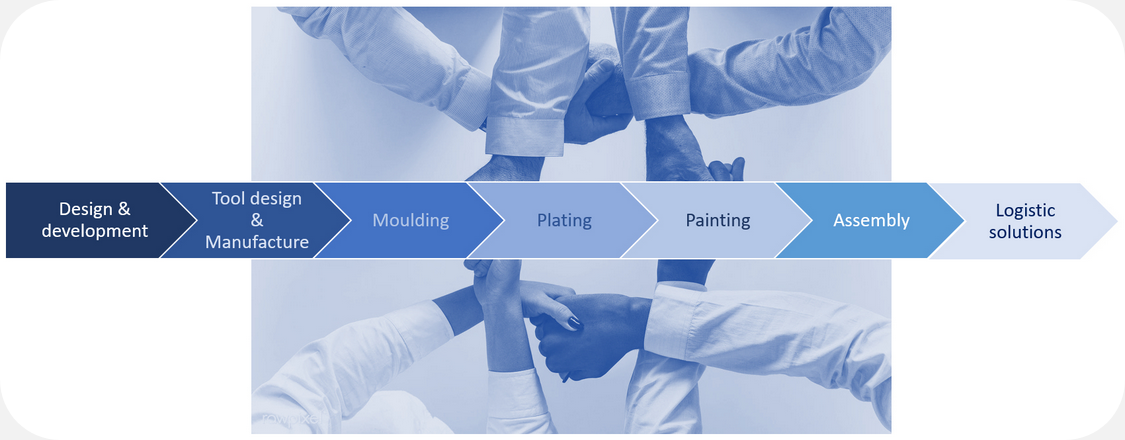

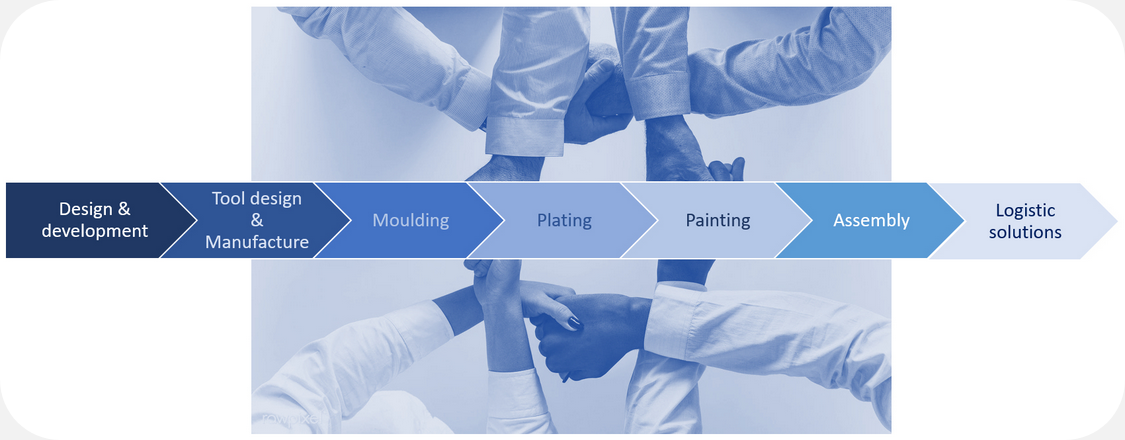

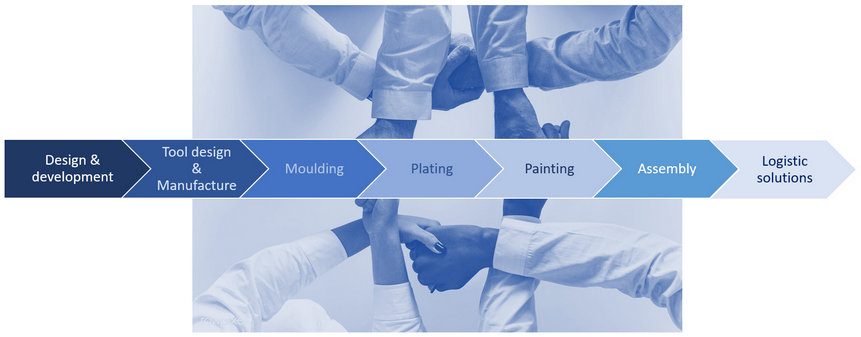

Since 1965, Quality Plated Plastics has built a strong reputation as a trusted and essential supplier of high-quality plastic components within the supply chain.

QPP has consistently led the way in product innovation, establishing itself as a market leader in Plating on Plastics. Over time, we’ve expanded our capabilities to offer a full design-to-delivery service, ensuring we meet all your project requirements from concept to completion.

Our Services Include:

Tooling & Engineering

From design to manufacture, we turn your ideas into reality, delivering tailored solutions every step of the way. Our team in Telford manufacture Injection mould tooling as well as having a full service & repair facility. We are able to take your product from an initial design and manuafture a tool to produce the parts you want.

Injection Moulding

On site in Birmingham we have a range of Injection Mould machines ranging from 55T to 1100T. Whether you require a single shot moulding or a 2K part we have the presses to suit. Parts can be produced in a range of plastic materials from ABS & PC ABS for plating as well as recycled material for a range for painting or non decorative applications

Electroplating

Our plating on plastics facilty offers a range of finishes including Bright, Satin or Dark Chrome in both Hex & Tri chrome. Platin gon Plastics offers a durable and cost effective alterantive to metal for a range of applications. Suitable for a range of applications our plating line in Birmingham plates for any industry including Automotive, Sanitaryware & Domestic Applicances.

Painted Finishes

Our on site facility has both a paint track and spray bake booths to allow for flexiblity in batch sizes. Painting in a range of paints from single coats to three coat systems for a range of applications including automotive - interior & exterior applications, bathoom fittings and domestic applicance components. We other a wide range of colours in matt, soft such and high gloss as well as chrome effect paints.

… And more.

Our goal as a company is to meet all our customers’ plastic needs. Operating from our manufacturing sites in Birmingham and Telford, we deliver complete plastic solutions. Our recently upgraded plating line is complemented by an onsite moulding facility, and since 2019, our in-house paint facility has provided quality painted finishes.

With the capacity to produce over 30 million parts annually, Quality Plated Products Ltd is the perfect partner for all your tooling, moulding, painting, and plating requirements.

Images