29 April 2025 | Tascomp Ltd

Leading Timber Manufacturer Invests In Bespoke Tally Beam System

A leading timber manufacturer came to PlantRun with a requirement for a bespoke tally beam system. By working with our engineers they managed to implement a system that suits their individual needs.

In the timber industry, maximising yield and minimising waste is a priority.

One timber manufacturer looked at using PlantRun to track a specific manufacturing process. However, due to the variability in timber sizes, they opted for a customised solution, which was developed alongside PlantRun engineers to suit their process.

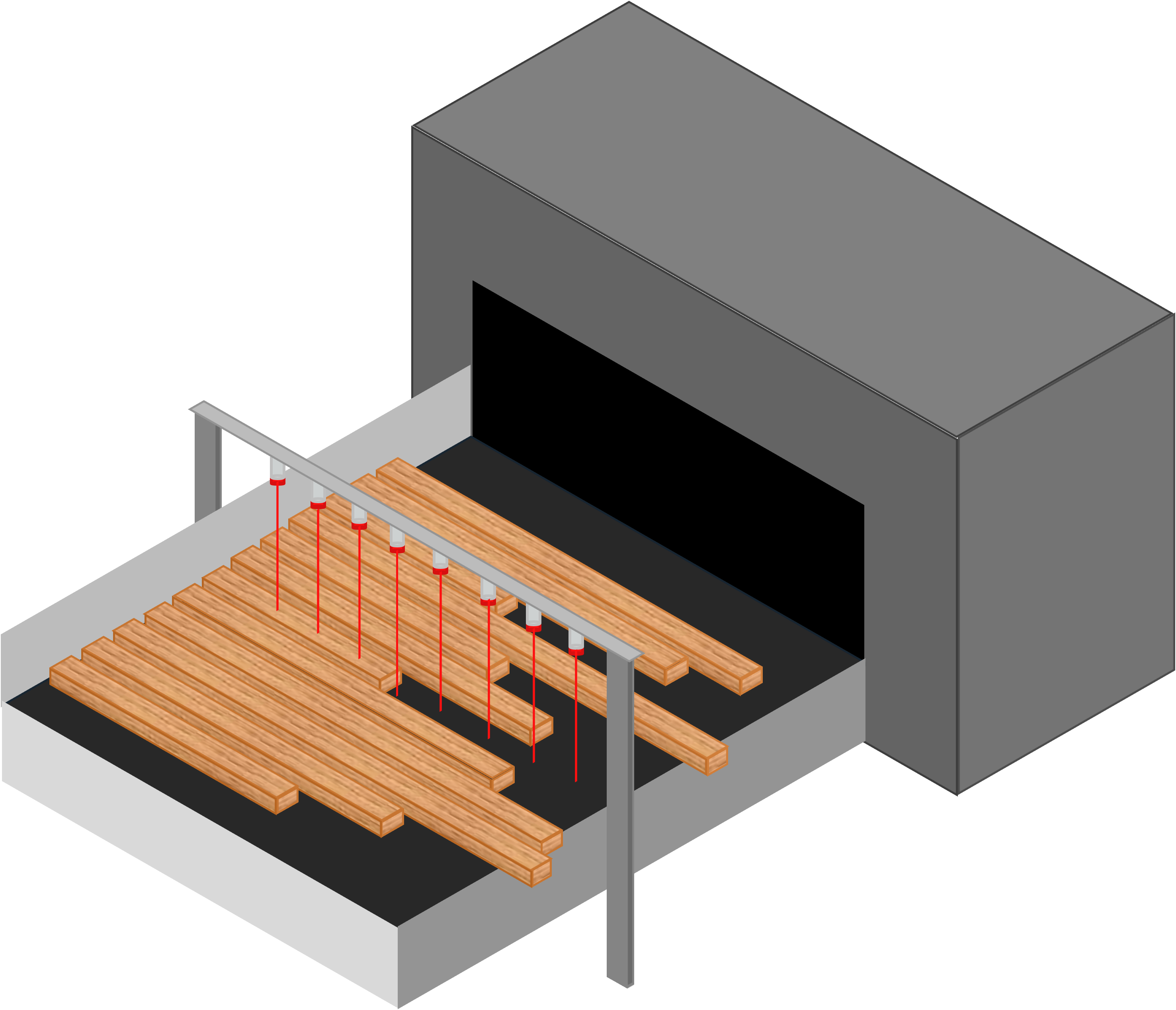

As a result, a bespoke tally beam tracking system was implemented, specifically designed to meet their needs. This system uses integrated optical sensors on a conveyor belt to measure the length of timber as it moves along the production line, ensuring accurate tracking and precise measurements of the timber produced.

KEY SYSTEM FEATURES

Real-Time Performance Monitoring: The system continuously records operational data, allowing managers to analyse production trends, identify inefficiencies, and reduce downtime

ERP Compatibility: The system supports digital tracking and reporting across multiple locations, ensuring seamless integration with existing production management tools

Predictive Maintenance Insights: By monitoring key production metrics, operators can proactively address slowdowns and potential maintenance needs, improving overall equipment reliability

HOW DOES THE SYSTEM WORK?

The system initially covered two different manufacturing lines, and has now been expanded to cover a sawmill. The sawmill consists of five key assets, and while these lines require the same core functionality, they also have distinct characteristics that must be considered in the system’s expansion.

Both existing and planned lines utilise a tally beam system with a series of 16 integrated sensors to capture real-time measurements of each timber beam’s length and width. The sawmill lines specifically use optical sensors positioned at 300mm intervals, measuring timber lengths from 1800mm to 6300mm. Each time a piece of timber passes through, the system determines its length based on the number of sensors that are activated.

Through this tracking mechanism, the sawmill can feed accurate measurements back to the PlantRun system, which results in better data on the process. With an impressive throughput of 84 pieces of timber per minute, the system allows the manufacturer to better understand their production rates to further optimise their process.

PlantRun also automatically prints out labels for the timber based on the length measured, removing a manual process from the line. Once the timber has passed the end of the line

PlantRun will automatically print another label out which includes batch information, the date and time it came off the line, and other information that allows them to better understand the process.

EXAMPLE LABEL

BENEFITS OF THE SYSTEM INCLUDE:

Accurate Sizing: Ensures precise cuts and optimises timber usage by reducing sizing discrepancies

Enhanced Efficiency: Real-time data provides actionable insights that accelerate production and minimise downtime

Cost Reduction: Reduces reliance on manual labour and boosts machinery performance, lowering overall production costs

Sustainability: Maximises timber utilisation, significantly reducing waste and promoting more sustainable production practices

CONCLUSION

The Tally Beam System represents a significant advancement in timber processing, combining sensor technology with data analytics to optimise accuracy and efficiency. With the manufacturer planning to expand to the sawmill with PlantRun monitoring five additional assets, the system will only continue to help them maximise the return of their processes.