04 June 2025 | Cranage EMC & Safety Ltd

Climatic testing facilities at Cranage EMC and Safety

Customers that are new to testing with Cranage EMC and Safety are often surprised by our capabilities and facilities when they visit our premises. As our name would suggest, we have extensive EMC and Safety testing capabilities, but we also have purpose built environmental testing facilities too.

Environmental testing, which incorporates climatic testing, is used to assess how well materials, components and equipment can withstand the environmental conditions they may be exposed to over their lifetime, including humidity, temperature, solar radiation, dust and water ingress.

At Cranage, we have a range of climatic chambers to simulate the effects of weathering, ageing and degradation of materials due to environmental conditions. These chambers allow us to accelerate the impact of environmental stresses, to help evaluate the reliability and longevity of an electronic product once in the intended environment.

Our chambers allow us to replicate worldwide climates, such as the cold dry conditions seen in the Artic, to the effects of the heat, low humidity and solar radiation seen in somewhere such as Saudi Arabia. We can test how your product will survive a tropical humid climate, with solar radiation and heavy rainfall typical of a monsoon, as well as the impact of hazards arising from atmospheric deposition, such as that from salt mist.

Benefits of climatic testing include:

•Ensuring product reliability, helping manufacturers to identify weaknesses and ensuring a product can withstand the environment for which it is intended.

•Identify potential failures. Testing will show how environmental factors might cause corrosion, mould or other failures.

•Meeting regulatory standards. Climatic tests are often an important part of regulatory compliance in industries such as military and aerospace. It also forms a key part of research and development, allowing manufacturers to demonstrate reliability.

Our capabilities include:

Salt spray- used to evaluate the products ability to withstand corrosion in salty environments. The temperature, pH and deposition rates are all carefully monitored during testing. Common standards include IEC 60068 and DEF-STAN 00-35.

Chamber dimensions are 800mm (w) x 500mm (h) x 1200mm (l), EUT weight 20kg.

Temperature and humidity- these chambers expose products to changes in temperature and humidity to evaluate the impact on materials and products.

We have several temperature and humidity chambers of various sizes available, with different ranges. We can provide testing services that include high and low temperature testing, combined temperature and humidity, temperature cycling and rapid rate of temperature change. Our largest chamber has a temperature range of -40 °C to 80 °C and humidity of 20% - 93%. The working space within this measures 2160mm (l) x 1920mm (w) x 2160mm (h).

Water and Dust Ingress Protection- used to assess how well a product can withstand the intrusion of solid objects and water. We have the ability to test up to IPX9, the highest level of water protection currently available.

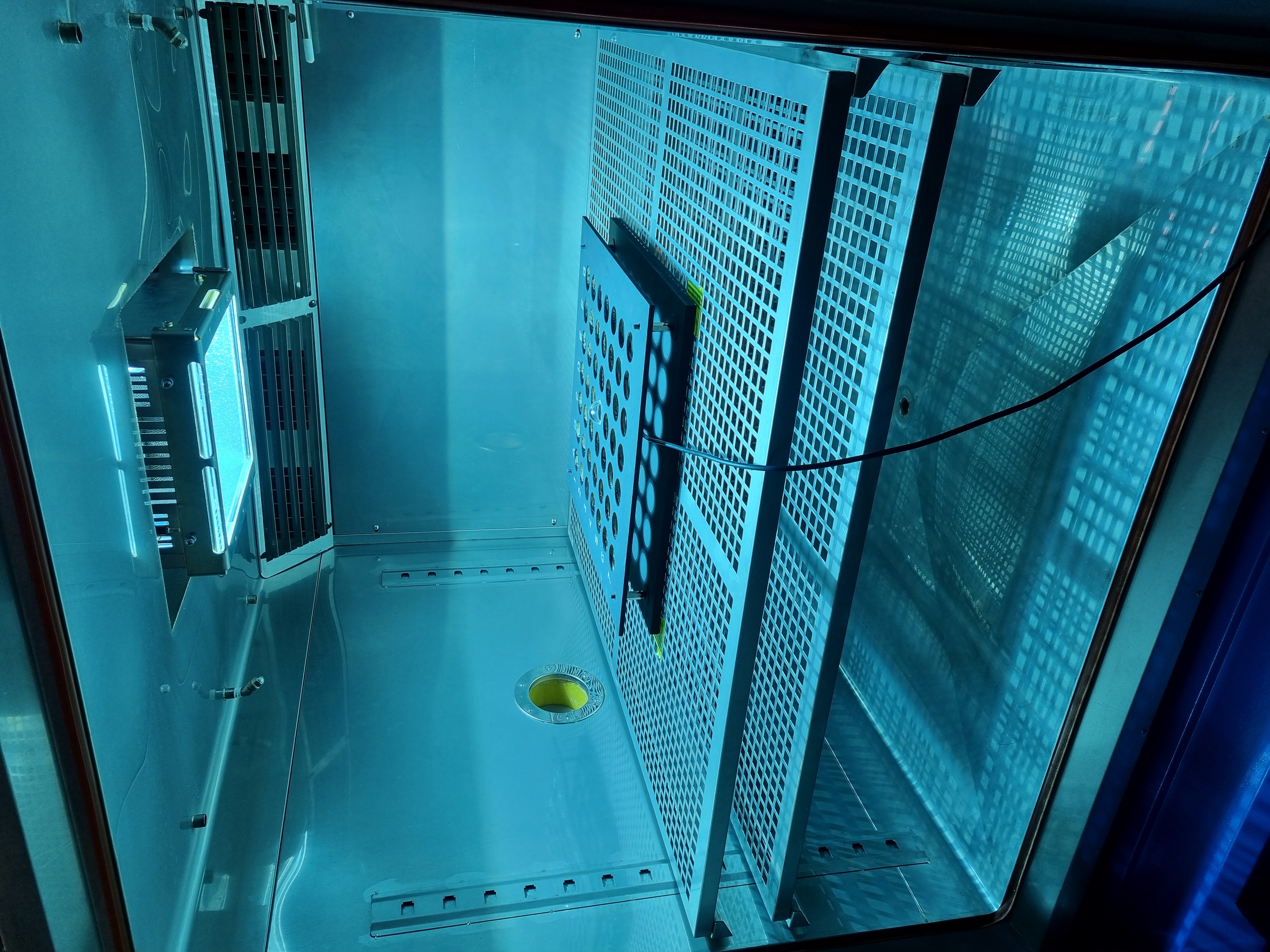

Solar radiation testing is used to simulate the deteriorating effects of UV sunlight on a product. Our specialist chamber can accelerate the effects of sunlight and allow manufacturers to identify potential degradation issues, and is a key part of standards such as MIL-STD-810F and DEF-STAN 00-35 part 3.

We have an irradiation capability of 280 to 3000nm to verify fatigue in enclosures.

View our website for more information on our environmental testing facilities, or discuss your requirements with our team of experts.