30 June 2025 | Cranage EMC & Safety Ltd

How to prepare for electrical product safety testing at Cranage EMC and Safety

Product safety testing is a critical step in ensuring that products meet regulatory standards and are safe for consumers. Whether you're developing a new product or modifying an existing one, preparing for safety testing requires careful planning, adherence to standards, and thorough documentation. Here we provide a roadmap for preparing a product for safety testing.

What is Product Safety Testing?

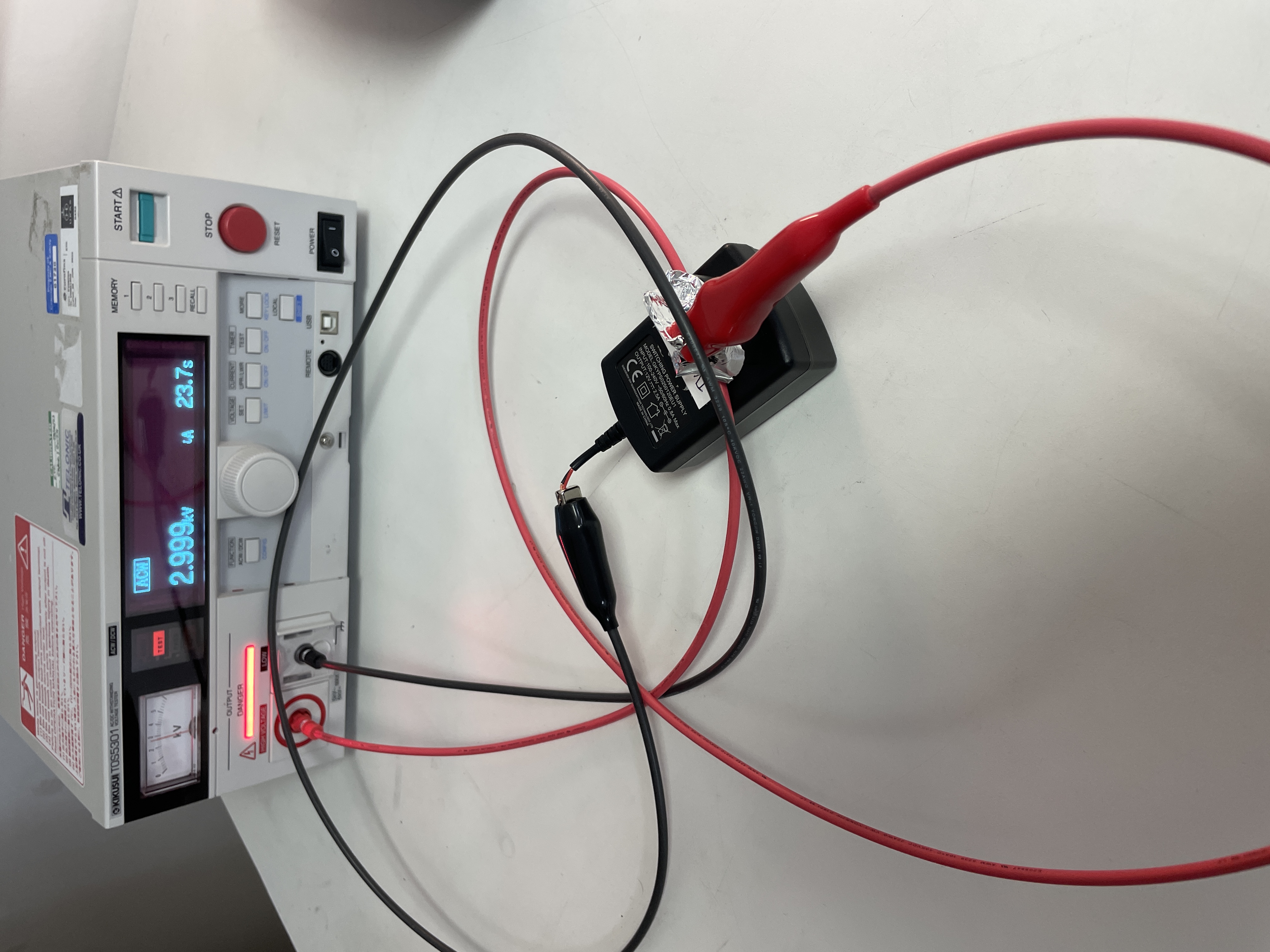

Product safety testing evaluates the product’s design, materials, and performance under various conditions to ensure compliance with industry standards and regulations. These tests are designed to identify potential hazards and verify that products meet safety requirements before they reach consumers. Common types of safety tests include durability tests, electrical safety tests, chemical composition analyses, and environmental impact assessments.

When preparing for testing, there are several steps that need to be considered.

1. Identify Relevant Standards and Regulations

The first step in preparing for product safety testing is to identify the standards and regulatory requirements applicable to your product. These vary depending on the product type, industry, and target market.

In UK/ Europe the UKCA/CE marking requirements such Electrical Equipment (Safety) Regulation 2016 and the Low Voltage Directive are relevant.

Specific industries, such as medical devices or automotive, have their own stringent regulations. These should be read thoroughly to understand the testing protocols, criteria and identify the relevant product specific standard that applies to the product.

2. Design Safety into the Product

Safety testing begins with the product design process. Engineers, designers, and material specialists should work together to incorporate safety features and eliminate potential hazards. Key considerations include:

•Using non-toxic materials that comply with chemical safety standards.

•Ensuring that electrical safety critical components are pre-approved and the circuit has adequate protection such as fuses.

•Eliminating sharp edges, small detachable parts, or any designs that pose choking or injury risks.

•Read the product standard and address any issues that may be a concern.

•Consider the environment that the product will be used in.

•Earthing of conductive accessible parts can alleviate any safety concerns.

Proactively addressing these factors reduces the likelihood of failure during testing.

3. Create Prototypes for Testing

Develop high-quality prototypes that are representative of the final product. Prototypes should:

•Match the specifications outlined in the product design ( functionality etc)

•Include all intended safety features and mechanisms ( interlocks etc)

•Be built using the same materials as the production model. ( flammability etc)

Having accurate prototypes ensures reliable testing outcomes.

4. Conduct Pre-Testing Evaluations

Before submitting the product for formal safety testing, conduct internal evaluations to identify potential weaknesses. Simulate test conditions and assess the product’s performance against safety criteria. Pre-testing evaluations may include:

•Stress tests to determine durability under pressure.

•Functionality tests to confirm operational safety.

Address any issues identified during pre-testing to improve the product’s readiness for formal testing.

5. Document Product Specifications

Comprehensive documentation is essential for product safety testing. Prepare a detailed file that includes:

•Specifications: Dimensions, components, materials, and intended use.

•Technical drawings: Including circuit diagrams

•Operating instructions: Guidelines for using the product safely.

•Material certifications: Evidence that materials comply with safety standards.

Clear and complete documentation supports transparency and facilitates the testing process.

6. Select an Accredited Testing Laboratory

Choose a reputable and accredited testing laboratory that specialises in your product category. Accredited laboratories have the expertise and facilities to conduct accurate and reliable safety tests. Factors to consider when selecting a laboratory include:

•Accreditation credentials: Look for certifications from organisations such as UKAS.

•Experience: Prior experience with similar products ensures familiarity with testing protocols.

•Communication: Labs that provide clear guidance and feedback are valuable partners in the testing process.

7. Prepare for Testing Day

When submitting your product for safety testing, ensure that everything is organised and ready. Key actions include:

•Double-checking prototypes for completeness and quality.

•Providing all required documentation to the testing lab.

•Communicating any special instructions or considerations for testing.

Proper preparation can prevent delays and streamline the testing process.

8. Address Test Results and Feedback

Once testing is complete, review the results and feedback provided by the laboratory. If the product passes all tests, it can proceed to production and distribution. If issues are identified, work with your design team and test laboratory to implement solutions and make necessary design modifications. Retesting will be required to ensure compliance.

Common Challenges and Solutions

Challenge: Variability in Standards

Products sold internationally must meet varying standards across different regions. Solution: Develop a universal testing approach or tailor testing to specific markets.

Challenge: Cost of Testing

Safety testing can be expensive, especially for complex products. It is best practice to budget for testing early in the development process and explore cost-effective laboratory options.

Challenge: Delays in Testing

Unexpected issues can cause testing delays. Thorough pre-compliance testing will help to reduce the risk of failure during formal testing.

Conclusion

Preparing a product for safety testing is a meticulous process that demands attention to detail, collaboration, and adherence to regulations. By following the steps outlined in this guide, businesses can ensure their products are better prepared for formal testing. Product safety not only protects consumers but also enhances brand reputation and builds trust in the marketplace.