02 December 2025 | Cranage EMC & Safety Ltd

What is the difference between CTI and PTI testing?

Comparative Tracking Index (CTI) and Proof Tracking Index (PTI) testing are both methods used to evaluate the electrical breakdown properties of insulating materials under tracking conditions. However, there are significant differences between the two tests.

Comparative Tracking Index (CTI) testing is a crucial evaluation method used to determine the electrical tracking resistance of insulating materials. This test helps in assessing the material's ability to resist the formation of conductive paths when exposed to moisture and contaminants, which can lead to electrical breakdown. CTI testing is essential for ensuring the safety and reliability of electrical components, especially in high voltage applications where tracking can cause serious hazards.

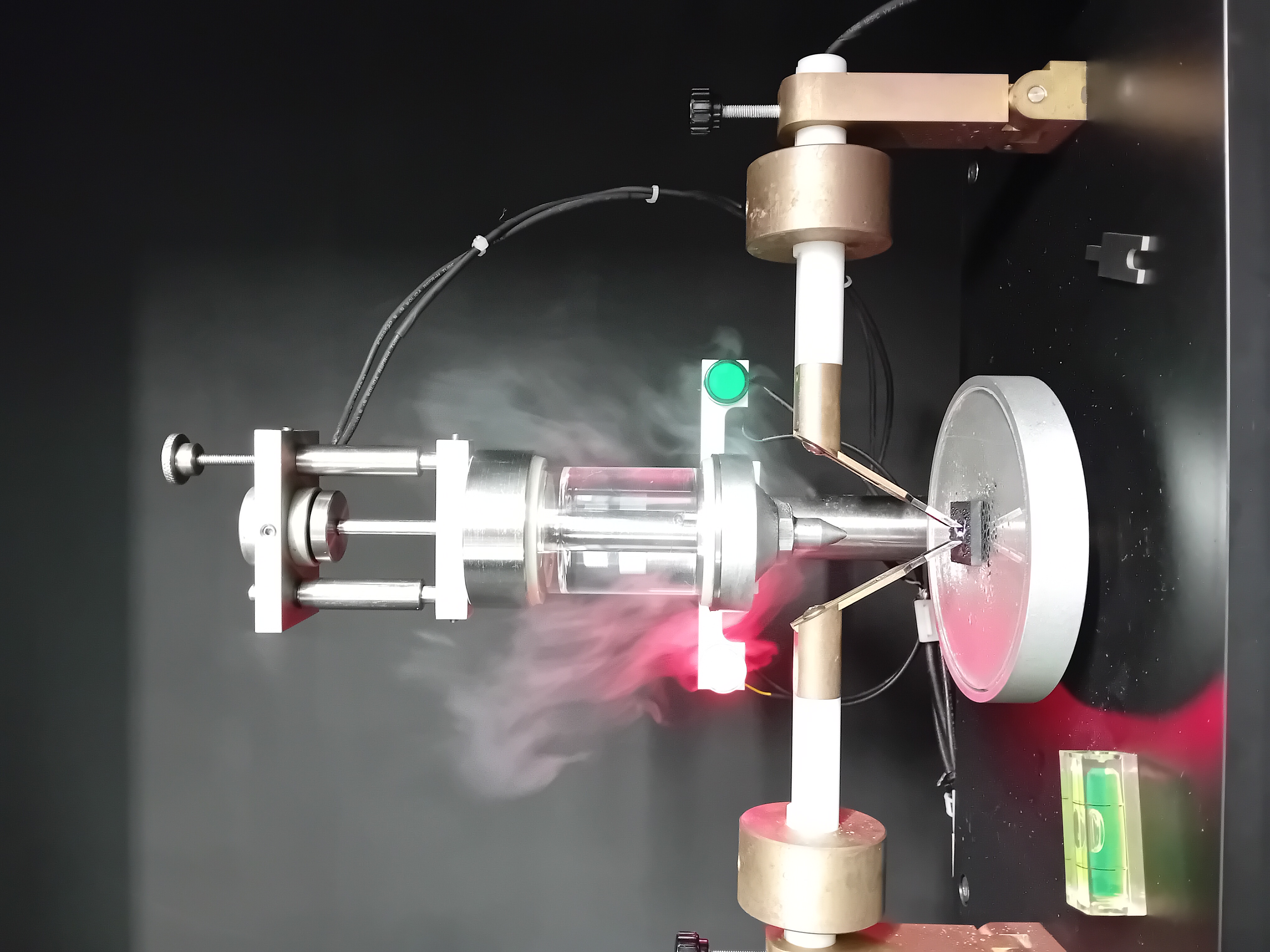

During the test, a high voltage is applied to the specimen while it is exposed to a conducting solution. The tracking index is then determined based on the number of drops required to cause tracking or the time taken for tracking to occur. Materials with a higher CTI value indicate better tracking resistance.

Overall, CTI testing provides valuable insights into the performance of insulating materials, helping manufacturers make informed decisions about their suitability for specific applications.

Proof Tracking Index (PTI) testing is a crucial process in the field of material science and electrical engineering. It is used to evaluate the electrical tracking and erosion resistance of insulating materials under high voltage stress conditions. PTI testing helps determine the ability of materials to withstand electrical tracking and prevent surface erosion, which is vital for ensuring the safety and reliability of electrical components and devices.

During PTI testing, a high voltage is applied to the material surface, and the tracking and erosion characteristics are observed and analyzed. This data is used to assess the material's performance and make informed decisions regarding its suitability for specific applications. By conducting PTI testing, manufacturers can ensure that their products meet industry standards and regulations, ultimately leading to improved quality and safety for end-users.

PTI testing is considered more rigorous as it evaluates the material's resistance to tracking over a prolonged period.

In summary, while CTI testing provides a voltage rating for tracking resistance, PTI testing gives a more comprehensive evaluation by considering both voltage and time factors in determining the material's tracking resistance. Both tests are essential in assessing the safety and reliability of insulating materials in electrical applications.