02 July 2025 | Tascomp Ltd

PlantRun Supplies Scalable OEE and Downtime Tracking Systems for SMEs

Many small and mid-sized manufacturers face the same production problems as large enterprises—unplanned downtime, inefficient use of labour, lack of visibility over shopfloor performance—but without the same level of budget or resource.

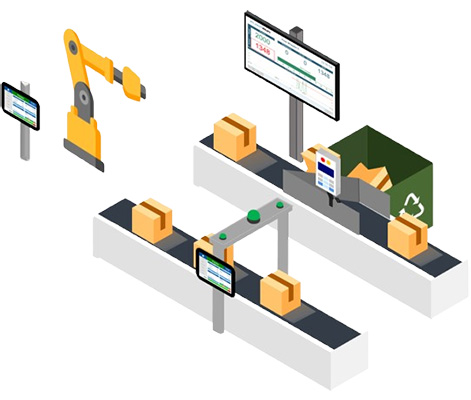

That’s why PlantRun, the real-time production monitoring system developed by UK-based automation experts Tascomp, is now being implemented by SMEs across the country looking to start small and scale as they grow.

A Practical Route to Digitisation

PlantRun allows manufacturers to track OEE (Overall Equipment Effectiveness), downtime, and utilisation from day one—often starting with just one or two key machines. The system uses robust I/O panels or non-invasive methods like current clamps to automatically collect data from machines of all types, without requiring expensive PLC integration or plant-wide changes. However, with over 1000 software drivers, PlantRun can seamlessly interface with a whole host of PLCs natively, allowing more information to be extracted in future phases.

The platform provides:

- 📉 Downtime reason tracking for visibility of production losses

- 📊 Live OEE dashboards and utilisation metrics

- 📥 Operator input terminals for job tracking, setup delays, and manual events

- 📈 Historical reports for continuous improvement and root cause analysis

“What makes PlantRun ideal for smaller manufacturers is its flexibility,” says a Tascomp spokesperson. “You can begin with a single asset and basic downtime tracking, and then grow into full OEE monitoring, KPI dashboards, and digital paperwork replacement over time. It’s all modular.”

Quick ROI with Phase-One Implementation

Most SME customers start with downtime tracking - a simple step that provides immediate insight into wasted time and is often enough to recover lost production capacity within weeks.

With downtime reasons recorded automatically or through simple operator input, businesses often uncover hidden inefficiencies, common changeover delays, or excessive waiting times that can be addressed quickly.

This low-risk first phase gives a fast return on investment while laying the foundation for:

- Job tracking and part counting

- Andon-style callout systems (engineer, supervisor, QA)

- Digital work instructions and shift logs

- Integration with ERP or scheduling software

- Energy and CO₂ tracking by asset or process

Designed to Scale as You Do

As your production grows, PlantRun can expand to monitor dozens or even hundreds of assets, with centralised data access for production, maintenance, management and planning teams. Everything remains managed through a single system that’s UK-developed and supported.

Whether your factory is producing springs, food products, castings or electronics, PlantRun adapts to your existing equipment and processes, with minimal disruption.