09 October 2025 | DEWESoft UK Ltd

e-NVH Testing: Combining Electric Power and NVH Analysis

It is common practice to consider testing domains, such as electric power and NVH (noise, vibration, and harshness), as separate entities.

However, the combination of these domains is crucial for simulation and prototype testing. In fact, “multiphysics” testing bridges the gap between theory and real-world performance. This integrated approach enables engineers to predict, validate, test, and optimize electric drives, such as traction motors and electric axles, with unprecedented accuracy and efficiency.

What is e-NVH?

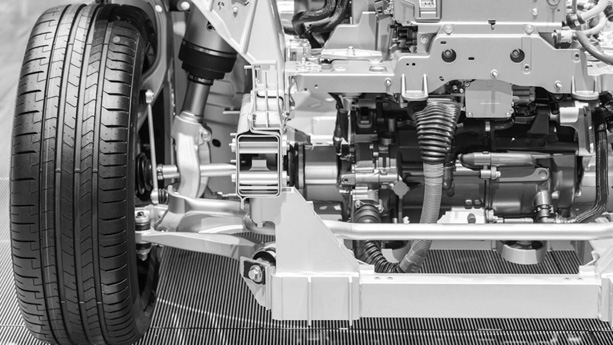

e-NVH (electric Noise, Vibration, and Harshness) is the study and measurement of noise and vibration phenomena associated with electric powertrains, such as motors, inverters, and gearboxes. It combines traditional NVH techniques with electric power analysis to identify and optimize sources of unwanted sound and vibration in electric vehicles and machines.

This multidisciplinary approach is essential for improving performance, comfort, and perceived quality in modern electric mobility systems. This article describes how e-NVH is performed and its advantages.

Bridging the gap between design and reality

One of the greatest strengths of combining simulation with physical testing is its ability to bridge the gap between design and reality.

During the early stages of product development, simulation tools can predict e‑NVH behavior and power losses by modeling phenomena such as electromagnetic forces in permanent magnet synchronous motors (PMSMs) or inverter switching noise.

However, physical testing remains indispensable for validating these predictions and uncovering effects that are not fully captured in simulation, such as variations introduced by manufacturing tolerances or material inconsistencies. For instance, an e‑motor simulation may predict low vibration levels. However, real‑world testing can expose unexpected resonances caused by slight variations in housing stiffness—issues that would remain hidden without empirical data.

This integrated approach also yields direct time and cost savings. Simulation allows NVH engineers to rapidly iterate on design choices, such as optimizing stator skewing or refining pulse‑width modulation strategies, well before hardware prototypes are built. Once physical components have been created, testing them with data acquisition platforms such as SIRIUS, using DewesoftX software, provides the empirical data needed to fine-tune designs and ensure compliance with performance and regulatory targets.

Many engineers, for example, use simulation tools such as COMSOL, Altair Flux, and ANSYS Maxwell to create predictive models, then validate them and optimize their prototypes by making real-world measurements using SIRIUS-based e-NVH and power analysis instruments.

Common e-NVH challenges & mitigations

Despite the numerous advantages of integrating electric power and NVH analysis into a unified e-NVH workflow, several challenges are frequently encountered during testing and simulation that should be addressed to ensure reliable results.

High-frequency electromagnetic noise

Modern traction motors and inverters often operate at high switching frequencies, generating electromagnetic interference (EMI) that can contaminate both electrical and acoustic measurements. This is particularly problematic when measuring subtle NVH signals such as tonal whines or casing vibrations.

Mitigation: High-quality signal conditioning, including isolated inputs, differential sensing, and proper cable shielding, is essential. Dewesoft SIRIUS modules, for example, feature galvanic isolation, automatic anti-aliasing filtering, and high dynamic range inputs that reduce susceptibility to common-mode noise, EMI, and signal aliasing.

Synchronization across domains

e-NVH analysis requires a precise correlation between time-domain signals from multiple domains, including electrical, mechanical, and acoustic. Even millisecond-level drift between these channels can obscure the root causes of vibration or noise.

Mitigation: Hardware-level synchronization using common time bases (e.g., GPS, IRIG, and PTP V2) and deterministic sampling across all DAQ modules ensures alignment of signals across domains. Any of these methods can be used to synchronize SIRIUS XHS modules.

Modeling Assumptions vs. real-world variability

Simulation models often assume ideal boundary conditions and uniform material properties. In practice, however, slight manufacturing variations such as rotor imbalance or stator misalignment can have a significant impact on vibration and noise.

Mitigation: Real-world testing should be used to validate and refine models. Correlating simulated outputs, such as radial force waves, with measured vibration and sound pressure level data enhances model fidelity and reduces the number of design iteration cycles.

Capturing transient events

Many noise and vibration phenomena, such as gear lash or torque ripple, are transient and occur under specific operating conditions (e.g., acceleration, regenerative braking). These may be missed during steady-state measurements.

Mitigation: High-speed, event-triggered acquisition with sufficient pre- and post-trigger buffers helps capture short-duration events. Real-world tests using high-speed mobile DAQ platforms, such as SIRIUS XHS, are ideal for this purpose.

Data volume and complexity

e-NVH testing generates large volumes of high-resolution, multi-domain data. This creates challenges in terms of storage, processing, and interpretation.

Mitigation: The use of integrated software platforms, such as DewesoftX, simplifies data handling by storing all synchronized data in a single file format. Automated analysis routines and real-time dashboards further streamline the interpretation and reporting process.

By proactively addressing these challenges through robust DAQ hardware, synchronized acquisition, validated simulation, and intelligent software workflows, engineers can maximize the accuracy and efficiency of their e-NVH testing programs, achieving faster time-to-market and more refined product performance.

Use cases for e‑NVH

Unlike internal combustion engines, which produce a wide range of mechanical and acoustic sources of noise, the noise and vibration in electric drives introduce new and often subtler sources of vibration and sound, making e-NVH analysis essential. The applications of e‑NVH testing extend far beyond motor whine analysis. It is routinely used in:

EV Drivetrain Testing: Identifying inverter‑induced tonal noise and harmonics in electric motors.

Electric Axle Development: Correlating efficiency maps with acoustic noise and vibration, and structural vibration

Battery Cooling Systems: Measuring pump‑induced vibrations and associated tonal noise.

Aerospace and Drone Applications (eVTOL’s): Linking inverter switching frequencies to propeller acoustic emissions.

These examples demonstrate how integrating electrical, acoustic, and vibrational domains enables engineers to diagnose issues that would be time-consuming to identify using separate measurement workflows.