Company details for:

Autolift Ltd

Quick Links:

Products / Services

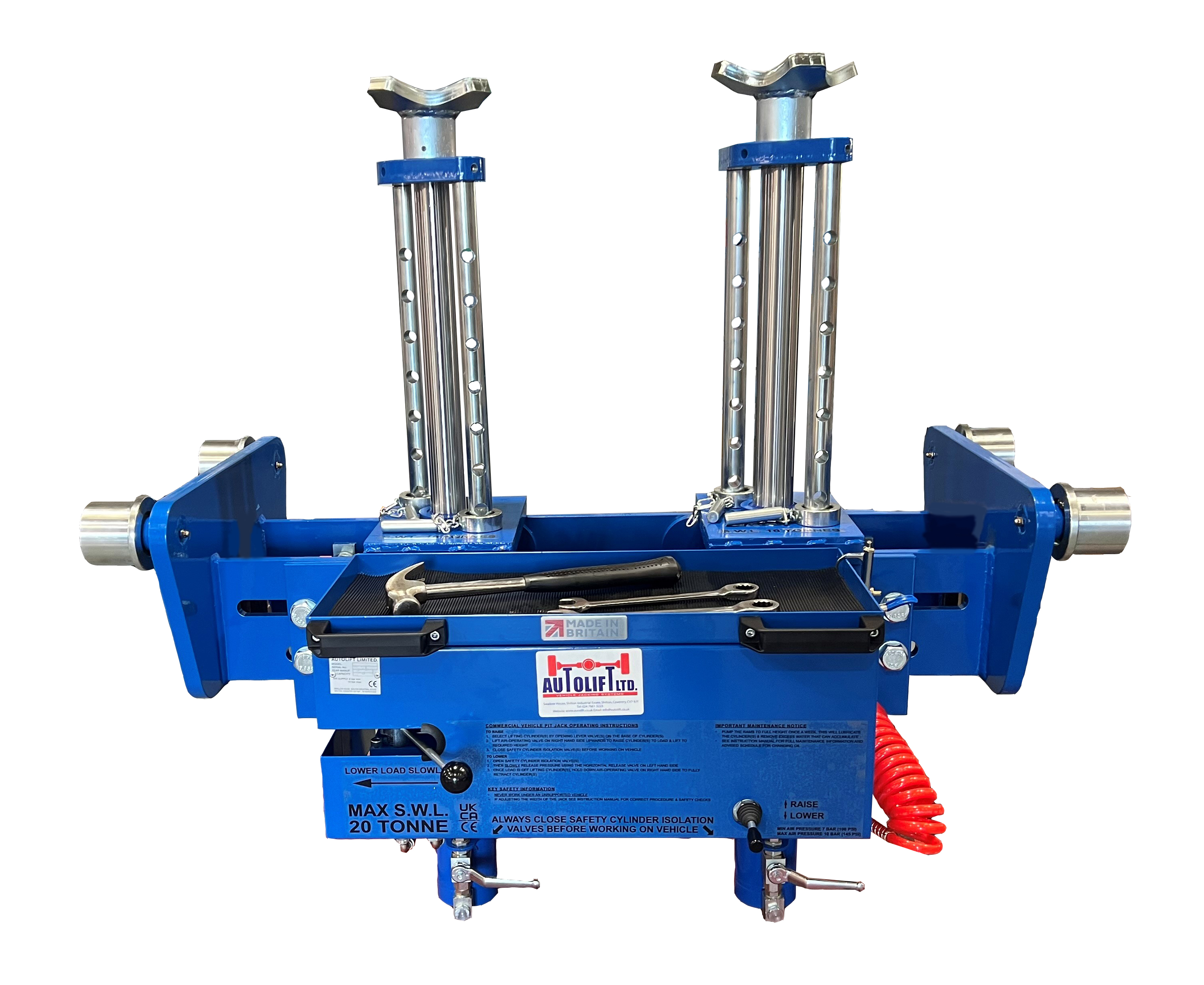

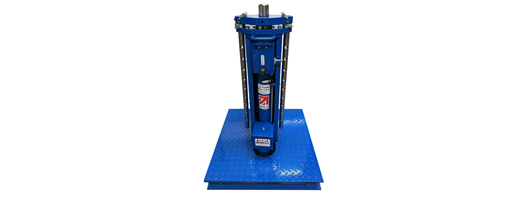

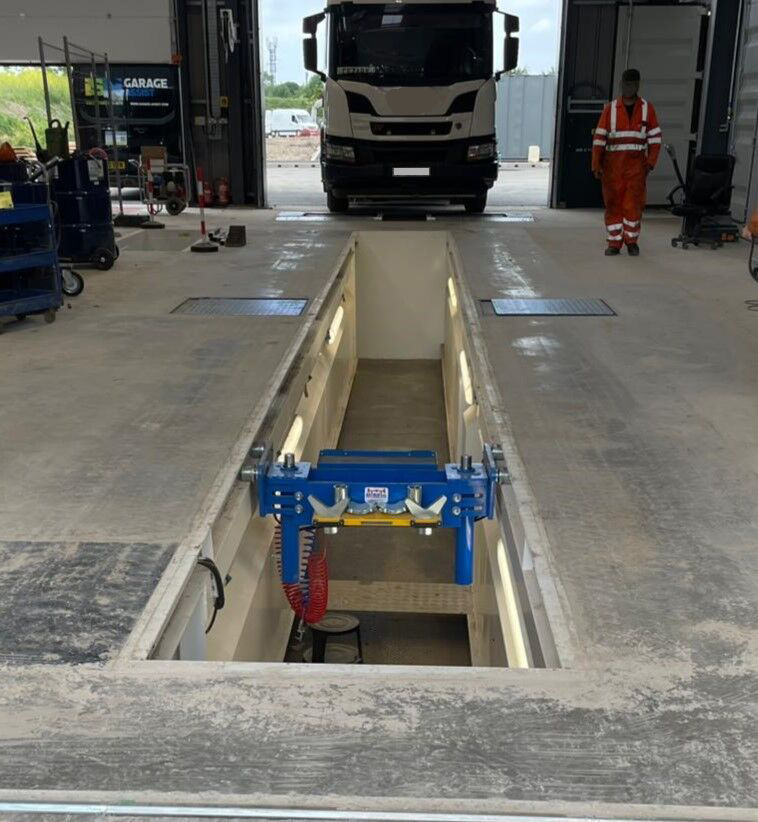

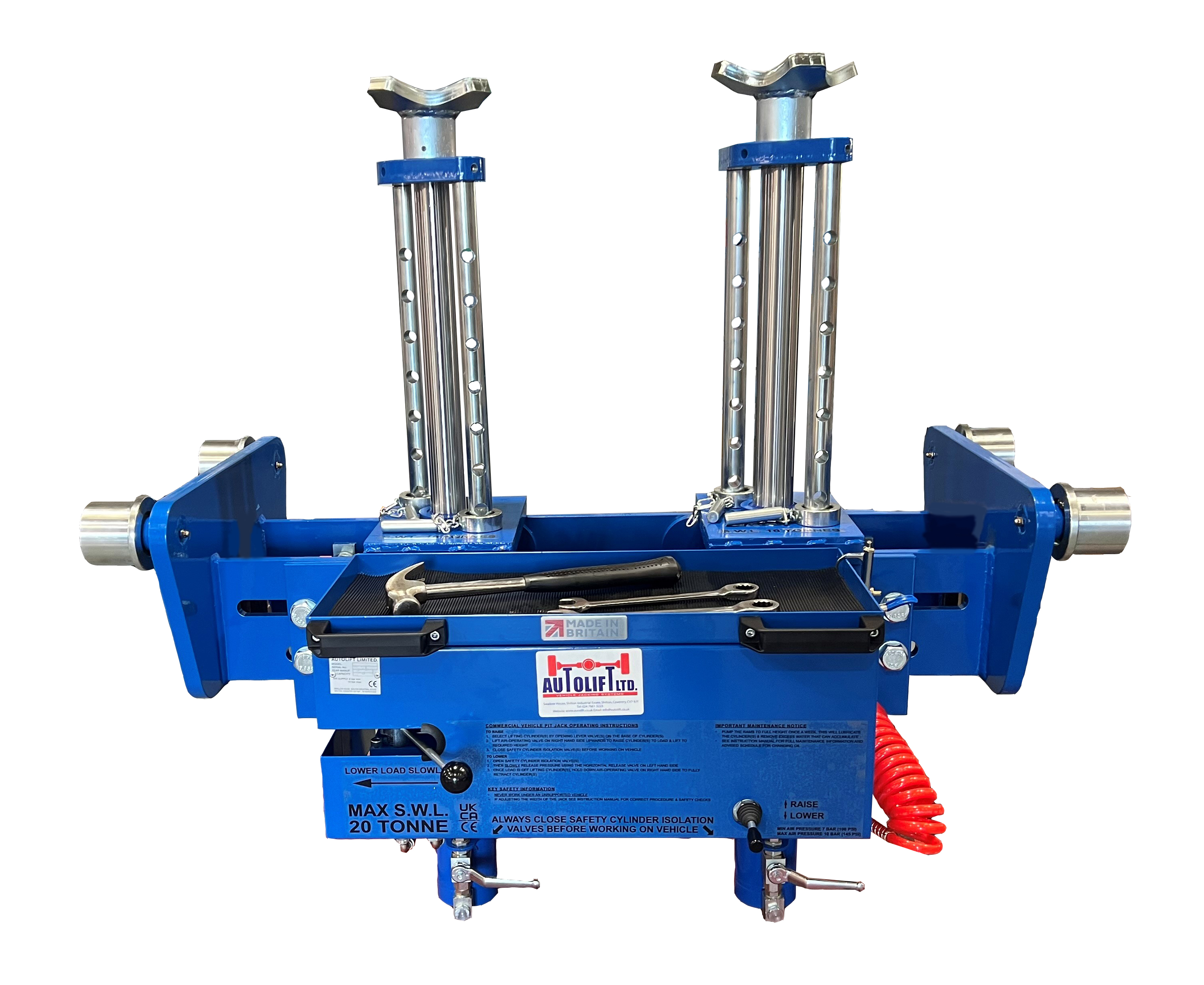

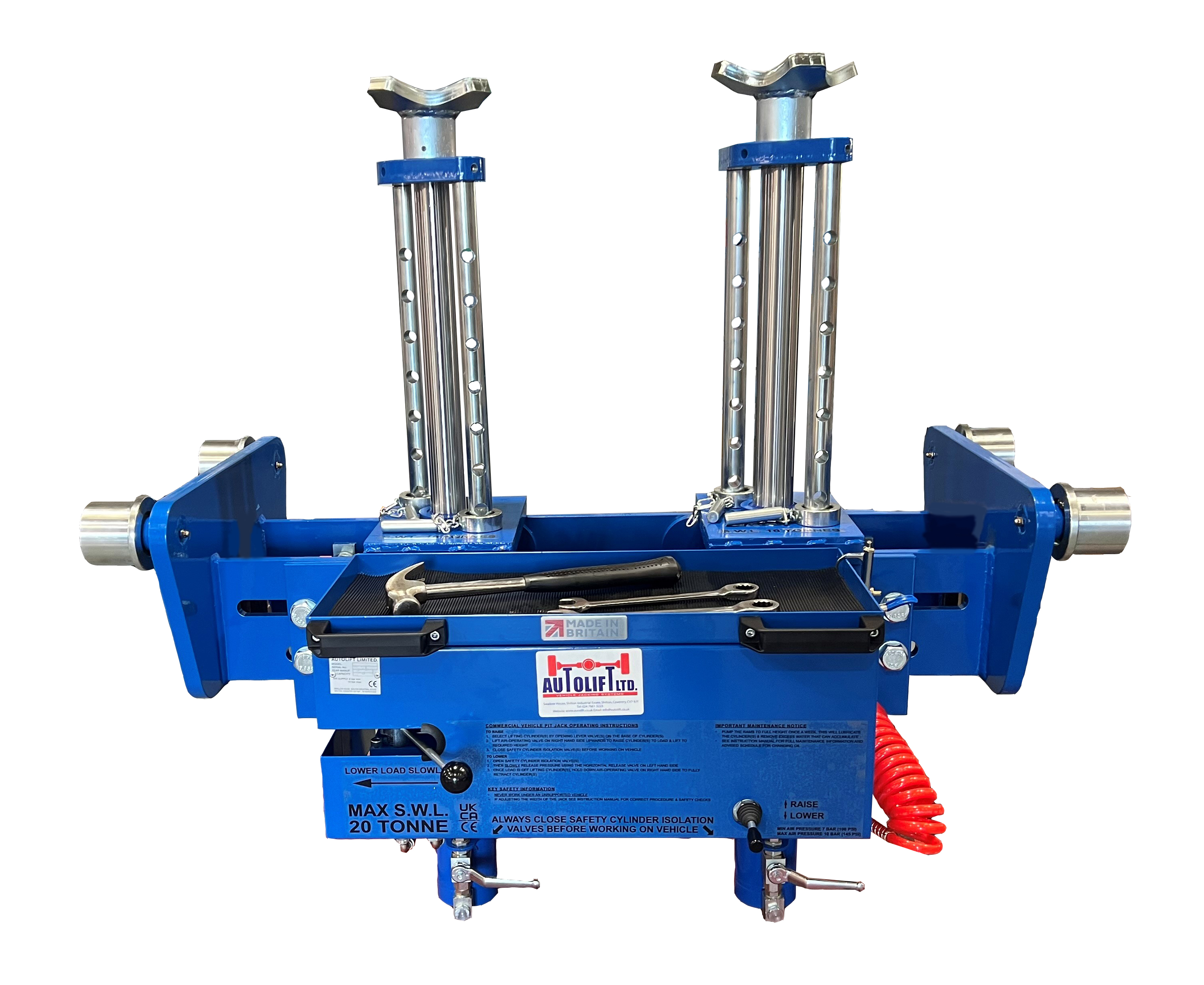

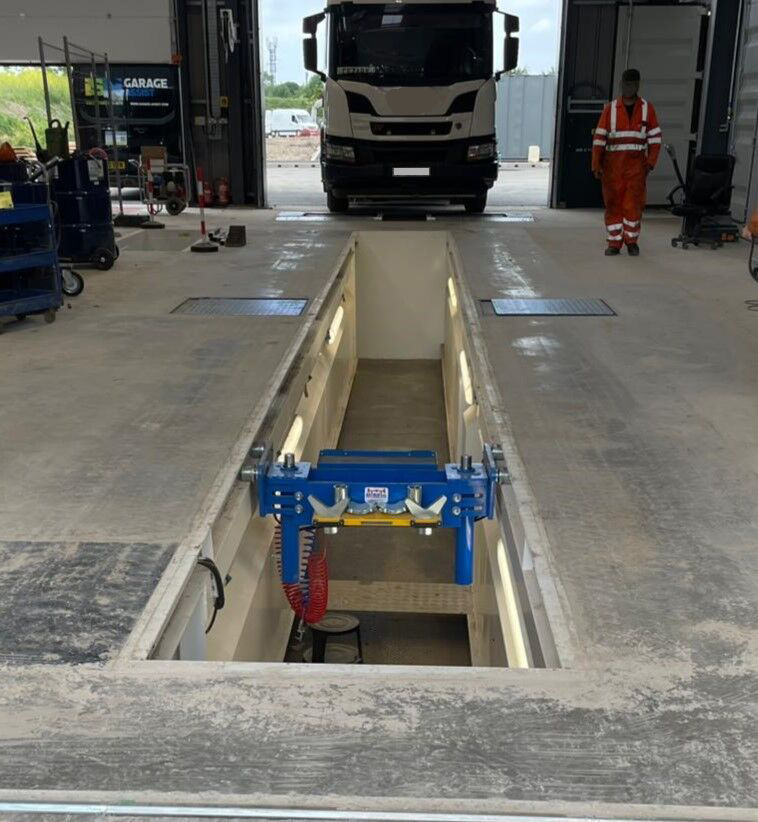

Twin Ram Pit Jacks

- 400mm lifting stroke

- Available in 3 sizes with a large range of adjustment (see table) for excellent versatility.

- Fast acting air pump

- Air over oil hydraulic design allows for increased performance and longevity of cylinder lifespan.

- Ergonomic handles to move the jack along the pit with ease.

- Tool tray to provide an easily accessible place for your tools or parts while working on a job.

- Cylinders can be operated independently and transversely sliding rams for accurate positioning.

- Suitable for ATF & MOT test lanes.

- Triple layer of safety features − Safety Lowering Valves, anti-burst valves & ram lock-off handles. (Security Struts can also be added as an optional extra to provide additional layer of security to the user). Security Stuts can be easily retrofitted after the jack is already in the pit with minimal equipment downtime.

- Each jack comes with included in the price with; 2x 125mm Extensions, 2x Vee Head Adapters, 2x Dish Head Pansies, Rear Adapter Rack Holder & Air Blow Gun.

- UKCA / CE marked, conforms to EC regulations.

- Covered by a 5 year warranty.

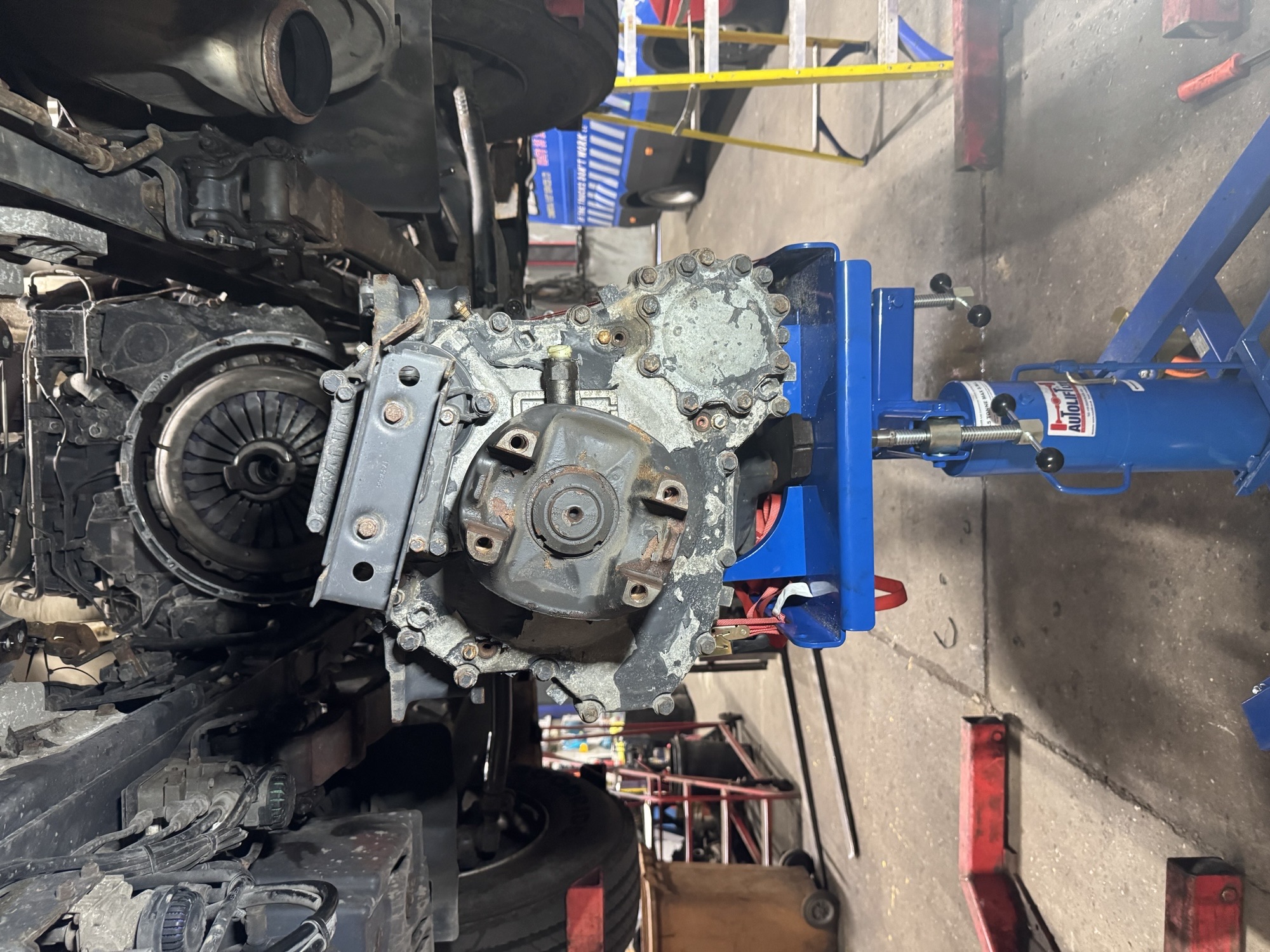

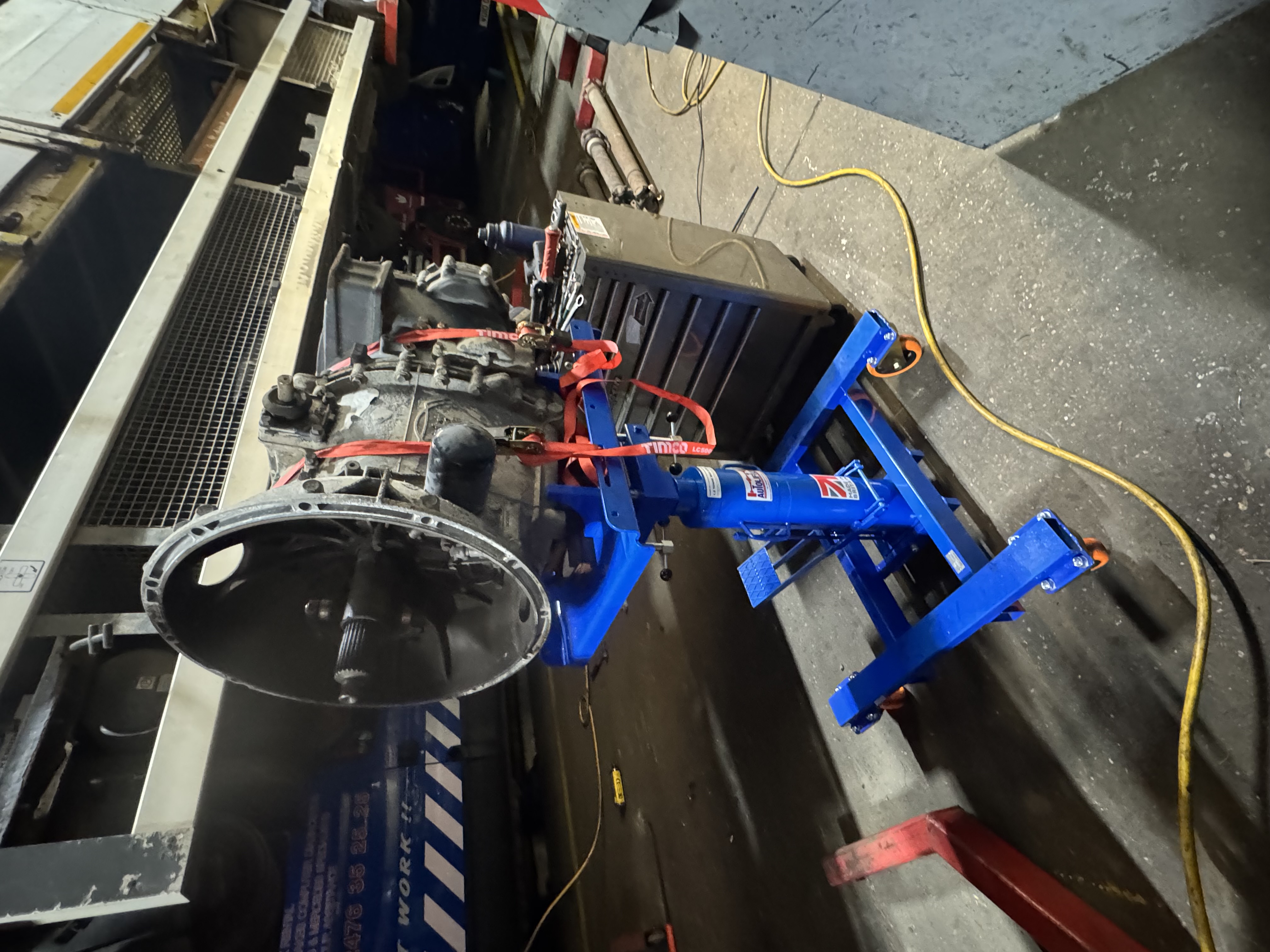

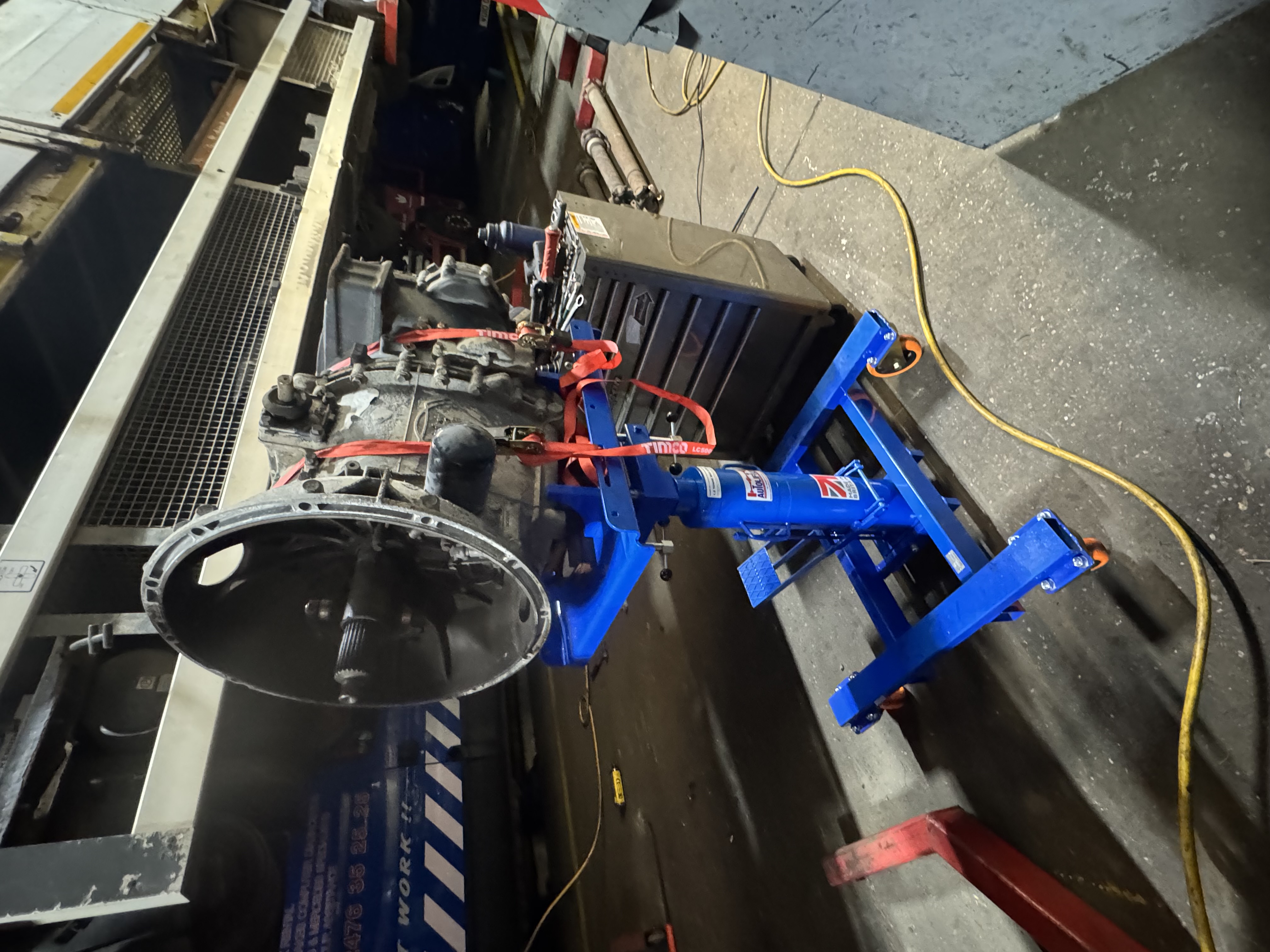

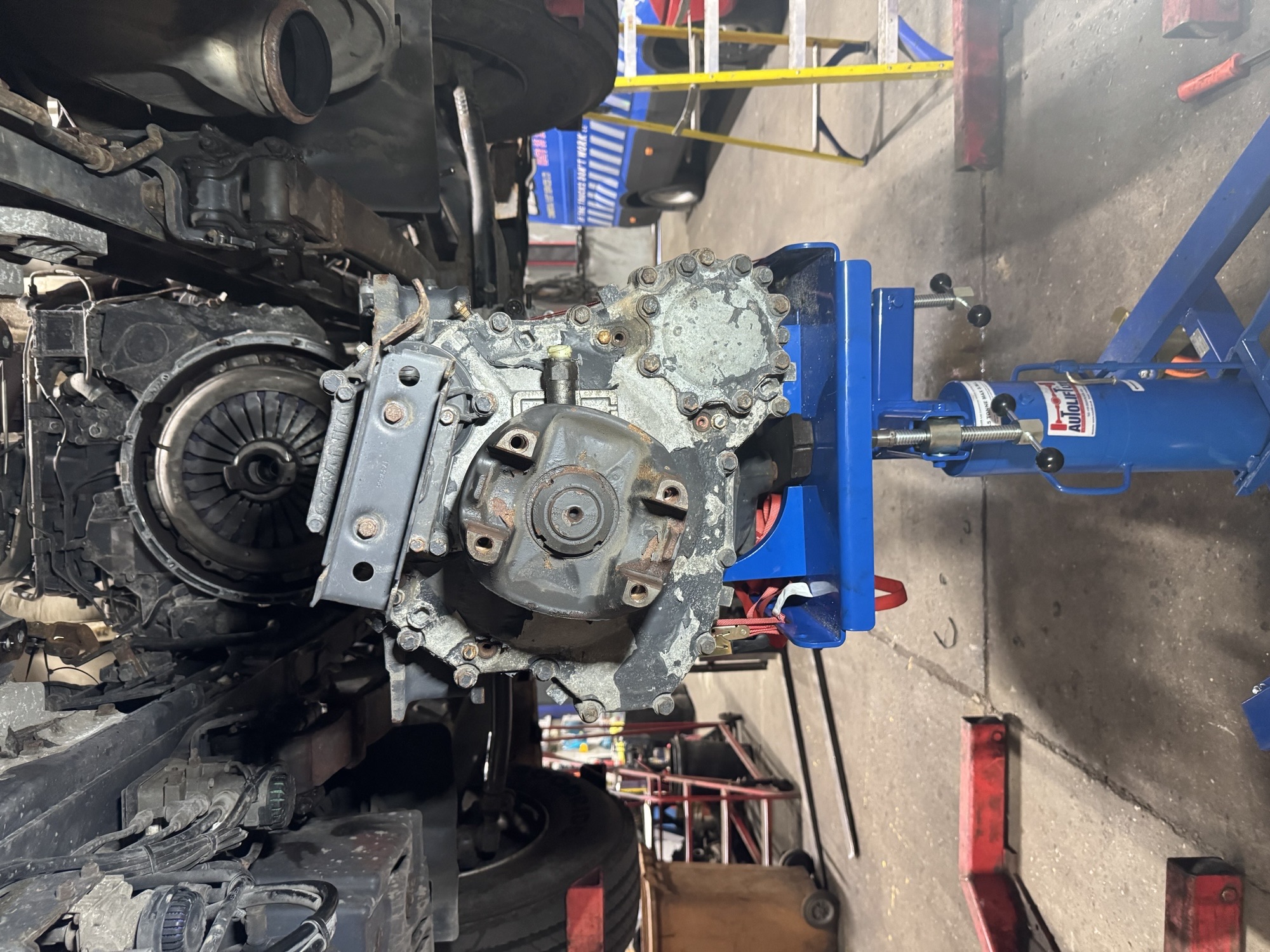

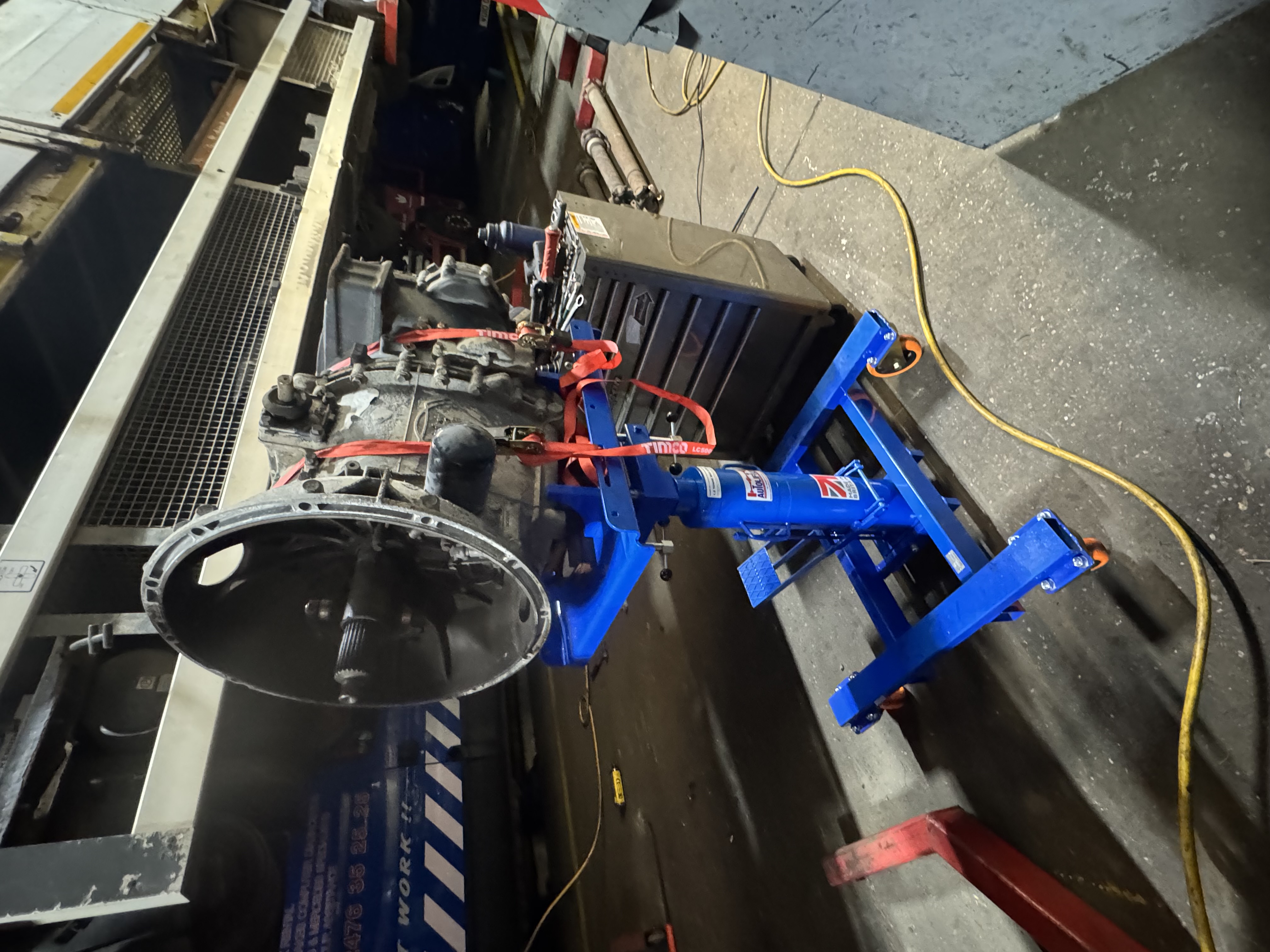

1.5 TONNE Air Operated Transmission Jack

With a narrow base width of 850mm it will fit into most pits − Full Dimensions in diagram below.

The jacks are designed and manufactured for long lasting reliability and ease of use. An air operated hydraulic pump allows an easy effortless lift and simple operation. Precision engineered valves allow a controlled lowering. High Quality Castor wheels and side handles allows the units to be easily moved.

The Jack comes with 2x ratchet straps to secure the gearbox in place when lowering or moving.

The top square plate is a universal design with moveable quadrants & the slots allow modifications to be made by the user to accommodate different gearboxes.

A proven reliable and well engineered premium product at a realistic cost effective price.

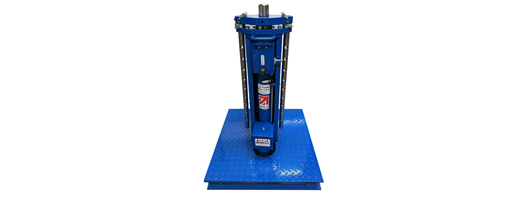

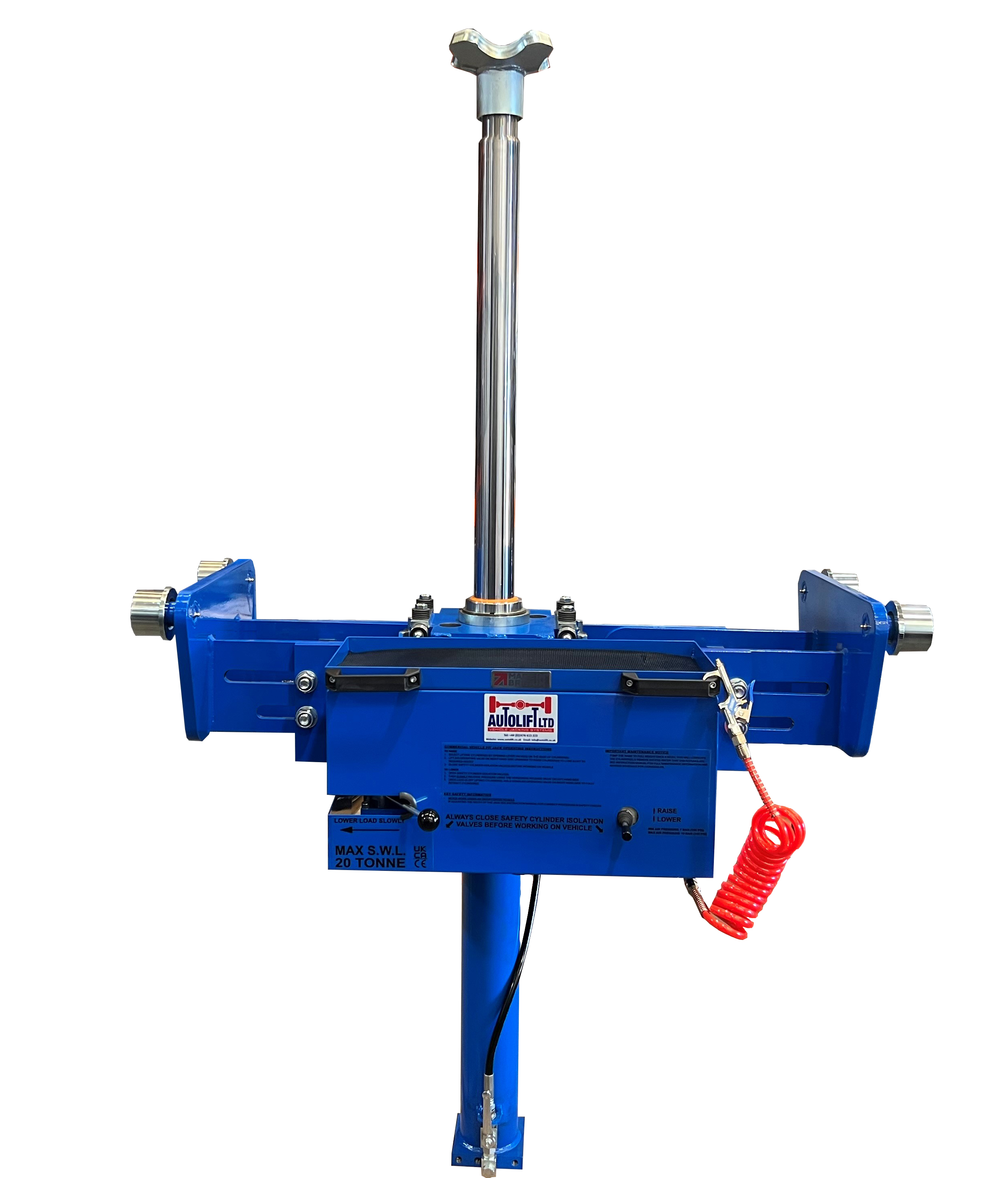

15 / 20 TONNE Air Operated Floor Jack with Security Struts

Minimum height of 1200mm & maximum height of 2000mm. (750mm lifting stroke)

This unit is used on the pit floor instead of a conventional jacking beam running on a pit floor.

It may also be used on the garage floor post or column lifts.

Quadruple layer of safety features − Safety Lowering Valve, anti-burst valve, ram lock-off handle & Security Struts.

Fitted with Security Struts to provide additonal layer of safety to the user.

Fast acting air pump

Air over oil hydraulic design allows for increased performance and longevity of cylinder lifespan.

Each jack comes with 1x Dish Head Pansy.

Front and rear handles for easy & ergonomic movement.

Covered by a 5 year warranty.

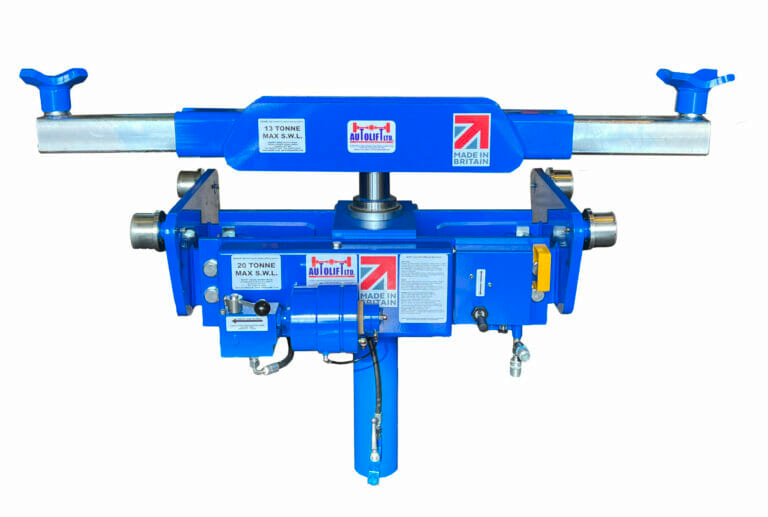

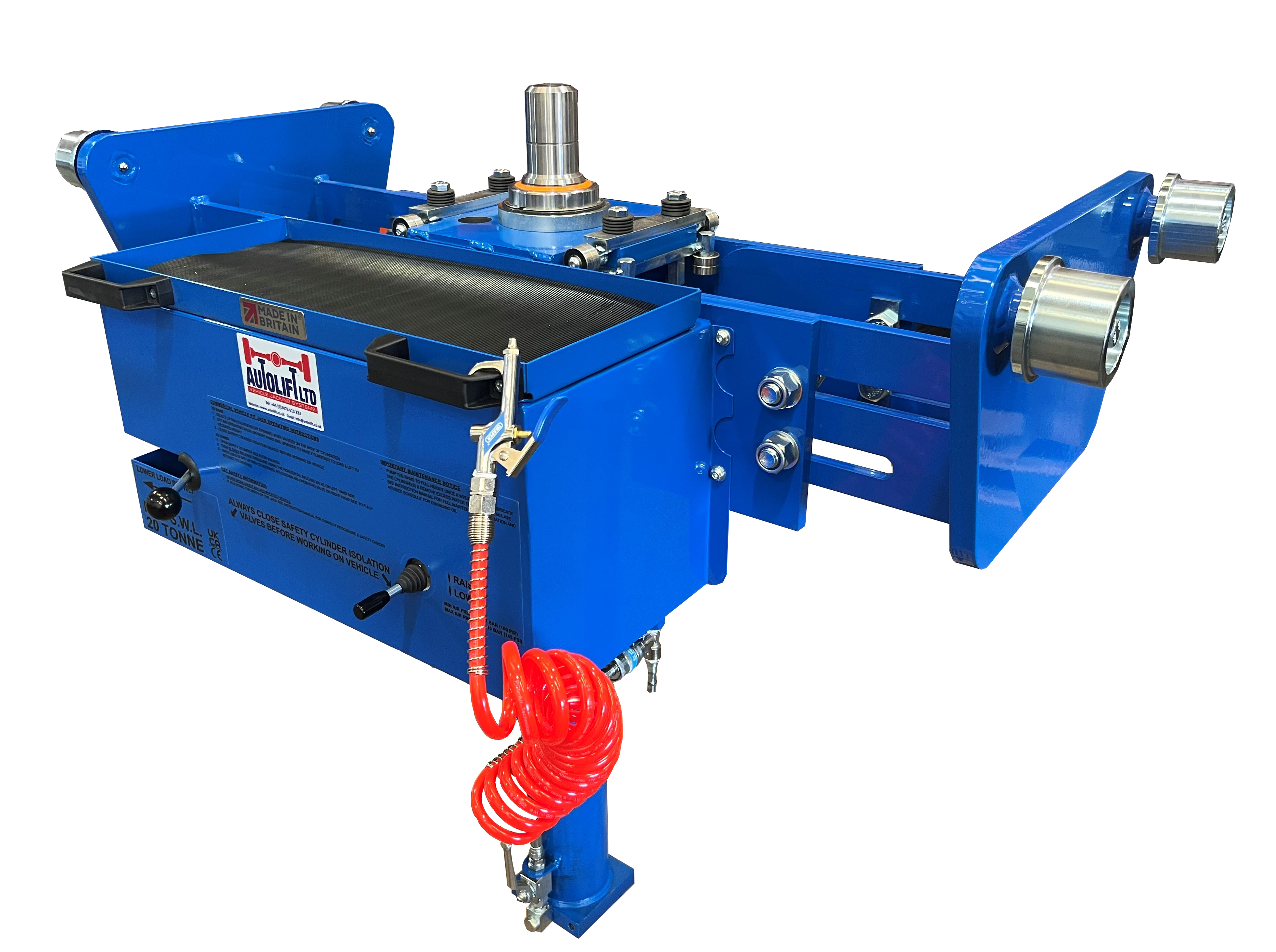

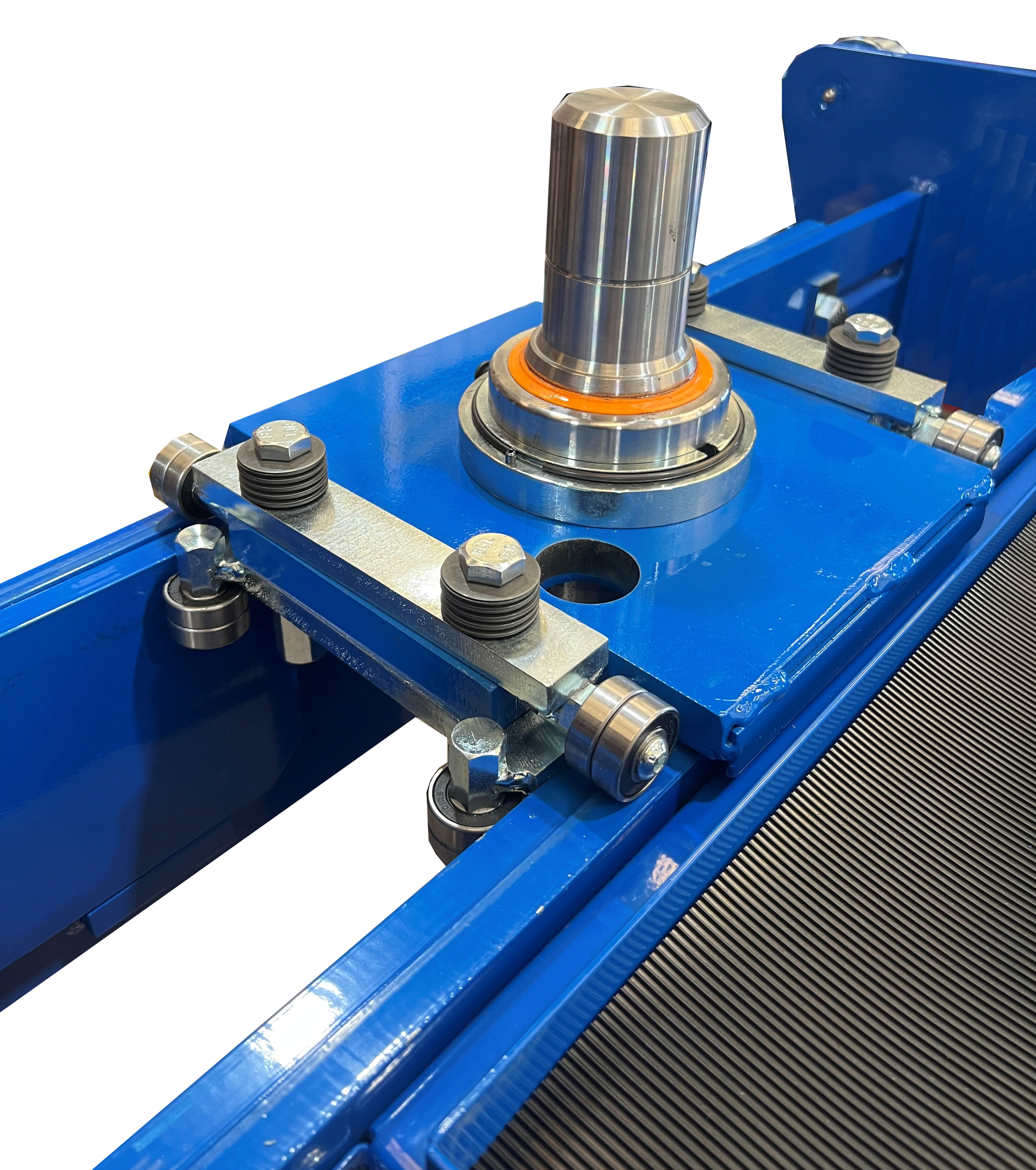

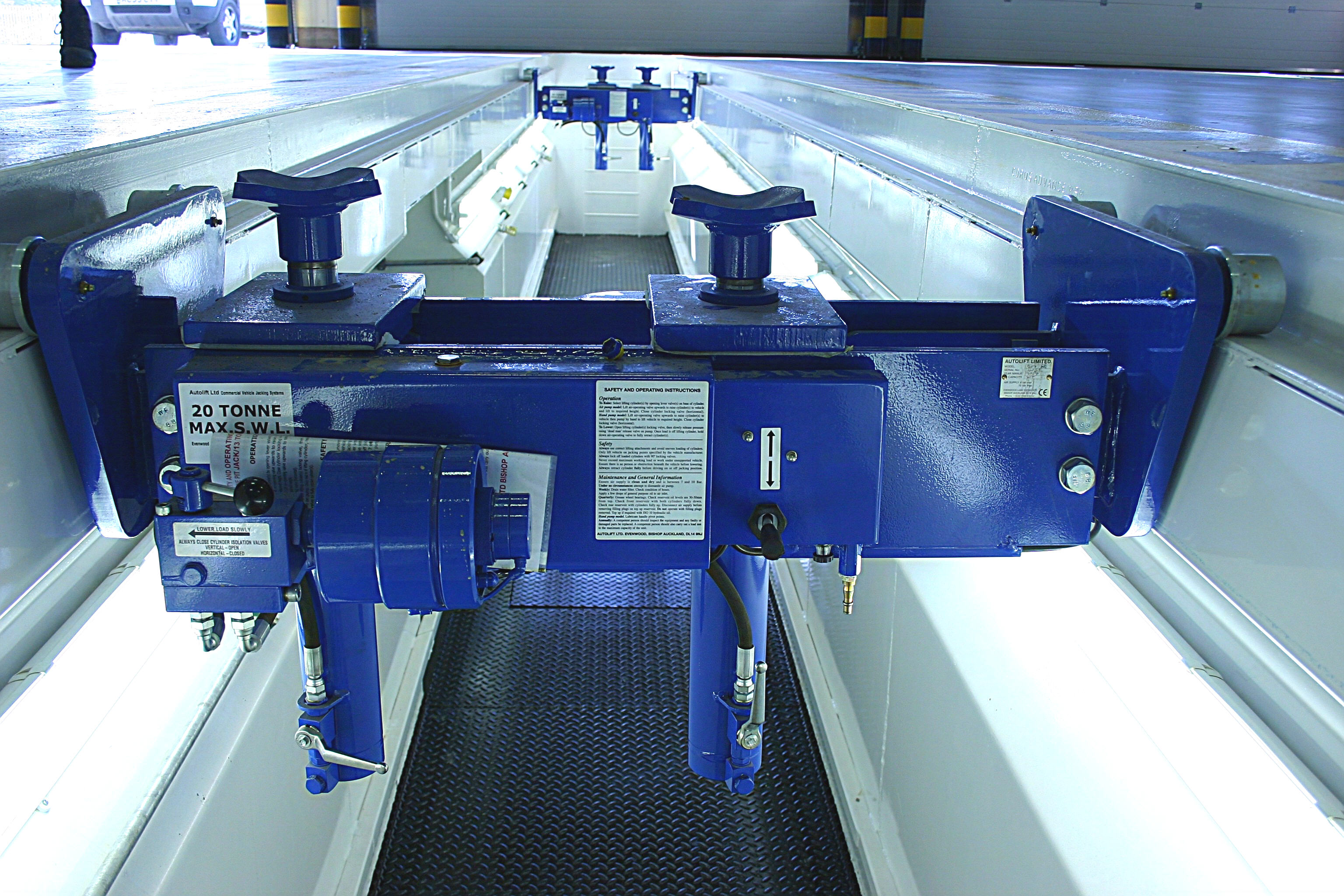

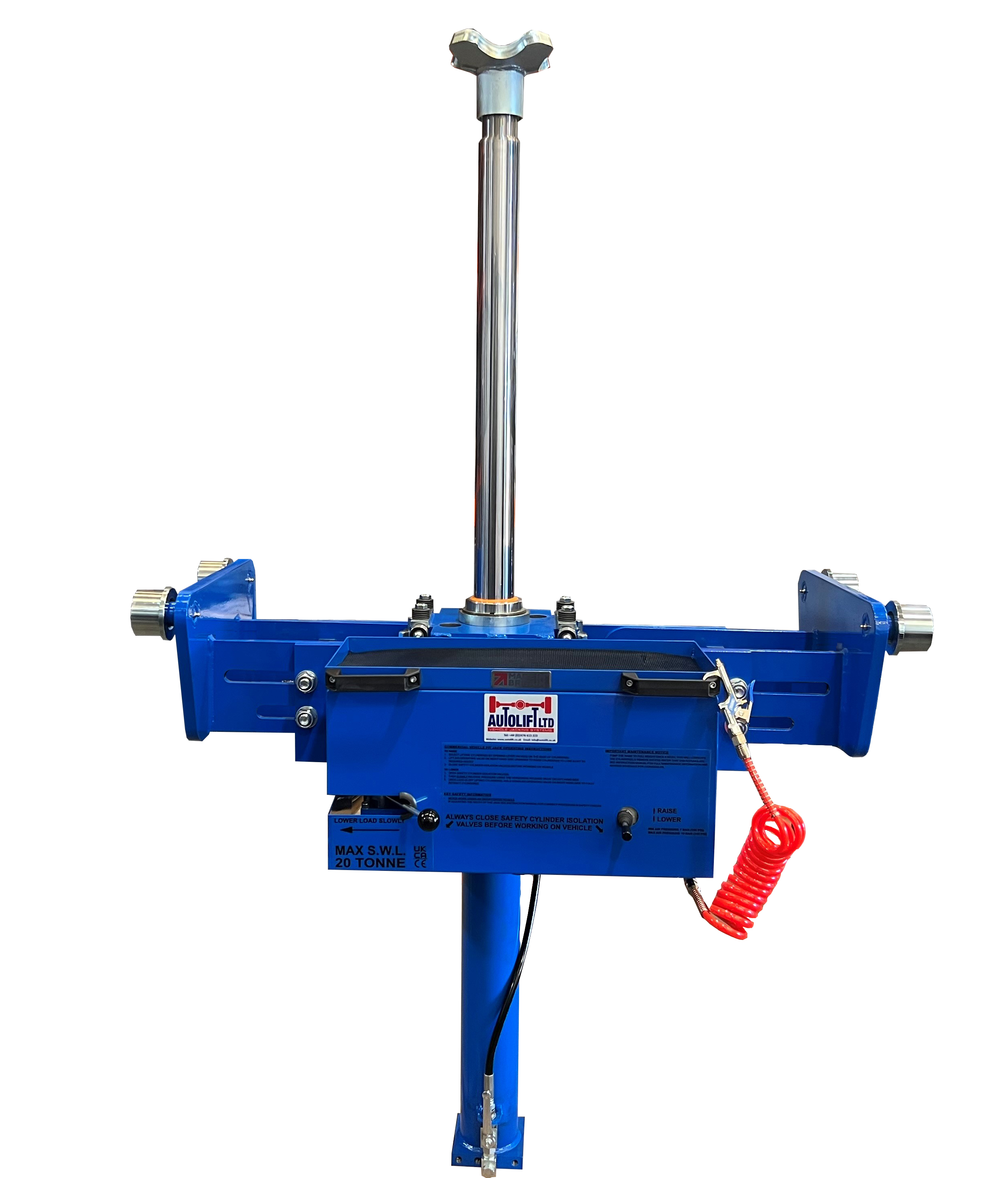

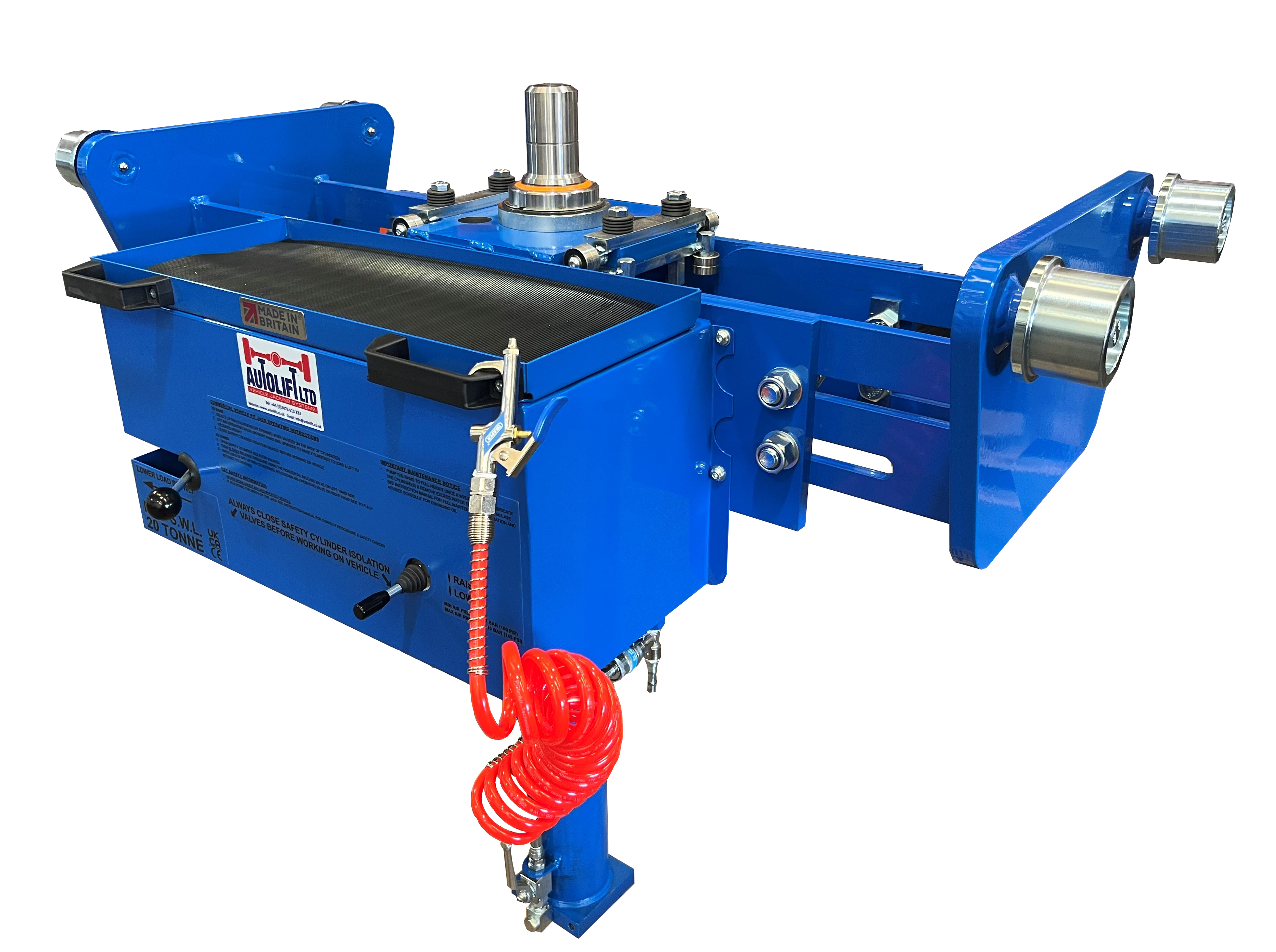

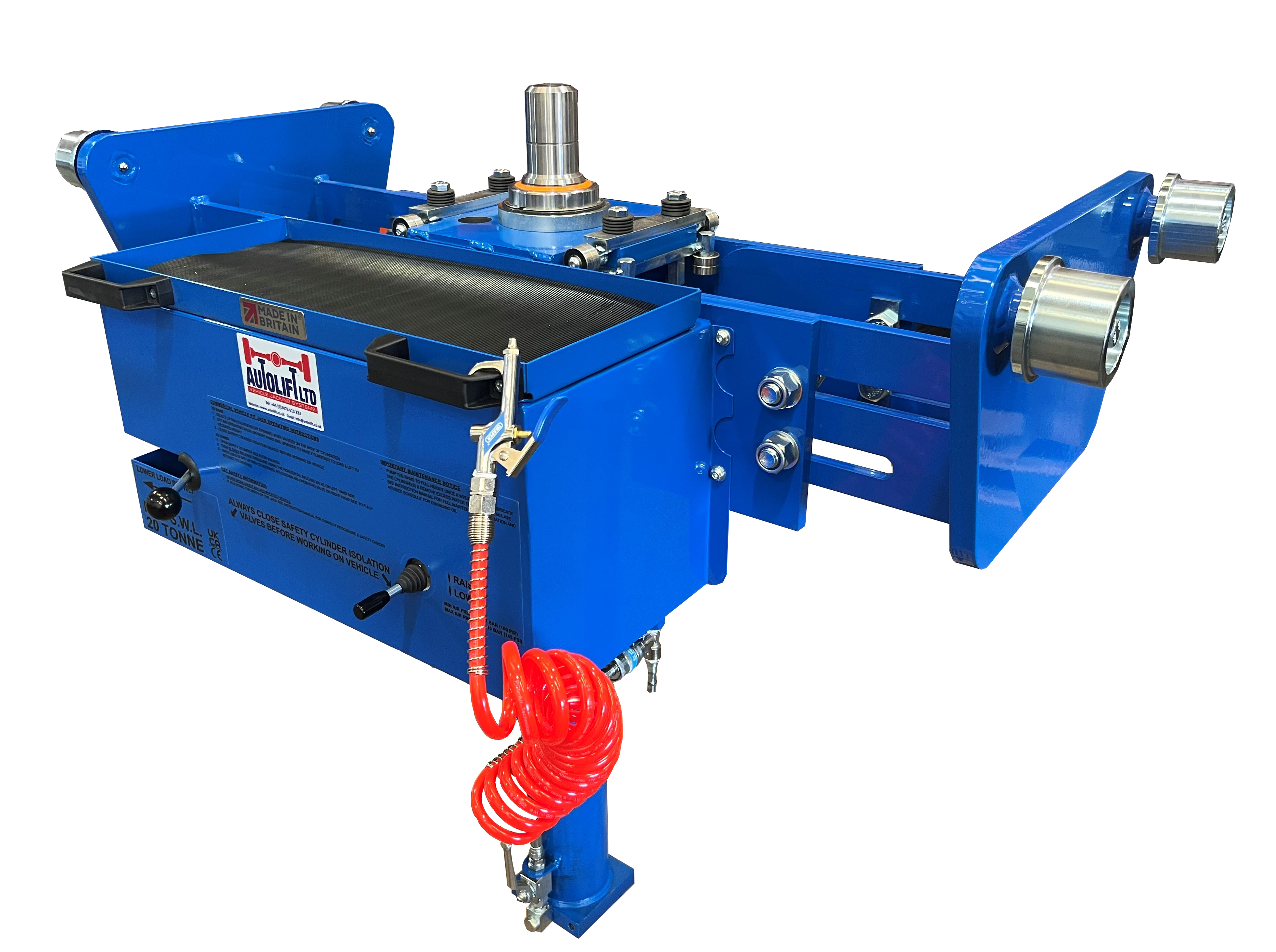

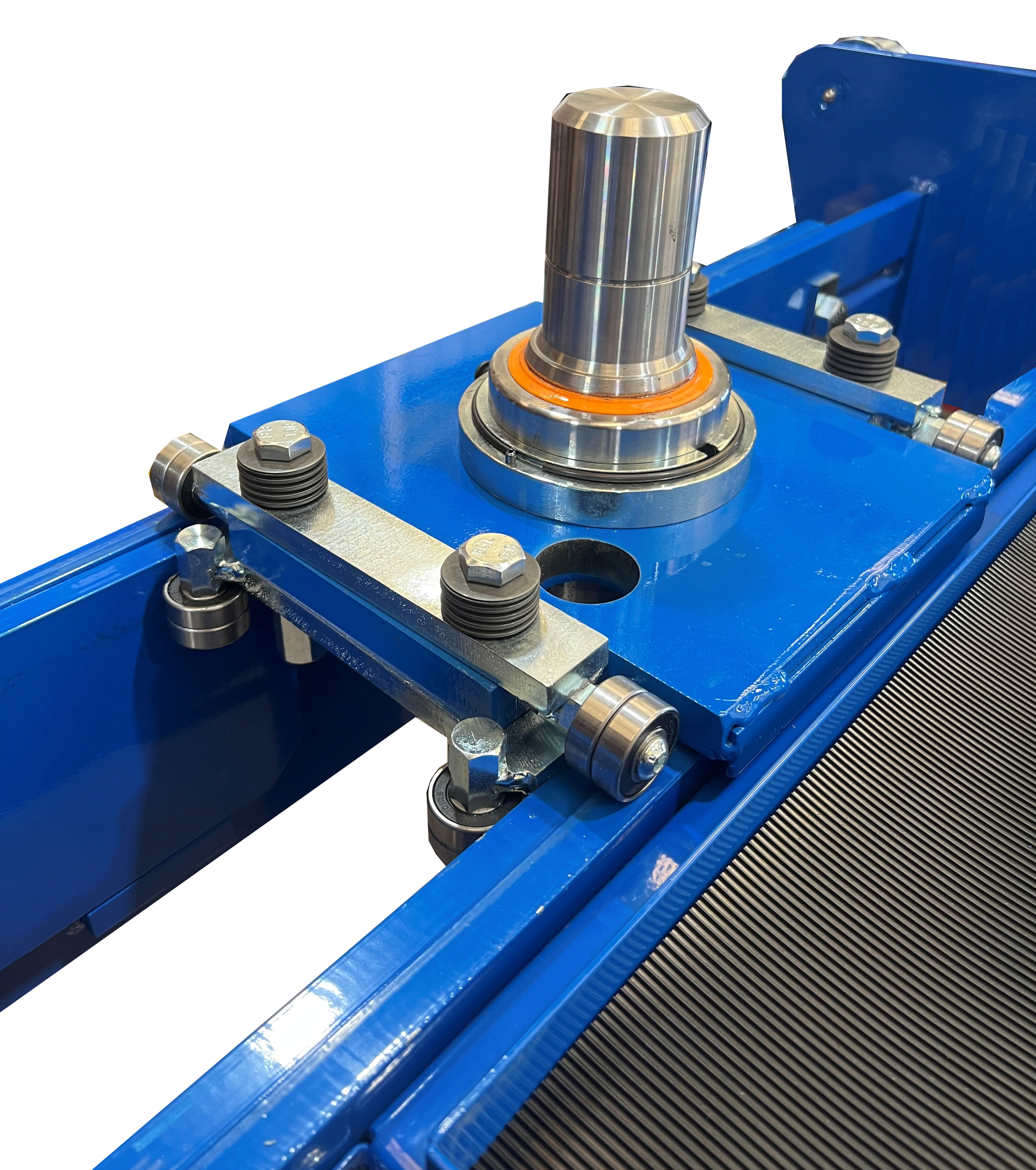

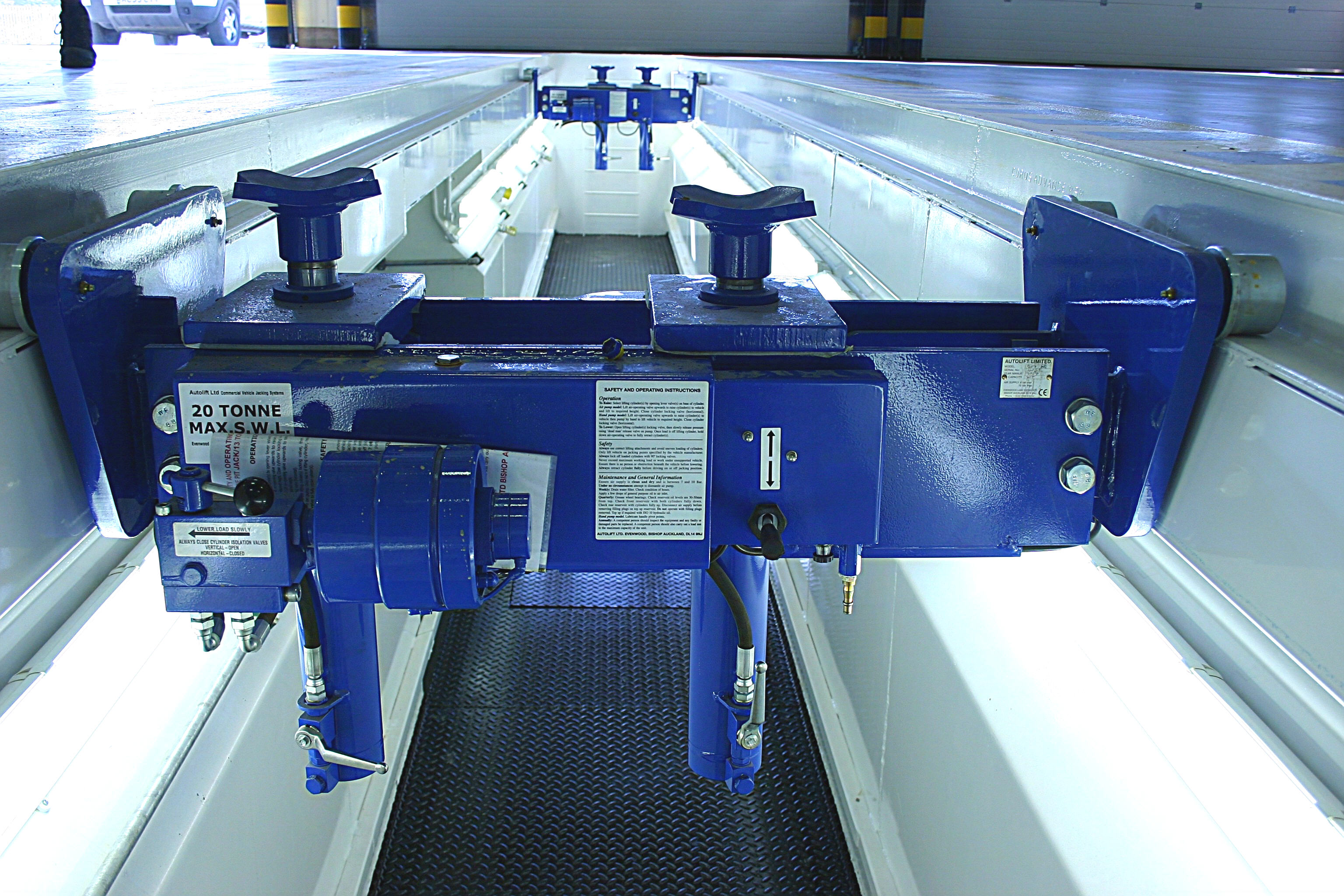

13 Tonne Air Operated Twin Ram Lift-Mounted Jacking Beam

170mm lifting stroke

Fast acting air pump

Our commercial jacking beams are manufactured to suit individual lift widths and specifications. *Please note − Price may vary depending on the results of a Survey form as these jacks are made to specification depending on the manufacturer specification of the lift*

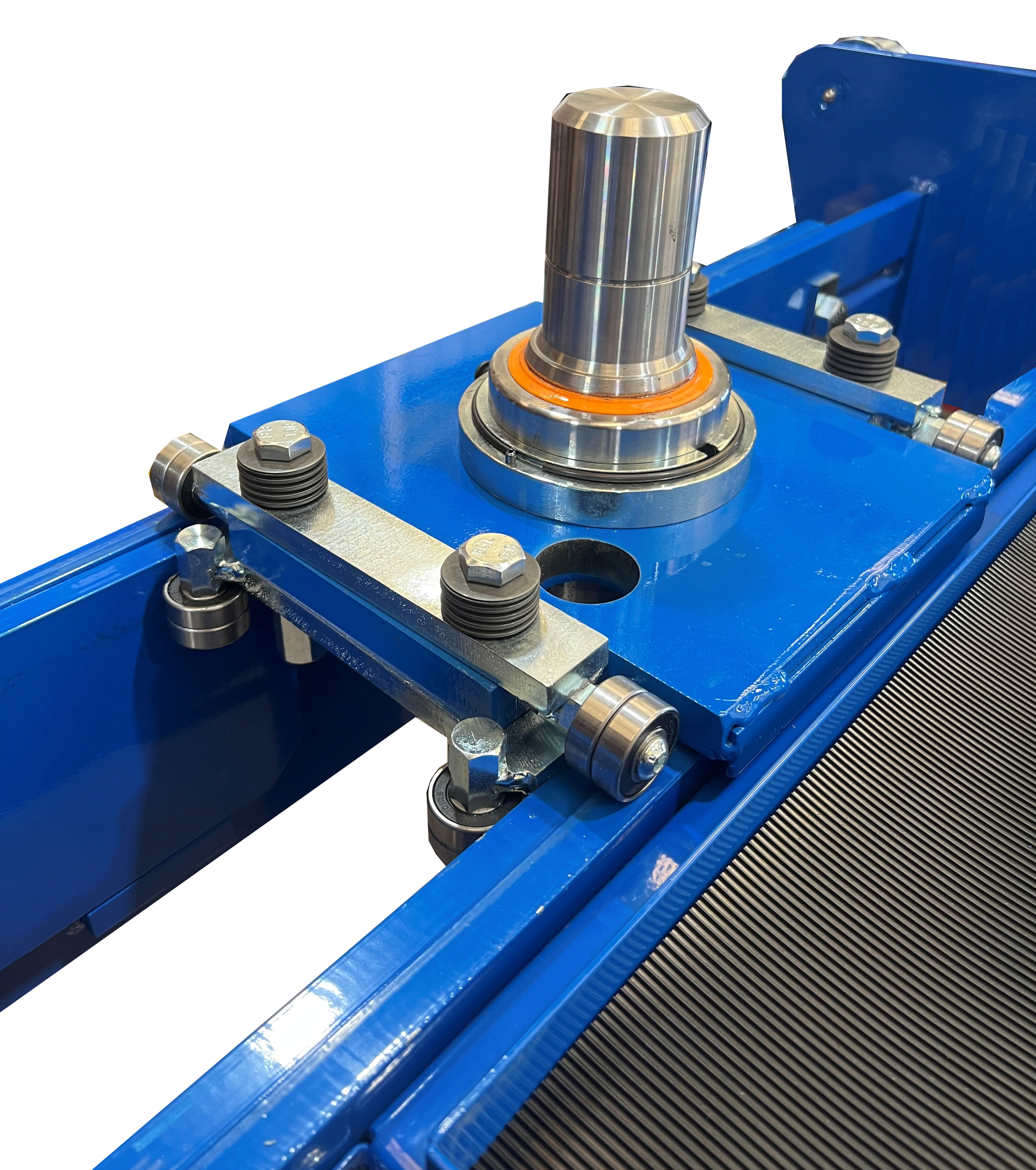

Air over oil hydraulic design allows for increased performance and longevity of cylinder lifespan.

Cylinders can be operated independently and transversely sliding rams for accurate positioning.

Triple layer of safety features − Safety Lowering Valves, anti-burst valves & ram lock-off handles.

Each jack comes with; 2x 200mm Extensions, 2x Vee Head Adapters & 2x Dish Head Pansies.

Covered by a 5 year warranty.

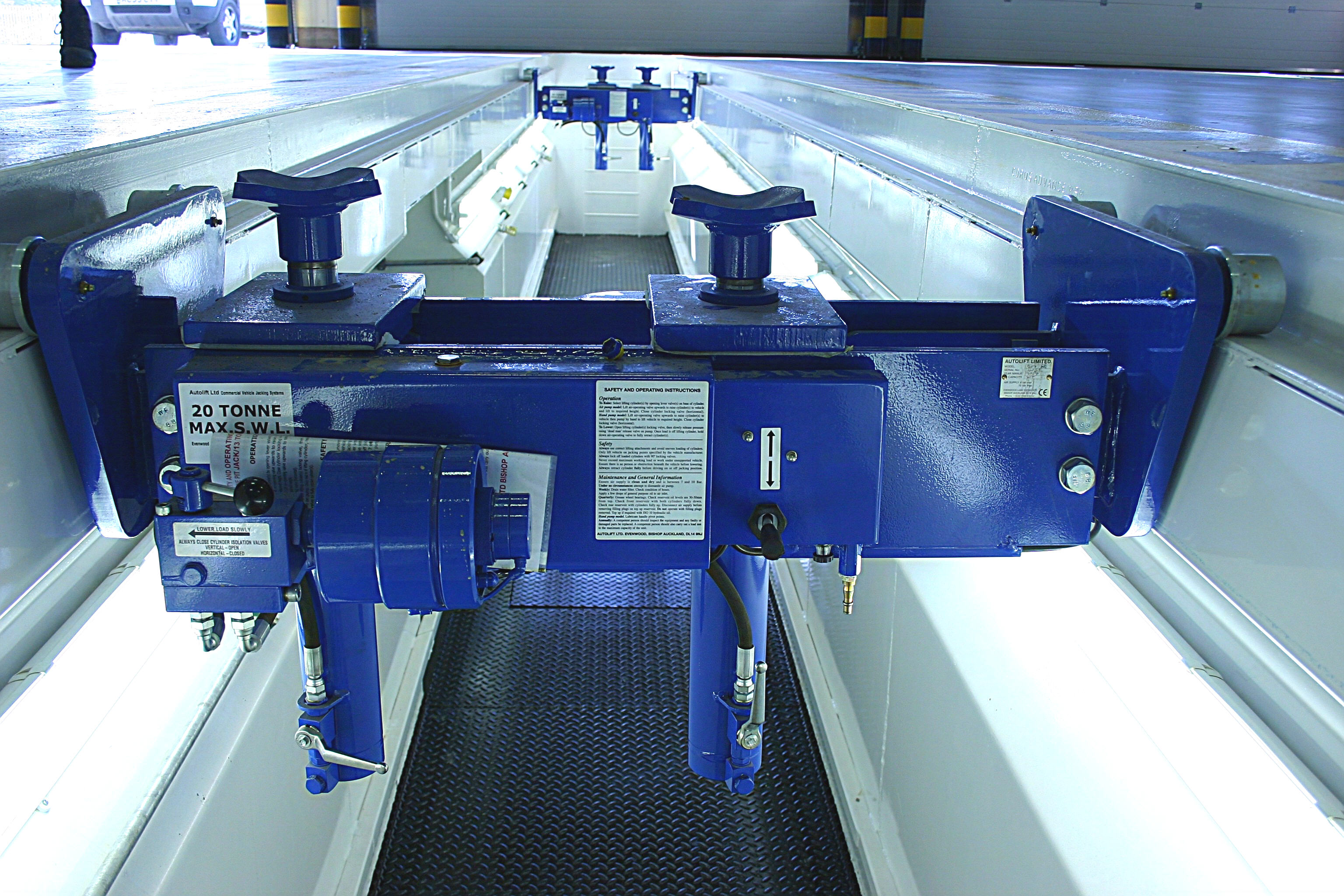

Heavy Duty 40 Tonne Commercial Twin Ram Pit Jack

400mm lifting stroke

Fast acting air pump

Our commercial pit jacks are manafactured to suit individual pit widths and specifications.

Air over oil hydraulic design allows for increased performance and longevity of cylinder lifespan.

Cylinders can be operated independenly and transversley sliding rams for accurate positioning.

Triple layer of safety features − Safety Lowering Valves, anti-burst valves & ram lock-off handles. (Security Struts can also be added as an optional extra to provide additional layer of security to the user.)

Each jack comes with included in the price with; 2x Dish Head Pansies & Airline Adapter.

Covered by a 5 year warranty.

Spreader Beams are available for this jack − 13 Tonne Fixed or Telescopic

*Please note − Price may vary depending on the results of a Pit Survey form*

13 TONNE Telescopic Spreader Beam for Single Ram / Floor Jack

15/20T Floor Jack

15/20T Single Ram Jack 750mm Stroke

15/20T Single Ram Jack 400mm Stroke

This spreader beam is designed to accommodate vehicles with independent front suspensions − particularly buses and coaches. This Spreader Beam also enables you to reach jacking points beyond the width of your pit.

Having a spreader beam is a legal requirement for ATF & MOT dedicated test lanes.

Fully closed the lifting points are 920mm apart and fully extended they are 1400mm apart.

320mm clearance required from top of jack frame to underside of vehicle.

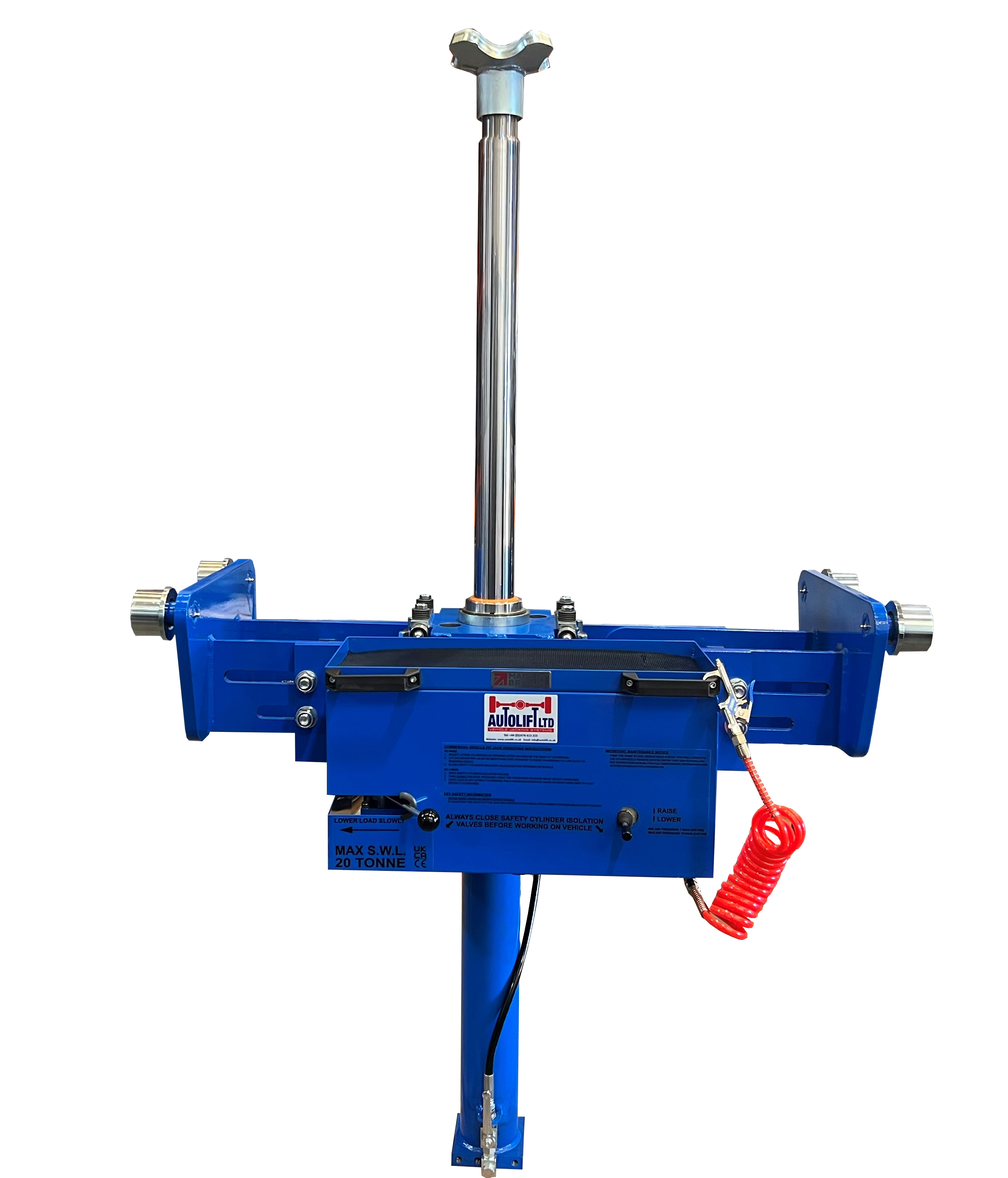

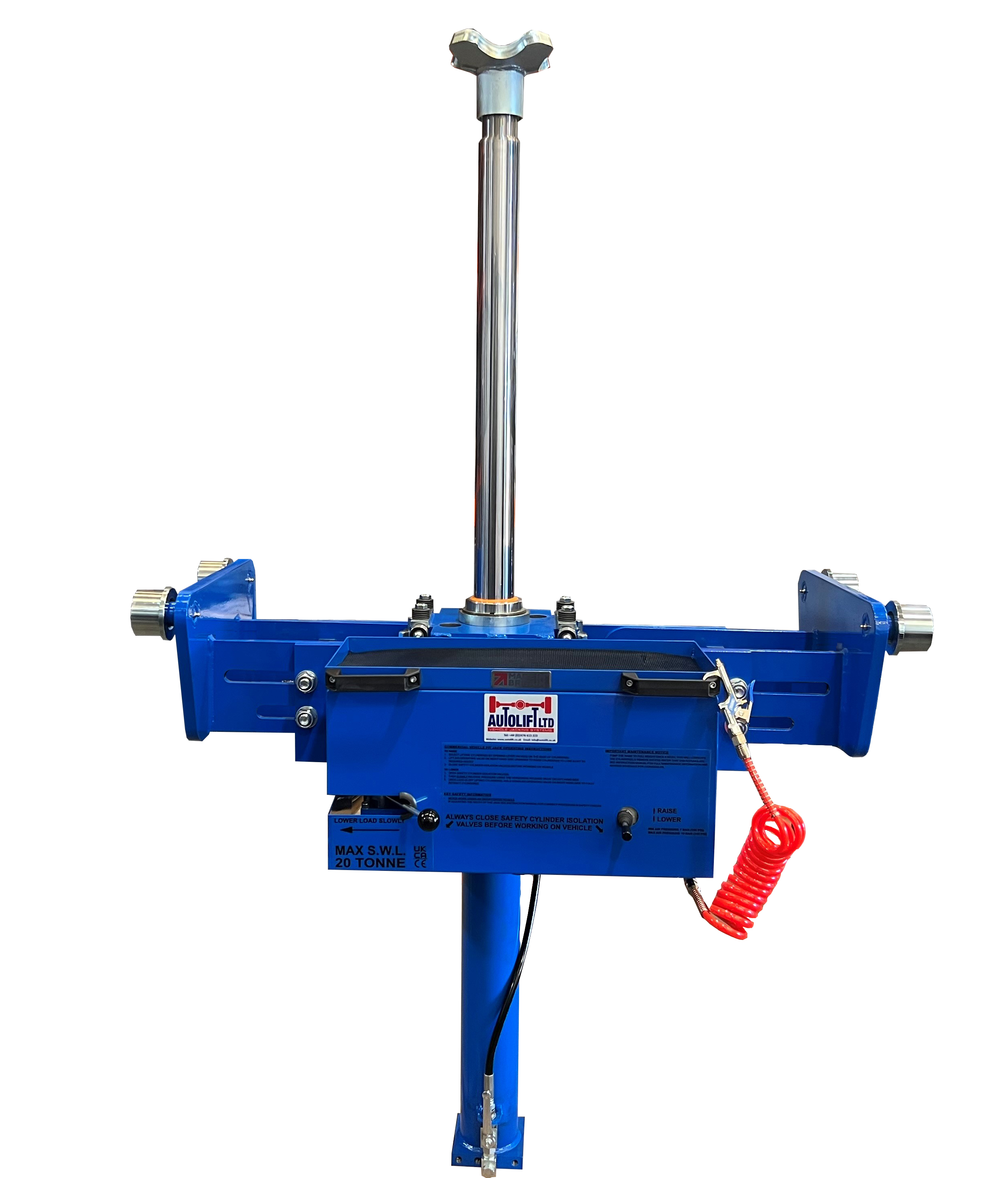

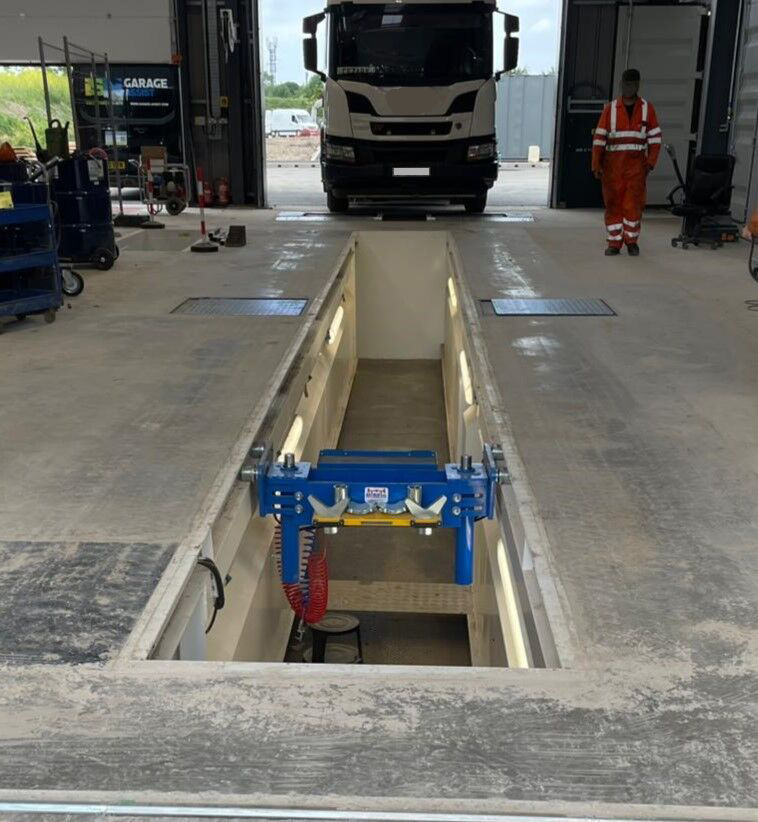

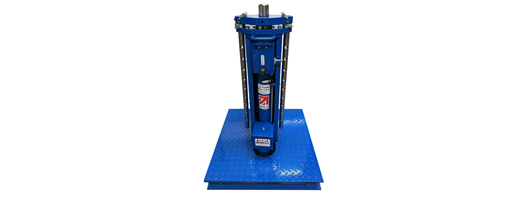

Single Ram Pit Jacks

Available in a 15 Tonne or 20 Tonne capacity.

750mm lifting stroke

Fast acting air pump

Our commercial pit jacks are manufactured to suit individual pit widths and specifications.

Air over oil hydraulic design allows for increased performance and longevity of cylinder lifespan.

Effortless movement of transversely sliding ram for accurate positioning.

Triple layer of safety features − Safety Lowering Valve, anti-burst valve & ram lock-off handle. (Security Struts can also be added as an optional extra to provide additional layer of security to the user).

Each jack comes with 1x Dish Head Pansy & Airline Adapter.

Covered by a 5 year warranty.

Floor Jacks

Minimum height of 1200mm & maximum height of 2000mm. (750mm lifting stroke)

This unit is used on the pit floor instead of a conventional jacking beam which run on pit edge rails.

It may also be used on the garage floor under post or column lifts.

Triple layer of safety features − Safety Lowering Valve, anti-burst valve & ram lock-off handle. (Security Struts can also be added as an optional extra to provide additional layer of security to the user).

Fast acting air pump

Air over oil hydraulic design allows for increased performance and longevity of cylinder lifespan.

Each jack comes with 1x Dish Head Pansy.

Front and rear handles for easy & ergonomic movement.

Covered by a 5 year warranty.

Transmission Jacks

With a narrow base width of 850mm it will fit into most pits − Full Dimensions in diagram below.

The jacks are designed and manufactured for long lasting reliability and ease of use. A foot pedal operated hydraulic pump allows an easy effortless lift and hands free operation. Precision engineered valves allow a controlled lowering. High Quality Castor wheels and side handles allows the units to be easily moved.

The Jack comes with 2x ratchet straps to secure the gearbox in place when lowering or moving.

The top square plate is a universal design with 4x moveable quadrants & the slots allow modifications to be made by the user to accommodate different gearboxes.

A proven reliable and well engineered premium product.

Spreader Beams

Having a spreader beam is a legal requirement for ATF & MOT dedicated test lanes.

Pit must be a minimum of 800mm wide for rams to be able to spread far enough apart to fit the Spreader Beam on.

*JACK NOT INCLUDED*

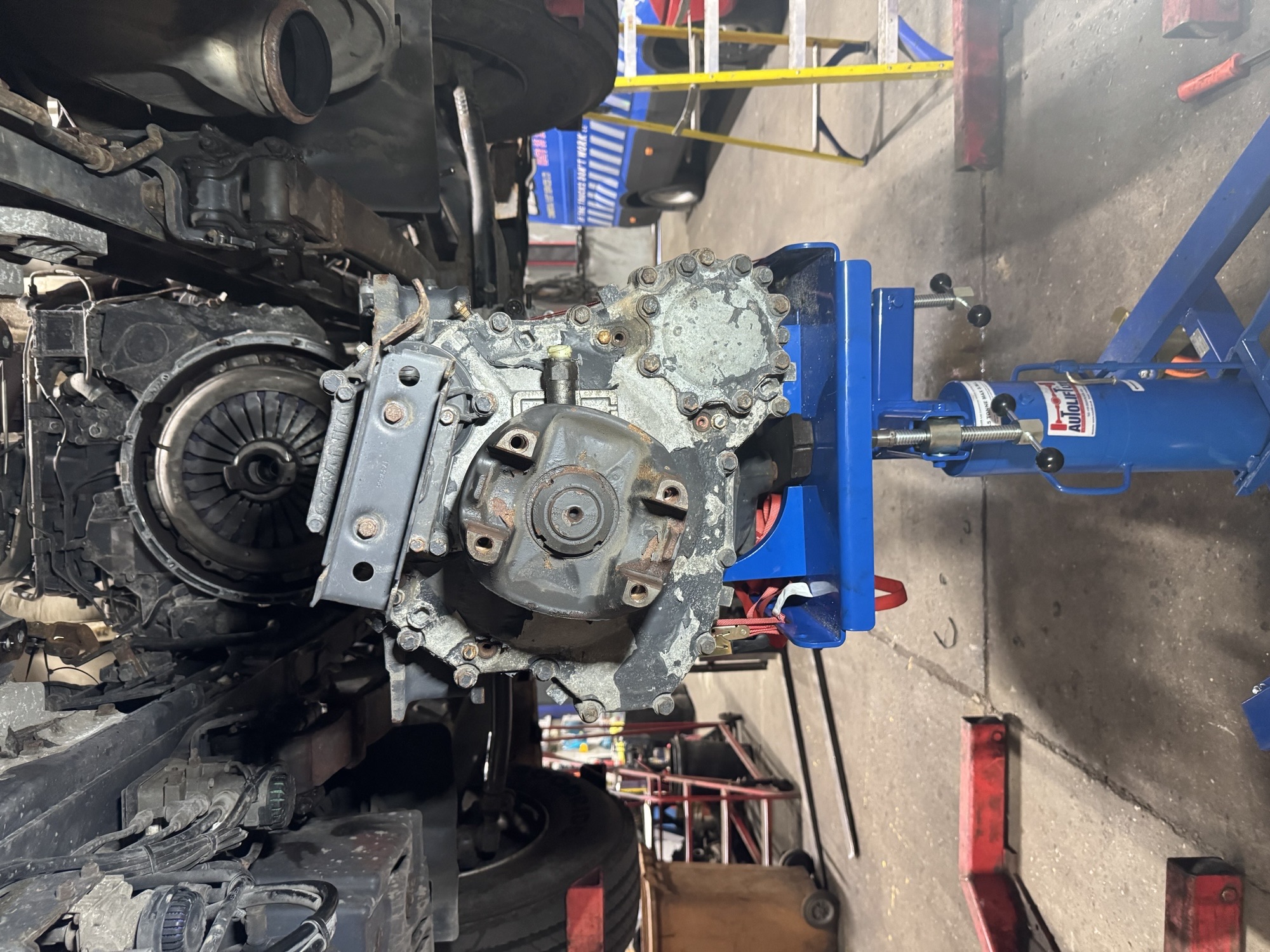

Jacking Beams

170mm lifting stroke

Fast acting air pump

Our commercial jacking beams are manufactured to suit individual lift widths and specifications. *Please note − Price may vary depending on the results of a Survey form as these jacks are made to specification depending on the manufacturer specification of the lift*

Air over oil hydraulic design allows for increased performance and longevity of cylinder lifespan.

Cylinders can be operated independently and transversely sliding rams for accurate positioning.

Triple layer of safety features − Safety Lowering Valves, anti-burst valves & ram lock-off handles.

Each jack comes with; 2x 200mm Extensions, 2x Vee Head Adapters & 2x Dish Head Pansies.

Covered by a 5 year warranty.

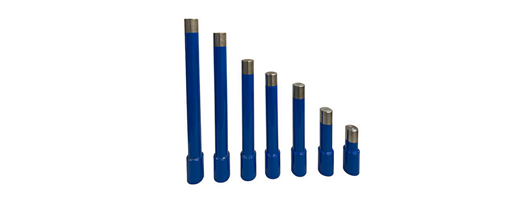

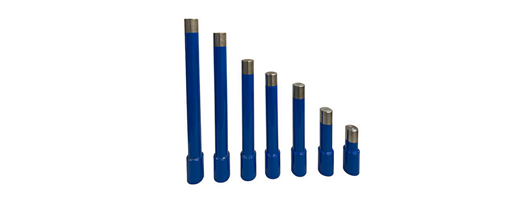

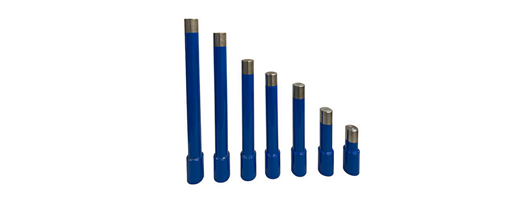

Adapters for Twin Ram Jacks

AL347EXTENSION (125MM) Each£45.61

AL348EXTENSION (200MM) Each£66.33

AL349EXTENSION (250MM) Each£69.31

AL350EXTENSION (300MM) Each£70.63

AL351EXTENSION (350MM) Each£74.73

AL352EXTENSION (400MM) Each£76.59

AL353EXTENSION (500MM) Each£86.14

AL354EXTENSION (550MM) Each£96.88

Servicing, Inspections & Repair

We are able to do on-site servcing/inspections to companies local to our factory or the jacks can be returned for us for this service (we can arrange collection by pallet courier if required). Once we have completed our assessment we will contact you with all our recommendations for authorisation prior to carrying out any works.

There is a legal requirement under LOLER regulations(Lifting Operations and Lifting Equipment Regulations 1998) for the regular maintenance and testing of your lifting equipment.

Adjustable Twin Ram Commercial Pit Jack

- 400mm lifting stroke

- Available in 3 sizes with a large range of adjustment (see table) for excellent versatility.

- Fast acting air pump

- Air over oil hydraulic design allows for increased performance and longevity of cylinder lifespan.

- Ergonomic handles to move the jack along the pit with ease.

- Tool tray to provide an easily accessible place for your tools or parts while working on a job.

- Cylinders can be operated independently and transversely sliding rams for accurate positioning.

- Suitable for ATF & MOT test lanes.

- Triple layer of safety features − Safety Lowering Valves, anti-burst valves & ram lock-off handles. (Security Struts can also be added as an optional extra to provide additional layer of security to the user). Security Stuts can be easily retrofitted after the jack is already in the pit with minimal equipment downtime.

- Each jack comes with included in the price with; 2x 125mm Extensions, 2x Vee Head Adapters, 2x Dish Head Pansies, Rear Adapter Rack Holder & Air Blow Gun.

- UKCA / CE marked, conforms to EC regulations.

- Covered by a 5 year warranty.

About us

Autolift Ltd is the UK’s foremost specialist in the design and manufacture of commercial vehicle pit jacks, jacking systems, and beams. Our mission is to supply workshops and fleets servicing heavy goods vehicles (HGVs), trucks, buses, and coaches (PSV) with safe, reliable, and cost-effective lifting solutions.

A family-owned business, Autolift has built its legacy over more than 25 years of engineering innovation and hands-on expertise. Our roots in the UK ensure every product is engineered, manufactured, assembled, and quality-tested to exacting British standards. Over time, the name “Autolift” has become synonymous with performance, dependability, and longevity in commercial vehicle lifting.

What We Do

Design & Manufacture

We specialise in the full development and production of pit jacks, jacking beams, spreader beams, and associated lifting systems. Our approach embraces:

Purpose-built solutions — We tailor our designs to meet individual pit widths, load requirements, and workshop constraints.

Robust engineering — Our heavy-duty mechanics and hydraulic/air systems are crafted to stand up to daily use in demanding commercial environments.

Multiple configurations — Whether a customer needs manual, air-assisted, or hydraulic assist, we offer variants to match operational preferences and workloads.

By maintaining complete control over design and fabrication in the UK, we maintain consistent quality, fast iteration, and excellent part support.

Product Portfolio

Our breadth of products ensures that workshops can source all their commercial lifting needs from a single, trusted supplier:

Twin Ram Pit Jacks — Available in capacities from 13, 20, 30 and 40 tonnes.

Single Ram Pit Jacks — Offered in 15 and 20 Tonne capacities with 400mm or 750mm lifting strokes.

Jacking Beam - For use on a 4 post lift.

Floor Jacks — Models with 15 T or 20 T capacity and lifting strokes up to 750 mm are offered.

Transmission Jacks — Heavy-duty 1.5 tonne units with universal headplates for gearbox work.

Spreader Beams — For lifting across vehicle frames when more than a single jack point is needed or the lifting points are beyond the edge of the pit.

Accessories & Spare Parts — Seals, valves, safety devices, replacement pistons, and more — all engineered to fit our systems.

These offerings are available with adjustable or fixed stroke options, and we provide custom adaptations when required. For example, our 13/20 tonne adjustable air twin ram pit jack offers flexible height adjustment and comes with multiple built-in safety features.

Safety, Reliability & Innovation

Safety is a core pillar of our design philosophy. All pit jacks are equipped with safety lowering valves, anti-burst valves, and fail-safe mechanisms to protect operators during lowering or in the event of power hydraulic pressure in the system.

Our products undergo rigorous testing under load, stroke cycles, and environmental stresses to ensure longevity and consistency in performance. This ensures that, when deployed in commercial workshops, the risk of failure, breakdown, or downtime is minimised.

Service, Support & After-Sales

Our commitment to customers extends well beyond delivery:

Servicing & Repairs — Autolift provides full overhaul, maintenance, and repair for our pit jacks at our UK facility.

On-site Support — We partner with authorised distributors across the country who can carry out inspections, maintenance, and servicing in situ, helping you reduce downtime.

Spare Parts Availability — Because we manufacture in the UK, spare parts are readily available and can often be shipped or delivered quickly.

Preventative Maintenance Plans — We offer scheduled servicing packages, inspections, and refurbishment programs to help extend the life of your equipment and maintain safety compliance.

Autolift Ltd is more than a manufacturer — we are a lifelong partner for commercial vehicle workshops. Whether you’re fitting a new inspection pit, upgrading lifting infrastructure, or maintaining your existing jacks.

Images

Videos

Articles / Press Releases

Brochures

Reviews

Trade Associations